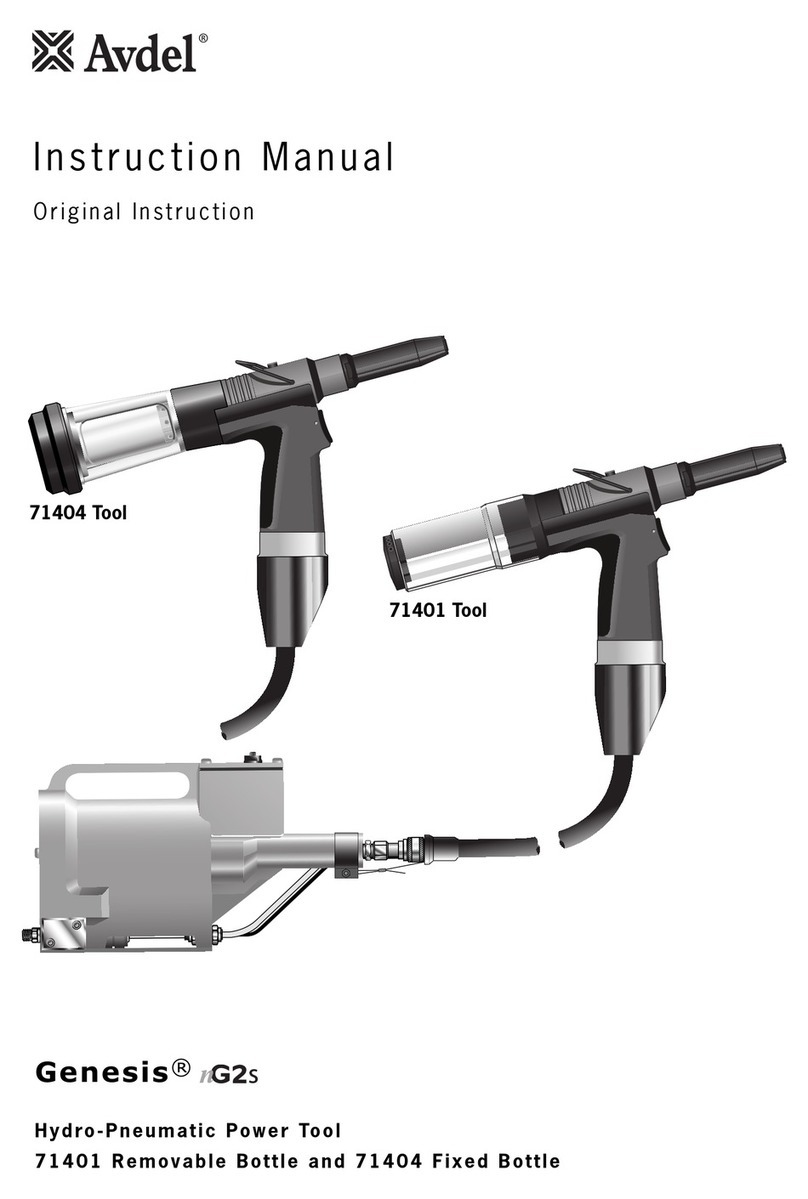

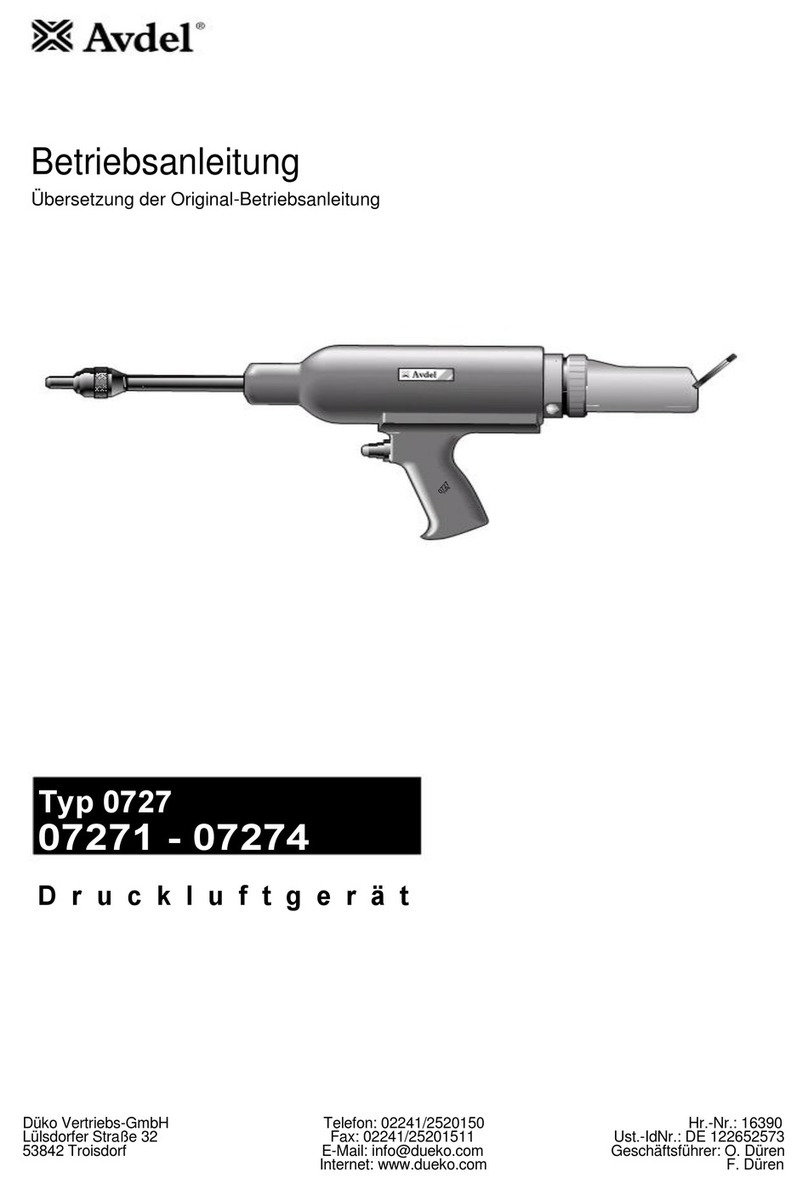

Avdel 73432-02000 User manual

Instruction Manual

Original Instruction

AV™15 Installation Tool –73432-02000

Hydro-Electric Power Tool

2

Contents

Safety Instructions 3 to 4

Specification 5

Intent of Use 5

Placing Tool Specification 5

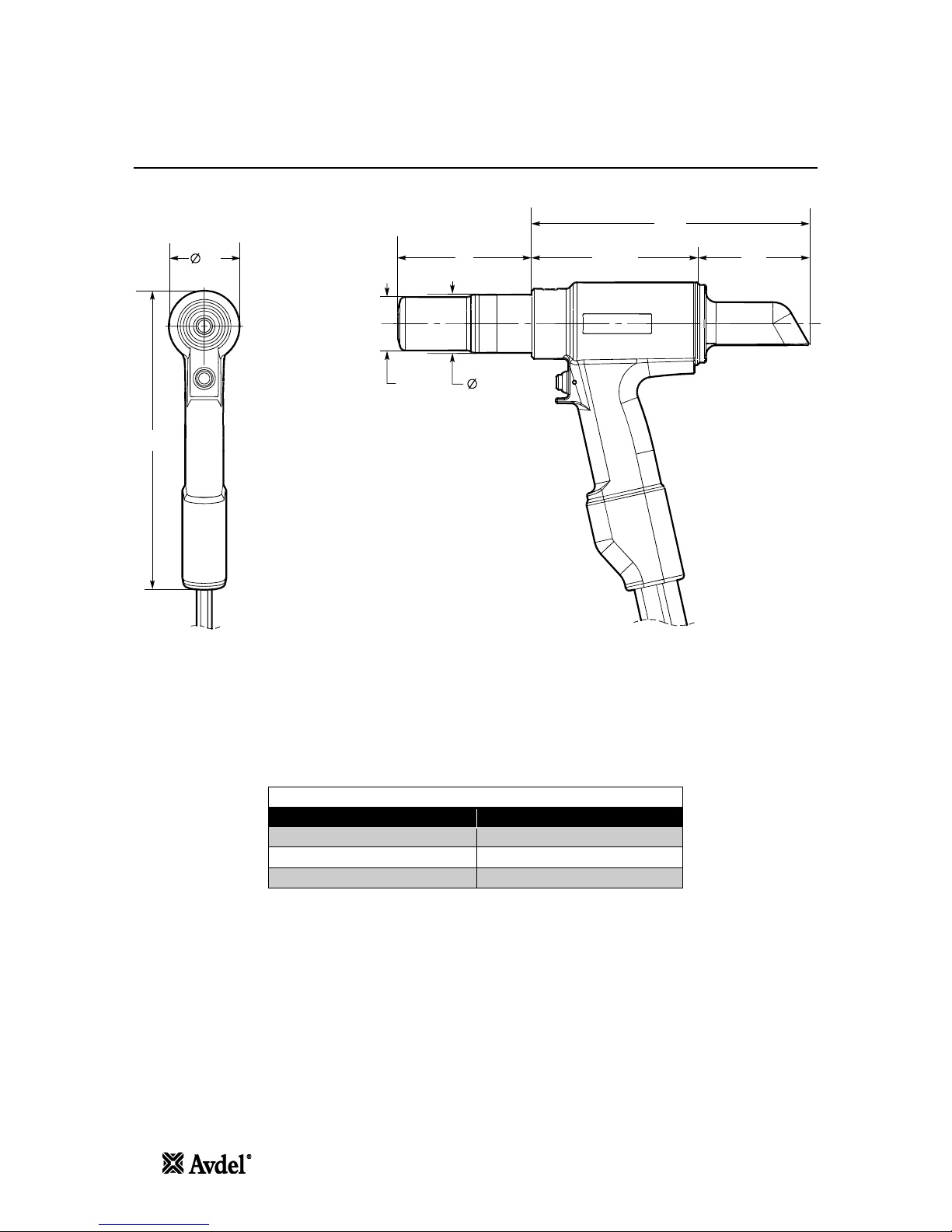

Placing Tool Dimensions 6

Putting Into Service 7

Principle of Operation 7

Preparation for Use 8

Operating Instructions 9

Servicing the Tool 10

Daily / Weekly / Annually 10

Service Kit 10

Dismantling Instructions 11 to 14

General Assembly of Installation Tool 73432-02000 15

General Assembly Drawing 15 to 16

Parts List 17

Safety Data 18

Enerpac®HF Hydraulic Oil - Safety Data 18

MolyLithium Grease EP 3753 - Safety Data 18

Molykote®111 Grease - Safety Data 19

Fault Diagnosis 20

Symptom / Possible Cause / Remedy 20 to 21

Declaration of Conformity 23

LIMITED WARRANTY

Avdel makes the limited warranty that its products will be free of defects in workmanship and materials which

occur under normal operating conditions. This Limited Warranty is contingent upon: (1) the product being

installed, maintained and operated in accordance with product literature and instructions, and (2) confirmation by

Avdel of such defect, upon inspection and testing. Avdel makes the foregoing limited warranty for a period of one

hundred and eighty (180) days following Avdel’s delivery of the product to the direct purchaser from Avdel. In the

event of any breach of the foregoing warranty, the sole remedy shall be to return the defective Goods for

replacement or refund for the purchase price at Avdel’s option. THE FOREGOING EXPRESS LIMITED WARRANTY

AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES. ANY

IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY ARE HEREBY

SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL.

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the

specification of any product without prior notice.

3

Safety Instructions

This instruction manual must be read with particular attention to the following safety rules, by any person

installing or operating this tool.

1Do not use outside the design intent.

2Do not use equipment with this tool/machine other than that recommended by Avdel®UK Limited.

3Any modification undertaken by the customer to the tool/machine shall be the customer’s entire responsibility.

4Always fully disconnect the tool from the hydraulic pump unit before attempting to adjust, remove or fit the nose

assembly.

5Do not operate a tool/machine that is directed towards any person(s).

6Always adopt a firm footing or a stable position before operating the tool/machine.

7It is recommended that ear and eye protection be worn by the operator and those in the vicinity.

