Avers Screens Avers Cumulus X User manual

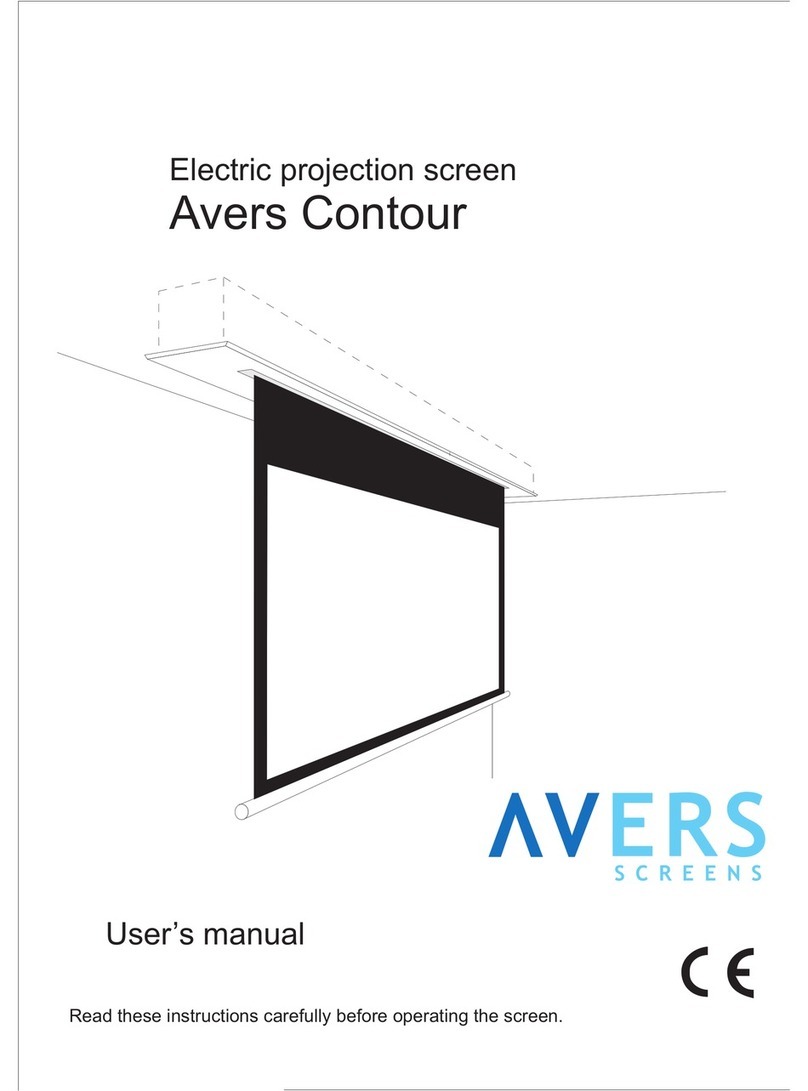

Electric projection screen

Avers Cumulus X

User’s manual

Read these instructions carefully before operating the screen.

2

Thank you very much for the purchase of our product. The manual booklet contains all operation information

you may require to install properly and operate the screen. We hope it will help you to get the most performance and

enjoyment of your new screen. Enjoy time with the Avers Screens product.

SAFETY INFORMATION

NOTICE: Important safety information.

Follow the instructions described in the operating manual for safety reasons. After reading the manual, please store

it in a safe place just in case you need it in the future.

NOTICE: THE DEVICE HAVE TO BE EARTHED.

WARNING:

1) Disconnect the device from the power supply if it will not be used within longer period of time.

2) Do not open the casing of the device in order to avoid possible electric shock. There are not any user operated

parts inside the case of the screen. All service work can be done by Avers Authorized Service Center personnel

only.

3) Do not remove the Ground pin from the power outlet neither connect the device to the socket without the Ground

pin. If you can't put the plug to the power outlet, please ask electrician for assistance.

