13

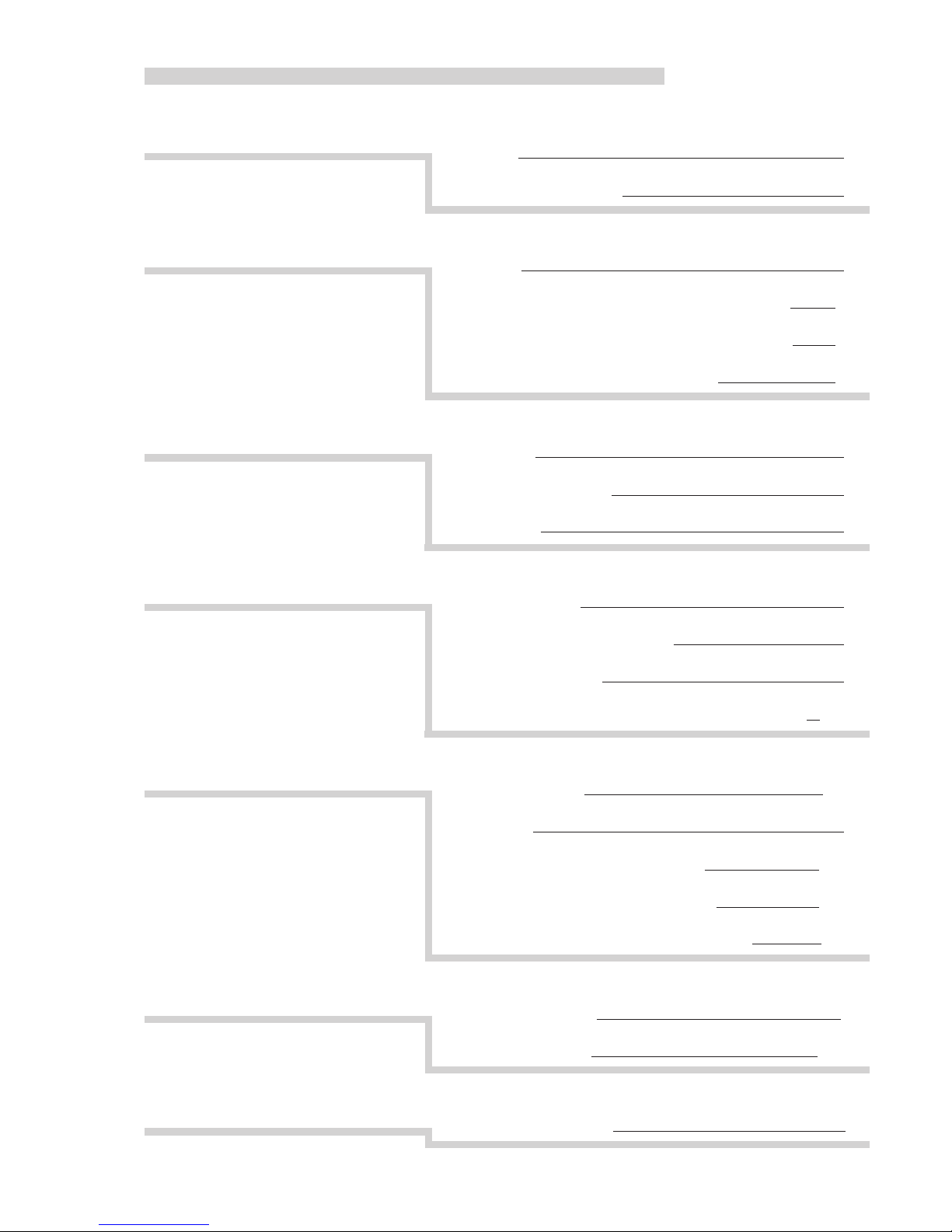

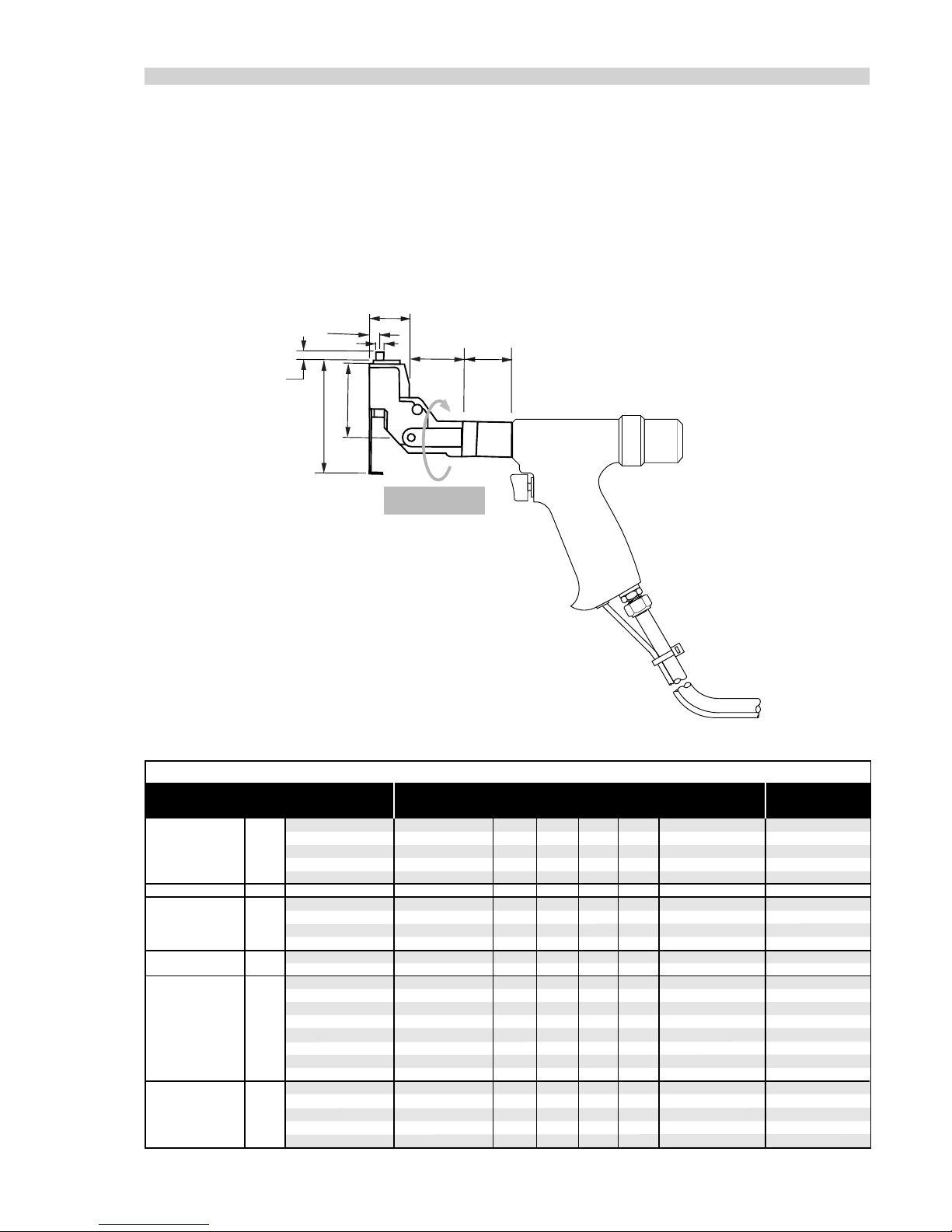

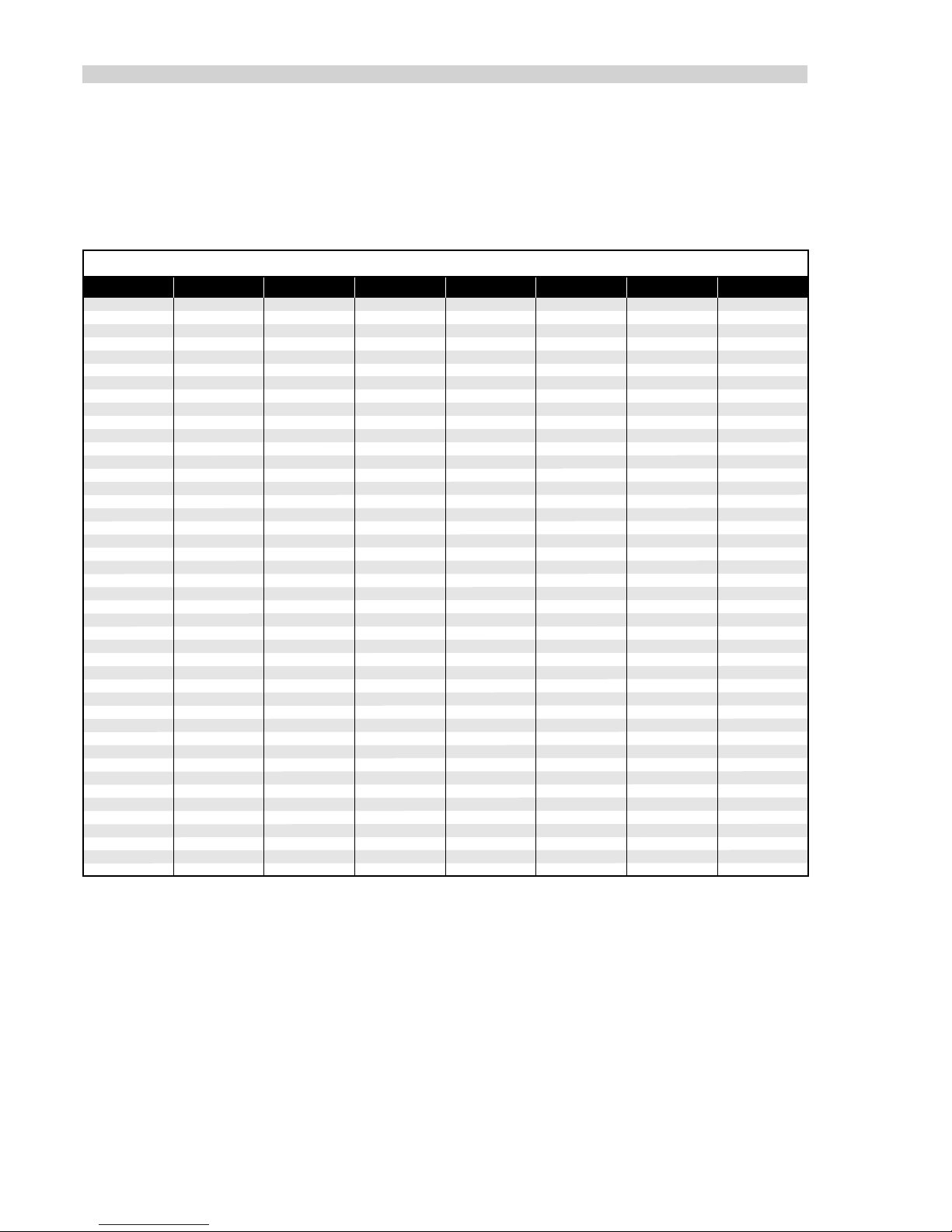