8Do not fit flexible hoses rated at less than 700bar (10,000 PSI) working pressure.

9Avoid damaging hydraulic hoses. Avoid sharp bends and kinks when routing hydraulic hoses. Using a bent or

kinked hose will cause severe back-pressure. Sharp bends and kinks will internally damage the hose leading to

premature hose failure.

10 Do not drop heavy objects on hoses. A sharp impact may cause internal damage to hose wire strands and lead

to premature hose failure.

11 Do not lift the placing tool by the hoses. Always use the placing tool handle.

12 Do not pull or move the hydraulic pump unit using the hoses. Always use the pump unit handle or roll cage.

13 The operating pressure shall not exceed 550bar (8,000 PSI).

14 Care shall be taken to ensure that spent pintails are not allowed to create a hazard.

15 The flexible pintail deflector must always be attached to the tool and in good condition.

16 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the

tool.

17 The tool should be kept clean and dry for the best possible grip.

18 When carrying the tool from place to place keep hands away from the trigger to avoid inadvertent start up.

19 The machine must be maintained in a safe working condition at all times and examined at regular intervals for

damage and function by trained competent personnel. Any dismantling procedure shall be undertaken only by

personnel trained in Avdel®procedures. Do not dismantle the machine without prior reference to the

maintenance instructions. Contact Avdel®with your training requirements.

20 The machine shall at all times be operated in accordance with relevant Health & Safety legislation. In the UK

the "Health & Safety at Work etc Act 1974" applies. Any question regarding the correct operation of the

machine must be directed to Avdel®.

4

Safety Instructions

AVDEL®RECOMMENDS THAT ONLY AVDEL®/ENERPAC®HYDRAULIC PUMP UNITS BE USED TO DRIVE

INSTALLATION TOOLS, AS OTHER MAKES OF HYDRAULIC POWER UNITS MAY NOT OPERATE AT THE SAFE

DESIGNED WORKING PRESSURES.

ENSURE THAT THERE IS ADEQUATE CLEARANCE FOR THE TOOL OPERATOR'S HANDS BEFORE PROCEEDING.

DO NOT ABUSE THE TOOL BY DROPPING OR USING IT AS A HAMMER.

KEEP DIRT AND FOREIGN MATTER OUT OF THE HYDRAULIC SYSTEM OF THE TOOL AS THIS WILL CAUSE THE

TOOL AND PUMP UNIT TO MALFUNCTION.

5

Specification

Intent of Use

The AV™15 Installation Tool is principally a piston and cylinder assembly. When coupled hydraulically and electrically to

a compatible hydraulic power source and the relevant nose assembly is attached, it is then used to install 1/2” Infalok®

and 1/2” Avbolt®in Industrial Environments.

The placing tool and hydraulic pump unit may only be used in accordance with the operating instructions for placing

Avdel®fasteners.