Dear Customer,

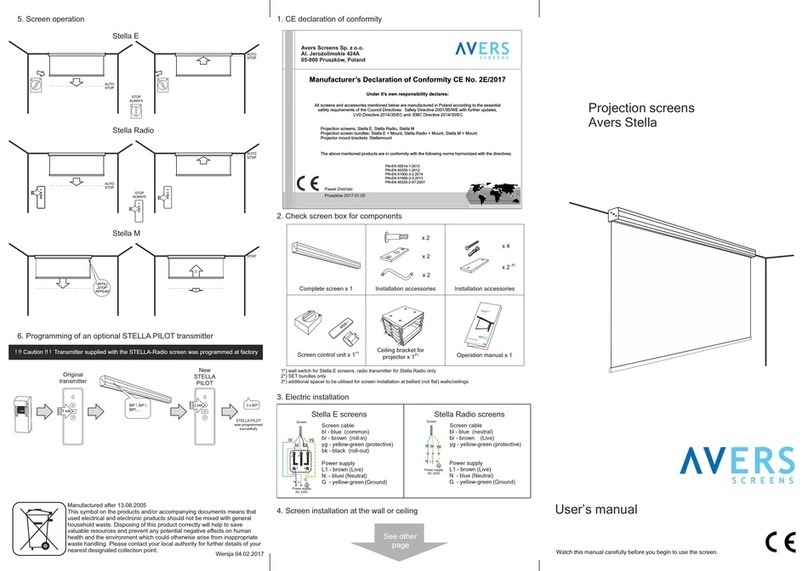

Table of contents:

1. Safety rules

1.1. Declaration of Conformity CE

2. Product specification

2.1. Contents of package

2.2. Technical data

3. Screen installation

3.1. Installation directions

3.2. Ceiling installation

3.3. Wall installation

3.4. Electric installation

3.5. Screen programming

3.6. +RCX remote control system programming

3.7. C12VRC+ triggered control system programming

4. Screen operation

Manual operation

Screen maintenance

4.4 Before asking for service

5. Warranty conditions

4.1 Automatic operation

4.2

4.3

1. SAFETY RULES

SAFETY INFORMATION

NOTICE: Important safety information. It is important for the safety of persons to follow these instructions.

After reading the manual, please save it just in case of need in the future

Do not allow children to play with the fixed controls (remote control).

Keep the remote control unit out of reach of children.

Frequently examine the screen installation for imbalance and signs of wear or damage to cables. Do not use if repair or

adjustment is necessary.

Watch the moving screen and keep the people away until the screen is completely rolled in/out. It will help to avoid

injuries caused with moving screen.

Do not attach any objects to the screen’s bottom bar. Screen damage and/or person injury danger.

All installation work should be carried out by the qualified technician.

Improper installation of the screen can cause device damage or health breakdown.

Ceiling/wall installation can be done with the originally supplied mounting brackets dedicated for this model only.

Do not do anything that may damage the power cable or power plug.

Do not damage the power cable: make any modifications by your own, put it near the hot objects, bend it strongly,

twist it, pull out the power cable, put the heavy objects on the cable, wrap it into the bundle.

Operation of the screen with damaged power cord can result with electric shock, electric short circuit and fire.

Do not touch the power cable and the power plug with wet hands.

Always follow the instructions described in the operating manual.

1.1. Declaration of Conformity CE

3

AVERS Screens Sp. z o.o.

