Avdel T51 User manual

Contents

Safety

4

Specifications

Intent of Use

5

Tool Specification

5

Tool Dimensions

5

Putting into Service

Principle of Operation

6

Preparation for Use

6

Hydraulic Hose Kit

6

Operating Instructions

7

Maintenance

Dismantling Instructions

8

Assembling the Tool

9

To Bleed the Tool

9

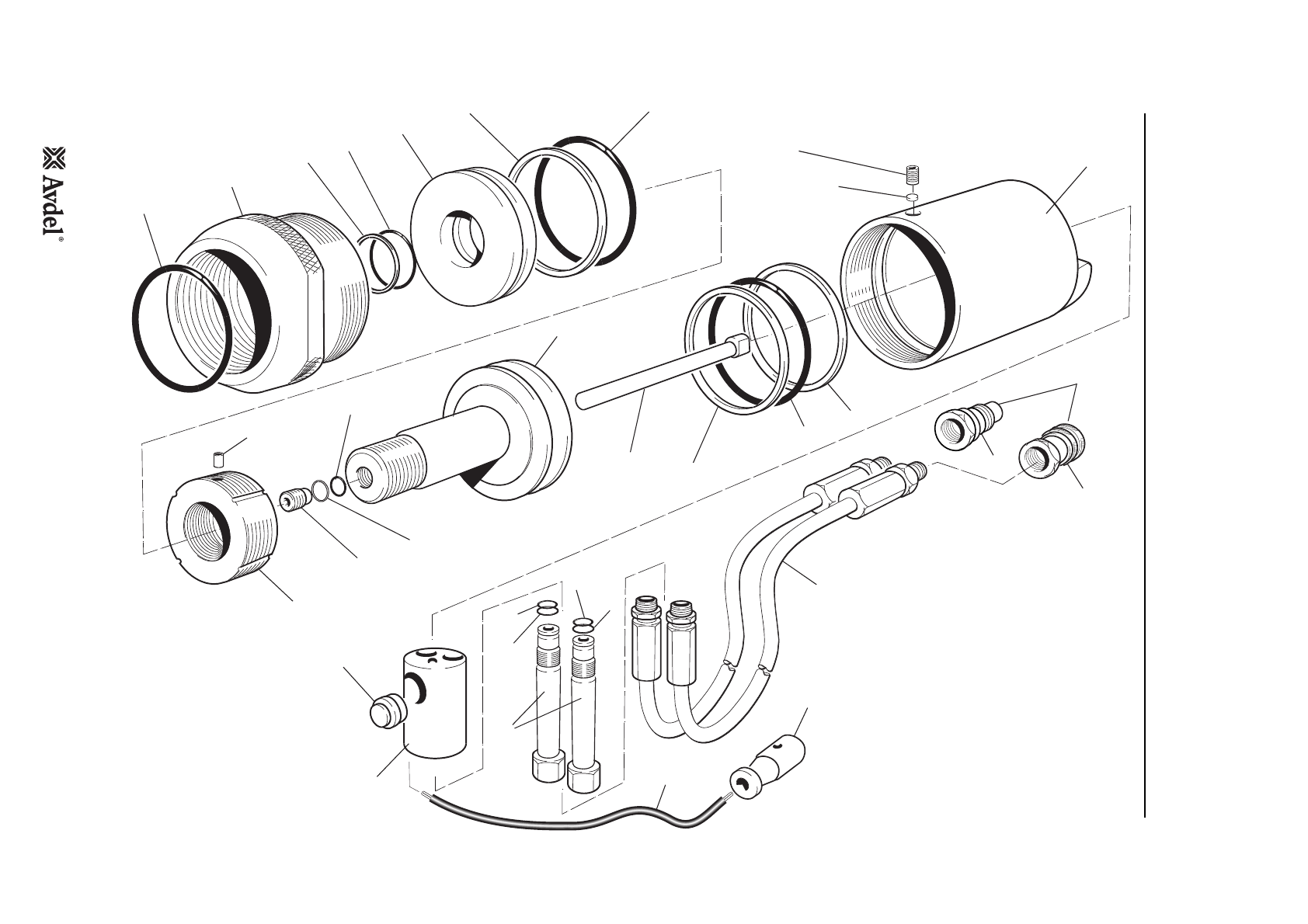

General Assembly of Installation Tool

73410-02000

10

General Assembly Parts List

73410-02000

11

Servicing the Tool

Daily /Weekly

12

Every 1200 Working Hours (at least once a year)

12

Service Tools

12

Hydraulic Oil General Safety Data

12

Fault Diagnosis

Symptom, Possible Cause & Remedy

13-14

Warranty

The ninety day warranty herein expressed shall be the exclusive warranty on items

manufactured by seller and shall be in the place and stead of any other warranty, expressed or

implied, including but not limited to the implied warranties of merchantability and fitness for a

particular purpose.

Seller shall not be liable for any loss or damage resulting from delays or non-fulfilment or

orders owing to strikes, fires, accidents, transportation companies or for any reason or

reasons beyond the control of seller or its suppliers.

All warranty claims must be submitted to the seller in writing, within 90 days from date of

shipment, and no returns will be accepted without written permission.

Other provisions hereof notwithstanding, seller shall not be liable for any loss of business

profits or any incidental or consequential damages incurred by Buyer or any third person in

connection with the items or use thereof, however caused.

Tool Warranty

Seller expressly disclaims any warranty express or implied, as to the condition, design,

operation, merchantability or fitness for use of any tool, or part(s) thereof not manufactured by

seller. The only warranties made with respect to such tool or part(s) thereof are those made

by the manufacturer thereof and seller agrees to cooperate with buyer in enforcing such

warranties when such action is necessary. Seller agrees to repair or replace F.O.B. seller's

plant, any tool or part(s) thereof manufactured by it and proved to seller to be defective due to

faulty workmanship or material.

Avdel UK Limited

policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

><

Avdel®

3

3

Contents

Safety 4

Specifications

Intent of Use 5

Tool Specification 5

Tool Dimensions 5

Putting into Service

Principle of Operation 6

Preparation for Use 6

Hydraulic Hose Kit 6

Operating Instructions 7

Maintenance

Dismantling Instructions 8

Assembling the Tool 9

To Bleed the Tool 9

General Assembly of Installation Tool

73410-02000 10

General Assembly Parts List

73410-02000 11

Servicing the Tool

Daily / Weekly 12

Every 1200 Working Hours (at least once a year) 12

Service Tools 12

Hydraulic Oil General Safety Data 12

Fault Diagnosis

Symptom, Possible Cause & Remedy 13-14

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

Warranty

The ninety day warranty herein expressed shall be the exclusive warranty on items

manufactured by seller and shall be in the place and stead of any other warranty, expressed or

implied, including but not limited to the implied warranties of merchantability and fitness for a

particular purpose.

Seller shall not be liable for any loss or damage resulting from delays or non-fulfilment or

orders owing to strikes, fires, accidents, transportation companies or for any reason or

reasons beyond the control of seller or its suppliers.

All warranty claims must be submitted to the seller in writing, within 90 days from date of

shipment, and no returns will be accepted without written permission.

Other provisions hereof notwithstanding, seller shall not be liable for any loss of business

profits or any incidental or consequential damages incurred by Buyer or any third person in

connection with the items or use thereof, however caused.

Tool Warranty

Seller expressly disclaims any warranty express or implied, as to the condition, design,

operation, merchantability or fitness for use of any tool, or part(s) thereof not manufactured by

seller. The only warranties made with respect to such tool or part(s) thereof are those made

by the manufacturer thereof and seller agrees to cooperate with buyer in enforcing such

warranties when such action is necessary. Seller agrees to repair or replace F.O.B. seller's

plant, any tool or part(s) thereof manufactured by it and proved to seller to be defective due to

faulty workmanship or material.