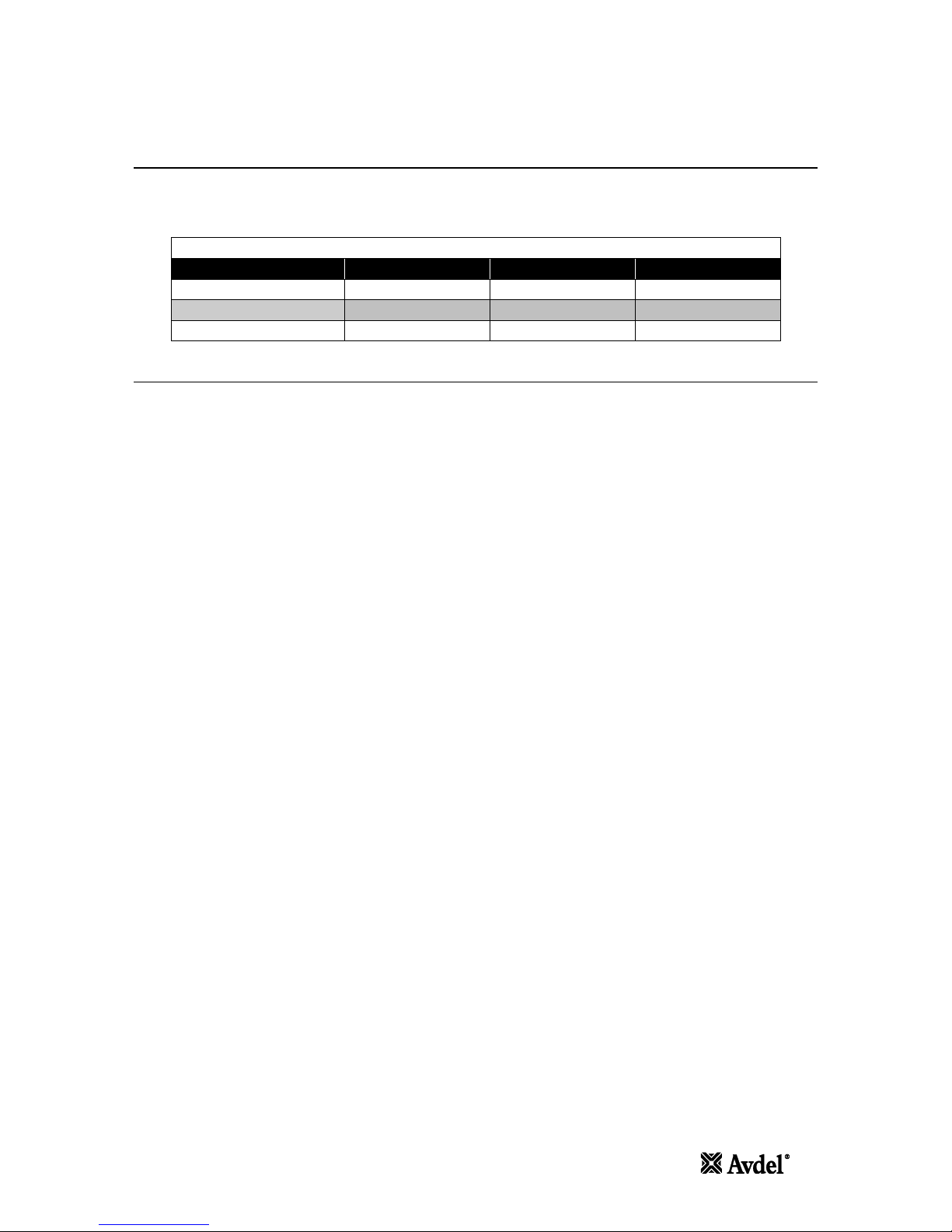

Refer to the table below for the list of applicable fasteners and associated nose equipment.

Refer to the datasheets listed in the table for the relevant nose assembly instructions.

FASTENER

NOSE ASSEMBLY

NOSE ASSEMBLY

DATASHEET

TYPE

SIZE

PART NUMBER

DIM. ‘A’

DIM. ‘B’

PART NUMBER

AVBOLT®

1/2”

73432-03100

108 mm

43 mm

07900-00905

73433-03100*

108 mm

43 mm

07900-00905

INFALOK®

1/2”

73432-03200

107 mm

43 mm

07900-00919

73433-03200*

107 mm

43 mm

07900-00919

*Nose assembly with jaw release.

Refer to the illustration on page 6 for the identification of the nose assembly dimensions ‘A’ and ‘B’.

The safety instructions must be followed at all times.

Placing Tool Specification

SPECIFICATION

METRIC

IMPERIAL

Force:

Pull at stated pull pressure

80.0 kN

17984.7 lbf

Push Off at stated return pressure

37.0 kN

8317.9 lbf

Pressure:

Pull

510 bar

7397 PSI

Return

200 bar

2901 PSI

Stroke:

Piston Stroke

32.0 mm

1.26 in

Weight:

Without nose equipment

4.5 kg

9.9 lb

Noise Level:

Less than

80 dB(A)

Vibration:

Less than

2.5 m/s2

8 ft/s2

Hydraulic Oil:

Enerpac®Hydraulic Oil –HF-95X

Product Range:

Avbolt®

12.7 mm

1/2 in

Infalok®

12.7 mm

1/2 in

Additional Features:

Stem Ejection –Front or Rear

Rear

Seal Arrangement

Twin Lip and Wiper Seals

Hydraulic Bearing Rings

Yes –Front and Rear

Protective Handle / Hose Gator

Yes

Protective Hose Guard

Yes

Hose / Cable Retention Clamps

Yes

6

Specification

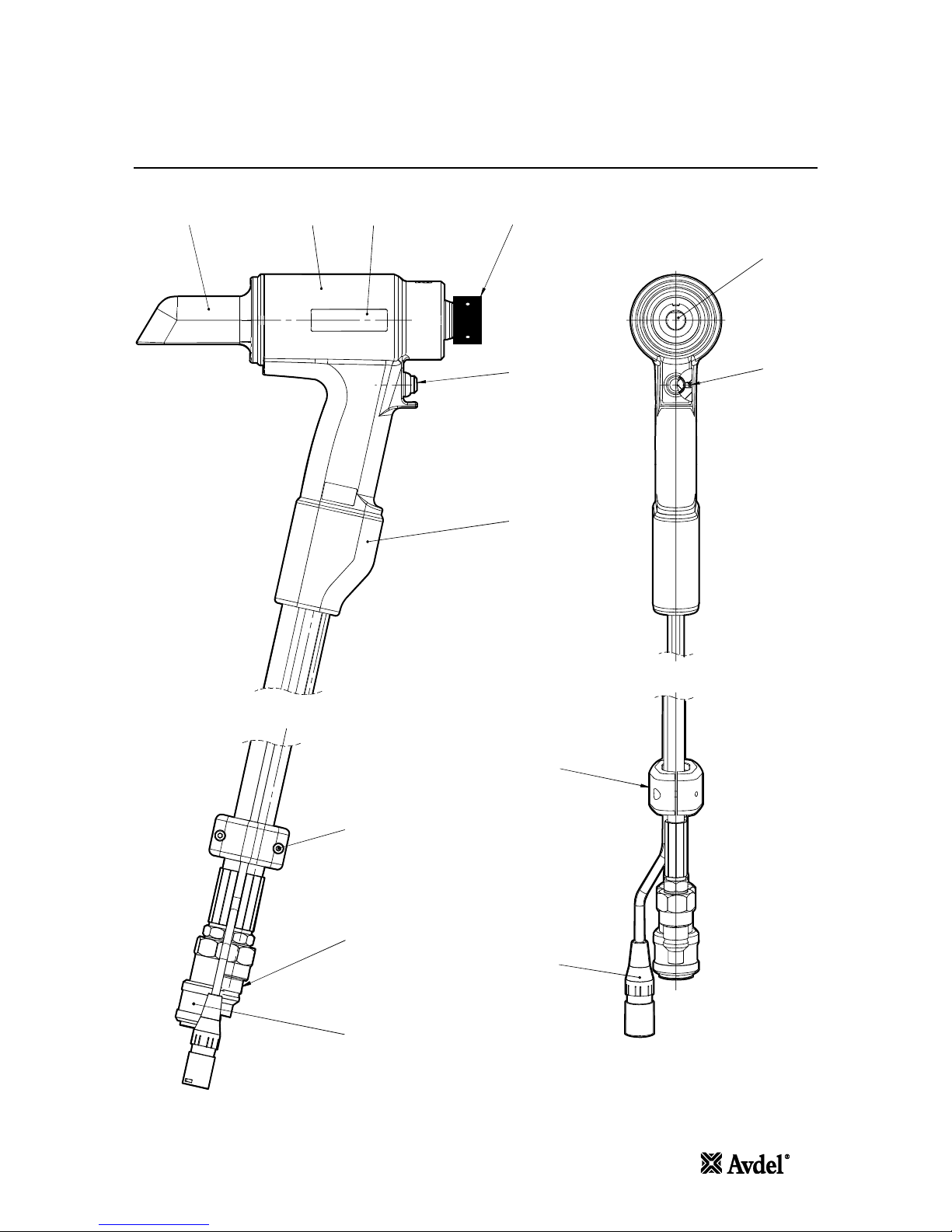

Placing Tool Dimensions

246

66 134.5

46.5

87

B

A

222

All dimensions are shown in millimetres.

Refer to the table on page 5 for the nose assembly dimensions ‘A’ and ‘B’.

The tool is fitted with two Hydraulic Hoses and an electrical Control Cable, 0.6m in length. Additional hydraulic hose and

cable extension lengths are available to order separately as required. Refer to the table below for the available hose

assembly lengths and associated part numbers.