Under it’s own responsibility declares:

All screensand accessories mentioned below are manufactured in Polandaccording to the essential safety

requirements of Council Directive 98/79/WE

Projection screens: Stratus, AkuStratus, Focus, Cumulus X, Solar, Solaris, Contour, Altus,

Cirrus CL, Cirrus X, Cirrus X crank

Projector mount brackets: Alumount, Promount, SimpleMount, Prolift

The above mentioned products are in conformity with the European Directives

and especially with the norms:

PN-EN 55014-1:2007(U)

PN-EN 50082-1:1997

PN-EN 60335-1:2004

PN-EN 61000-3-2:2007

PN-EN 61000-3-3:1997

IEC 60335-2-97:2007

Manufacturer’s Dedlaration of ConformityCE

2. Product specification

Electrically rolled projection screen designed for fixed installation at projection systems for business presentations

and/or home cinema applications. Screen case made with aluminium alloy, decorative elements at the screen main body

and bottom bar available optionally in colors: white, yellow, blue, green, brown, grey or black. Best picture quality can be

reached when the selection of the type of projection surface and size will be optimal for the, projection device (projector)

and projection conditions at the planed installation place. Built-in radio frequency remote or triggered control systems

(factory installable options) allows comfortable automatic operation.

2.1. Contents of packaging

Please, check carefully if any physical damage of the screen has not happen during transportation.

Inspect the package for all accessories presented below:

*) standard equipment for the screens without built-in control system

**) standard equipment for the screens with built-in +RCX control system

***) standard equipment for the screens with built-in C12VRC+ control system

Screen x 1

Radio Frequency

remote transmitter**) x 1

x 2

M6x20 x 2

Installation accessories

Wall control switch *)

x 1

x 2

x 2

Installation brackets

Regulation wrench x 1

***) x 1

Trigger transmitter Operation manual x 1

2.2 Technical Data

Projection fabrics characteristics:

- Matt White P (MWP) – a special screen dedicated polyester fabric double side covered with vinyl, black back surface

and white front (projection) surface, recommended for application with DLP and LCD multimedia projectors.

Neutral color of the surface enables projection from any directions. Gain: 1.0, viewing angle: 150 degrees,

thickness: 0,7 mm.

- Matt White (MW) – a special screen dedicated polyester fabric double side covered with vinyl, black back surface

and white front (projection) surface, recommended for application with DLP and LCD multimedia projectors.

Neutral color of the surface enables projection from any directions. Gain: 1.0, viewing angle: 150 degrees,

thickness: 0,35 mm.

- Matt Grey (MG) – a special screen dedicated polyester fabric double side covered with vinyl, black back surface

and grey front (projection) surface, recommended for application with high brightness DLP and LCD multimedia

projectors. The surface offers deeper level of black and more realistic rich dark colors recognized as a feeling of higher

image contrast. Recommended for home cinema applications. Gain: 0,8. viewing angle: 150 degrees,

thickness: 0,35 mm.

- White Ice (WI) – White color vinyl mono foil, matt front size (projection), gloss rear side, dedicated for projection with

LCD and DLP projectors. Fabrics with slightly directional characteristics dedicated for business presentations. Fabrics

of screens bigger than 200cm in height is welded with 2 parts, welding line remains invisible during projection.

Gain 1,2 , viewing angle 120 degrees, thickness 0,4mm.

4

350 357 x 12,3 x 12,8

340 x 191,3 16:9 241,5

272,5

207

207

272,5

35

8

8

-

-

18,9

19,0

18,2

18,2

19,0

BT

BB

BB

-

-

4:3

16:9

16:9

4:3

340 x 255

340 x 191,3

350 x 196,9

350 x 262,5

Dimensions of projection screens.

*) BT and BB versions are available with fabrics

**) approximate value for the screen with Matt White fabrics

Version BB – 5 cm width black border surrounding the viewing area

Version BT – 5 cm width black border surrounding the viewing area and additional black top 30 cm above the top black border.

MW, MG or WI

Motor:

Electric tubular engine AC:

Voltage:

Power consumption:

Rotation speed:

Torque:

)

Max. operation time Engine single cycle operation time, operation cycle can be repeated in 20 minutes intervals.