Safety Rules

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

1

Do not use outside the design intent.

2

Do not use equipment with this tool/machine other than that recommended by Avdel UK Limited.

3

Any modification undertaken by the customer to the tool/machine shall be the customer's entire responsibility.

4

Always disconnect the tool from the HydraPac before attempting to adjust, remove or fit the nose assembly.

5

Do not operate a tool/machine if directed towards any person(s).

6

Always adopt a firm footing or a stable position before operating the tool/machine.

7

If cycling the tool without the nose assembly, care must be taken to avoid contact with the pintail ejector pin and not to trap the fingers in

between the anvil retainer (T514) and the collet adaptor (T517).

8

Ear protection

must

be worn by the operator and others in the vicinity as noise levels exceed the permitted maximum. For values see

technical specifications on page 5.

9

Do not fit flexible hoses rated at less than 10,000 psi (69 mPa) working pressure.

10 The operating pressure shall not exceed 8,000 psi (55.2 mPa).

11

Care shall be taken to ensure that spent pintails are not allowed to create a hazard.

12

When using the tool, the operator and others in the vicinity are recommended to wear safety glasses.

13

Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool.

14

The tool should be kept clean and dry for the best possible grip.

15

When carrying the tool from place to place keep hands away from the trigger to avoid inadvertent start up.

16

The machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and function by

trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel® procedures. Do not

dismantle the machine without prior reference to the maintenance instructions. Contact Avdel® with your training requirements.

17

The machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the UK the "Health & Safety at

Work etc Act 1974" applies. Any question regarding the correct operation of the machine must be directed to Avdel®.

CAUTIONS

AVDEL RECOMMENDS THAT ONLY HYDRAPAC UNITS BE USED TO DRIVE INSTALLATION TOOLS, AS OTHER MAKES OF

HYDRAULIC POWER UNITS MAY NOT OPERATE AT THE SAFE DESIGNED WORKING PRESSURES.

ENSURE THAT THERE IS ADEQUATE CLEARANCE FOR THE TOOL OPERATOR'S HANDS BEFORE PROCEEDING.

DO NOT ABUSE THE TOOL BY DROPPING OR USING IT AS A HAMMER.

KEEP DIRT AND FOREIGN MATTER OUT OF THE HYDRAULIC SYSTEMS OF THE TOOLS AS THIS WILL CAUSE THE TOOL AND

HYDRAPAC TO MALFUNCTION

4

Vi Avdel®

4

Safety Rules

1Do not use outside the design intent.

2Do not use equipment with this tool/machine other than that recommended by Avdel UK Limited.

3Any modification undertaken by the customer to the tool/machine shall be the customer’s entire responsibility.

4Always disconnect the tool from the HydraPac before attempting to adjust, remove or fit the nose assembly.

5Do not operate a tool/machine if directed towards any person(s).

6Always adopt a firm footing or a stable position before operating the tool/machine.

7If cycling the tool without the nose assembly, care must be taken to avoid contact with the pintail ejector pin and not to trap the fingers in

between the anvil retainer (T514) and the collet adaptor (T517).

8Ear protection must be worn by the operator and others in the vicinity as noise levels exceed the permitted maximum. For values see

technical specifications on page 5.

9Do not fit flexible hoses rated at less than 10,000 psi (69 mPa) working pressure.

10 The operating pressure shall not exceed 8,000 psi (55.2 mPa).

11 Care shall be taken to ensure that spent pintails are not allowed to create a hazard.

12 When using the tool, the operator and others in the vicinity are recommended to wear safety glasses.

13 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool.

14 The tool should be kept clean and dry for the best possible grip.

15 When carrying the tool from place to place keep hands away from the trigger to avoid inadvertent start up.

16 The machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and function by

trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel®procedures. Do not

dismantle the machine without prior reference to the maintenance instructions. Contact Avdel®with your training requirements.

17 The machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the UK the "Health & Safety at

Work etc Act 1974" applies. Any question regarding the correct operation of the machine must be directed to Avdel®.

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

CAUTIONS

AVDEL RECOMMENDS THAT ONLY HYDRAPAC UNITS BE USED TO DRIVE INSTALLATION TOOLS, AS OTHER MAKES OF

HYDRAULIC POWER UNITS MAY NOT OPERATE AT THE SAFE DESIGNED WORKING PRESSURES.

ENSURE THAT THERE IS ADEQUATE CLEARANCE FOR THE TOOL OPERATOR'S HANDS BEFORE PROCEEDING.

DO NOT ABUSE THE TOOL BY DROPPING OR USING IT AS A HAMMER.

KEEP DIRT AND FOREIGN MATTER OUT OF THE HYDRAULIC SYSTEMS OF THE TOOLS AS THIS WILL CAUSE THE TOOL AND

HYDRAPAC TO MALFUNCTION

TYPE

SIZE

DIM. 'A'

HAT REF.

PART N°

7/

8

,,

73410-03200

N53

157mm

07900-00919

LD Avdelok®

07900-00919

1"

73410-03100

N50

183mm

1

1

/

8

"

07900-00919

73410-03300

187mm

N52

FASTENER

NOSE ASSEMBLY

NOSE ASSEMBLY

DATASHEET

PART N°

Specifications

Intent of use

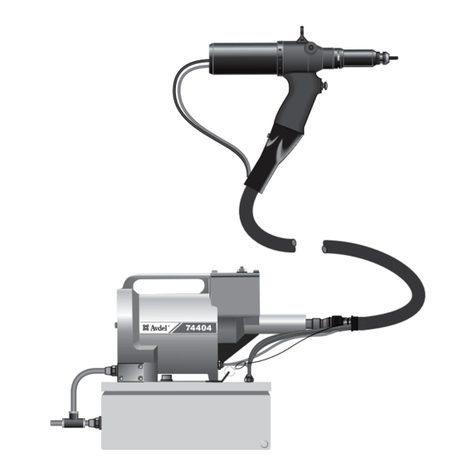

The T51 Installation Tool is basically a Piston and Cylinder Assembly. When coupled Hydraulically and Electrically to a compatible

Hydraulic Power Source and the relevant Nose Assembly is attached, it is then used to install

7

/

8

" to 1

1

/

8

” Avdelok® in Industrial

Environments.

Refer to the table below for the list of applicable fasteners and associated nose equipment.

Refer to the datasheets listed in the table for the relevant nose assembly instructions.

Tool Specification

Length

205 mm

8.07 in

Body Diameter

122 mm

4.30 in

Height

217 mm

8.54 in

Weight

18 kg

39.7 lbs

Stroke

65 mm

2.56 in

Pull Force

350kN

78680 lbf

Pull pressure

55.2 mPa

8000 psi

Return Pressure

20.7 mPa

3000 psi

Hydraulic Oil

ISO VG 46 OR EQUIVALENT

Fastener Range

Avdelok®

7

/

8

" to 1

1

/

8

"

Noise Level

126.2 dB(A)

Sound Power

100.9 dB(A)

Vibration

8.6 m/sec

3

Tool Dimensions

205 mm

122 mm

•

N.)

3

3

><

Avdel®

5

Intent of use

Tool Specification

Tool Dimensions

Specifications

5

The T51 Installation Tool is basically a Piston and Cylinder Assembly. When coupled Hydraulically and Electrically to a compatible

Hydraulic Power Source and the relevant Nose Assembly is attached, it is then used to install 7/8” to 11/8” Avdelok®in Industrial

Environments.

Refer to the table below for the list of applicable fasteners and associated nose equipment.

Refer to the datasheets listed in the table for the relevant nose assembly instructions.

