p. 9/46

TLxx-MT-EN-04

4. INTRODUCTION

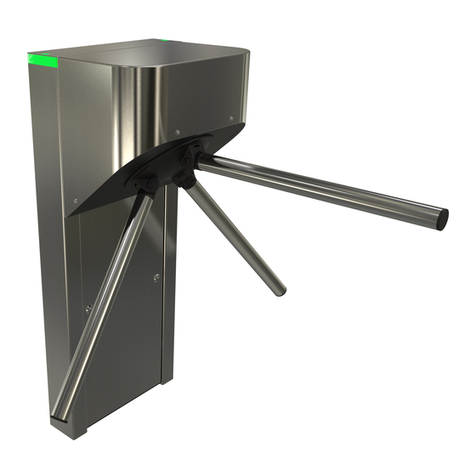

The tripod turnstiles in the TriLane range are designed for deterrent and economical access control, and allow the

incorporation of control equipment such as proximity readers, barcode scanners, badge collectors, etc. .

The assembly is finished to a level that ensures proper sealing and acoustic insulation from the surrounding environment.

The rotation control mechanism for the arms is the result of many years' experience in the development and manufacture

of access control equipment and the marketing of tens of thousands of units in all corners of the world.

The mechanical and electronic assembly is located in the central part of the tripod, under the protective cover, and

therefore out of reach for users; the connection and the fixation to the ground do not require any particular construction

work.

The mechanism, which has a robust and reliable design, can be integrated into two bodywork models:

• The compact version with single leg, called TL1 in this manual;

• The version with two legs, allowing easier integration of one or two readers, and called TL2 in this manual.

The design is nevertheless modular, because the same kinematic assembly is found in the TL1 and TL2 models.

Many configurations and options are available to cover all cases that are likely to be encountered in pedestrian access

control: functional pictograms, motorised movement, dropping arms, presence detection, full stainless steel finish...

4.1. TERMINOLOGY

AS Automatic Systems.

CMD Command

DI Digital input

DO Digital output

I/O Input / Output

O/S Out of service

HMI Man-Machine Interface

CRA Card reader direction A

CRB Card reader direction B

NC Normally closed(contact)

NO Normally open(contact)

OP Opening

MVT Movement

RGBW Red – Green – Blue - White

TL1 TriLane version with single leg

TL2 TriLane version with two legs

TOF TOF camera (Time of Fly): This camera calculates the time necessary for a light beam to be reflected

on each point of the object or user present in the passage, which gives a 3D representation and

enables a presence and its uniqueness to be checked to a good approximation.

TOR All or nothing

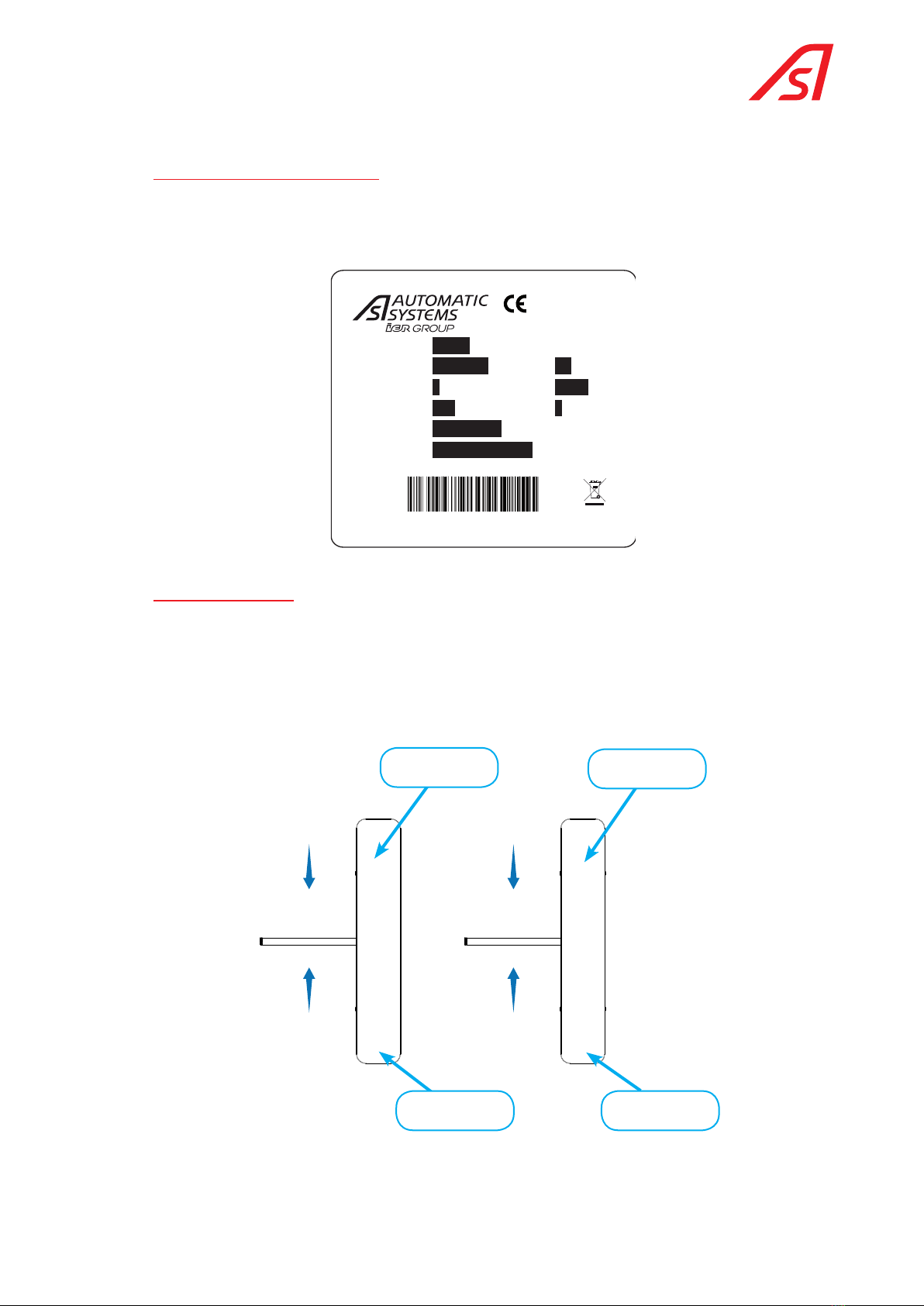

Direction A By convention, direction A is the passage from the uncontrolled area to the controlled area.

Direction B Passage in opposite direction to direction A

Direction B corresponds to passing from the controlled area to the uncontrolled area.

ZC Controlled area

ZNC Uncontrolled area

ZCZNC Direction from the controlled area to the uncontrolled area