220-240V AC 50 Hz, 125 W

0,52A

28 obr./min

3 Nm

*) *

: 4 min

5

180

210

240

270

300

187 x 12,3 x 12,8

217 x 12,3 x 12,8

247 x 12,3 x 12,8

277 x 12,3 x 12,8

307 x 12,3 x 12,8

170 x 95,6 16:9 141

153

123,5

123,5

150

190

158

168

130,5

130,5

168

220

174,5

195

215

190

212,5

235

147

161

179

147

161

179

190

212,5

235

250

280

310

35

8

8

-

-

-

35

8

8

-

-

-

35

35

35

8

8

8

8

8

8

-

-

-

-

-

-

-

-

-

7,7

7,8

7,5

7,5

7,8

8,0

9,7

9,8

9,5

9,5

9,8

10,0

11,6

13,8

15,8

11,7

14,0

15,6

11,3

13,5

14,0

11,3

13,5

14,0

11,7

14,0

15,6

12,0

14,0

16,0

BT

BB

BB

-

-

-

BT

BB

BB

-

-

-

BT

BT

BT

BB

BB

BB

BB

BB

BB

-

-

-

-

-

-

-

-

-

4:3

16:9

16:9

4:3

1:1

16:9

4:3

16:9

16:9

4:3

1:1

16:9

16:9

16:9

4:3

4:3

4:3

16:9

16:9

16:9

16:9

16:9

16:9

4:3

4:3

4:3

1:1

1:1

1:1

170 x 127,5

170 x 95,6

180 x 118,2

180 x 135

180 x 180

200 x 112,5

200 x 150

200 x 112,5

210 x 118,2

210 x 157,5

210 x 210

230 x 129,5

260 x 146,3

290 x 163,1

230 x 172,5

260 x 195

290 x 217,5

230 x 129,5

260 x 146,3

290 x 163,1

240 x 135

270 x 151,9

300 x 168,8

240 x 180

270 x 202,5

300 x 225

240 x 240

270 x 270

300 x 300

- New Coral (NC) – Rear projection white vinyl mono foil, gloss front side (projection), matt rear side, dedicated for rear

projection with LCD and DLP projectors. Recommended for business presentations due to directional optical

characteristics of the fabrics. Fabrics of screens bigger than 200cm in height is welded with 2 parts, welding line

remains invisible during projection. Gain 3,2 , viewing angle 90 degrees, thickness 0,6mm.

Screen width

[cm] Viewing area

size [cm] Screen

aspect

ratio

Screen case size

W x H x D [cm] Projection fabrics

max. length

[cm]

Top belt

width [cm] Version *)

Net

weigth**)

3. Screen installation

3.1. Installation precautions

- Installation work should be carried out by a qualified technician in accordance with the instructions described below.

- Fixed installation of the screen should be done with use of the screws and anchors suitable for the walls/ceilings

materials at the installation place and the genuine installation brackets delivered with the screen.

- Check carefully after installation if the screen is perfectly leveled. Do not roll out the screen not installed in horizontal

position. In case the screen leveling is not perfect correct the installation.

3.2. Ceiling installation

- Appoint the location of the ceiling mount brackets fixing points.

- Drill holes for anchors fixing the screen brackets to the ceiling.

- Fix the ceiling brackets with anchors (see picture 1).

- Slide screen fixing bolts into the casette chanels (see Picture 2).

- Twist the screen casette and slide the chanel onto the ceiling brackets front hinge (see Picture 3).

- Twist the screen casette back to the horizontal position (see Picture 4)

- Slide locking bolts to the lock position (see Picture 4).

The mounting screws diameter should be not smaller than Ø8 mm. In case of the cartboard-plaster ceiling installation,

use cartboard-plaster dedicated steel anchors with Ø11mm diameter screws.

Picture 1 Fixing screen ceiling brackets

Picture 3 Screen ceiling installation - phase 2

Picture 2 Screen ceiling installation - phase 1

Picture 4 Screen ceiling installation - phase 3

D = (3/4W+55)±W/6

W - screen width in milimeters

Check the screen case leveling before first unrolling the screen.

