AUTOLIFT SP1400 User manual

INSTRUCTION MANUAL

WHEELCHAIR LIFT

MODEL

SP1400

ORIGINAL INSTRUCTIONS

00

REVISIONE

04 / 2020

ANNO

TABLE OF CONTENTS

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

2

1. GENERAL WARNINGS ....................................................................................................................3

1.1 MANUFACTURER..................................................................................................................3

1.2 MARKING...............................................................................................................................3

1.3 Identification of operators........................................................................................................4

1.4 structure and use of the manual..............................................................................................5

1.5 safety –general rules..............................................................................................................6

2.1 components............................................................................................................................9

2.2 Dimensions...........................................................................................................................10

2.3 TECHNICAL DATA...............................................................................................................10

3.1 INTENDED USE...................................................................................................................11

3.2 IMPROPER USE..................................................................................................................11

7.1 RECEIPT AND INSPECTION...............................................................................................15

7.2 Storage and NON-USE of the lift ..........................................................................................15

7.3 transport ...............................................................................................................................15

7.4 handling................................................................................................................................16

7.5 installation on a vehicle.........................................................................................................16

8.1 normal use............................................................................................................................17

8.2 Emergency Use....................................................................................................................19

8.2.1 MANUALLY OPENING THE PLATFORM.............................................................................19

8.2.2 EMERGENCY RAISING.......................................................................................................20

8.2.3 EMERGENCY LOWERING ..................................................................................................21

8.2.4 RESTORING NORMAL CONDITIONS AFTER EMERGENCY MANOEUVRES...................22

10.1 PERIODIC INSPECTION......................................................................................................24

10.2 Frequency of CHECKS........................................................................................................25

10.3 TOPPING UP AND DRAINING THE HYDRAULIC CONTROL UNIT....................................29

11. DEMOLITION AND DISPOSAL .........................................................................................................36

12. TROUBLESHOOTING.....................................................................................................................37

13. WIRING DIAGRAM.........................................................................................................................38

14. HYDRAULIC DIAGRAM...................................................................................................................40

15. ANNEXES ....................................................................................................................................41

GENERAL WARNINGS

1

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

3

1.1 MANUFACTURER

AUTOLIFT SRL

Via Ferri 3 –46020 Pegognaga (MN) - Italy

Tel. +39 0376 550375 –info@autoliftsrl.com

1.2 MARKING

The lift device is manufactured in compliance with the relevant EC directives applicable on the date of

entering the market. As it is considered a "medical device" pursuant to article 2, point 1), letter a), first

paragraph of directive 2007/47/EC, the device carries a specific identification plate which, in addition to

the specific technical data also includes the CE marking, which guarantees the compliance of the device

to the directives/standards referred to the enclosed Declaration of Conformity.

The plate, a facsimile of which is shown here, is stamped with the data indicating the specific model and

unit.

CUSTOMER NAME:

INSTALLER NAME:

DATE OF INSTALLATION:

SERIAL NUMBER:

IT IS PROHIBITED TO REMOVE OR TAMPER WITH THE

IDENTIFICATION PLATE.

GENERAL WARNINGS

1

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

4

1.3 IDENTIFICATION OF OPERATORS

The lift user is the physical or legal person who purchases it and has it operated by an

operator.

The operator, also defined as the accompanying person, is the person who uses the

device.

A disabled person can be identified as the user and/or operator; their disabilities in this

case must not, however, invalidate the characteristics outlined below.

Operators working with devices designed to transport persons with motor deficiencies or disabilities must

be competent to act in all situations; they must always be mentally aware; they must comply with the

physical and mental requirements for ensuring sufficient reactivity in the event of an emergency or a

hazard. They shall therefore not only acknowledge all the details given in this manual but shall possess

the following characteristics.

PHYSICAL: good eyesight, hearing, coordination, ability to safely perform all the functions required to use

the lift, no disorders or debilitating or disabling infirmities caused by the intake of substances altering the

person's emotional state (e.g. drugs and/or alcohol).

MENTAL: ability to understand and apply the established rules and safety precautions; they shall be

attentive, use common sense to ensure theirown safety andthat of others; they shall be willing to correctly

and responsibly perform the tasks of assistant and operator during the transport, loading and unloading of

disabled and other passengers.

EMOTIONAL: they must be calm and able to cope with stress and use common sense over their own

physical and mental conditions; they must be able to manage normal and abnormal situations,

understanding their own limits and, at the same time, how to deal with an emergency.