HYDRAULIC HOSE ASSEMBLY

PART NUMBER

HOSE LENGTH

07008-00448

5 Metre

07008-00449

10 Metre

07008-00450

15 Metre

7

Putting Into Service

Principle of Operation

IMPORTANT - READ BOTH THE SAFETY INSTRUCTIONS ON PAGE 3 AND 4 AND THE PUMP UNIT INSTRUCTION

MANUAL CAREFULLY BEFORE PUTTING INTO SERVICE

When both hoses and control cable are connected to the Avdel®/Enerpac®hydraulic pump unit, the pull and return cycles

of the tool are controlled by depressing and releasing the trigger located in the handle.

When the switch is depressed the solenoid valve, located in the hydraulic pump unit, is energised and directs the

pressurised oil flow to the pull side of the piston in the placing tool. This also allows the oil in the return side of the

placing tool to return to the reservoir.

During the pull cycles the piston/collet assembly moves towards the rear of the tool allowing the O-ring type cushion to

push the follower and jaws forward. If a fastener pin has been inserted in the nose assembly, the jaw set will clamp onto

the pintail and assembly will commence.

For Avbolt®and Infalok®the cycle of installation will first clamp the joint to be fastened and then as the anvil continues

to move forward the collar will be swaged into the locking grooves of the pin. At the end of the swaging cycle the anvil

will come up against the joint and as movement continues the pintail will be broken off.

The trigger switch should be released immediately after pin break occurs. Releasing the trigger switch will cause the

solenoid to de-energise and reverse the flow of pressurised oil.

If the trigger is not released, the placing tool piston will continue to move towards the rear of the tool until it reaches the

end of its stroke. The pressure in the pull side will then increase until a preset ‘High Pressure’ value is achieved at the

pump. At this point the solenoid valve will automatically de-energise and reverse the flow of pressurised oil to the return

side of the placing tool.

In either case, pressurised oil will now flow into the return side of the placing tool, with the oil in the pull side returning

to the reservoir.

The forward movement of the piston/collet assembly will eject the installed fastener from the anvil.

At the point of releasing the trigger or when the ‘High Pressure’ value is achieved, the solenoid valve will de-energise and

activate a preset ‘Return Timer’. This controls the time that the pump motor will continue run before switching to the idle

mode. The timer can be manually set between 5 and 20 seconds to ensure that the placing tool piston always fully

returns to the forward position (refer to pump manual 07900-01030, pages 10 and 13).

When the piston returns to the fully forward position, the pressure will increase to preset low pressure value - c200bar.

The pump motor will continue to run until the Return Timer has expired. After this time period the motor will stop

automatically and valve will switch to the idle position. The solenoid valve will then automatically cycle to release

pressurised oil to the reservoir from both the pull and return side of the placing tool.

This keeps the installation tool in the forward position. No pressure will be present in the hydraulic system at this point.

The hydraulic pump unit will automatically start up on depression of the tool trigger switch.

8

Putting Into Service

Preparation for Use

CAUTION - CORRECT PULL AND RETURN PRESSURES ARE IMPORTANT FOR PROPER FUNCTION OF THE

ISTALLATION TOOL. PERSONAL INJURY OR DAMAGE TO EQUIPMENT MAY OCCUR WITHOUT CORRECT

PRESSURES. THE PULL AND RETURN PRESSURES SUPPLIED BY THE HYDRAULIC PUMP UNIT MUST NOT

EXCEED THOSE PRESSURES LISTED IN THE PLACING TOOL SPECIFICATION

IMPORTANT –BEFORE PUTTING THE PLACING TOOL AND HYDRAULIC HOSE SET INTO SERVICE:

ENSURE THAT THE PUMP PRESSURE RELIEF VALVES HAVE BEEN SET IN ACCORDANCE WITH THE PUMP

INSTRUCTIONS AND THE MAXIMUM PRESSURES SPECIFIED FOR THE PLACING TOOL AND HOSES.

ENSURE THAT THE HOSE KIT IS PRIMED WITH HYDRAULIC FLUID IN ACCORDANCE WITH THE PROCEDURE IN

THE PUMP INSTRUCTION MANUAL 07900-01030.

Ensure the mains power supply to the hydraulic pump unit is switched off.

Connect the placing tool hydraulic hose quick couplers directly to the pump unit before connecting the electrical

control cable. Hoses and control cable must be connected in this order and disconnected in reverse order.

Switch on the mains supply to the hydraulic pump unit. Wait 5 seconds for the pump unit to complete the boot

sequence, before pressing the trigger switch. When all set the LCD screen on the pump unit will display

‘AVDEL’.

During the boot sequence the pump control system identifies any trigger operation as a potential malfunction

and prevents the motor from starting. The LCD screen will display ‘BUTTON FAULT’ in this instance. Reset by

switching off the power supply for 10 seconds.

Ensure that the placing tool is positioned below the pump reservoir tanks. Depress and release the placing tool

trigger switch a few times to almost the full stroke of the tool to circulate hydraulic fluid and expel any air from

the tool.

Observe action of tool. Check for fluid leaks and ensure that in the idler mode the piston is in the fully forward

position. The placing tool will now be primed.

Switch off the mains power supply to the hydraulic pump unit and then disconnect the placing tool from the

pump unit in reverse order to that described above.

Now connect the placing tool to the primed hydraulic hose kit and electrical control cable. Then connect

hydraulic hose kit quick couplers and the electrical control cable to the pump unit.

Attach the nose assembly to the tool as per the instructions in the relevant nose assembly datasheet.

Switch on the mains supply to the hydraulic pump unit as described above.

Depress and release the placing tool trigger switch a few times to almost the full stroke of the tool to circulate

hydraulic fluid.

The placing tool is now ready for use.

9

Putting Into Service

Operating Instructions

To Install an Avbolt®Fastener

Check work and remove excessive gap. (Gap is the space between components of the Joint. Gap is excessive if

not enough pintail sticks through the collar for the nose assembly jaws to grab onto).

Put Avbolt®fastener into hole.

Push nose assembly onto pin until the nose assembly anvil stops against the collar. Tool and nose assembly

must be held at right angles (90°) to the work.

Depress tool trigger switch to start installation cycle.

When the forward motion of the nose assembly anvil stops and the pintail breaks off, release the trigger. The

tool will go into its return stroke and push off the installed fastener. At the end of the return stroke the jaws will

partially release the expended pintail which can then be pushed through the jaws with the next installation and

then ejected through the rear of the tool.

Once the installed fastener been ejected, the tool and nose assembly is ready for the next installation.

To Install an Infalok® Fastener

Check work and remove excessive gap. (Gap is the space between components of the Joint. Gap is excessive if

not enough pintail sticks through the collar for the nose assembly jaws to grab onto).

Put Infalok®fastener into hole.

Slide Infalok®collar over pin. (The beveled end of the collar must be towards the nose assembly and tool.)

Push nose assembly onto pin until the nose assembly anvil stops against the collar. Tool and nose assembly

must be held at right angles (90°) to the work.

Depress tool trigger switch to start installation cycle.

When the forward motion of the nose assembly anvil stops and the pintail breaks off, release the trigger. The

tool will go into its return stroke and push off the installed fastener. At the end of the return stroke the jaws will

partially release the expended pintail which can then be pushed through the jaws with the next installation and

then ejected through the rear of the tool.

Once the installed fastener been ejected, the tool and nose assembly is ready for the next installation.

CAUTION - DO NOT ATTEMPT TO BREAK OFF A PINTAIL WITHOUT THE INSTALLATION OF A COLLAR AS THIS

WILL CAUSE THE UNSECURED PORTION OF THE AVBOLT®OR INFALOK®PINTAIL TO EJECT FROM THE NOSE

AT A HIGH SPEED AND FORCE.

10

Servicing the Tool

IMPORTANT - READ SAFETY INSTRUCTIONS ON PAGE 3 AND 4. THE EMPLOYER IS RESPONSIBLE FOR

ENSURING THAT TOOL MAINTENANCE INSTRUCTIONS ARE GIVEN TO THE APPROPRIATE PERSONNEL. THE

OPERATOR SHOULD NOT BE INVOLVED IN MAINTENANCE OR REPAIR OF THE TOOL UNLESS PROPERLY

TRAINED. THE TOOL SHALL BE EXAMINED REGULARLY FOR DAMAGE AND MALFUNCTION.

Daily

Check placing tool, hoses and quick couplers for oil leaks.

Worn or damaged hoses and couplings should be replaced.

Check that the stroke of tool meets the specification.

Check that the stem deflector is fitted.

Check that the pump pull / advance pressure relief valve is functioning correctly.