Do not use the screen if it is not properly installed (leveled).

6

RF remote controller: Triggered transmitter:

Dimensions: Dimensions:

Power supply: battery Power supply:

110 x 58 x 20 mm 90 x 58 x 65 mm

1 x 12V typ 23A AC 220V, 50Hz

m i n. 1 0 0 m m

The mounting screws diameter should be not smaller than Ø8 mm. In case of the cartboard-plaster walls

installation, use cartboard-plaster dedicated steel anchors with Ø11mm diameter screws.

3.3. Wall installation

- Appoint the location of the ceiling mount brackets fixing points.

- Drill holes for anchors fixing the screen brackets to the ceiling.

- Fix the screen wall brackets to the wall with anchors (see Picture 5).

Picture 5 Fixing screen wall brackets Picture 6 Screen wall installation - phase 1

Check the screen case leveling before first unrolling the screen.

Do not use the screen if it is not properly installed (leveled).

- Fix the ceiling brackets and the wall brackets with the screws supplied with the screen.

- Slide screen fixing bolts into the casette chanels (see Picture 6).

- Twist the screen casette and slide the chanel onto the ceiling brackets front hinge (see Picture 7).

- Twist the screen casette back to the horizontal position (see Picture 8).

- Slide locking bolts to the lock position (see Picture 8).

Picture 7 Screen wall installation - phase 2 Picture 8 Screen wall installation - phase 3

3.4. Electric installation

- Lead out the power cables to:

a) the place of screen installation (screens with built-in remote control system),

b) the place of installation of the wall switch and between wall switch and screen (screenss without built--in control

systems).

- Screen power line should be fused with 1A fuse.

- Switch off the screen power line during installation work.

- Manual wall steering switch should be installed at the place meeting the following conditions:

a) installation150-180 cm above the floor level,

b) the screen should be visible by the wall switch operator during the screen operation,

c) wall switch operator cannot stay in reach of any of the screen’s moving parts during the screen operation .

d) the wall switch must be visible from the each part of the room irrespective of the screen position.

7

D = (3/4W+55)±W/6

W - screen width in milimeters

40

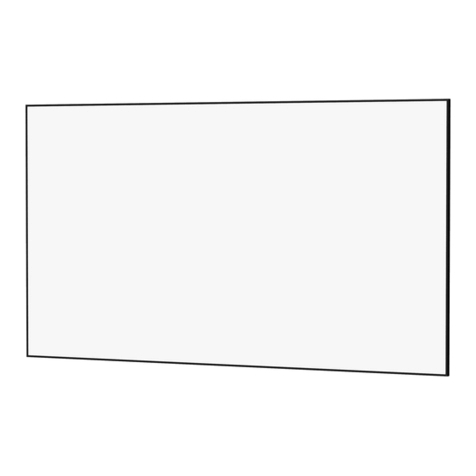

Picture 9 Screen without remote control system

electric installation

Screen

bl - blue (common)

br - brown (rolling down)

yg - yellow-green (protective)

bk - black (rolling up)

Power line

L1 - brown (live)

N - blue (neutral)

G - yellow-green (protective)

bl yg

bk

br

ATTENTION: Electric installation work should be carried out by a certified electrician.

Picture 10 Screen with built-in +RCX control

system electric installation

Picture 11 Screen with built-in C12VRC+ triggered

control system electric installation

Screen

bl - blue (common)

br - brown (live)

yg - yellow-green (protective)

Power line

L1 - brown (live)

N - blue (neutral)

G - yellow-green (protective)

Screen

bl - blue (common)

br - brown (live)

yg - yellow-green (protective)

bk - black (manual control)

Power line

L1 - brown (live)

N - blue (neutral)

G - yellow-green (protective)

- Connect trigger signal transmitter to the wall outlet you plan to connect projector power cord.