TRAINING: this manual and any annexed diagrams and layouts, the hazard warning plates and stickers

applied to the electro-hydraulic lift must be read, studied and fully understood; the operatormust be familiar

with the use of the controls and the lift movements, having performed all tests (without loads) required to

learn all the operating phases.

TASKS AND RESPONSIBILITIES: in this context we refer only to the operator's tasks concerning the use

of the lift, which include switching on the power circuit, moving the various parts, assembly and removal

of any optional parts, and maintenance. The operator must therefore be fully familiar with the safety

regulations and relative devices, the use of the controls and the manual emergency devices.

The operator is personally responsible for the use of the lift and its correct operation, maintenance, the

handled load and all actions which are performed within the above-mentioned tasks.

If any situations occur which could compromise the physical and mental state of the transported person,

following the non-compliance or poor knowledge of the operator, they shall personally be civilly and

criminally liable towards the injured party.

This applies also to any tampering or modifications by the operator of parts or components of the lift which

no longer guarantee its safety and reliability for the transported persons.

Autolift Srl shall bear no liability in the event of such situations occurring.

GENERAL WARNINGS

1

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

5

The user is responsible for distributing this manual to all staff working with the lift.

In addition to complying strictly with the instructions given in this manual, operators

shall not use the lift and shall report directly to their managers, or if they do not have

one, directly to the manufacturer AUTOLIFT srl, concerning any shortcomings or

potentially hazardous situation which may occur.

1.4 STRUCTURE AND USE OF THE MANUAL

USERS AND OPERATORS MUST READ THIS MANUAL PRIOR TO

USING THE LIFT.

This manual aims to provide users and operators with all the information they require to ensure that they

are able both to use the lift appropriately and manage it as independently and safely as possible.

Before performing any operations on the lift, users and operators must carefully read the instructions given

in this publication.

In the event of any doubt over the correct interpretation of the instructions, contact the AUTOLIFT srl

technical department to obtain the required clarifications.

This manual is an integral part of the lift, it must be kept safely by the purchaser and made available for

use by the operators.

The contents of this manual comply with the Directive 2007/47/EC and were drafted following the

guidelines given in UNI 10893:2000. They also comply with the requirements of ISO 10535:2007.

This manual has 45 pages, including the cover, and annexes (see section 1.6).

Data and drawings are provided as examples only; with a view to the continuous development and

updating of its products, the manufacturer may modify the contents without notice.

It is prohibited to disclose, edit or use this manual for any other purposes.

In drafting the manual, we have chosen to use a limited number of clear symbols to draw the reader's

attention to important concepts and to make consultation simpler and more immediate.

THE INDICATIONS MARKED BY THIS SYMBOL REPRESENT A

POTENTIAL HAZARD, WITH THE RISK OF PHYSICAL DANGER FOR

THE USERS.

GENERAL WARNINGS

1

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

6

THE INDICATIONS MARKED BY THIS SYMBOL ARE DEEMED

PARTICULARLY IMPORTANT FOR THE OPERATION OF THE LIFT.

THE INDICATIONS MARKED WITH THIS SYMBOL ARE IMPORTANT

FOR COMMUNICATION BETWEEN THE MANUFACTURER AND THE

USER.

THE SPECIFIC INSTALLATION MANUAL IS AVAILABLE FOR THE

INSTALLER.

1.5 SAFETY –GENERAL RULES

The lift must not be operated by untrained persons.

Examine the hydraulic lift carefully before each use. If there are any hazardous

conditions or if you notice unusual noises or movements, do not use the lift and contact

an Autolift agent or authorised workshop for the necessary inspections and repairs.

Read and comply with the labels and warning symbols affixed to the hydraulic lift or

near the loading area of the vehicle used to transport wheelchairs.

When using the hydraulic lift, a hazardous situation may be caused by parking the

vehicle on a slope.

Use the lift with the vehicle parked on flat ground, where possible

GENERAL WARNINGS

1

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

7

The vehicle must always be parked safely with the emergency brakes on before

starting to operate the lift.

Make sure that the wheelchair is braked and placed securely on the platform, and that

it does not extend over the edge.

Do not operate with a load of over 350 kg and with any load other than a wheelchair

with passenger.

When using the hydraulic lift, the occupant of the wheelchair should, where possible,

face outwards; i.e. with the larger wheels facing the vehicle.

