AVENTICS | LP04 | R402000482–BDL–001–AE | English 9

English

1 Presentation of information

Warnings

In this document, there are warning notes before the steps

whenever there is a danger of personal injury or damage

to equipment. The measures described to avoid these

hazards must be observed.

Structure of warnings

Meaning of the signal words

Symbols

2 Safety notes

Please observe these safety notes

WThis valve system is to be used for industrial

applications only.

WInstallation may only be performed in a voltagefree and

pressure-free state and only by a qualified person.

WIn order to avoid accidents, electrical start-up is to be

carried out only in a pressure-free state.

WPlease, familiarize yourself thoroughly with the

contents of the operating instructions before installing

the valve system and connecting it to the compressed

air or electrical systems.

WBefore connecting or disconnecting the plugs, switch

off the operating voltage to prevent damage to the

electrical system.

WIf the valve system is disassembled, do not place it in

operation until it has been completely reassembled.

WIf the valve system is subject to continuous actuation of

the solenoids, be sure to provide adequate ventilation

or air-cooling.

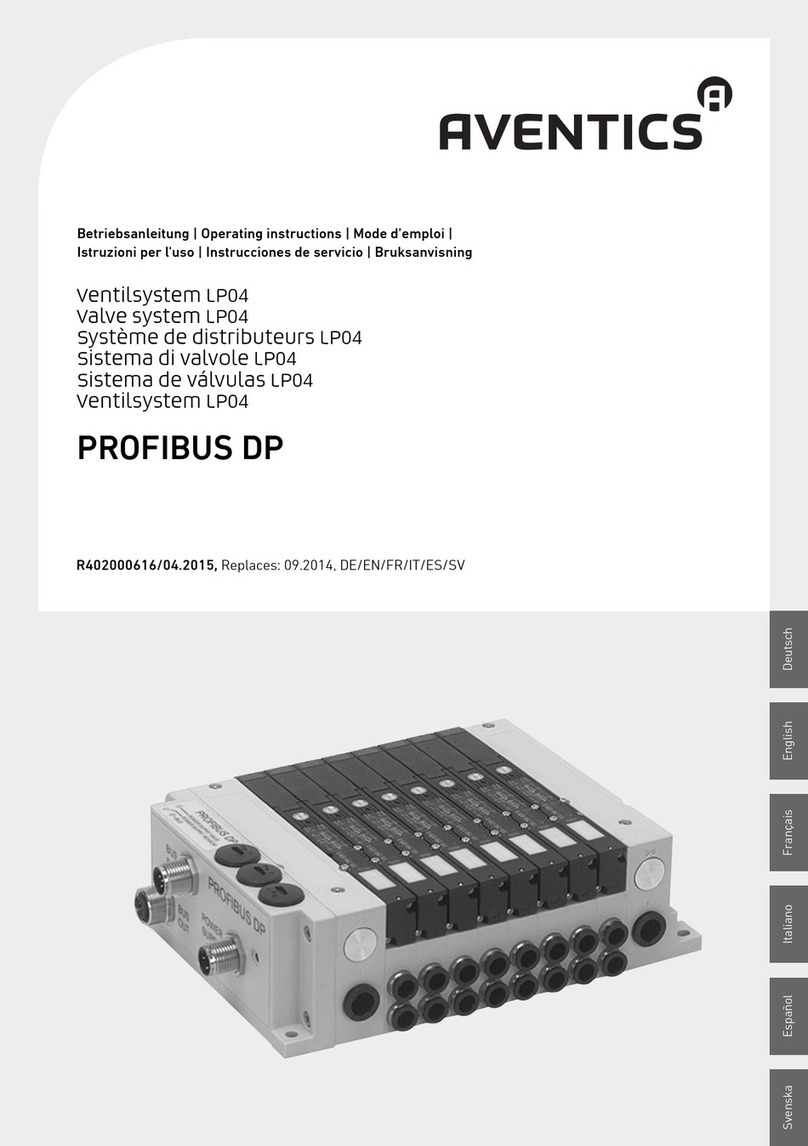

3 System architecture

This manual applies to all standard versions of the valve

system (VS) LP04.

The LP04 is designed for space-limited automation

applications. Size is therefore prioritized over modularity.

One VS can consist of 2*, 4, 6, 8, 10, 12, 14 or 16 valve

positions (* = only version 33–35). After delivery it is

extendable with one double sub-base (= 2 valve positions).

Note! Versions 33–35 and 80–81 are not extendable.

Fig. – shows the different available versions.

Design

The LP04 valve system is composed of the following

components:

WRight end plate for pneumatic connections.

W2–16 sub-bases for valves, blanking plates or air

supply plates.

WLeft end plate for pneumatic connection.

WConnection piece for electrical connections.

Valves

Directional-control valves complete with pilot control

valve. The valves have a manual override of turn and

detent type, (yellow knob) or, turn type (red knob).

Yellow LEDs for side 14 and side 12.

Pneumatic components

Spare parts and accessories are listed under section

„Spare parts“.

Electrical connection

The valve system is controlled via either Sub-D connection

or fieldbus connection. Available fieldbus protocols are

Profibus DP, CANopen, Device-Net and AS-i. Also the

fieldbus system Drive and Diagnostic Link (DDL) is available

with or without inputs.

Function

The valve system is connected to the pneumatic system

via two end plates for air supply and exhaust for both main

and pilot valves. Channel 1 supplies all valves with

compressed air. The pilots may be supplied with air either

from channel 1 (internal supply) or from an external pilot

air supply port (port X) on the right end plate. The exhaust

air from all main valves is evacuated through integrated

silencers or port 3/5 in the end plates.

The exhaust air from all pilot valves is evacuated through an

integrated silencer or through port Rx in the right end plate.

Air supply connections are provided on both sides of the

VS, through the two end plates (port 1). It is recommended

to connect the air supply lines to both sides.

The valves direct the air to the pneumatic drives. The

connection is made via the valve’s sub-base (sub-base

connection port 2 and 4).

SIGNAL WORD

Hazard type and source

Consequences of non-observance

OMeasures to avoid these hazards

NOTICE

Indicates damage to property: The product or its

environment may be damaged.

Operation may be impaired if this information is

disregarded.

Each valve has a manual override which is

activated by a turning motion. Do not push!