- Apply projector power cord wall plug to the power outlet located at the trigger signal transmitter

! !!! NOTICE !!! Do not connect any any electric devices except multimedia projector to the power outlet located at the

trigger transmitter. Maximum projector power consumption 600W.

optional wall

switch

WS-C12VRC+

8

~

bl yg

br

~

bk

br

yg

bl

~

Picture 12 Lower bar fine tuning

3.5. Screen programming.

Programing the length of the rolled out screen (screen bottom bar position).

- Roll up the screen until it will stop automatically in the upper position.

- Insert regulation wrench included in the screen set into the regulation slot (see picture. 6) located in the left bottom

part of the screen .

Regulation knob “2” (red) enables setting of the lower extreme position of the screen bottom bar:

„+” - means increasing the lenght of the fabrics is rolled down when the screen is rolled out,

„–” - means decreasing the length of the fabrics is rolled down when the screen is rolled out.

!!! NOTICE !!! The screen was programmed properly at the factory and there is no need to reprogram it without any

important reason. Setting of screen extreme positions was made by manufacturer.

If you need to change the screen extreme position follow the instructions described below.

Regulation knob “1” (white) enables setting of the upper extreme position of the screen bottom bar:

“-“ - means increasing the lenght of the fabrics is rolled down when the screen is rolled in,

“+” - means decreasing the length of the fabrics is rolled down when the screen is rolled in.

!!! IMPORTANT !!!

Do not decrease (tuning knob 1+) the range of the rolled down surface. It can damage the screen.

Do not increase (regulation 2+) the range of the surface which was rolled down behind the STOP mark, placed in

the upper right corner of the screen. Rolling down the screen behind the mark can damage the screen.

3.6. +RCX remote control system programing

Parallel operation of a few screens with built-in +RCX installed in the same room is possible; in such case control

systems of each screen must be programmed with dedicated control code. The screen with +RCX remote control system

is supplied with single remote transmitter, it is possible to purchase optional transmitters. The optional transmitters must be

programmed at the controller.

A) Setting of the new transmitter

Controller can memorize 10 individual control codes of remote transmitters.

Connect power supply to the screen.

Press 3 times P2 button of the remote transmitter within 12 seconds after the screen’s sound signal.

Transmitter is not set to the control system with individual code (random generated code).

B) Deleting of the transmitter

Connect power supply to the screen.

Press P2 button of the remote transmitter once.

Press the “Stop” button of the remote transmitter within the next 4 seconds.

Press P2 button within the next 4 seconds again.

The remote transmitter was deleted from the controller memory.

C) Appending new remote transmitter

New remote transmitter will obtain the same individual control code as the original one when appended, or new

individual control code if set. We suggest appending new remote transmitters in case some screen with +RCX control

systems (or controlled with DRC control systems) are installed in the near neighbourhood (transmitter operation range).

Connect power supply to the screen.

Press P2 button of the original remote transmitter twice.

Press P2 button of the new remote transmitter once within the next 4 seconds .

Appending of the new remote transmitter is done.

D) Converting direction

It is possible to convert direction of the operation of the remote transmitter buttons, i.e. the “” button will cause the

screen to roll out instead of causing the screen to roll inn, and the “‚” button will cause the screen to roll inn instead of

causing the screen to roll out.

Connect power supply to the screen.

Press P2 button of the remote transmitter once.

Press the “‚” button of the remote transmitter within the next 4 seconds once.

Press P2 button of the new remote transmitter once within the next 4 seconds once.

Converting direction is done.

3.7 C12VRC+ triggered control system programming

C12VRC+ triggered control systems radio frequency connection between transmitter and controller is coded with individual

control code. Coding of the control system can be performed during screen production at the Avers factory only. You can

find information about the individual number of control code of your screen at the transmitter enclosure. Parallel operation

of a screens with built-in C12VRC+ control systems is possible without any problem, if the screen’s control systems are

programmed with different individual control codes (for individual screen control) or the screen’s control systems are

programmed with the same individual control code (for group screen control).