Check for worn anvil indicated by score marks on the installed collar. This can also be confirmed by referring to

the installed data in the fastener catalogue. Excessive wear can cause the anvil to rupture.

Weekly

Dismantle and clean the nose assembly especially the jaws as described in the relevant nose assembly

datasheet.

Check for oil leaks in placing tool, hoses and quick couplers.

Annually or every 250k operations

Every 250,000 cycles the tool should be completely dismantled and new components should be used where

worn, damaged or as recommended. All O-rings, back-up rings and seals should be renewed and lubricated

with MolyKote®111 grease before assembling.

Service Kit

For a complete service the following Service Kit is available:

SERVICE KIT: 73432-99990

PART NUMBER

DESCRIPTION

PART NUMBER

DESCRIPTION

07005-10118

Quick Coupler - Male

07900-00966

AV15 Piston Guide Sleeve

07005-10120

Quick Coupler - Female

07900-00967

AV15 End Cap Assembly Tool

07900-00961

AV15 Piston Bullet - Front

07992-00020

Grease –MolyLithium EP3753

07900-00962

AV15 Piston Bullet - Rear

07900-00755

Grease –Molykote®111

07900-00965

AV15 Front Gland Guide Rod

07900-00756

Loctite®243 Threadlocker

The following standard tools are also required:

Allen Key: 2.0 / 3.0 mm

Open End Flat Spanner: 12 / 14 / 18 / 24 / 45 mm A/F

PTFE Tape: 10 mm

Engineers Vice with Jaw Guards –150 mm

11

Servicing the Tool

Use only Enerpac®HF hydraulic oil –the use of any other oil may cause the placing tool and pump to malfunction and

will render the placing tool warranty null and void. Hydraulic oil is available to order under the following part numbers.

HYDRAULIC OIL

PART NUMBER

07992-00081

07992-00082

07992-00083

Enerpac®Part Number

HF-95X

HF-95Y

HF-95T

Volume

1 Litre

5 Litres

20 Litres

Viscosity

32 mm2/s

32 mm2/s

32 mm2/s

Dismantling Instructions

IMPORTANT –ENSURE THE MAINS POWER SUPPLY TO THE HYDRAULIC PUMP UNIT IS SWITCHED OFF

BEFORE REMOVING THE NOSE ASSEMBLY OR DISMANTLING THE PLACING TOOL.

Before Dismantling:

Uncouple the Quick Couplers 10 and 11 and the electrical Control Cable 14 between the placing tool and the

Hydraulic Hose Assembly.

Remove the nose assembly from the placing tool as per the instructions in the nose assembly datasheet.

For a complete service of the tool, we advise that you proceed with dismantling the tool in the order shown on pages 11

to 14. After dismantling the tool we recommend that you replace all seals.

All numbers in bold refer to the General Assembly and Parts List on pages 15, 16 and 17.

Head Piston Assembly:

Using a small flat screwdriver, remove the Pin 41 from the Collet Adapter 40.

Unscrew and remove the Collet Adapter 40 from the Piston 1.

Remove the Deflector 3, from the End Cap 17.

Clamp the tool handle in a vice with soft jaws so that the tool is pointing nose down. Insert the dowel pins on

the *End Cap Assembly Tool into the three holes in the End Cap 17.

Using a 24 mm A/F spanner, unscrew and remove the End Cap 17, from the Body 2.

Using a small flat screwdriver, remove O-Ring 21 from the End Cap 17 and discard.

Connect the spare *Quick Coupler - Male to the Quick Coupler –Female 11 on the Hydraulic Hose - Return 18.

This will release pressure from the return side of the Piston and ease the removal of the Rear Seal Gland 16.

Insert three M4 screws into the Rear Seal Gland 16, and use them to pull the part off the rear shaft of the

Piston 1and out of the Body 2.

Using a small flat screwdriver or similar tool, remove O-Ring 30 and Spiral Back-up Ring 36, from the external

groove on the Rear Seal Gland 16, and discard. When removing the seals, take care not to damage the surface

of the Rear Seal Gland with the screwdriver.

Remove Rod Seal 28 and Wiper Seal 31, from the internal grooves on the Rear Seal Gland 16, and discard.

When removing the seals, take care not to damage the surface of the Rear Seal Gland with the screwdriver.

All numbers in bold refer to the General Assembly and Parts List on pages 15, 16 and 17.

*Service Kit on page 10

12

Servicing the Tool

Remove Rear Bearing Ring 29 and check the part for wear or damage. Discard if necessary.

Remove the placing tool from the vice and empty the hydraulic oil from the rear of the tool. Remove the spare

*Quick Coupler –Male from the Quick Coupler - Female 11.

Connect the spare *Quick Coupler - Female to the Quick Coupler - Male 10 on the Hydraulic Hose –Pull 19.

This will release any pressure from the pull side of the Piston 1and ease the removal of the Piston.

Screw the *Piston Bullet - Front on to the front of the Piston 1.

Place the Body 2nose up on a bench. Then using a soft mallet, tap the Piston 1towards the rear of the Body

and out the back end, taking care not to damage the bore within the Body.

Note that when removing the Piston 1, oil on the pull side of the Piston will leak from the front and rear of the

Body 2.

When removing the Piston 1, the Front Seal Gland 15 may be retained on the Piston shaft. If this is the case,

unscrew the *Piston Bullet - Front and pull the Front Seal Gland off of the Piston.

Using a small flat screwdriver remove Piston Seal 26 and the two Anti-Extrusion Rings 27, from the external

groove on the Piston 1, and discard. When removing the seals, take care not to damage the surface of the

Piston with the screwdriver.

If the Front Seal Gland 15 is still retained in the Body 2. Place the Body nose up on a bench and then push the

Front Seal Gland from the front until it is free from the recess within Body. The Front Seal Gland can then be

removed from the back end of the Body. Take care not to damage the bore within the Body when doing so.

Using a small flat screwdriver remove O-Ring 23 and Spiral Back-up Ring 34, from the external groove on the

Front Seal Gland 15, and discard. When removing the seals, take care not to damage the surface of the Front

Seal Gland with the screwdriver.

Remove Rod Seal 25 and Wiper Seal 22, from the internal grooves on the Front Seal Gland 15, and discard.

When removing the seals, take care not to damage the surface of the Front Seal Gland with the screwdriver.

Remove the Front Bearing Ring 24 and check the part for wear or damage. Discard if necessary.

Using a small flat screwdriver, remove O-Ring 21 from the Body 2and discard.

Remove the spare *Quick Coupler - Female from the Quick Coupler –Male 10 on the Hydraulic Hose –Pull 19.

Do not remove Set Screw 42 from the Body 2.

Assemble in reverse order to dismantling noting the following points:

Clean all components before assembling.

To aid assembly of seals apply a light coating of Molykote®111 grease to all seals, seal grooves, back-up rings

and the assembly tools.

Slide O-Ring 23 over the Front Seal Gland 15 and into the external groove. Insert the Spiral Back-up Ring 34 in

the same groove, in front of the installed O-Ring. Refer to the General Assembly and Parts List for the correct

orientation of the O-Ring and Spiral Back-up Ring.

All numbers in bold refer to the General Assembly and Parts List on pages 15, 16 and 17.

*Service Kit on page 10

13

Servicing the Tool

Press the Front Bearing Ring 24 into the internal recess within the Front Seal Gland 15 and then install Rod

Seal 25 behind the Front Bearing Ring. Install the Wiper Seal 22 in the front recess of the Front Seal Gland.

Refer to the General Assembly to ensure the correct orientation of the Rod Seal and Wiper Seal.

Lubricate the surface and leading edge of the Body 2bore into which the Front Seal Gland 15 is to be installed

with Molykote®111 grease.

Lubricate the spigot on the *Front Gland Guide Rod tool and then place the Front Seal Gland 15, Rod Seal 25

end first, fully over spigot. Insert *Front Gland Guide Rod into the rear of the Body 2and then push the Front

Seal Gland fully into the bore within the Body. Reasonable force is required to insert Front Seal Gland into the

Body, so the use of a press or vice may be necessary. Remove the *Front Gland Guide Rod while ensuring that

the Front Seal Gland stays in place.

Lubricate the seal groove and major external diameter of the Piston 1with Molykote®111 grease. Slide the

Piston Seal 26 over the front of the major Piston diameter and into the seal groove. Install two Anti-Extrusion

Rings 27 into the Piston seal groove, one either side of the Piston Seal.