07241 & 07244 NOSE ASSEMBLY COMPONENTS

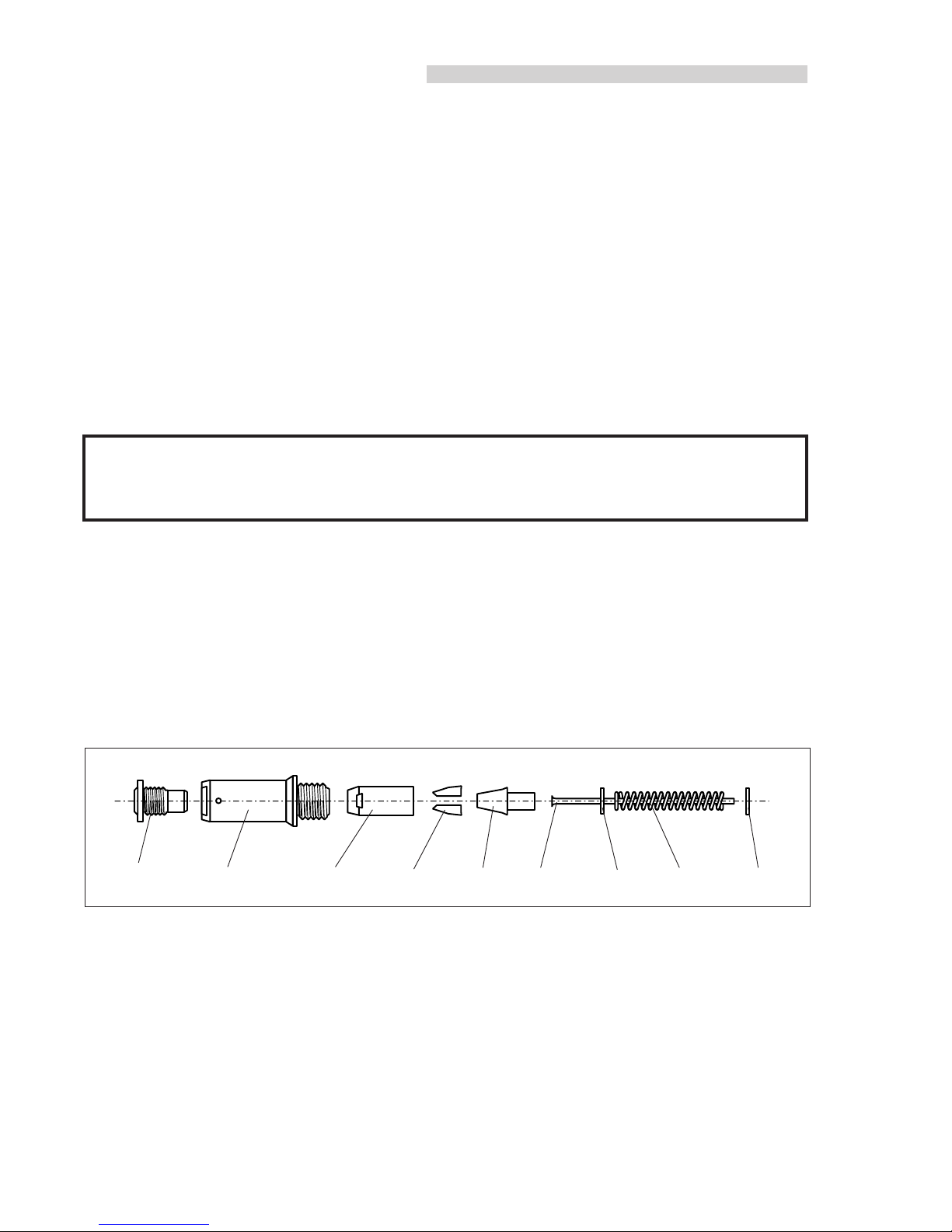

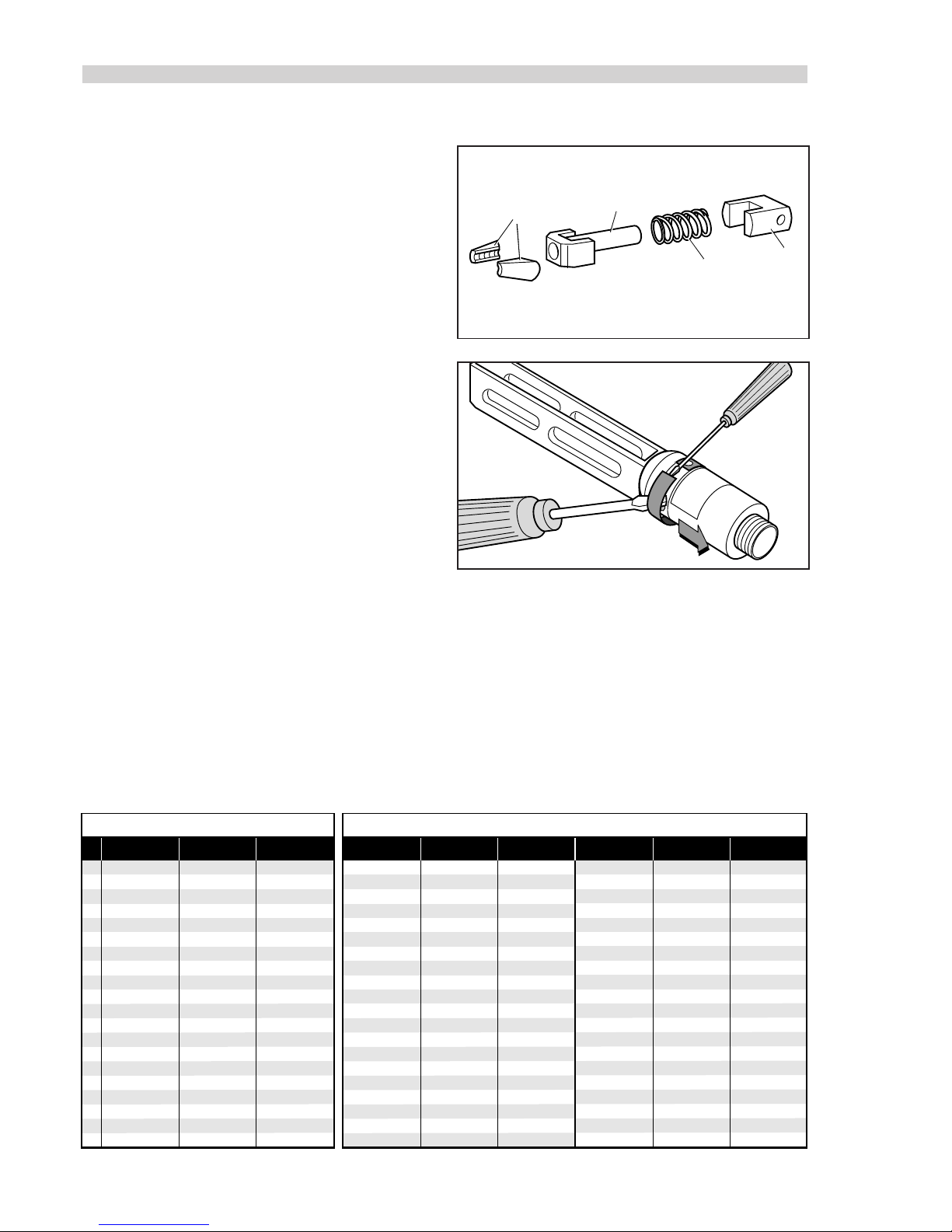

Each nose assembly represents a unique assembly of components which can be ordered individually. Component numbers refer to the

illustration on the opposite page. We recommend some stock as items will need regular replacement. Read the Nose Assemblies

servicing instructions opposite carefully. All nose assemblies also include a locking ring part number 07340-00327 (see illustration

opposite).