GENERAL WARNINGS

1

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

8

Ensure that there are no persons or objects within the lift's range of action

DO NOT PLACE ARMS, LEGS OR CLOTHING NEAR THE MOVING OR

PROTRUDING PARTS OF THE PLATFORM.

RISK OF CRUSHING AND SHEARING

Unauthorised persons must not stand nearby during the use of the lift, and must not

stand between the vehicle and the platform, even for quick checks with the platform

at a standstill. These checks and adjustments must be performed exclusively by

authorised Autolift staff.

Take care when driving over roads with large humps or dips since the vehicle ground

clearance is reduced at the lift housing.

After completing the lifting operations, replace the lift inside the housing.

Do not drive or manoeuvre the vehicle if the housing is not completely closed.

ALWAYS CHECK THAT THE VEHICLE BATTERY IS SUFFICIENTLY

CHARGED BEFORE USING THE LIFT.

GENERAL DESCRIPTION

2

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

9

2.1 COMPONENTS

1

Housing

6

Handles

2

Transfer strip (rear flap)

7

Push-button panel

3

Jointed drive arms

8

Electrical control unit

4

Aluminium platform

9

Hydraulic power unit

5

Front flap

-

-

The drawing shown represents all models

5

3

7

8

9

GENERAL DESCRIPTION

2

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

10

2.2 DIMENSIONS

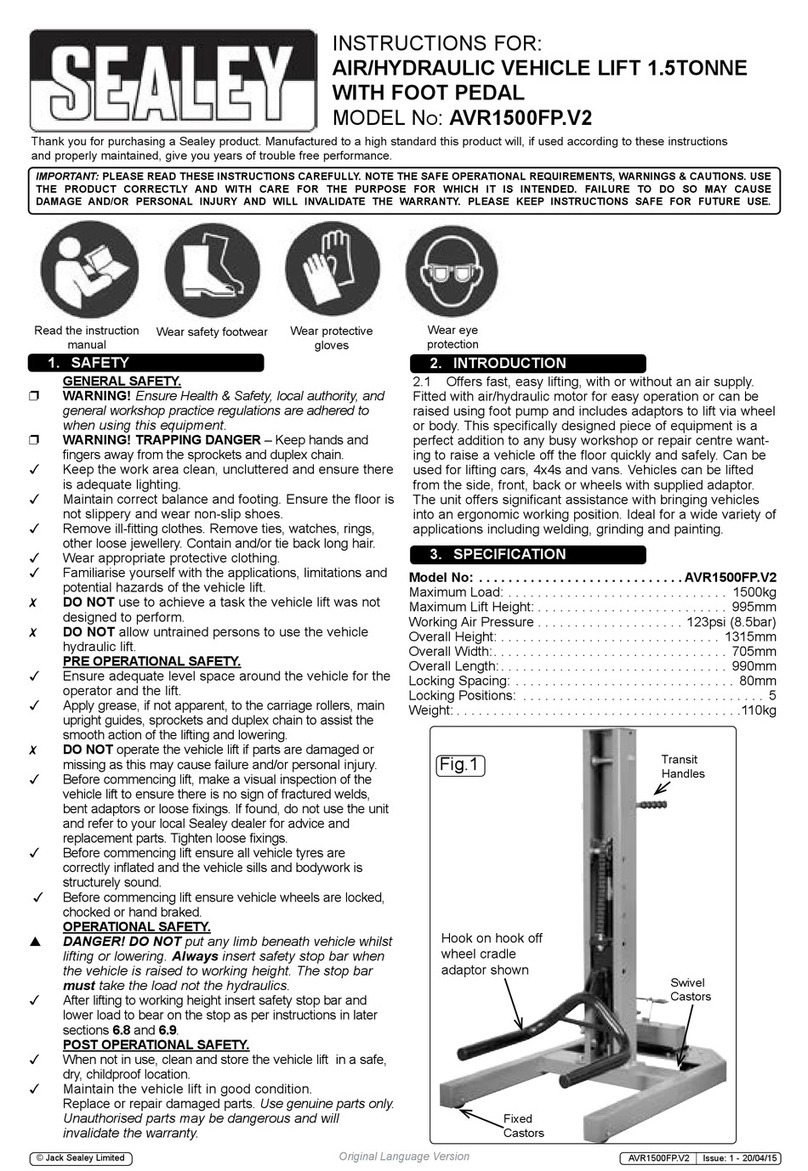

2.3 TECHNICAL DATA

Capacity

kg

400

Weight

kg

177

Power supply

Volts

12 /24Vdc

Max. pressure

bar

200

Platform

mm

810 x 1414

Max. overhang

mm

1049

Aux emergency pump

YES

Airborne noise

Db(A)

< 70

FIELD OF USE

3

LIFT

DEVICE

SP 1400

MODEL

11

3.1 INTENDED USE

The lift is designed for installation on the loading floor of a vehicle designed for transportation of wheelchair

users, within the limits of the performance and capacities indicated in the technical characteristics.

