p. 10/11

TL2-QSG-EN-03

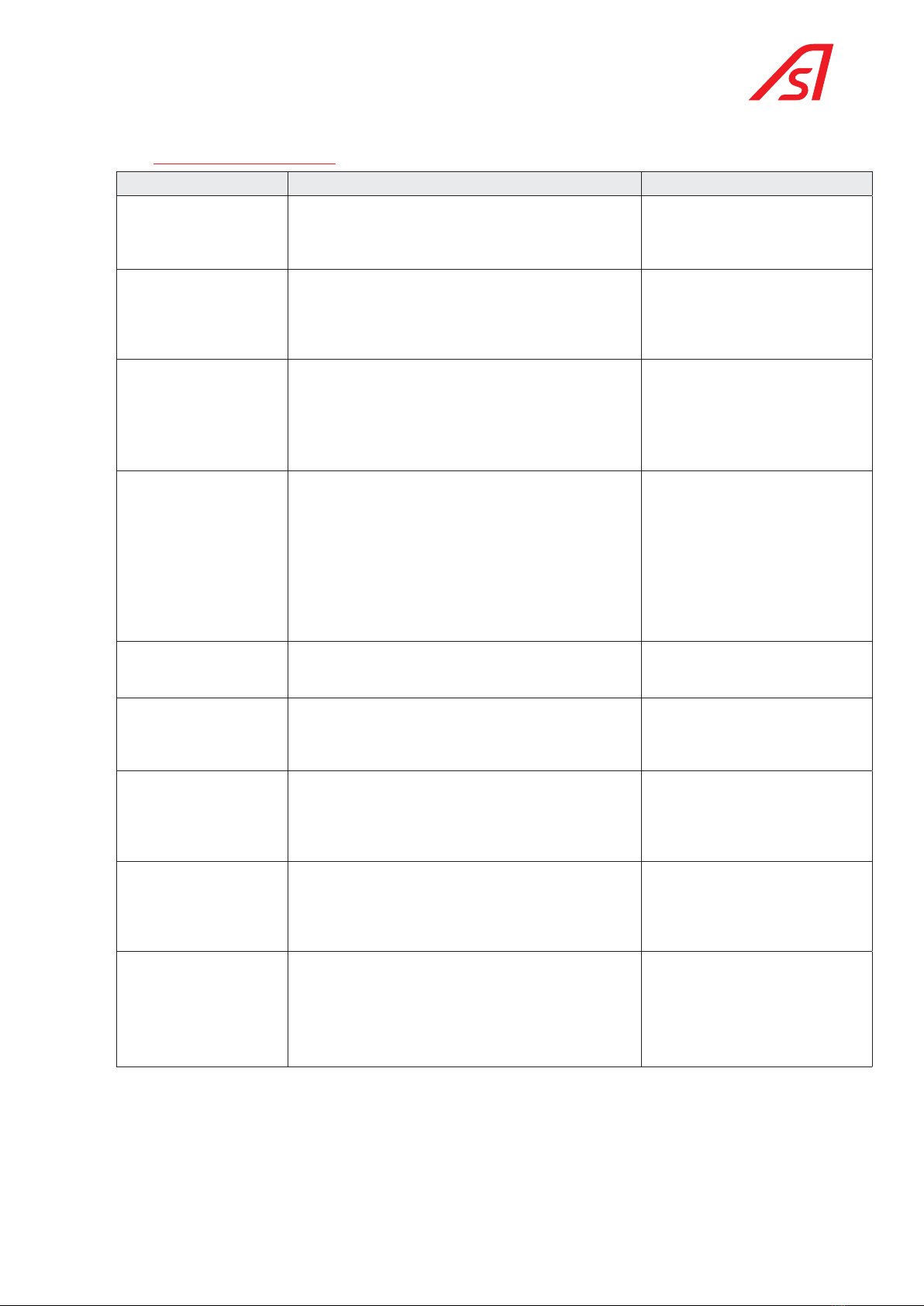

5.10. FAULT DIAGNOSIS

Failure description Possible cause Comment

The Trilane is not powered

(pictogram not lit, drive

not lit, free passage in

both directions, etc.)

Remove the cover and check the 230 VAC connection and

the position of the main circuit breaker. Check the correct

24 VDC supply voltage.

In the A5/B5 configuration, the de-

energised TriLane is free in both

directions of passage.

A pictogram is not lit. On the AS1635 circuit board, check the connection of

the CN10 connectors (pictogram direction A) and CN11

(pictogram direction B).

Replace the pictograms if necessary.

CN10(or 11)-1 red

CN10(or 11)-2 green

CN10(or 11)-3 blue

CN10(or 11)-4 white

CN10(or 11)-5 0V ref

The passage

authorisation is not taken

into consideration.

Using the HMI, check that the TriLane is not in blocked

mode.

Check the connection between the reader and the AS1635

circuit board (24 VDC pulse in CN2-1 for authorisation in

the A direction and in CN2-2 for authorisation in the B

direction).

Default configuration of the inputs,

can be modified via the PC interface.

The TriLane does not lock

itself (in direction A or

direction B)

Check the programmed operating mode in direction A and

B via the HMI (free, controlled, blocked).

Check that the TriLane is not in Emergency mode

(connection between CN1.3 and 4 for normal operation).

Check the supply voltage of the electro-magnet, between

CN5-1 and CN5-2 (direction A) or CN5-3 and CN5-4

(direction B).

If the electro-magnet is functioning correctly, check the

locking mechanism

Note: the 24 VDC voltage is only

applied during the first moments The

holding voltage is reduced to prevent

the electro-magnet from heating up.

The turret will not re-lock

during rotation.

Check the operation of the angular sensor and the

connecting cable (CN17 on the AS1635 circuit board).

In the case of an angular sensor

problem, an error appears on the HMI

display.

The TriLane does not

operate and the LED LD1

on the AS1635 circuit

board is off.

The AS1365 control circuit board is not powered with

24 VDC. Check the 24 VDC power supply module and the

connection cable to CN1-1 and CN1-2.

The TriLane does not work

and the LED LD6 on the

AS1635 circuit board is off.

The program is not running. Turn off the power to

reinitialise the program or press the Reset button (see the

position in the technical manual of the AS1635).

As a last resort, replace the AS1635 control circuit board.

If the control circuit board is

replaced, a new calibration operation

will be required at power on. Refer to

the unit test chapter in the AS1635

manual.

The horizontal arm does

not fall in the case of

a power failure or an

emergency. (Dropping-arm

option retained)

Check the condition of the two actuating springs of the

arm release mechanism (See the technical manual)

The motor does not

engage (motorisation

option retained)

Check that the CAN bus cable W6 is connected to the CN13

connector of the AS1635 circuit board.

Check the connection between the motor circuit board AS

1636 and the motor.

If necessary, replace the motor circuit board or the gear

motor.

The information contained in this document is the property of Automatic Systems and is confidential. The recipient shall refrain from using this information for any purpose

other than the use of the products or the execution of the project to which it refers and from communicating it to third parties without prior written agreement of Automatic

Systems. The document is subject to change without notice.