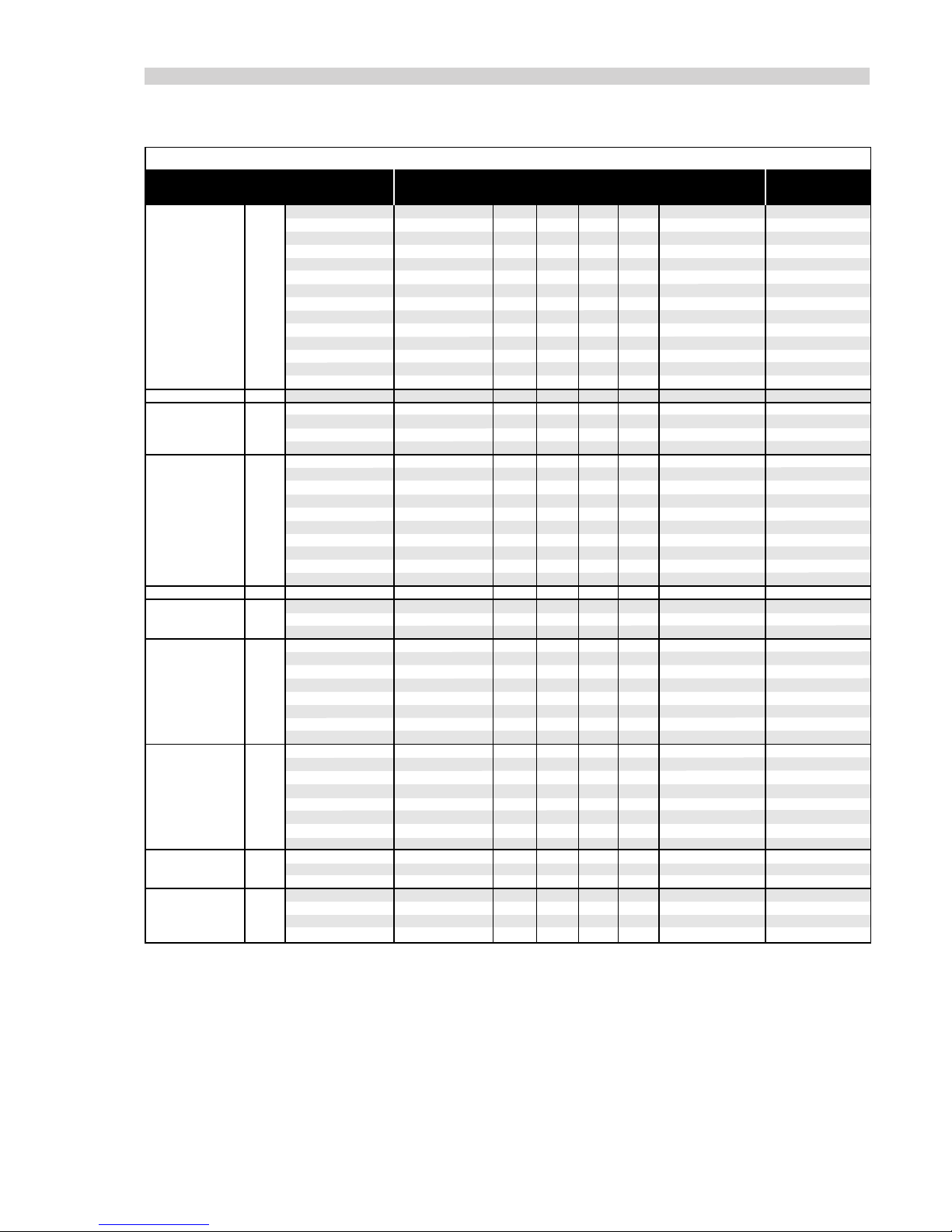

NOSE ASSY 1 2 3 4596

07244-02100 07381-04501 07340-00306 07340-00304 07340-00213 07241-03002 07241-02001 07241-02603

07244-02200 07244-02202 07244-02201 07340-00304 07340-07502 07241-03702 07241-02001 07241-03003

07244-02300 07381-04701 07340-00306 07340-00304 07340-00213 07241-03002 07241-02001 07241-02603

07245-02200 07381-04601 07340-00306 07340-00304 07340-00213 07241-02602 07241-02001 07241-03003

07245-02800 07498-01401 07340-00306 07340-00304 07340-07502 07241-03702 07241-02001 -

07244

NOSE ASSY 1 2 3 4569

07241-02000 07340-06000 07340-00306 07340-00304 07340-00213 07241-02002 07241-02001 07241-02003

07241-02100 07340-02805 07340-02804 e 07340-00304 07340-00213 07241-02002 07241-02001 07241-02003

07241-02200 07344-02101 07344-02001 07340-00304 07340-00213 07241-02202 07241-02001 07241-03003

