Automatic Systems TR491-TR6-GB-a YD-JMW20/01/00 Installation TR491 2-1106GB Rev.: C p. 8/12

3.2. Preliminary work on site

•This is basically the following:

Check the positioning and location of the equipment according to the site's general lay-out.

Preparation of fixing holes in the floor as in Fig. 3. Make sure to drill holes with the diameter

adapted to the expansion bolts that will be used (type recommended: model B15/30, ref.

-/3413/000). Ensure that the drilling positions do not conflict with any cables, pipes, ducts or

steelwork in the floor structure. If this does occur, a slight repositioning of the turnstile may

be needed.

Preparation of electrical supply and control cabling: all power and control cables enter the

turnstiles through the floor at either end section (rear or front). Mark and drill entry holes in

floor as described for the fixing holes. A single-phase, 230V 2Amp (max.) power supply is

required, installed to the country Regulations, relevant for this installation, complete with

earth bonding for the metalwork. Control cables for remote desk consoles (if supplied), and

other access control devices (when applicable) will also be required, installed to conform

with relevant regulations and control device specifications.

Note: All cables to have a 2 meter tail.

Note: If you add any flammable elements (see EN60950, paragraph 4.4.5. standard) into the

end sections of the turnstile, make sure that the floor is fireproof.

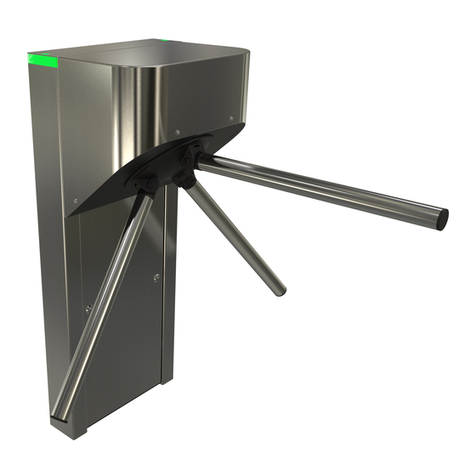

3.3. Installing the tripod turnstile

•Position the turnstile on site precisely.

•Fix the 4 expansion bolts to the floor.

•Put the two fixing brackets inside the front and rear end sections, at the bottom of the housing, as

illustrated in Fig. 3. The fixing brackets are supplied as accessories.

•Carefully pull the power or control cables into the end sections of the turnstile (ensure cables are

not trapped between the floor and the end sections or the fixing brackets).

•Check turnstile for alignment and level, and tighten fixing brackets firmly.

•When the turnstiles are fitted in banks (rows), of more than 1 unit, attention should be given to the

linear, vertical and horizontal alignment. Packing shims can be used.