The lift must only be used by an authorised and trained operator, known as the accompanying person,

who possesses the knowledge and physical requirements to safely perform operations with disabled

persons.

3.2 IMPROPER USE

Anything that is not explicitly referred to in chapter 3.1 is considered IMPROPER USE.

IT IS FORBIDDEN to drive or manoeuvre the vehicle if the housing is not completely

closed.

IT IS FORBIDDEN to climb onto the lift or any of its parts and go up or down while

standing.

IT IS FORBIDDEN to use the lift to transport animals or objects.

IT IS FORBIDDEN to use the lift with the vehicle not parked on a flat surface.

THE MANUFACTURER SHALL BEAR NO RESPONSIBILITY FOR

DAMAGE CAUSED TO PERSONS OR PROPERTY OR TO THE RAMP

ITSELF DUE TO ANY USE OTHER THAN THAT DESCRIBED IN THIS

MANUAL.

SAFETY DEVICES

4

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

12

1

Transfer strip (rear flap)

2

Front flap

3

Overload limit valve

IT IS FORBIDDEN TO ELIMINATE, REMOVE OR TAMPER WITH THE

EXISTING SAFETY SYSTEMS.

1

2

3

WARNING SIGNS

5

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

13

THE LIFT HAS THE FOLLOWING MARKINGS

Read the manual before using

the lift

It is forbidden for untrained

persons to operate the lift

Risk of crushing

IT IS FORBIDDEN TO TAMPER WITH/REMOVE THE MARKINGS.

RESIDUAL RISKS

6

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

14

Although protective measures have been integrated in the lift design, including supplementary protective

measures, the residual risks specified below nevertheless remain.

If a person should insert a body part (hand, arm etc.) inside the levers making up each side of the machine

during the lift's operation, they expose themselves to a crushing/shearing hazard. A further potential

crushing point is the feet between the front flap/platform and the supporting surface (floor).

This is considered a residual risk.

IT IS FORBIDDEN FOR ANYONE TO APPROACH THE MOVING PARTS.

Potential crushing

points

Potential crushing

points

INSTALLATION

7

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

15

7.1 RECEIPT AND INSPECTION

On receipt of the ramp, you must perform the following inspections:

-Check that the supplied items correspond to the order specifications and the transport docket.

-Check that the packaging is intact and that no parts have been broken or damaged during

transportation.

-Carefully check that the devices have not been damaged during transportation and that no parts

have been removed and/or tampered with.

-Check that all documentation necessary for installation has been provided.

IF THE DELIVERED DEVICE DOES NOT COMPLY WITH THESE

REQUIREMENTS, NOTIFY THE MANUFACTURER IMMEDIATELY.

7.2 STORAGE AND NON-USE OF THE LIFT

If the lift is not to be used for a period, proceed as follows:

-Store the ramp in a covered location away from the elements.

-All electrical / electronic parts must be kept wrapped to protect against moisture.

-The storage temperature must be between +5°C and +50°C.

-All sliding parts (guides, cylinders etc.) must be protected from dust and rust.

-Do not store for over 6 months. For longer periods of storage, before putting into service contact the

manufacturer to have the lift conditions inspected.

7.3 TRANSPORT

The ramp must be transported using a vehicle (van, lorry etc.) of an appropriate size and capacity.

The lift is shipped by the manufacturer packed in a crate measuring 150 x 125 cm.

The total height of the crate with the lift is 50 cm.

For the weight, refer to the Technical Data chapter

STORAGE OF THE LIFT IN CONDITIONS THAT DO NOT COMPLY

WITH THE ABOVE DESCRIPTION SHALL INVALIDATE THE

WARRANTY FOR ANY PARTS TO BE REPLACED.

INSTALLATION

7

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

16

7.4 HANDLING

The packaged lift must be handled by a pallet truck, forklift

truck or similar.

The method used for safe handling must have a load

capacity suited to the load to be transported (see weight

indicated in the Technical Data table).

HANDLING STAFF MUST WEAR: SAFETY SHOES WITH STEEL TOE

CAP AND NON-SLIP SOLES.