A

205 mm 122 mm

217 mm

FASTENER

TYPE SIZE

NOSE ASSEMBLY

PART Nº H AT REF. DIM. ‘A’

NOSE ASSEMBLY

DATASHEET

PART Nº

®

07900-00919

07900-00919

07900-00919

73410-03200

73410-03100

73410-03300

N50

N52

LD Avdelok

7/8”

1/8”

1

1

”

157mm

183mm

187mm

N53

Length 205 mm 8.07 in

Body Diameter 122 mm 4.30 in

Height 217 mm 8.54 in

Weight 18 kg 39.7 lbs

Stroke 65 mm 2.56 in

Pull Force 350kN 78680 lbf

Pull pressure55.2 mPa 8000 psi

Return Pressure20.7 mPa 3000 psi

Hydraulic Oil ISO VG 46 OR EQUIVALENT

Fastener Range Avdelok®7/8” to 11/8”

Noise Level 126.2 dB(A)

Sound Power 100.9 dB(A)

Vibration 8.6 m/sec3

www.aboveboardelectronics.com

1-800-453-1692

Request Info

HYDRAULIC HOSE KITS

PART NUMBER

HOSE LENGTH

07005-10014

6 METRE

07005-10034

10 METRE

07005-10035

15 METRE

Putting into Service

IMPORTANT

Read the safety rules on page 4 carefully

Principal of Operation

When both hoses and control cord are connected to the HydraPac, the pull and return cycles of the tool are controlled by depressing

and releasing the trigger switch located in the handle respectively.

When the switch is depressed the solenoid valve located in the HydraPac is energised and directs the pressurised oil flow to the pull

side of the piston in the tool. This also allows the oil in the return side of the tool to return to the tank. The piston/collet assembly

now moves towards the rear of the tool allowing the cushion to push the follower and jaws forward. If a Avdelok® fastener has been

inserted in the nose for assembly, the jaw set will clamp onto the pintail and assembly will commence.

The cycle of installation will first clamp the joint to be fastened and then as the anvil continues to move forward the collar will be

swaged into the locking grooves of the pin. At the end of the swaging cycle the anvil will come hard up against the joint and as

movement continues the pintail will be broken off.

The trigger switch must be released immediately after pin break occurs. Releasing the trigger switch will cause the solenoid to de-

energise and reverse the flow of pressurised oil.

Pressurised oil will now flow into the return side of the installation tool with the oil in the pull side returning to the tank.

The forward movement of the piston/collet assembly firstly ejects the installed fastener from the anvil and as the forward movement

continues, the jaw release mechanism will cause the jaws to open and release the broken off pintail, which will then be ejected.

When the piston returns to the fully forward position the pressure build up in the system will cause the Hydrapac to go into idle mode.

This keeps the installation tool in the forward position. Once the pintail has been ejected from the nose, the tool is ready for the next

installation.

Please note that with all HydraPacs there is a built in "Sleep Mode which in effect means that the electric motor will automatically

switch off if the trigger switch is not operated for approximately 25 seconds. The HydraPac will automatically start up on depression

of the tool trigger switch.

Preparation for Use

Attach the correct nose assembly to tool as per instructions in the relevant nose assembly data sheet.

Ensure the HydraPac is not running.

Connect hoses and the control cord to the Hydrapac, the tool is supplied with a 0.7m hose length.

Additional hydraulic hose lengths are available to order separately as required. Refer to the table below for the available lengths

and associated part numbers.

Start the HydraPac. Depress and release the trigger switch a few times to almost the full stroke of the tool to circulate hydraulic

fluid. Observe action of tool. Check for fluid leaks and ensure that in the idler mode the piston is in the fully forward position.

6

PA Avdel®

6

Principal of Operation

Preparation for Use

Putting into Service

When both hoses and control cord are connected to the HydraPac, the pull and return cycles of the tool are controlled by depressing

and releasing the trigger switch located in the handle respectively.

When the switch is depressed the solenoid valve located in the HydraPac is energised and directs the pressurised oil flow to the pull

side of the piston in the tool. This also allows the oil in the return side of the tool to return to the tank. The piston/collet assembly

now moves towards the rear of the tool allowing the cushion to push the follower and jaws forward. If a Avdelok®fastener has been

inserted in the nose for assembly, the jaw set will clamp onto the pintail and assembly will commence.

The cycle of installation will first clamp the joint to be fastened and then as the anvil continues to move forward the collar will be

swaged into the locking grooves of the pin. At the end of the swaging cycle the anvil will come hard up against the joint and as

movement continues the pintail will be broken off.

The trigger switch must be released immediately after pin break occurs. Releasing the trigger switch will cause the solenoid to de-

energise and reverse the flow of pressurised oil.

Pressurised oil will now flow into the return side of the installation tool with the oil in the pull side returning to the tank.

The forward movement of the piston/collet assembly firstly ejects the installed fastener from the anvil and as the forward movement

continues, the jaw release mechanism will cause the jaws to open and release the broken off pintail, which will then be ejected.

When the piston returns to the fully forward position the pressure build up in the system will cause the Hydrapac to go into idle mode.

This keeps the installation tool in the forward position. Once the pintail has been ejected from the nose, the tool is ready for the next

installation.

Please note that with all HydraPacs there is a built in "Sleep Mode" which in effect means that the electric motor will automatically

switch off if the trigger switch is not operated for approximately 25 seconds. The HydraPac will automatically start up on depression

of the tool trigger switch.

•Attach the correct nose assembly to tool as per instructions in the relevant nose assembly data sheet.

•Ensure the HydraPac is not running.

•Connect hoses and the control cord to the Hydrapac, the tool is supplied with a 0.7m hose length.

Additional hydraulic hose lengths are available to order separately as required. Refer to the table below for the available lengths

and associated part numbers.

•Start the HydraPac. Depress and release the trigger switch a few times to almost the full stroke of the tool to circulate hydraulic

fluid. Observe action of tool. Check for fluid leaks and ensure that in the idler mode the piston is in the fully forward position.

IMPORTANT

Read the safety rules on page 4 carefully

PART NUMBER HOSE LENGTH

HYDRAULIC HOSE KITS

07005-10014

07005-10034

07005-10035

6 METRE

10 METRE

15 METRE

www.aboveboardelectronics.com

1-800-453-1692

Request Info

Putting into Service

Operating Instructions

To Install an Avdelok® Fastener

Check work and remove excessive gap. (Gap is the space between components of the Joint. Gap is excessive if not enough

pintail sticks through the collar for the nose assembly jaws to grab onto.)

Put Avdelok® fastener into hole.

Slide Avdelok® collar over pin. (The bevelled end of the collar must be towards the nose assembly and tool.)

Push nose assembly onto pin until the nose assembly anvil stops against the collar. Tool and nose assembly must be held at right

angles (90°) to the work.

Depress tool trigger switch to start installation cycle.

When the forward motion of the nose assembly anvil stops and the pintail breaks off, release the switch. The tool will go into its

return stroke and push off the installed fastener. At the end of the return stroke the jaws will release the expended pintail which

can be removed by tilting the tool down.

Once the expended pintail has been ejected, the tool and nose assembly is ready for the next installation cycle.

CAUTION

DO NOT ATTEMPT TO BREAK OFF A PINTAIL WITHOUT THE INSTALLATION OF A COLLAR AS THIS WILL CAUSE THE

UNSECURED PORTION OF THE AVDELOK® PIN TO EJECT FROM THE NOSE AT A HIGH SPEED AND FORCE.

><

Avdel®

7

Operating Instructions

7

To Install an Avdelok®Fastener

•Check work and remove excessive gap. (Gap is the space between components of the Joint. Gap is excessive if not enough

pintail sticks through the collar for the nose assembly jaws to grab onto.)

•Put Avdelok®fastener into hole.

•Slide Avdelok®collar over pin. (The bevelled end of the collar must be towards the nose assembly and tool.)

•Push nose assembly onto pin until the nose assembly anvil stops against the collar. Tool and nose assembly must be held at right

angles (90°) to the work.

