Table of Contents

x © Copyright Reserved Autonics Co., Ltd.

6.2 Frame Size 86mm .............................................................................................34

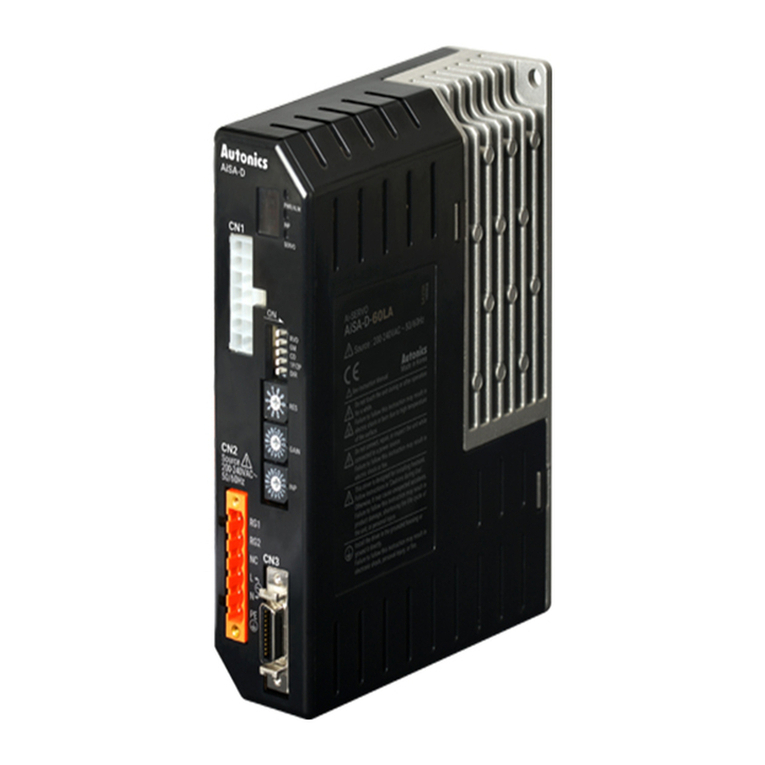

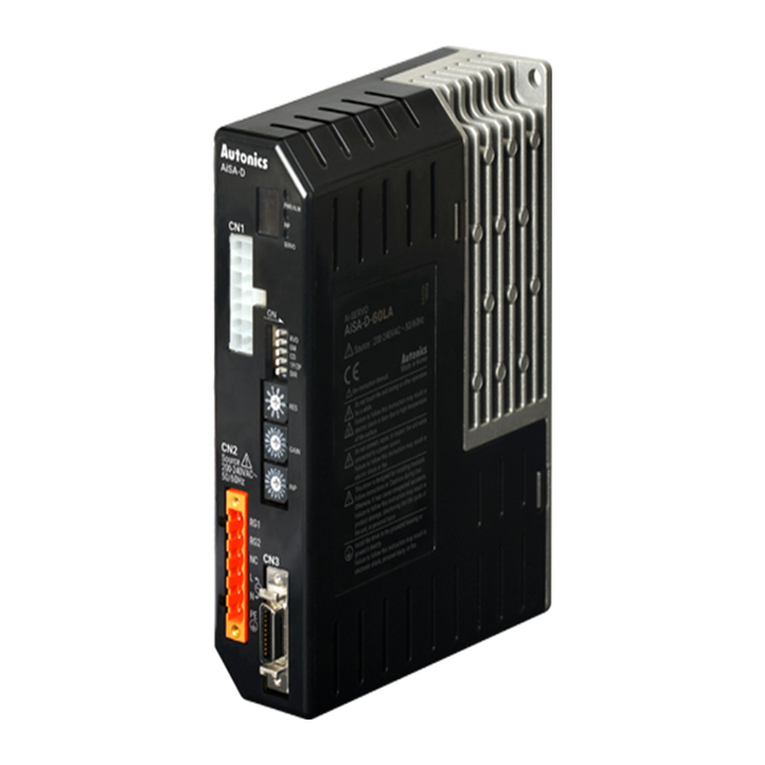

7Driver Unit Descriptions ..............................................................36

7.1 Driver Status Indicator .....................................................................................37

7.2 Switches............................................................................................................38

7.2.1 ID Sel ..........................................................................................................38

7.2.2 ID, TERM.....................................................................................................38

7.3 ConnConnectors...............................................................................................39

7.3.1 CN1: Motor+Encoder Connector ..............................................................39

7.3.2 CN2: Power Connector..............................................................................39

7.3.3 CN3: RS485 Communication Cable Connector .......................................39

7.3.4 CN4: I/O Connector ...................................................................................40

7.3.5 Brake connector ........................................................................................41

7.4 Connector Specifications.................................................................................42

7.5 Sold Separately.................................................................................................43

7.5.1 I/O Cable (CO50-MP□-R, standard: AiC TAG)...........................................43

7.5.2 Motor+Encoder Cable (Normal: C1D14M-□/Moving: C1DF14M-□).......44

7.5.3 Communication Converter.......................................................................44

8Electromagnetic Brake ................................................................45

8.1 Brake Connection.............................................................................................45

8.2 Brake Operation ...............................................................................................46

9Control Input/Output ..................................................................47

9.1 Input..................................................................................................................47

9.1.1 Example of Input Circuit Connection.......................................................47

9.1.2 Exclusive Input ..........................................................................................48

9.1.3 General Input.............................................................................................62

9.2 Output ...............................................................................................................63

9.2.1 Example of Output Circuit Connection....................................................63

9.2.2 Exclusive Output .......................................................................................64

9.2.3 General Output..........................................................................................67

10 Drive ..........................................................................................68

10.1 I/O Signal Control Drive ...................................................................................69

10.1.1 Index Mode ................................................................................................69

10.1.2 Jog Mode ...................................................................................................71

10.1.3 Continuous Mode......................................................................................73

10.1.4 Program Mode...........................................................................................75

10.1.5 Home Search .............................................................................................77

10.2 atMotion Control Drive.....................................................................................85

10.2.1 Jog Mode ...................................................................................................89

10.2.2 Continuous Mode......................................................................................90

10.2.3 Position Mode............................................................................................91

10.2.4 Torque Mode .............................................................................................93

10.2.5 Program Mode...........................................................................................94

10.2.6 Home Search Mode...................................................................................95

11 Program Instructions ................................................................100

11.1 Drive Instruction............................................................................................ 101