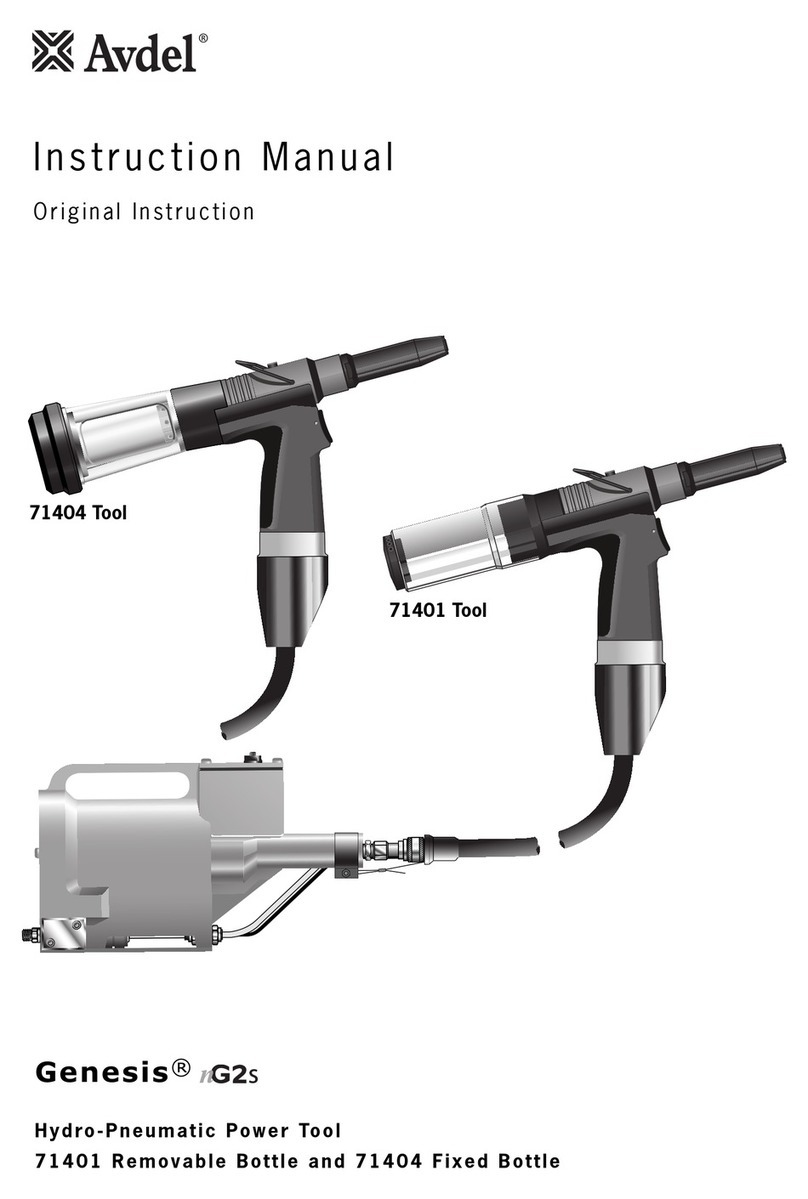

Avdel GenesisG2-s User manual

This manual suits for next models

1

Table of contents

Languages:

Other Avdel Power Tools manuals

Avdel

Avdel Genesis G3 User manual

Avdel

Avdel Genesis 7537 User manual

Avdel

Avdel 7265 User manual

Avdel

Avdel G3LB Tool User manual

Avdel

Avdel Genesis G1 User manual

Avdel

Avdel T40 User manual

Avdel

Avdel 07572 User manual

Avdel

Avdel 74200 User manual

Avdel

Avdel 74100 User manual

Avdel

Avdel Genesis nG3 User manual

Avdel

Avdel 73432-02000 User manual

Avdel

Avdel 7900 User manual

Avdel

Avdel Genesis 71210-20310 User manual

Avdel

Avdel Avbolt 07220 User manual

Avdel

Avdel 7241 User manual

Avdel

Avdel 71404 User manual

Avdel

Avdel Genesis G1 71204 User manual

Avdel

Avdel Genesis G4 HD Heavy Duty User manual

Avdel

Avdel 7557 User manual

Avdel

Avdel 74201 User manual

Popular Power Tools manuals by other brands

Greenlee

Greenlee LCS-144 instruction manual

Dake

Dake 25H Instructional manual

Clarke

Clarke STRONG-ARM CS4BRK Operation & maintenance instructions

Cembre

Cembre ECW-H3D Operation and maintenance manual

Hitachi Koki

Hitachi Koki EM4028 R2 Handling instructions

Stanley

Stanley BOSTITCH 02011 instruction manual

BASETech

BASETech 1666211 Original instructions

Makita

Makita HM1500 instruction manual

Chicago Electric

Chicago Electric 66301 Assembly, operation and maintenance instructions

OLI

OLI MICRO MVE SHORT INSTALLATION OPERATING INSTRUCTIONS

Fein

Fein ABLK18-1.3TE instruction manual

Snap-On

Snap-On TECHANGLE STEEL ATECH2FS100 manual