•Depress tool trigger switch to start installation cycle.

•When the forward motion of the nose assembly anvil stops and the pintail breaks off, release the switch. The tool will go into its

return stroke and push off the installed fastener. At the end of the return stroke the jaws will release the expended pintail which

can be removed by tilting the tool down.

•Once the expended pintail has been ejected, the tool and nose assembly is ready for the next installation cycle.

CAUTION

DO NOT ATTEMPT TO BREAK OFF A PINTAIL WITHOUT THE INSTALLATION OF A COLLAR AS THIS WILL CAUSE THE

UNSECURED PORTION OF THE AVDELOK®PIN TO EJECT FROM THE NOSE AT A HIGH SPEED AND FORCE.

Putting into Service

Maintenance

Dismantling Instructions

IMPORTANT

Be sure the HydraPac is turned off before removing tool or nose.

Uncouple the two Hydraulic Hoses

27

and disconnect the Control Cord

25.

Unscrew and remove the Anvil by hand.

Unscrew the Collet and remove the inner assembly by hand.

•

Loosen the Grub Screw

18

using a 5 mm Allen Key.

r

Unscrew the Anvil Retainer

2.

•

Place a tray under tool to catch the oil.

•

If a hand pump (73010-00001) is available, connect to female coupling and slowly pump Piston

13

out of Cylinder

19.

•

Otherwise clamp the Piston

13

in a soft jawed vice and tap the Cylinder

19

backwards with a soft mallet.

•

Remove the Brass Plug

8

by inserting a sharp object (eg a small screwdriver) into the keyway and levering out the Plug.

•

Unscrew the Collet Adaptor

9

(the Nylon Plug

8

will shear).

Remove the Gland

5.

Inspect and replace '0' Rings and Back-up Rings if necessary (Service Kit

29).

Remove the Ejector Pin

14

by pushing it out of the back of the Piston

13.

Unscrew the Screw

10

in front of the Piston

13

using a 6 mm Allen Key and remove Back-up Ring 11 and '0' Ring

12.

Item numbers in

bold

refer to the general assembly drawing and parts list on pages 10-11.

8

PA Avdel®

8

Dismantling Instructions

Maintenance

•Uncouple the two Hydraulic Hoses 27 and disconnect the Control Cord 25.

•Unscrew and remove the Anvil by hand.

•Unscrew the Collet and remove the inner assembly by hand.

•Loosen the Grub Screw 18 using a 5 mm Allen Key.

•Unscrew the Anvil Retainer 2.

•Place a tray under tool to catch the oil.

•If a hand pump (73010-00001) is available, connect to female coupling and slowly pump Piston 13 out of Cylinder 19.

•Otherwise clamp the Piston 13 in a soft jawed vice and tap the Cylinder 19 backwards with a soft mallet.

•Remove the Brass Plug 8by inserting a sharp object (eg a small screwdriver) into the keyway and levering out the Plug.

•Unscrew the Collet Adaptor 9 (the Nylon Plug 8will shear).

•Remove the Gland 5.

•Inspect and replace 'O' Rings and Back-up Rings if necessary (Service Kit 29).

•Remove the Ejector Pin 14 by pushing it out of the back of the Piston 13.

•Unscrew the Screw 10 in front of the Piston 13 using a 6 mm Allen Key and remove Back-up Ring 11 and 'O' Ring 12.

IMPORTANT

Be sure the HydraPac is turned off before removing tool or nose.

Item numbers in bold refer to the general assembly drawing and parts list on pages 10-11.

Maintenance

Assembling the Tool

Examine and replace all worn parts. Fit a new Service Kit

29.

Apply hydraulic oil to all '0' rings, back-up rings and contact surfaces before fitting.

Fit new '0' Rings

4, 7

and Back-up Rings

3, 6

to the Gland

5.

Fit '0' Ring

16

and Back-up Rings

15

to Piston

13.

Fit new '0' Ring

12

and Back-up Ring

11

into the Piston

13

and secure with the Screw

10

using a 6 mm Allen Key.

Insert the Ejector Pin

14

into the Piston

13

ensuring it protrudes at the front of the piston.

Install the Piston

13

into the Cylinder

19.

•

Install the Gland

5.

•

Install the Anvil Retainer

2.

Re-clamp the Grub Screw

18

using a 5 mm Allen Key.

Refit the Collet Adaptor

9.

Align the hole with the Keyway.

Insert the Nylon/Brass Plug

8.

Bleed the Tool.

To Bleed the Tool

Couple the short Tool Hoses directly onto a HydraPac or compatible hydraulic power source.

Note: Do not use long extension hoses as these will prevent the air from escaping into the HydraPac.

Plug in a Hydrapac Test Trigger.

Position the Tool so that the piston rod side faces vertically up.

Cycle a few times.

Reverse the vertical position and cycle again.

Item numbers in

bold

refer to the general assembly drawing and parts list on pages 10-11.

><

Avdel•

9

Assembling the Tool

Maintenance

9

Examine and replace all worn parts. Fit a new Service Kit 29.

•Apply hydraulic oil to all 'O' rings, back-up rings and contact surfaces before fitting.

•Fit new 'O' Rings 4, 7and Back-up Rings 3, 6to the Gland 5.

•Fit 'O' Ring 16 and Back-up Rings 15 to Piston 13.

•Fit new 'O' Ring 12 and Back-up Ring 11 into the Piston 13 and secure with the Screw 10 using a 6 mm Allen Key.

•Insert the Ejector Pin 14 into the Piston 13 ensuring it protrudes at the front of the piston.

•Install the Piston 13 into the Cylinder 19.

•Install the Gland 5.

•Install the Anvil Retainer 2.

•Re-clamp the Grub Screw 18 using a 5 mm Allen Key.

•Refit the Collet Adaptor 9.

•Align the hole with the Keyway.

•Insert the Nylon/Brass Plug 8.

•Bleed the Tool.

To Bleed the Tool

•Couple the short Tool Hoses directly onto a HydraPac or compatible hydraulic power source.

Note: Do not use long extension hoses as these will prevent the air from escaping into the HydraPac.

•Plug in a Hydrapac Test Trigger.

•Position the Tool so that the piston rod side faces vertically up.

•Cycle a few times.

•Reverse the vertical position and cycle again.

Item numbers in bold refer to the general assembly drawing and parts list on pages 10-11.

23*

000Z

0

-

0IV

EL

18

19

28

12

*

16

*

15*

22*

r

22

10

*29 SUPPLIED ONLY

26

AS SERVICE KIT

24

21

20

C

.

)

CD

CD

0)

CD

3

cr

0

-h

(.71

0)

I.