Screw the *Piston Bullet - Front on to the front of the Piston 1. Lubricate the *Piston Bullet - Front, Piston shaft

and Piston Seal 26 with Molykote®111 grease.

Screw the *Piston Guide Sleeve fully into the rear of the Body 2. Lubricate the bores in both the Body and the

*Piston Guide Sleeve with Molykote®111 grease.

Connect the spare *Quick Coupler - Female to the Quick Coupler - Male 10 on the Hydraulic Hose –Pull 19.

This will allow air to be released from the pull side Piston 1when inserting the Piston.

Insert the assembled Piston 1into the rear of the Body 2and through the assembled Front Seal Gland 15. Push

the Piston into the fully forward position until it stops against the Front Seal Gland. Hydraulic oil will be

expelled from the Hydraulic Hose –Pull 19.

Remove the spare *Quick Coupler - Female from the Quick Coupler - Male 10 on the Hydraulic Hose 19.

Remove the *Piston Guide Sleeve from the rear of the Body 2.

Slide O-Rring 30 over the Rear Seal Gland 16 and into the external groove. Insert the Spiral Back-up Ring 36 in

the same groove, behind the installed O-Ring. Refer to the General Assembly and Parts List for the correct

orientation of the O-Ring and Spiral Back-up Ring.

Press the Rear Bearing Ring 29 into the internal recess within the Rear Seal Gland 16 and then install Rod Seal

28 behind the Rear Bearing Ring. Install the Wiper Seal 31 in the rear recess of the Rear Seal Gland. Refer to

the General Assembly to ensure the correct orientation of the Rod Seal and Wiper Seal.

Clamp the tool handle in a vice with soft jaws so that the tool is pointing nose down.

Lubricate the surface and leading edge of the Body 2bore into which the Rear Seal Gland 16 is to be installed

with Molykote® 111 grease. Lubricate the rear Piston 1shaft with Molykote®111 grease.

Insert the *Piston Bullet - Rear into the rear Piston 1shaft and Lubricate with Molykote®111 grease.

Fill the rear of the Body 2with Enerpac®HF hydraulic oil. Oil level should be just above the rear inlet bore into

the Body.

Connect the spare *Quick Coupler - Male to the Quick Coupler - Female 11 on the Hydraulic Hose - Return 18.

This will allow air to be released from the return side of the Piston when inserting the Rear Seal Gland 16.

All numbers in bold refer to the General Assembly and Parts List on pages 15, 16 and 17.

*Service Kit on page 10

14

Servicing the Tool

Place the Rear Seal Gland 16 over the *Piston Bullet - Rear. Then push the Rear Seal Gland over the Piston 1

shaft and into the rear of the Body 2. Push the Rear Seal Gland into the Body until a few internal threads are

exposed at the rear of the Body. Take care not to damage the O-Ring 30 and Spiral Back-up Ring 36 on the

threads when inserting the Rear Seal Gland.

Lubricate both the internal thread in the Body 2and the external thread on End Cap 17 with MolyLithium

Grease.

Screw the End Cap 17 fully into the rear of the Body 2using the *End Cap Assembly Tool. In doing so, the

Rear Seal Gland 16 will be pressed into position within the Body and a small amount of oil will be expelled

from the Hydraulic Hose - Return 18.

Remove spare *Quick Coupler - Male from the Quick Coupler - Female 11 on the Hydraulic Hose –Return 18.

Push the Deflector 3, on the End Cap 17.

Screw the Collet Adapter 40 on to the Piston 1until the front face is flush with the end of the Piston. Align the

hole in the Collet Adapter with the slot in the end of the Piston and then insert Locking Pin 41.

Prime the placing tool as described in Preparation for Use on page 8.

Hose Assembly:

Remove the two Screws 9from the Hose Clamp 13 using a 3.0mm Allen Key. Remove the Hose Clamp and

Clamp Insert 20 from the Protective Sleeve 37 and Hydraulic Hoses 18 and 19.

Using the small flat screwdriver prize the Handle Gator 8from the handle of Body 2. Pull the Handle Gator over

the Protective Sleeve 37, Hydraulic Hoses 18 and 19 and remove.

Cut the Cable Tie 35 and slide back the Protective Sleeve 37 to expose the fittings on the Hydraulic Hoses 18

and 19. The Hydraulic Hoses can be removed form the Body 2using 12mm and 14mm spanners.

The Quick Couplers 10 and 11 can be removed from the Hydraulic Hoses 18 and 19 using 18mm and 24mm

spanners.

To remove Trigger Switch 7, first loosen Cable Gland 38, so that the Control Cable 14 is free to move within the

Body 2. Then undo M4 Set Screw 12 using a 2.0mm Allen Key.

Push the Control Cable 14 into the Body 2and simultaneously pull the Trigger Switch 7out of the Body to

expose the solder joints on the Trigger Switch terminals. Unsolder the terminals to remove the Trigger Switch

and Trigger Insert 39. The Trigger Insert is bonded to the Trigger Switch and cannot be removed.

The Control Cable 14 can now be pulled from the Body 2and removed from the Protective Sleeve 37.

Assemble in reverse order to dismantling noting the following points:

Prior to assembly clean all threads on the Quick Couplers - Male 10 and Female 11 and the Hydraulic Hoses –

Return 18 and Pull 19. Apply 2 to 3 layers of 10mm PTFE tape to the male threads of both Hydraulic Hoses.

When replacing the Trigger Switch 7apply Loctite®243 to the male thread on the Trigger Switch before

assembling the Trigger Insert 39.

Apply Loctite®243 to M4 Set Screw 12 prior to assembly.

Once assembled, prime the tool as per the instructions on page 8.

All numbers in bold refer to the General Assembly and Parts List on pages 15, 16 and 17.