4. Screen operation

Projection screen AVERS can be operated manually or automatically (screens with built-in C12VRC+ triggered control

system). Both operation methods can be used simultaneously if optional dedicated wall switch is installed.

4.1 Automatic operation (screens with C12VRC+ control system)

Automatic screen operation is provided with use of the triggered signal radio frequency transmitter.

- Press “POWER” button at the projector’s remote control transmitter or at the projector itself. Projector lamp will light on,

the screen will begin rolling out and it will stop automatically when the bottom bar will reach the bottom position.

9

- Press “POWER” button at the projector’s remote control transmitter or at the projector itself. Projector lamp will light off,

the screen will begin rolling in and will stop automatically when the bottom bar will reach the upper position.

4.2 Manual operation

Manual screen operation is possible with the wall control switch or by radio frequency transmitter of the optional remote

control system.

- Push button „€”, the screen will begin to roll down and stop automatically at the bottom position after rolling down.

- Push “Stop” button of the remote transmitter, screen rolling operation will be stopped.

- Push button „”, the screen will begin to roll up and stop automatically in the upper position after rolling up.

4.3. Screen maintenence

Pojection screen Avers do not require periodical service maintenance. Clean dust from the screen case and fabrics with

dry soft cloths. If needed use moisturized cloth with soft detergent to remove stains. After stain removal dry the cleaned

surface with cloth carefully.

4.4. Before calling the service

5. Warranty conditions

1) Avers screens warranty period is 24 months from the date of purchase confirmed with the original purchase invoice.

2) Extended warranty period for electric engine is 60 month.

3) Surety commits to fix free of charge any failures (component or production defects) of the product which appear during

warranty period.

4) Warranty exclusions :

a) the failures caused by the usage of the screen against the rules described in operation manual,

b) the failures caused by improper storage or transportation,

c) mechanical defects of the screen other than mentioned at point 3),

d) damages caused with overvoltage at power network,

e) deinstallation and reinstallation of the screen.

5) Avers Screens Service department will remove all defects within 21 days after receiving the demaged product.

6) Warranty claims should be passed to the screen supplier (dealer).

At other cases please contact service.

The screen fabrics does not

roll down/up automatically Projector power cord plug is not connected

to the trigger transmitter outlet. Connect projector power cord plug to the

trigger transmitter outlet

Symptoms

The screen fabrics does not

roll down

Reasons

Power failure

Remedy

Check the screen’s circuit fuse and the

power cable

The screen fabrics does not

roll down smoothly

The screen stops in the

middle position.

The screen was not installed properly in

horizontal position.

There are some objects on the bottom bar

way.

Power failure

Check if the screen case is properly leveled.

Reinstall the screen correctly.

Remove the objects which can block the

proper work of the screen or are at the

bottom bar way.

Check the propriety of electric installation

and the state of the power wires.

Manufactured after 13.08.2005

This symbol on the products and/or accompanying documents means that used electrical and

electronic products should not be mixed with general household waste. Disposing of this

product correctly will help to save valuable resources and prevent any potentialnegative effects

on human health and the environment which could otherwise arise from inappropriate waste

handling. Please contact your local authority for further details of your nearest designated

collection point.

Table of contents

Other Avers Screens Projection Screen manuals

Avers Screens

Avers Screens Stella Series User manual

Avers Screens

Avers Screens Solar Pro User manual

Avers Screens

Avers Screens Electric projection screen User manual

Avers Screens

Avers Screens Cirrus X User manual

Avers Screens

Avers Screens Cirrus X Crank User manual

Avers Screens

Avers Screens Akustratus 2 Tension User manual

Avers Screens

Avers Screens Cumulus X Tension User manual

Avers Screens

Avers Screens Stratus 2 User manual

Avers Screens

Avers Screens Cirrus CL User manual

Avers Screens

Avers Screens Solaris User manual