0

0

10

General Assembly of T51 Installation Tool

73410-02000

18

17

19

15

15

16

5

*

*

**

*

*

*

*

*

*

*

*

*

7

6

4

3

1

2

8

9

25

26

27

*29 SUPPLIED ONLY

AS SERVICE KIT

14

20

28

P

R

11

12

13

10

22

22

23

23

24

21

000Z

0

-

0IV

EL

u

oq.

ell

ei.

sui

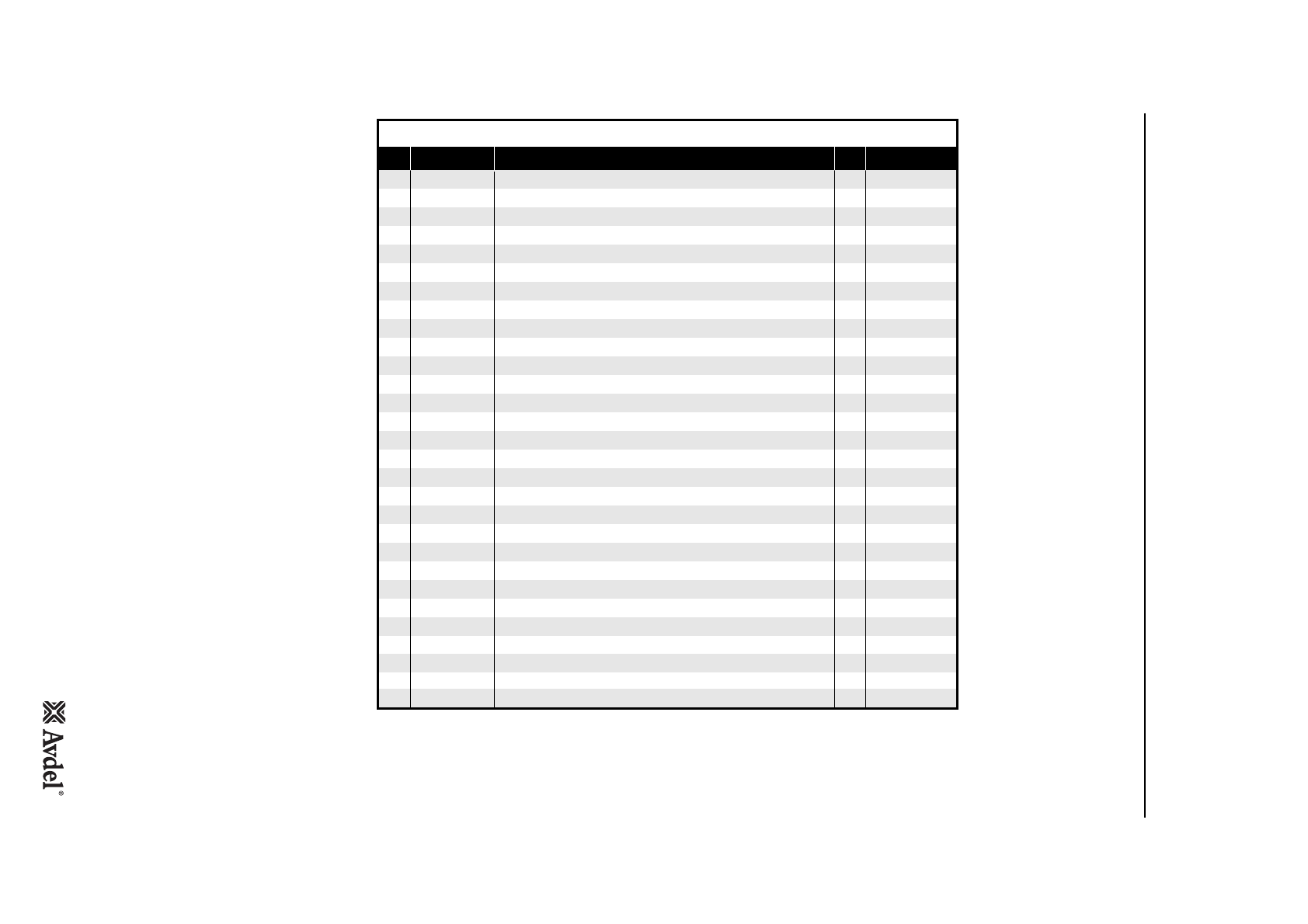

ITEM

T51 INSTALLATION TOOL PARTS LIST

PART N°

DESCRIPTION

QTY

SERVICE KIT

1

R236

'0' RING

1

2

T514

ANVIL RETAINER

1

3

B222

BACK-UP RING

1

*

4

R341

'0' RING

1

*

5

T513

GLAND

1

6

B240

BACK-UP RING

2

*

7

R240

'0' RING

1

*

8

M522

NYLON/BRASS PLUG

1

9

T517

COLLET ADAPTOR

1

10

T519

SCREW

1

11

1010

BACK-UP RING

1

*

12

R010

'0' RING

1

*

13

T512

PISTON

1

14

T518

EJECTOR PIN

1

15

B341

BACK-UP RING

2

*

16

R341

'0' RING

1

*

17

MS10

PAD

1

18

GS29

GRUB SCREW

1

19

T511

CYLINDER

1

20

111142

TRIGGER SWITCH

1

21

T516

HANDLE

1

22

R012

'0' RING

2

*

23

B341

BACK-UP RING

2

*

24

T515

HANDLE STEM

2

25

C106

CONTROL CORD

1

26

C112

MALE PLUG

1

27

H502

HYDRAULIC HOSE

2

28

HS01

QUICK COUPLER SET

1

29

SK51

SERVICE KIT

1

* '0' Rings and Back-up Rings only supplied in Service Kit SK51

Parts List for T51 Installation Tool

73410-02000

11

ITEM PART Nº DESCRIPTION QTY SERVICE KIT

T51 INSTALLATION TOOL PARTS LIST

* 'O' Rings and Back-up Rings only supplied in Service Kit SK51

1 R236 'O' RING 1 *

2 T514 ANVIL RETAINER 1

3 B222 BACK-UP RING 1 *

4 R341 'O' RING 1 *

5 T513 GLAND 1

6 B240 BACK-UP RING 2 *

7 R240 'O' RING 1 *

8 M522 NYLON/BRASS PLUG 1

9 T517 COLLET ADAPTOR 1

10 T519 SCREW 1

11 I010 BACK-UP RING 1 *

12 R010 'O' RING 1 *

13 T512 PISTON 1

14 T518 EJECTOR PIN 1

15 B341 BACK-UP RING 2 *

16 R341 'O' RING 1 *

17 MS10 PAD 1

18 GS29 GRUB SCREW 1

19 T511 CYLINDER 1

20 I11142 TRIGGER SWITCH 1

21 T516 HANDLE 1

22 R012 'O' RING 2 *

23 B341 BACK-UP RING 2 *

24 T515 HANDLE STEM 2

25 C106 CONTROL CORD 1

26 C112 MALE PLUG 1

27 HS02 HYDRAULIC HOSE 2

28 HS01 QUICK COUPLER SET 1

29 SK51 SERVICE KIT 1 *

www.aboveboardelectronics.com

1-800-453-1692

Request Info

Servicing the Tool

Daily

Check for oil leaks.

Check the stroke of tool.

Check for worn anvil indicated by score marks on the installed collar. This can also be confirmed by referring to the installed data in the

fastener catalogue. Excessive wear can cause the anvil to rupture.

Check function of pull pressure safety valve.

Weekly

Dismantle and clean the nose assembly especially the jaws.

Check for oil leaks.

Every 1200 working hours (at least once a year)

The tool should be completely dismantled and worn components replaced including '0' rings and back-up rings.

Service Tools

Open Ended Flat Spanners - 17, 19, 24

Allen Keys - 5 mm, 6 mm

150 mm Engineers Vice with Jaw Guards

Hydraulic Hand Pump if Available (73010-00001).

Hydraulic Oil General Safety Data

First Aid

SKIN:

Under normal conditions skin irritation will not occur, contaminated skin should however be washed thoroughly with soap and water. Launder

contaminated clothing.

ORAL:

If swallowed and person is conscious give water or milk. Do not induce vomiting unless on advice of medical personnel. Take person to

nearest medical centre.

EYES:

Flush immediately with water for several minutes

DISPOSAL:

Remove all spills with inert absorbent material. Ventilate spill area. Place contaminated materials in a disposable container and dispose in a

manner consistent with local regulations.

Fire

FLASH POINT: 200°C.

Extinguish with either dry chemical, foam or carbon dioxide. Do not enter confined space without self contained breathing apparatus.

Handling

Use barrier cream or oil resistant gloves.

Storage

Undercover and consistent with local regulations for inflammable material.

12

Vi Avdel®

12

Daily

Weekly

Service Tools

Hydraulic Oil General Safety Data

Every 1200 working hours (at least once a year)

Servicing the Tool

•Check for oil leaks.

