EN

WIKA operating instructions DELTA-plus, DELTA-comb and DELTA-switch4

14093265.04 04/2016 EN/DE

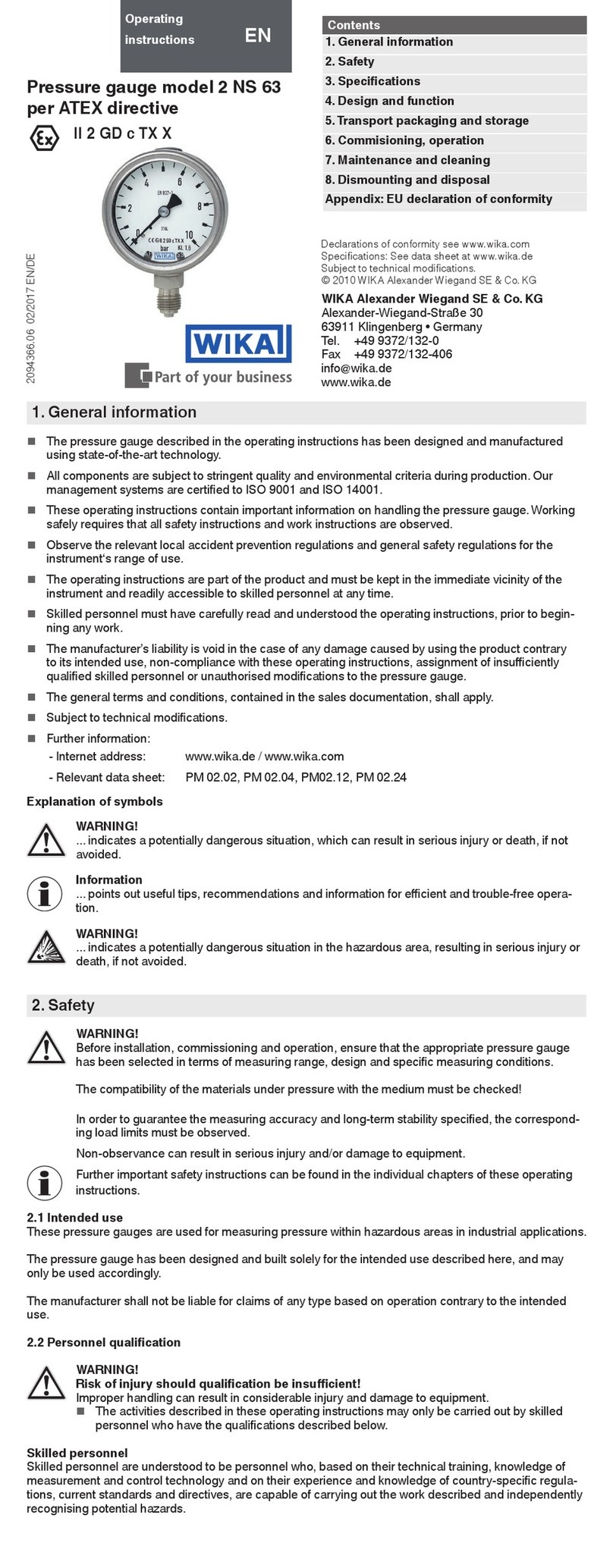

1. General information

■

The dierential pressure gauges described in the operating instructions

have been designed and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria

during production. Our management systems are certied to ISO 9001 and

ISO 14001.

■

These operating instructions contain important information on handling the

instrument. Working safely requires that all safety instructions and work

instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the

immediate vicinity of the instrument and readily accessible to skilled personnel

at any time.

■

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by

using the product contrary to its intended use, non-compliance with these

operating instructions, assignment of insuciently qualied skilled personnel

or unauthorised modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall

apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheets: PM 07.20, PV 27.20, PV 27.21

- For Ex version: Additional Information for hazardous areas (Ex i)

1. General information

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in

serious injury or death, if not avoided.

Information

... points out useful tips, recommendations and information for

ecient and trouble-free operation.