MAKE SURE THAT NO UNAUTHORISED PERSONS ARE STANDING

WITHIN THE RADIUS OF ACTION OF THE LIFTING/HANDLING

EQUIPMENT (FORKLIFT TRUCK, PALLET TRUCK ETC.) DURING THE

LIFTING, TRANSPORT AND HANDLING OPERATIONS.

If a cardboard box has been used for packaging, to unpack the lift, cut the cardboard packaging with a

Stanley knife (max. blade length 1 cm) on the 4 sides of the base of the packaging, then lift and remove.

Otherwise, if a wooden crate has been used, remove the nails from the wooden crate starting from the top

and then remove the side walls.

STAFF REMOVING THE PACKAGING MUST WEAR: SAFETY SHOES

WITH STEEL TOE CAP AND NON-SLIP SOLES AND GLOVES.

7.5 INSTALLATION ON A VEHICLE

Installation on a vehicle must be performed exclusively by authorised installers.

Autolift shall bear no liability for injury or damage to property or the machine itself due

to installation on a vehicle not performed by authorised persons.

USE

8

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

17

8.1 NORMAL USE

The electro-hydraulic lift control is a wired portable remote control known as push-button control panel,

equipped with two rectangular dual-command buttons.

There are raised symbols on the buttons corresponding to each of the four control functions.

Specific movements of the lift, described below, correspond to each press of a button.

BEFORE USE, READ AND FOLLOW THE INSTRUCTIONS IN CHAPTER

1.7 OF THIS MANUAL.

8.1.2 HOW TO GET INTO THE VEHICLE

1. Press “OUT” to extract the platform from the housing. Hold the button down until the platform stops

automatically;

2. Manually open the front platform, the 2 handles (if available) and the rear flap.

3. Press the “Down” button until the platform reaches the ground and the front flap opens fully.

4. The wheelchair user must now move their wheelchair onto the platform, position themselves in the

centre and lock the wheelchair brakes

5. Press the “LIFT” button until the vehicle’s floor level is reached;

6. The wheelchair user must now release the wheelchair brakes and enter the vehicle, completely

leaving the platform

7. Manually close the rear flap, the handles (if available) and the front platform.

8. Press the “IN” button; the platform is lowered and automatically returned inside its housing.

LIFT

LOWER

OUT

IN

USE

8

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

18

8.1.3 HOW TO GET OUT OF THE VEHICLE

1. Press “OUT” to extract the platform from the housing. Hold the button down until the platform stops

automatically.

2. Open the front platform manually, the two handles (if available) and the rear flap.

3. Press the “Lift” button until the platform reaches the vehicle floor level.

4. The wheelchair user must now move their wheelchair onto the platform, position themselves in the

centre and lock the wheelchair brakes

5. Press the “Down” button until the platform reaches the ground and the front flap opens fully.

6. The wheelchair user must now release the wheelchair brakes and completely leave the platform

7. Close the rear flap manually, the handles (if available) and the front platform.

8. Press the “IN” button; the platform is raised and automatically returned inside its housing.

USE

8

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

19

8.2 EMERGENCY USE

8.2.1 MANUALLY OPENING THE PLATFORM

TWO PEOPLE ARE REQUIRED TO PERFORM THIS OPERATION.

The following manoeuvres must be performed in sequence to open the platform manually:

A. Turn the nut (1) on the front of the housingclockwise by 90° using the supplied

spanner (2). This operation frees the motor pinion from the teeth of the rack

connected to the platform.

B. Next, extract the platform from the housing manually.

1

2

USE

8

WHEELCHAIR LIFT

DEVICE

SP 1400

MODEL

20

8.2.2 EMERGENCY RAISING

The following manoeuvres must be performed in sequence to raise the platform manually in anemergency:

C. Take the lever (3) supplied

D. Introduce it all the way into the hand pump (4)

housing. Use alternating movements to raise the

platform to the required level.

3

3

4

Table of contents

Other AUTOLIFT Lifting System manuals

Popular Lifting System manuals by other brands

AMGO

AMGO A440-HP Installation and service manual

BraunAbility

BraunAbility Century 2 NCL10000 Series Service manual

Plymovent

Plymovent BALANCER-200 Series Installation and user manual

NRS Healthcare

NRS Healthcare M48611 User instructions

Vestil

Vestil CART-600-S-HR instruction manual

Terex

Terex Genie GS-1532 Service and repair manual