•Check the stroke of tool.

•Check for worn anvil indicated by score marks on the installed collar. This can also be confirmed by referring to the installed data in the

fastener catalogue. Excessive wear can cause the anvil to rupture.

•Check function of pull pressure safety valve.

•Dismantle and clean the nose assembly especially the jaws.

•Check for oil leaks.

The tool should be completely dismantled and worn components replaced including 'O' rings and back-up rings.

•Open Ended Flat Spanners - 17, 19, 24

•Allen Keys - 5 mm, 6 mm

•150 mm Engineers Vice with Jaw Guards

•Hydraulic Hand Pump if Available (73010-00001).

First Aid

SKIN:

Under normal conditions skin irritation will not occur, contaminated skin should however be washed thoroughly with soap and water. Launder

contaminated clothing.

ORAL:

If swallowed and person is conscious give water or milk. Do not induce vomiting unless on advice of medical personnel. Take person to

nearest medical centre.

EYES:

Flush immediately with water for several minutes

DISPOSAL:

Remove all spills with inert absorbent material. Ventilate spill area. Place contaminated materials in a disposable container and dispose in a

manner consistent with local regulations.

Fire

FLASH POINT: 200°C.

Extinguish with either dry chemical, foam or carbon dioxide. Do not enter confined space without self contained breathing apparatus.

Handling

Use barrier cream or oil resistant gloves.

Storage

Undercover and consistent with local regulations for inflammable material.

