6Pneumatic Directional Control Valves AVENTICS Corporation

Summary of Specifications For Ceram Valves

TECHNICAL DATA:

Port Sizes: 1/4” - 3/8” ISO Size 1, 3/8” - 1/2” ISO Size 2

1/2” - 3/4” ISO Size 3, 3/4” - 1” ISO Size 4

Working Pressure: 0 to 150 PSI (0 to 10.3 bar)

(Intrinsically Safe versions: Maximum internal pilot valve

pressure is 115 PSI or 7.9 bar)

Vacuum applications: to 24” Hg

Pilot Pressure: SIZES 1 & 2

29 PSI (2.0 bar) minimum, all 2 position valves

44 PSI (3.0 bar) minimum, all 3 position valves

150 PSI (10.3 bar) maximum

(Intrinsically Safe versions: Maximum external pilot

pressure is 115 PSI or 7.9 bar)

SIZES 3 & 4

36 PSI (2.5 bar) minimum, all 2 position valve

44 PSI (3.0 bar) minimum, all 3 position valve

150 PSI(10.3 bar) maximum

(Intrinsically Safe versions: Maximum external pilot

pressure is 115 PSI or 7.9 bar)

Flow:

Valve Size 1 2 3 4

C

v 1.1 2.4 4.3 7.5

Nl/min 1100 2400 4300 7500

Temperature Range:

Solenoid Valves: +5°F to +150°F (-15°C to 66°C)

(-10°F or –23°C operation possible with low temperature solenoid

operators. Available for 2-position double solenoid and air

Spring return valves.)

Air Pilot Valves: -10°F to +175°F (-23°C to 79°C)

Media: Air, either Lubricated or Non-lubricated

Service Life: over 150 million Cycles with or without Line Lubrication

Material: Body - Die Cast Anodized Aluminum (Sizes 2 - 4)

Die Cast Zinc (Size 1)

Valve Elements - Ceramic Slide Plates (AI2O3)

Combination Manual Override:

Explosion-proof models: Non-locking only

Other models: Locking & Non-Locking sizes 1 - 4 (3 and 4: Oct. ‘92 & later)

Non-Locking sizes 3 & 4 (Prior to Oct. ‘92)

Ceram™ Valves, ISO 5599-1 Sizes 1-4

Specifications and features

ELECTRICAL DATA:

ISO Valve

Size

Standard Voltages

(All coils are rated for

continuous duty)

Power Consumption

Inrush Holding

1 and 2

(3 and 4

Oct. ‘92

and later)

24 VAC - 50/60 Hz

110 VAC - 50 Hz/120 VAC - 60 Hz

220 VAC - 50 Hz/240 VAC - 60 Hz

6.4 VA

3.7 VA

12, 24 VDC 2.7 W

120, 240 VAC (50/60 Hz) 15.6 VA 9.4 VA

12, 24 VDC 6.1 W

3 and 4

(Prior to Oct.

‘92)

Voltage Tolerance: +/- 10% (Except for Explosion proof and

Intrinsically safe solenoids.)

All standard valves are rated for NEMA 4.

SOLENOID CONNECTORS AND SUBBASES:

Plug-in solenoid connectors conform to DIN standard #43650 and must

be ordered separately. Order one connector per solenoid. Connector

options Include strain relief and one-half inch (1/2”) conduit. Both are

available in Lighted and non-lighted versions. 1/2” conduit connector

also available in metallic version; see page main solenoid connectors

page. Subbases, manifold and accessories are ordered separately.