*Service Kit on page 10

15

General Assembly of Installation Tool 73432-02000

3 4, 2 5 40

7

8

12

1

9

10

11

13

14

16

General Assembly of Installation Tool 73432-02000

21 22 34 23 24 25 26 27

39

28 29 30 36 31 21

35

37

38

DETAIL B

DETAIL C

DETAIL D

DETAIL E

42

DETAIL F

41 15 1 17

E

D

18

19

16

B

C

F

20

17

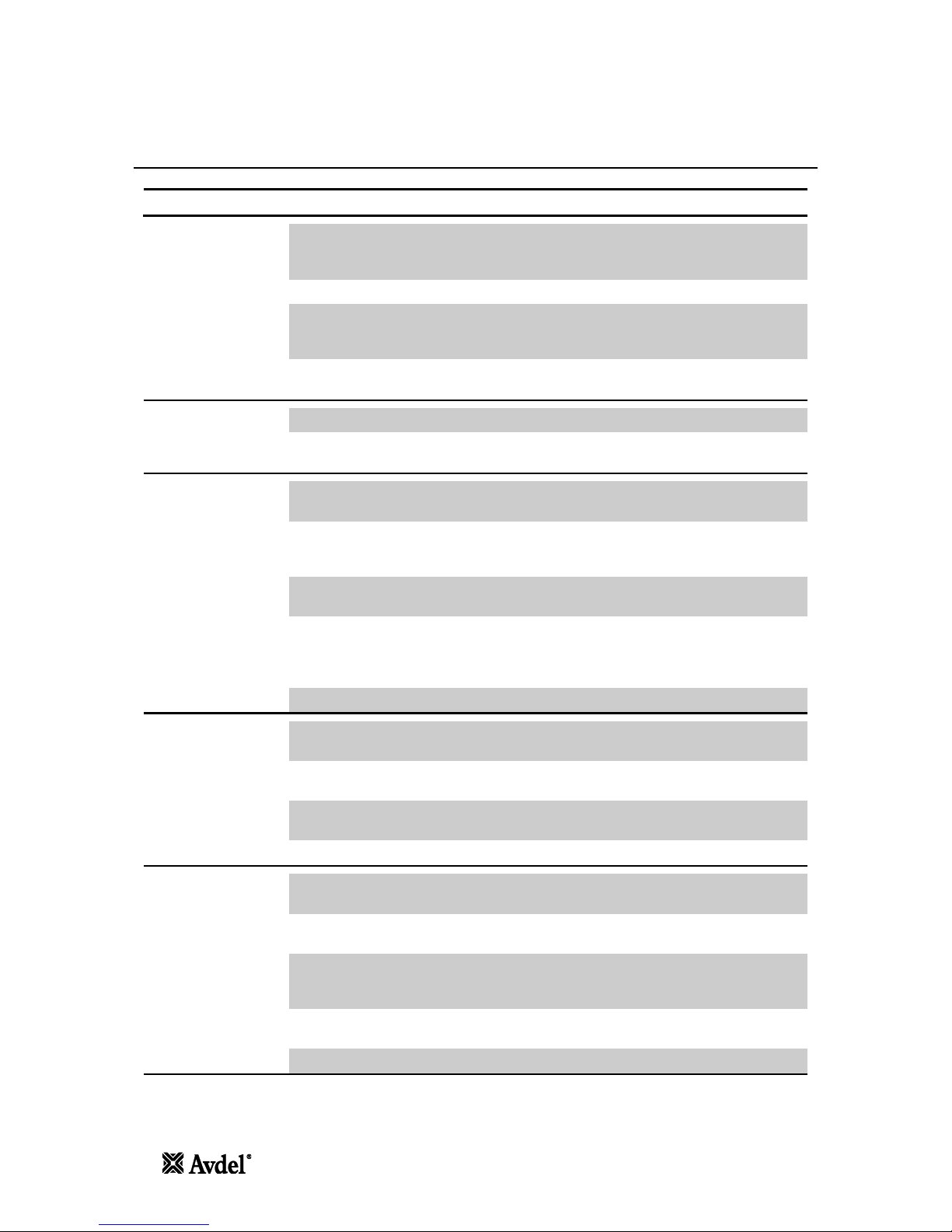

Parts List for Installation Tool 73432-02000

73432-02000 Parts List

ITEM

PART NUMBER

DESCRIPTION

QTY.

1

73432-02003

PISTON

1

2

73432-02001

BODY

1

3

73432-02011

DEFLECTOR

1

4

73430-02025

SAFETY LABEL

1

5

73432-02026

AV15 LABEL

2

6

7

07007-02103

TRIGGER SWITCH

1

8

73430-02020

HANDLE GATOR

1

9

07001-00686

M4 X 16 SKT CAP HD SCREW

2

10

07005-10118

QUICK COUPLER - MALE

1

11

07005-10120

QUICK COUPLER - FEMALE

1

12

07001-00479

M4 X 4 SKT SET SCREW

1

13

73430-02023

HOSE CLAMP

1

14

07007-02105

CONTROL CABLE

1

15

73432-02004

FRONT SEAL GLAND

1

16

73432-02006

REAR SEAL GLAND

1

17

73432-02005

END CAP

1

18

07005-10119

HYDRAULIC HOSE - RETURN

1

19

07005-10117

HYDRAULIC HOSE - PULL

1

20

73430-02024

CLAMP INSERT

1

21

07003-00460

O-RING

2

22

07003-00446

WIPER SEAL

1

23

07003-00459

O-RING

1

24

73432-02009

FRONT BEARING RING

1

25

07003-00445

ROD SEAL

1

26

07003-00449

PISTON SEAL

1

27

07003-00450

ANTI-EXTRUSION RING

2

28

07003-00447

ROD SEAL

1

29

73432-02010

REAR BEARING RING

1

30

07003-00462

O-RING

1

31

07003-00448

WIPER SEAL

1

32

33

34

07003-00493

SPIRAL BACK-UP RING

1

35

07007-02032

CABLE TIE

1

36

07003-00495

SPIRAL BACK-UP RING

1

37

07005-10121

PROTECTIVE SLEEVE

0.6m

38

07007-02104

CABLE GLAND

1

39

73430-02008

TRIGGER INSERT

1

40

73432-02012

COLLET ADAPTER - AV15

1

41

73432-02013

LOCKING PIN - AV15

1

42

07001-00481

M5 X 5 SKT SET SCREW

1

-

07900-01021

AV15 TOOL INSTRUCTION MANUAL

1

18

Safety Data

Enerpac®HF Hydraulic Oil - Safety Data

FIRST AID

SKIN:

Unlikely to cause harm to the skin on brief or occasional contact but prolonged or exposure may lead to dermatitis. Wash

skin thoroughly with soap and water as soon as reasonably practicable. Remove heavily contaminated clothing and wash

underlying skin.

ORAL:

Unlikely to cause harm if accidentally swallowed in small doses, though larger quantities may cause nausea and

diarrhea. If contamination of the mouth occurs, wash out thoroughly with water. Except as a deliberate act, the ingestion

of large amounts of product is unlikely. If it should occur, do not induce vomiting; obtain medical advice. Take person to

nearest medical centre.

EYES:

Unlikely to cause more than transient stinging or redness if accidental eye contact occurs. Wash eyes thoroughly with

copious quantities of water, ensuring eyelids are held open. Obtain medical advice if any pain or redness develops or

persists.

MEDICAL ADVICE:

Treatment should in general be symptomatic and directed to relieving any effects.

Note: High Pressure Applications:

Injections through the skin, resulting from contact with the product at high pressure, constitute a major medical

emergency. Injuries may not appear serious at first but within a few hours tissue becomes swollen, discoloured and

extremely painful with extensive subcutaneous necrosis.

Surgical exploration should be undertaken without delay. Thorough and extensive debridement of the wound and

underlying tissue is necessary to minimize tissue loss and prevent or limit permanent damage. Note that high pressure

may force the product considerable distances along tissue planes.

DISPOSAL

Remove all spills with inert absorbent material. Ventilate spill area. Place contaminated materials in a disposable

container and dispose in a manner consistent with local regulations.

FIRE

FLASH POINT: 200°C.

Extinguish with either dry chemical, foam or carbon dioxide. Do not enter confined space without self contained breathing

apparatus.

HANDLING

Use barrier cream or oil resistant gloves.

STORAGE

Undercover and consistent with local regulations for inflammable material.

MolyLithium Grease EP 3753 - Safety Data

Grease can be ordered as a single item, the part number is shown in the Service Kit page 10.

FIRST AID

SKIN:

As the grease is completely water resistant it is best removed with an approved emulsifying skin cleaner.

INGESTION:

Ensure the individual drinks 30ml Milk of Magnesia, preferably in a cup of milk.

EYES:

Irritant but not harmful. Irrigate with water and seek medical attention.

19

Safety Data

FIRE

FLASH POINT: Above 220°C.

Not classified as flammable.

Suitable extinguishing media: CO2, Halon or water spray if applied by an experienced operator.

ENVIRONMENT

Scrape up for incineration or disposal on approved site.

HANDLING

Use barrier cream or oil resistant gloves

STORAGE

Away from heat and oxidising agent.

Molykote®111 Grease - Safety Data

Grease can be ordered as a single item, the part number is shown in the Service Kit page 10.

FIRST AID

SKIN:

No first aid should be needed.

INGESTION:

No first aid should be needed.

EYES:

No first aid should be needed.

INHALATION:

No first aid should be needed.

FIRE

FLASH POINT: Above 101.1°C. (closed cup)

Explosive Properties: No

Suitable Extinguishing Media: Carbon Dioxide Foam, Dry Powder or fine water spray. Water can be used to cool fire

exposed containers.

ENVIRONMENT

No adverse effects are predicted.

HANDLING

General ventilation is recommended. Avoid eye contact.

STORAGE

Do not store with oxidizing agents. Keep container closed and store away from water or moisture.