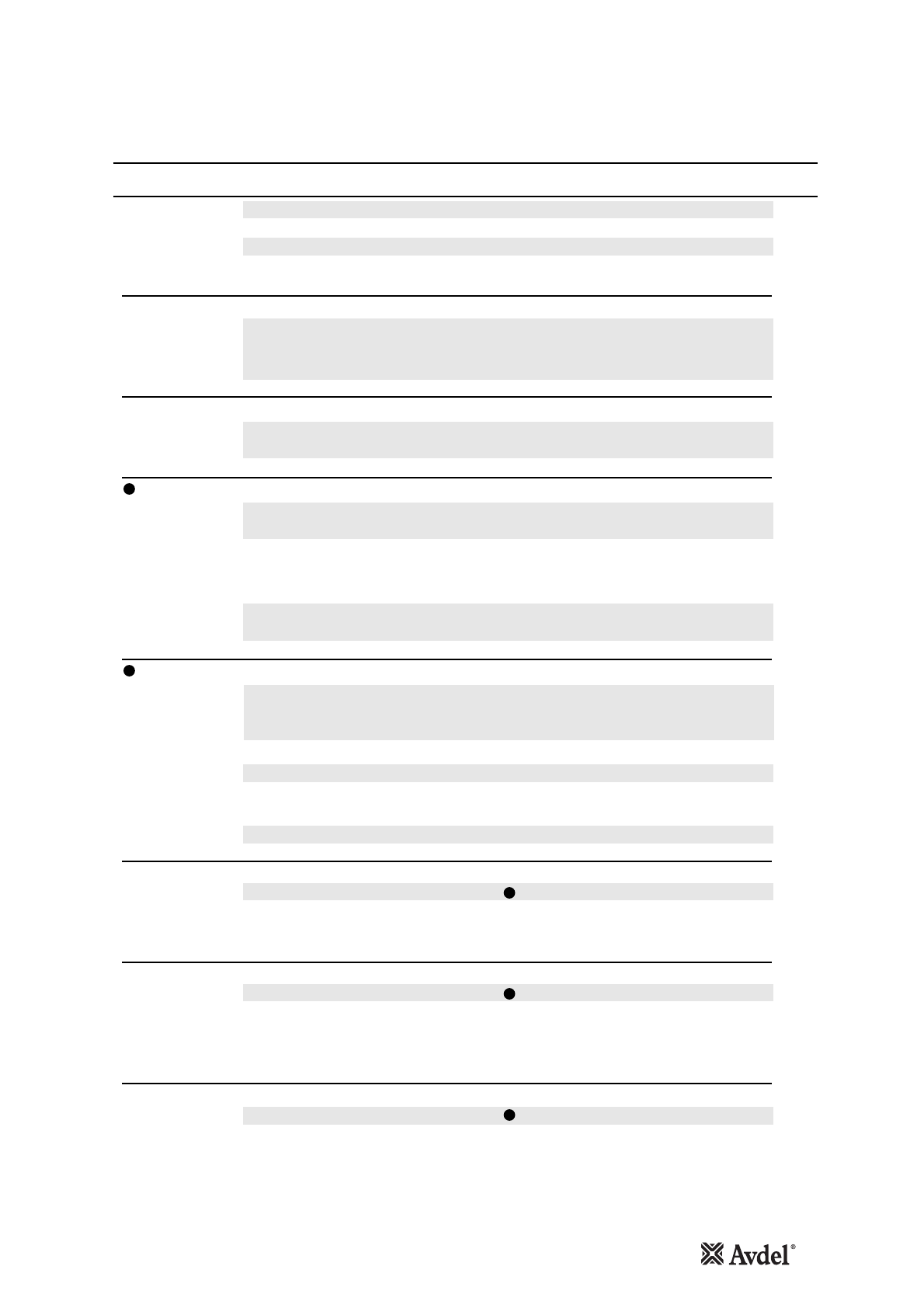

Fault Diagnosis

Symptom

Possible Cause

Remedy

Page Ref

Tool fails to operate

Inoperative HydraPac

Check power supply to HydraPac

Loose or disconnected control cord

Check for loose or broken wires

Defective switch assembly

Replace switch assembly

Faulty hydraulic hose couplings

Replace faulty couplings

Tool leaks hydraulic

Depending on what leaks occur,

Check and replace '0' rings

oil

defective or worn '0' rings, loose

and back-up rings, or

hydraulic hose connections at tool

tighten hydraulic hose

Hydraulic oil

Restriction in hydraulic line

Check couplings and replace

overheats

if necessary

0

Tool operates

erratically and fails

to install fastener

properly

Low or erratic hydraulic

pressure supply

Defective or excessively worn

piston, '0' ring and back-up rings

and back-up rings in tool

Excessive wear or scoring of

sliding surface of tool parts

See HydraPac instruction

manual

Replace '0' ring and back-up

rings

Check and replace defective

parts

Pull grooves on

fastener pintail

stripped during pull

stroke

Operator not pushing nose

completely onto fastener pintail

before operating tool

Incorrect fastener length

Worn or damaged jaw segments

Metal chips accumulated in pull

grooves of jaw segments

Excessive sheet gap

Instruct operator in proper

installation methods

Use correct length fastener

Check and replace jaw set

Clean jaw segments

Eliminate excessive gap

Collar of Hydraloc

Improper tool operation

See 6:0

fastener not

Worn anvil in nose

Check and replace anvil

completely swaged

Tool "hang up" on

Improper tool operation

See 0

swaged collar

HydraPac in idler mode

Switch HydraPac off and

on and restart by

depressing trigger switch

Pintail of fastener

Pull grooves on fastener stripped

See CO

fails to break

Improper tool operation

Instruct operator in correct

tool operation

continued overleaf

Avdel®

13

Fault Diagnosis

13

Tool fails to operate Inoperative HydraPac Check power supply to HydraPac

Loose or disconnected control cordCheck for loose or broken wires

Defective switch assembly Replace switch assembly

Faulty hydraulic hose couplings Replace faulty couplings

Tool leaks hydraulic Depending on what leaks occur,Check and replace 'O' rings

oil defective or worn 'O' rings, loose and back-up rings, or

hydraulic hose connections at tool tighten hydraulic hose

Hydraulic oil Restriction in hydraulic line Check couplings and replace

overheats if necessary

Tool operates Low or erratic hydraulic See HydraPac instruction

erratically and fails pressure supply manual

to install fastener Defective or excessively worn Replace 'O' ring and back-up

properly piston, 'O' ring and back-up rings rings

and back-up rings in tool

Excessive wear or scoring of Check and replace defective

sliding surface of tool parts parts

Pull grooves on Operator not pushing nose Instruct operator in proper

fastener pintail completely onto fastener pintail installation methods

stripped during pull before operating tool

stroke Incorrect fastener length Use correct length fastener

Worn or damaged jaw segments Check and replace jaw set

Metal chips accumulated in pull Clean jaw segments

grooves of jaw segments

Excessive sheet gap Eliminate excessive gap

Collar of Hydraloc Improper tool operation See

fastener not Worn anvil in nose Check and replace anvil

completely swaged

Tool "hang up" on Improper tool operation See

swaged collar HydraPac in idler mode Switch HydraPac off and

on and restart by

depressing trigger switch

Pintail of fastener Pull grooves on fastener stripped See

fails to break Improper tool operation Instruct operator in correct

tool operation

continued overleaf

2

1

2

2

1

Symptom Possible Cause Remedy Page Ref

Fault Diagnosis

Symptom

Possible Cause

Remedy

Page Ref

Jaw segments do not Improper operation of jaw

Check internal parts of the

maintain proper

follower

collet for wear i.e. jaws,

position in collet

follower, cushion and end cap.

Clean before reassembling

Hydraulic couplers

Defective or worn '0' ring in

Replace '0' ring and back-up ring

leak oil

coupler body

Pintail fails to release Incorrect assembly of Nose

Refer to nose assembly drawing on page 5

14

Vi Avdel®

14

Fault Diagnosis

Jaw segments do not Improper operation of jaw Check internal parts of the

maintain proper follower collet for wear i.e. jaws,

position in collet follower, cushion and end cap.

Clean before reassembling

Hydraulic couplers Defective or worn 'O' ring in Replace 'O' ring and back-up ring

leak oil coupler body

Pintail fails to release Incorrect assembly of Nose Refer to nose assembly drawing on page 5

Symptom Possible Cause Remedy Page Ref

Declaration of Conformity

We, Avdel UK Limited, Watchmead Industrial Estate, Welwyn Garden City, Herts, AL7 1LY

declare under our sole responsibility that the product:

Model: 73410-02000

Serial No.

to which this declaration relates is in conformity with the following standards:

EN ISO 12100 - parts 1 & 2

BS EN ISO 8662 - part 6

BS EN ISO 11202

BS EN ISO 3744

BS EN 982

ISO EN 792 part 13 - 2000

BS EN 983

following the provisions of the Machine Directive 2006/42/EC

A. Seewraj - Product Engineering Manager - Automation Tools

Date of issue

CE

This box contains a power tool which is in

conformity with Machines Directive

2006/42/EC. The 'Declaration of Conformity'

is contained within.

gl Avdel®

15

15

This box contains a power tool which is in

conformity with Machines Directive

2006/42/EC. The ‘Declaration of Conformity’

is contained within.

Declaration of Conformity

We, Avdel UK Limited, Watchmead Industrial Estate, Welwyn Garden City, Herts, AL7 1LY

declare under our sole responsibility that the product:

Model: 73410-02000

Serial No. ................................................

to which this declaration relates is in conformity with the following standards:

EN ISO 12100 - parts 1 & 2

BS EN ISO 8662 - part 6 BS EN ISO 11202

BS EN ISO 3744 BS EN 982

ISO EN 792 part 13 - 2000 BS EN 983

following the provisions of the Machine Directive 2006/42/EC

Date of issue

A. Seewraj - Product Engineering Manager - Automation Tools

r:J.

Avdel®

iForm

Since 1922 Since 1 936

2010

(n

‘

fastech

m

OurTechnology,Your Success

AUSTRALIA

Infastech (Australia) Pty Ltd.

891 Wellington Road

Rowville

Victoria 3178

Tel: +61 3 9765 6400

Fax: +61 3 9765 6445

CANADA

Avdel Canada Limited

1030 Lorimar Drive

Mississauga

Ontario L5S 1R8

Tel: +1 905 364 0664

Fax: +1 905 364 0678

CHINA

Infastech (China) Ltd.

RM 1708, 17/F., Nanyang Plaza,

57 Hung To Rd., Kwun Tong

Hong Kong

Tel: +852 2950 0631

Fax: +852 2950 0022

FRANCE

Avdel France S.A.S.

33 bis, rue des Ardennes

BP4

75921 Paris Cedex 19

Tel:

+33 (0) 1 4040 8000

Fax: +33 (0) 1 4208 2450

GERMANY

Avdel Deutschland GmbH

Klusriede 24

30851 Langenhagen

Tel:

+49 (0) 511 7288 0

Fax: +49 (0) 511 7288 133

INDIA

Infastech Fastening Technologies

India Private Limited

Plot No OZ-14, Hi Tech SEZ,

SIPCOT Industrial Growth Center,

Oragadam, Sriperumbudur Taluk,

Kanchipuram District,

602105 Tamilnadu

Tel:

+91 44 4711 8001

Fax: +91 44 4711 8009

ITALY

Avdel Italia S.r.l.

Viale Lombardia 51/53

20047 Brugherio (MI)

Tel: +39 039 289911

Fax: +39 039 2873079

JAPAN

Infastech Kabushiki Kaisha

Center Minami SKY,

3-1 Chigasaki-Chuo, Tsuzuki-ku,

Yokohama-city,

Kanagawa Prefecture

Japan 224-0032

Tel: +81 45 947 1200

Fax: +81 45 947 1205

MALAYSIA

Infastech (Malaysia) Sdn Bhd

Lot 63, Persiaran Bunga Tanjung 1,

Senawang Industrial Park

70400 Seremban

Negeri Sembilan

Tel:

+606

676

7168

Fax:

+606

676

7101

SINGAPORE

Infastech (Singapore) Pte Ltd.

31 Kaki Bukit Road 3

#05-03/06 Techlink

Singapore, 417818

Tel:

+65

6372

5653

Fax:

+65

6744

5643

SOUTH KOREA

Infastech (Korea) Ltd.

212-4, Suyang-Ri,

Silchon-Eup, Kwangju-City,

Kyunggi-Do, Korea, 464-874

Tel:

+82

31

798

6340

Fax:

+82

31

798

6342

SPAIN

Avdel Spain S.A.

C/ Puerto de la Morcuera, 14

Poligono Industrial Prado Overa

Ctra. de Toledo, km 7,8

28919 Leganes (Madrid)

Tel:

+34

91

3416767

Fax:

+34

91

3416740

TAIWAN

Infastech/Tri-Star Limited

No 269-7, Baodong Rd,

Guanmiao Township,

71841 Tainan County,

Taiwan, R.O.0

Tel:

+886 6

596

5798 (ext 201)

Fax:

+886 6

596

5758

UNITED KINGDOM

Avdel UK Limited

Pacific House

2 Swiftfields

Watchmead Industrial Estate

Welwyn Garden City

Hertfordshire AL7 1LY

Tel:

+44

(0)

1707

292000

Fax:

+44

(0)

1707

292199

USA

Avdel USA LLC

614 NC Highway 200 South

Stanfield, North Carolina 28163

Tel:

+1

704

888

7100

Fax:

+1

704

888

0258

Manual No.

Issue

Change Note No.

Date

07900-00819

B

07/044

05-02-07

B2

07/103

03-07

B3

08/131

06-08

B4

11/061

03-11

www.avdel-global.com

www.infastech.com

02.

