SL 90X-91X

Technical Manual

NAM-SL 90X-91X-TM-04-EN-E

With a constant view to adopting the latest technological developments, Automatic Systems reserves the right to amend the above information at any time

.

p. 3/66

www.automatic-systems.com

Table of contents

DOCUMENT REVISIONS.......................................................................................................................................................2

TABLE OF CONTENTS.........................................................................................................................................................3

1. SAFETY WARNINGS.......................................................................................................................................................5

1.1. User safety ...................................................................................................................................................................................................5

1.2. Technical staff safety ..................................................................................................................................................................................5

2. ABOUT THE MANUALS ...................................................................................................................................................7

2.1. Manual structure ..........................................................................................................................................................................................7

2.2. About this manual ........................................................................................................................................................................................7

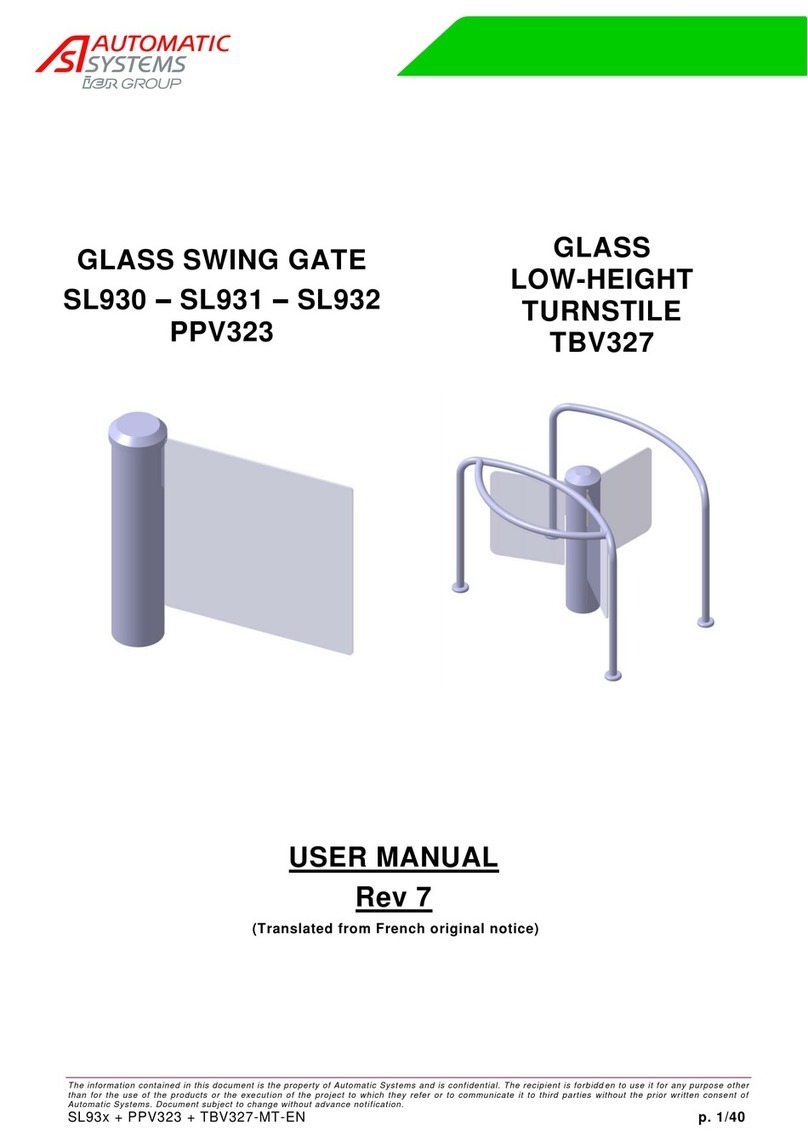

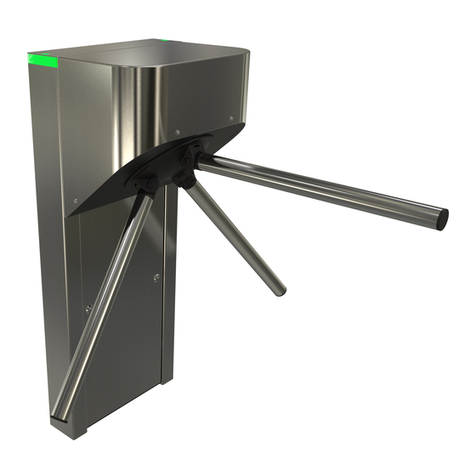

3. PRODUCT AT A GLANCE .................................................................................................................................................8

4. DEFINITIONS ................................................................................................................................................................9

5. TYPES OF UNITS ......................................................................................................................................................... 11

6. CONFIGURATIONS ....................................................................................................................................................... 12

6.1. Master/slave single configuration .............................................................................................................................................................12

6.2. Multiple lane configuration of the SL 90X or SL 91X lane............................................................................................................................13

6.2.1. Intermediate unit................................................................................................................................................................................................................13

6.2.2. Hybrid intermediate unit ....................................................................................................................................................................................................14

7. COMPONENTS............................................................................................................................................................. 15

7.1. External components..................................................................................................................................................................................15

7.2. Internal components ..................................................................................................................................................................................16

7.2.1. Mechanical assembly.........................................................................................................................................................................................................17

7.2.2. Logic panels .......................................................................................................................................................................................................................18

7.2.3. Power supply panel ............................................................................................................................................................................................................19

7.2.4. DIRAS assemblies ...............................................................................................................................................................................................................20

8. MAINTENANCE GUIDELINES.......................................................................................................................................... 21

8.1. Ordering parts.............................................................................................................................................................................................22

8.2. Required tools............................................................................................................................................................................................23

8.3. Maintenance schedule ...............................................................................................................................................................................24