20

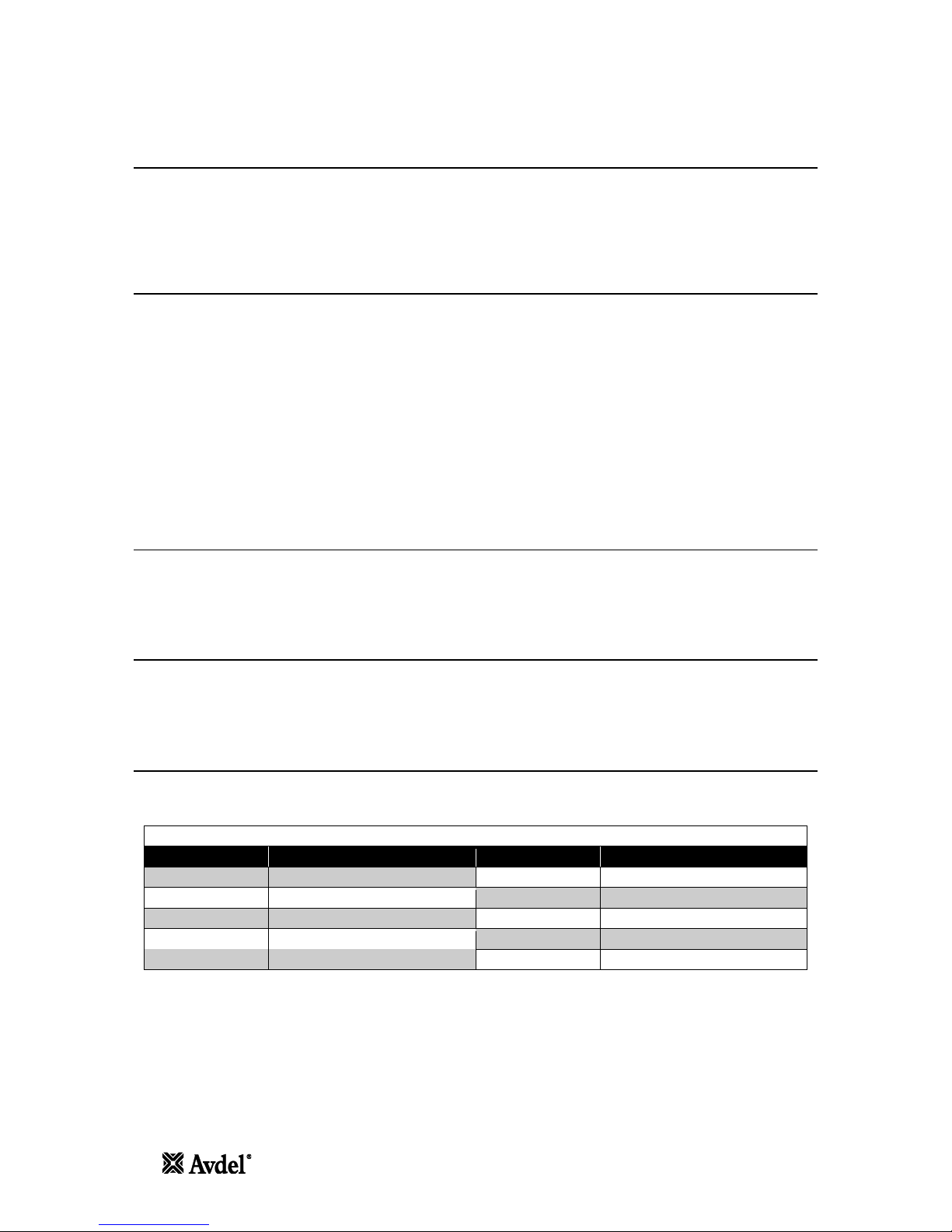

Fault Diagnosis

SYMPTOM

POSSIBLE CAUSE

REMEDY

PAGE REF.

Placing Tool will not

operate

Inoperative pump unit

Check pump power supply and

refer to pump unit instruction

manual

Faulty Quick Couplers 10 and 11

Replace Quick Couplers

14

Trigger Control Cable 14 not

connected correctly

Check Control Cable is correctly

connected at pump and placing

tool

8

Damaged Trigger Switch 7or

Control Cable 14

Replace Trigger Switch and/or

Control Cable

14

Trigger Switch 7does

not function

Pump in local mode

Refer to pump instruction manual

Trigger Switch 7, Control Cable

14 or connector damaged

Replace Trigger Switch and/or

Control Cable

14

Pump running but

placing tools does not

function

Hydraulic Hoses not connected

Check for correct connections at

pump and placing tool

8

Low oil level

Ensure placing tool is filled with

oil and correctly primed

Refer to pump instruction manual

8

Placing tool external oil leak

Inspect placing tool –replace

worn or damaged components

11 - 14

Hose Assembly external oil leak

Inspect Hose Assembly –ensure

hose connections are tight and/or

replace damaged hose

connectors

14

Pump internal/external oil leak

Refer to pump instruction manual

Placing tool operates

erratically

Low or erratic hydraulic pressure

supply

Refer to pump instruction manual

Worn or damaged hydraulic seals

in placing tool

Inspect placing tool –replace

worn or damaged seals

11 - 14

Worn or damaged hydraulic

sealing surfaces in placing tool

Inspect placing tool –replace

worn or damaged components

11 - 14

Pump internal/external oil leak

Refer to pump instruction manual

Pump builds full

pressure, but pintail

does not break

Breakload greater than placing

tool capacity at full pressure

Refer to placing tool specification

5

Flow to placing tool blocked

Check Quick Couplers 10 and 11

for full engagement

8

Pump pressure relief value set

too low

Adjust pressure relief valve

settings –refer to pump

instruction manual

Pull grooves on fastener pintail

stripped

See Symptom on page 21

9

Improper tool operation

9

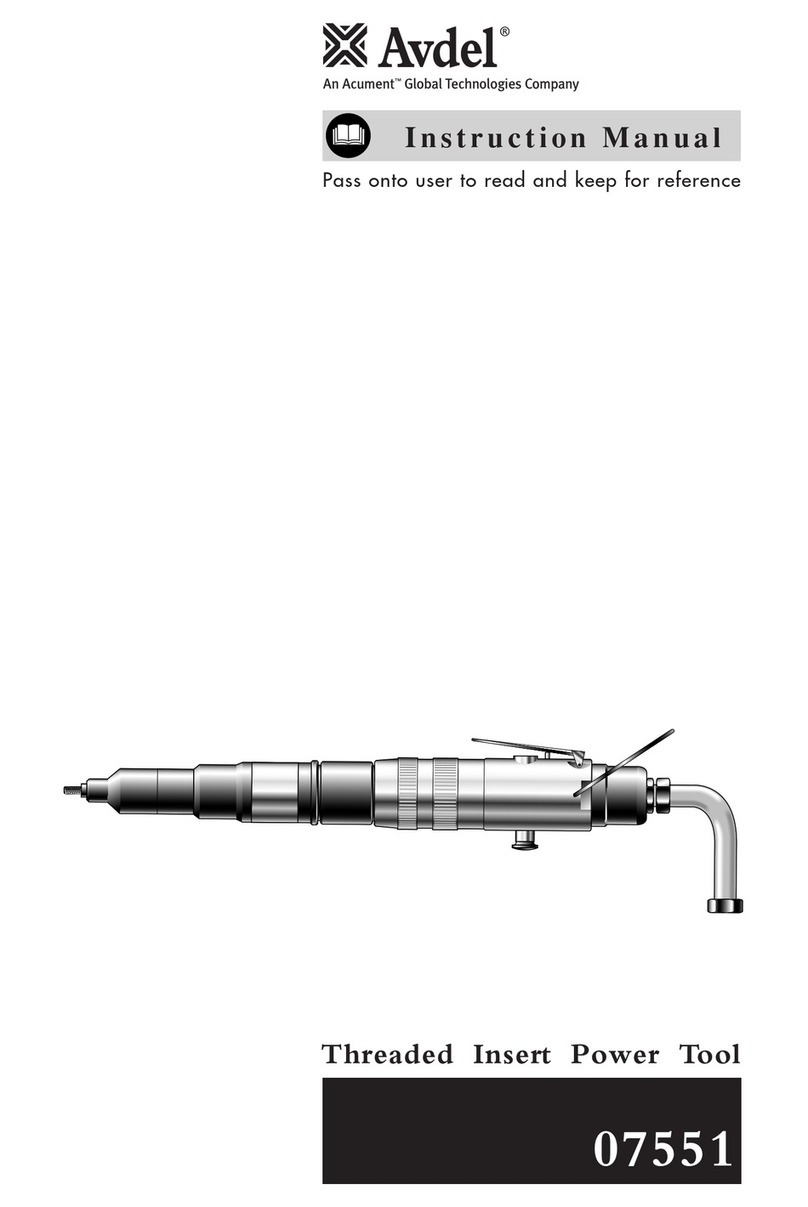

Table of contents

Other Avdel Power Tools manuals

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel 71234 User manual

Avdel

Avdel 7539-300X Series User manual

Avdel

Avdel 7265 User manual

Avdel

Avdel 0727 User manual

Avdel

Avdel TX2000 User manual

Avdel

Avdel 7530 User manual

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel genesis g2 User manual

Avdel

Avdel 07281 User manual