FEATURES

Ceramic plates guaranteed for life of valve

Sliding ceramic plates form seal

Operates with or without line lubrication

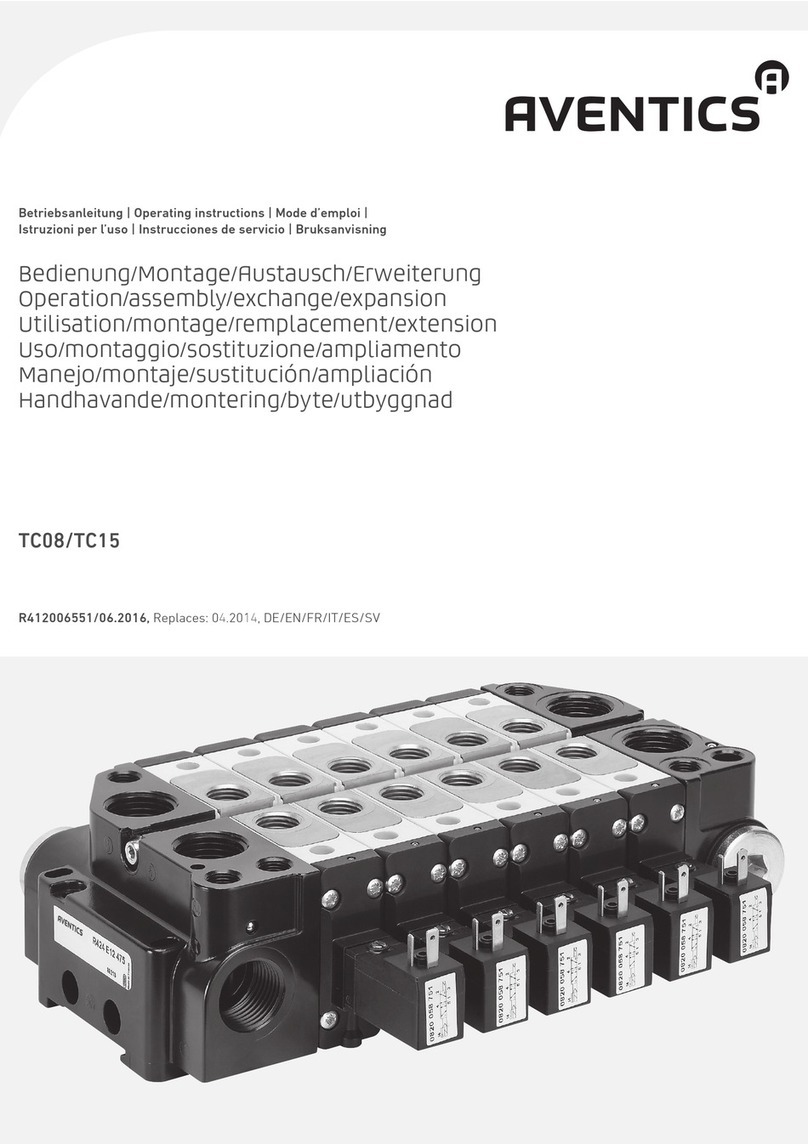

Interchangeable with other ISO valves

Expected service life exceeds 150 million

cycles

NEMA 4 Standard

Sub-bases and manifolds available 1/4” thru

1” NPT ISO G1/8 to G1 piping

Wide range of accessories, including

sandwich speed controls and regulators

Explosion-proof and intrinsically safe

solenoids available.

Brad Harrison® Connector Solenoids

cURus (Dual CSA / UL Recognized)

solenoids

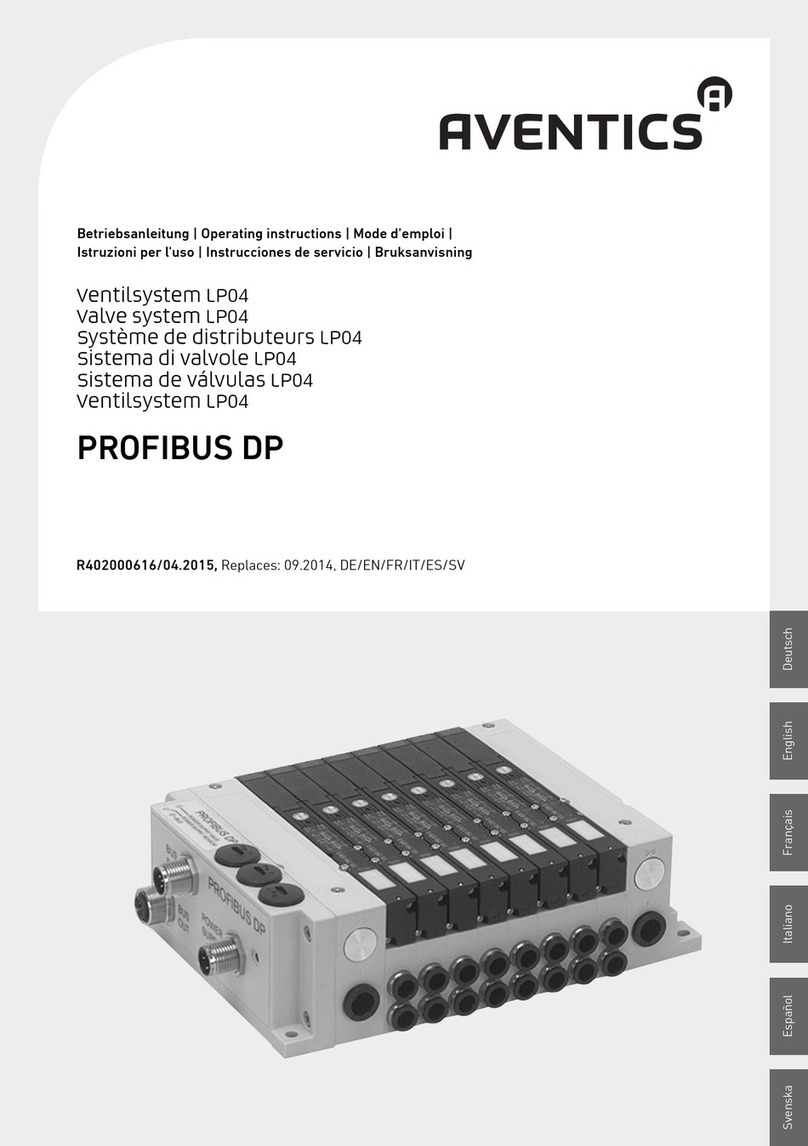

ISO I pictured