Page 8

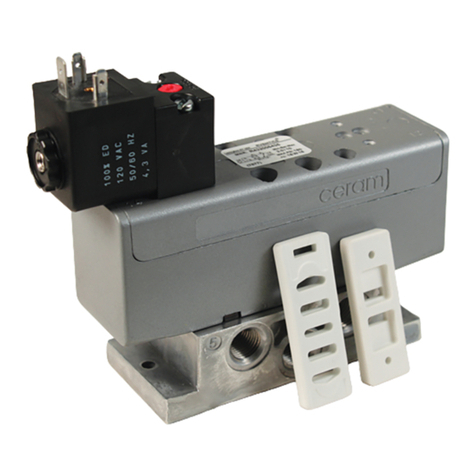

AVENTICS “A” PILOTAIR®VALVE SERVICE INFORMATION

DISASSEMBLY

Refer to Figure 16, and completely disassemble the

valve portion in sequence shown.

CLEANING

1. Clean all metal parts with a nonflammable solvent.

2. Wash all rubber parts with soap and water.

3. Rinse parts thoroughly and blow dry with a low-

pressure air jet.

4. Inspect all parts and replace those which are worn or

damaged.

REASSEMBLY

Refer to Figures 11 and 16, and reassemble the valve

portion.

1. The cartridge valve assembly (6) is designed to

simplify repairs and eliminate possible problems in

assembly.

2. Lubricate all metal-to-metal contact surfaces with

Number 107 Lubriplate.

3. Lubricate all rubber parts with Dow Corning No. 55

Pneumatic Grease.

4. After reassembly is complete, install the operator

and test for correct operation and evidence of leakage.

ADJUSTMENT

The “A” PILOTAIR Valve requires no adjustment after

reassembly.

CAM HOUSING MAINTENANCE

NOTE: Before performing maintenance on the cam

housing, the following information must be noted.

All cams in the “A” PILOTAIR Valve are marked for

position on the shaft and for the valve cavity that

they are to operate.

1. The position index mark indicates the position

of the cam on the shaft when the handle is in the

upright position. This mark appears on the edge of

the cam.

2. The engraved cavity number indicates the valve

cavity that the cam is to operate. This marking

appears as an Arabic numeral on the same side of

the cam as the position index mark.

With the front (vertical side) of the cam housing

facing the operator and with the handle facing

toward the right (single handle models), the

position index marks and engraved cavity numbers

appear on the right side of the cams.

The valve cavities are numbered 1, 2, 3 and 4 from

the left with the cam housing in the same position

as above.

Valve Portion Maintenance

2-BA-1 PILOTAIR VALVE

HOUSING DISASSEMBLY

Refer to Figure 17 (page 17). Disassemble the housing

in sequence shown.

CLEANING

1. Clean all parts with a nonflammable solvent.

2. Rinse parts thoroughly and blow dry with a low-

pressure air jet.

3. Lubricate Driv-lok pin, shaft of push-button and both

sides of cam dog with Number 107 Lubriplate.

REASSEMBLY

Refer to Figure 17, and reassemble the housing.

2-HA-1 PILOTAIR VALVE

HOUSING DISASSEMBLY

Refer to Figure 18, and disassemble the cam housing in

sequence shown.

CLEANING

1. Clean all parts with a nonflammable solvent.

2. Rinse parts thoroughly and blow dry with a low-

pressure air jet.

3. Lubricate bronze bearings located in cam housing

with Number 107 Lubriplate.

4. Lubricate cam surfaces and cam follower surfaces

with Number 107 Lubriplate after they have been

reassembled in cam housing.

REASSEMBLY

Refer to Figure 18

1. Position handle hub (7) onto shaft (13). Hub end

must be flush with end of shaft.

2. Insert rubber plug (6) into hole of handle hub.

Screw handle (5) into hub and tighten to secure hub

against shaft.

3. Position washer (8) onto shaft.

4. Insert handle and hub assembly into right side of

cam housing just enough to allow cam (9) to be

positioned on shaft.

5. Position cam (9) on shaft so that the position index

mark is facing toward the handle and, at the same time,

appears at bottom center when the handle is in the

upright position.

6. Place spacer (10) on shaft.

7. Slide shaft through hole in left side of cam housing.

8. Add washer (8) and secure with retaining ring (14).