8.4. Recommended spare parts list (recommended quantities for every set of 6 SL units)............................................................................... 28

9. INSPECTION GUIDELINES ............................................................................................................................................. 30

9.1. Tightening torques .....................................................................................................................................................................................30

9.2. Motors ........................................................................................................................................................................................................31

9.3. Fuses..........................................................................................................................................................................................................31

9.4. Crankshaft assembly ..................................................................................................................................................................................32

9.5. Mechanical release system: Lever and spring ............................................................................................................................................ 33

9.6. Locking mechanism....................................................................................................................................................................................33

9.7. Inductive position sensor...........................................................................................................................................................................34

9.8. Rods and rockers........................................................................................................................................................................................34

9.9. Plinth..........................................................................................................................................................................................................35

9.10. Balancing springs and adjustment...........................................................................................................................................................36

9.11. Shutter, shutter guides, protectors and sliding bands............................................................................................................................ 36

9.12. DIRAS........................................................................................................................................................................................................37

9.13. Plexiglas surfaces....................................................................................................................................................................................38

9.14.Pictograms ...............................................................................................................................................................................................38

9.15. PLC and VFD .............................................................................................................................................................................................38

9.16. Cables and connections...........................................................................................................................................................................38

9.17. Nuts and bolts..........................................................................................................................................................................................38

9.18. Panel locks...............................................................................................................................................................................................39

9.19. Mobile and fixed glass Obstacles.............................................................................................................................................................39

9.20. Stainless steel housing............................................................................................................................................................................39

10. INSTRUCTIONS: MECHANICAL ADJUSTEMENTS AND OPERATIONS .................................................................................. 40

10.1. Instructions: Removing a panel................................................................................................................................................................40

10.2. Instructions: Removing the cover plate ...................................................................................................................................................41

10.3. Instructions: Adjusting the obstacle clearance space............................................................................................................................. 42

10.4. Instructions: Replacing the balancing spring ..........................................................................................................................................43

10.5. Instructions: Adjusting the balancing spring...........................................................................................................................................45

10.6. Instructions: Replacing a moving glass obstacle..................................................................................................................................... 46