07241-02400 07140-02104 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-02500 07340-06300 07340-00306 07340-00304 07340-00222 07241-02002 07241-02001 07241-02003

07241-02600 07340-06100 07340-00306 07340-00304 07340-00213 07241-02602 07241-02001 07241-03003

07241-02700 07340-02806 07340-02804 e 07340-00304 07340-00213 07241-02602 07241-02001 07241-02603

07241-02800 07344-02401 07344-02001 07340-00304 07340-00213 07241-02002 07241-02001 07241-03003

07241-02900 07140-02105 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-03000 07340-06200 07340-00306 07340-00304 07340-00213 07241-03002 07241-02001 07241-03003

07241-03100 07340-02807 07340-02804 e 07340-00304 07340-00213 07241-03002 07241-02001 07241-03003

07241-03200 07140-02106 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-03300 07340-06400 07340-00306 07340-00304 07340-00213 07241-02002 07241-02001 07241-02003

07241-03400 07340-06500 07340-00306 07340-00304 07340-00213 07241-02602 07241-02001 07241-02603

07241-03500 07340-06600 07340-00306 07340-00304 07340-00213 07241-03002 07241-02001 07241-03003

07241-03600 07340-04800 07340-00306 07340-00304 07340-00213 07241-03002 07241-02001 07241-03003

07241-03700 07490-04400 07340-00306 07340-00304 07340-07502 07241-03702 07241-02001 07241-03003

07241-03800 07498-01400 07340-00306 07340-00304 07340-07502 07241-03702 07241-02001 -

07241-03900 07344-02901 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-04000 07344-03001 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-04100 07344-03101 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-04200 07498-03001 07340-00306 07498-04503 07498-04501 07241-04202 07241-02001 07241-03003

07241-04300 07340-06701 07344-02001 07340-00304 07340-00229 07241-02602 07241-02001 07241-02603

07241-04400 07340-06801 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-04500 07340-06901 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-04600 07340-07001 07344-02001 07340-00304 07498-00229 07241-02602 07241-02001 07241-02603

07241-04700 07340-07101 07344-02001 07340-00304 07340-00229 07241-02202 07241-02001 07241-03003

07241-04800 07605-00220 07340-00306 07498-04503 07498-04501* 07241-04202 07241-02001 07241-03003

07241-04900 07340-08301 07340-00306 07340-00304 07340-07502 07241-03702 07241-02001 07241-03003

07241-05000 07340-07601 07340-00306 07340-00304 07340-00213 07241-02602 07241-02001 07241-02603

07241-05400 07498-09101 07340-00306 e 07340-00304 07340-07502 07241-03702 07241-02001 07241-03003

07241-05500 07498-08401 07340-00306 e 07340-00304 07340-00213 07241-02602 07241-02001 07241-02603

07241-06800 07340-06701 07344-02001 07498-04503 07498-04501* 07241-06802 07241-02001 07241-02603

07241-06900 07340-06801 07344-02001 07498-04503 07498-04501* 07241-06802 07241-02001 07241-03003

07241-07000 07340-06901 07498-02601 07340-04503 07498-04501* 07241-04202 07241-02001 07241-03003

07241-07100 07241-07101 07340-02804 e 07340-00304 07340-00213 07241-03002 07241-02001 07241-03003

07245-03100 07340-07701 07340-00306 07340-00304 07100-08203 07241-03702 - 07241-03003

07245-03200 07340-07801 07340-00306 07340-00304 07340-07502 07241-03702 07241-02001 07241-03003

07245-03400 07340-07901 07340-00306 07340-00304 07340-07502 07241-03702 07241-02001 07241-03003

07245-04100 07498-08501 07340-00306 e 07340-00304 07100-08203 07241-03702 - 07341-03003

07245-04200 07498-08601 07340-00306 e 07340-00304 07340-07502 07241-03702 07241-02001 07241-03003

07245-04400 07498-08701 07340-00306 e 07340-00304 07340-07502* 07241-03702 07241-02001 07241-03003

07241

The number of jaws is normally two.

* indicates three jaws.

'e' indicates extended nose casing.