2011 •

©

201

0 In

fas

tec

h

Autosert® (equipment), Avbolt®, Avdel®, Avdelmate®, Avdel TX2000®, Avdelok®, Avex®, Avibulb®, Avinox®, AvinutTM, Avlug®, Avmatic®, Avplas®,

Avseal®, Avsert®, Avtainer®, Avtronic®, Briv®, Bulbex®, Chobert®, Eurosert®, Fastriv®, Finsert®, Genesis®, Grovit®, Hemlok®, Hexsert®, Holding

your world together®, Hydra®, Interlock®, Klamp-Tite®, Klamptite KTR®, Kvex®, Maxlok®, Monobolt®, Monobulb®, Neobolt®, Nutsert®, Nutsert

SQ®, Portarie, Rivmatic®, RivscreW, Speed Fastening®, Squaresert®, Stavex®, Supersert®, Thin Sheet Nutsert®, Titan®, T-Lok®, TLR®, TSN®,

TX2000®, Versa-Nut®, Viking® and Viking 360® are trademarks of Avdel UK Limited. InfastechTM and Our Technology, Your SuccessTM are

trademarks of Infastech Intellectual Properties Pte Ltd. The names and logos of other companies mentioned herein may be trademarks

of their respective owners. This document is for informational purposes only. Infastech makes no warranties, expressed or implied, in this

document. Data shown is subject to change without prior notice as a result of continuous product development and improvement policy.

Your local Avdel representative is at your disposal should you need to confirm latest information.

Since 1 936 2010Since 1922

www.avdel-global.com

www.infastech.com

02.2011 • © 2010 Infastech

Autosert®(equipment), Avbolt ®, Avdel®, Avdelmate®, Avdel TX2000®, Avdelok®, Avex®, Avibulb®, Avinox®, Avinut™, Avlug

®, Avmatic®, Avplas®,

Avseal®, Avsert®, Avtainer®, Avtronic®, Briv®, Bulbex®, Chobert®, Eurosert®, Fastriv®, Finsert®, Genesis®, Grovit®, Hemlok®, Hexsert®, Holding

your world together®, Hydra®, Interlock®, Klamp-Tite®, Klamptite KTR®, Kvex®, Maxlok®, Monobolt®, Monobulb ®, Neobolt®, Nutsert®, Nutsert

SQ®, Portariv®, Rivmatic®, Rivscrew®, Speed Fastening®, Squaresert®, Stavex®, Supersert®, Thin Sheet Nutsert®, Titan®, T-Lok®, TLR®, TSN

®,

TX2000®, Versa-Nut®, Viking®and Viking 360®are trademarks of Avdel UK Limited. Infastech™ and Our Technology, Your Success™ are

trademarks of Infastech Intellectual Properties Pte Ltd. The names and logos of other companies mentioned herein may be trademarks

of their respective owners. This document is for informational purposes only. Infastech makes no warranties, expressed or implied, in this

document. Data shown is subject to change without prior notice as a result of continuous product development and improvement policy.

Your local Avdel representative is at your disposal should you need to confirm latest information.

AUSTRALIA

Infastech (Australia) Pty Ltd.

891 Wellington Road

Rowville

Victoria 3178

Tel: +61 3 9765 6400

Fax: +61 3 9765 6445

info@infastech.com.au

CANADA

Avdel Canada Limited

1030 Lorimar Drive

Mississauga

Ontario L5S 1R8

Tel: +1 905 364 0664

Fax: +1 905 364 0678

infoA[email protected]

CHINA

Infastech (China) Ltd.

RM 1708, 17/F., Nanyang Plaza,

57 Hung To Rd., Kwun Tong

Hong Kong

Tel: +852 2950 0631

Fax: +852 2950 0022

infochina@infastech.com

FRANCE

Avdel France S.A.S.

33 bis, rue des Ardennes

BP4

75921 Paris Cedex 19

Tel: +33 (0) 1 4040 8000

Fax: +33 (0) 1 4208 2450

AvdelF[email protected]

GERMANY

Avdel Deutschland GmbH

Klusriede 24

30851 Langenhagen

Tel: +49 (0) 511 7288 0

Fax: +49 (0) 511 7288 133

AvdelDeutschland@infastech.com

INDIA

Infastech Fastening Technologies

India Private Limited

Plot No OZ-14, Hi Tech SEZ,

SIPCOT Industrial Growth Center,

Oragadam, Sriperumbudur Taluk,

Kanchipuram District,

602105 Tamilnadu

Tel: +91 44 4711 8001

Fax: +91 44 4711 8009

info-in@infastech.com

ITALY

Avdel Italia S.r.l.

Viale Lombardia 51/53

20047 Brugherio (MI)

Tel: +39 039 289911

Fax: +39 039 2873079

vendite@infastech.com

JAPAN

Infastech Kabushiki Kaisha

Center Minami SKY,

3-1 Chigasaki-Chuo, Tsuzuki-ku,

Yokohama-city,

Kanagawa Prefecture

Japan 224-0032

Tel: +81 45 947 1200

Fax: +81 45 947 1205

info@infastech.co.jp

MALAYSIA

Infastech (Malaysia) Sdn Bhd

Lot 63, Persiaran Bunga Tanjung 1,

Senawang Industrial Park

70400 Seremban

Negeri Sembilan

Tel:

+606 676 7168

Fax: +606 676 7101

info-m[email protected]

SINGAPORE

Infastech (Singapore) Pte Ltd.

31 Kaki Bukit Road 3

#05-03/06 Techlink

Singapore, 417818

Tel: +65 6372 5653

Fax: +65 6744 5643

info-sg@infastech.com

SOUTH KOREA

Infastech (Korea) Ltd.

212-4, Suyang-Ri,

Silchon-Eup, Kwangju-City,

Kyunggi-Do, Korea, 464-874

Tel: +82 31 798 6340

Fax: +82 31 798 6342

info@infastech.co.kr

SPAIN

Avdel Spain S.A.

C/ Puerto de la Morcuera, 14

Poligono Industrial Prado Overa

Ctra. de Toledo, km 7,8

28919 Leganés (Madrid)

Tel: +34 91 3416767

Fax: +34 91 3416740

ventas@infastech.com

TAIWAN

Infastech/Tri-Star Limited

No 269-7, Baodong Rd,

Guanmiao Township,

71841 Tainan County,

Taiwan, R.O.C

Tel:

+886 6 596 5798 (ext 201)

Fax: +886 6 596 5758

info-tw@infastech.com

UNITED KINGDOM

Avdel UK Limited

Pacific House

2 Swiftfields

Watchmead Industrial Estate

Welwyn Garden City

Hertfordshire AL7 1LY

Tel: +44 (0) 1707 292000

Fax: +44 (0) 1707 292199

enquiries@infastech.com

USA

Avdel USA LLC

614 NC Highway 200 South

Stanfield, North Carolina 28163

Tel: +1 704 888 7100

Fax: +1 704 888 0258

infoA[email protected]

Manual No. Issue Change Note No. Date

B07/044 05-02-07

B2 07/103 03-07

B3 08/131 06-08

B4 11/061 03-11

07900-00819

www.aboveboardelectronics.com

1-800-453-1692

Request Info

Table of contents

Other Avdel Power Tools manuals

Avdel

Avdel nG2S 71401 User manual

Avdel

Avdel 7539-300X Series User manual

Avdel

Avdel 74110 User manual

Avdel

Avdel 73432-02000 User manual

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel 7555 User manual

Avdel

Avdel 0749 MkII type User manual

Avdel

Avdel 0727 User manual

Avdel

Avdel 74405 User manual

Avdel

Avdel Genesis G3 User manual

Avdel

Avdel TX2000 User manual

Avdel

Avdel Genesis G3 User manual

Avdel

Avdel Genesis G3 User manual

Avdel

Avdel Avbolt 07220 User manual

Avdel

Avdel genesis g2 User manual

Avdel

Avdel 7557 User manual

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel 74200 User manual

Avdel

Avdel 0753 MkII User manual

Avdel

Avdel Genesis G2LB User manual