[EN] English - 3

K0405 Revision B

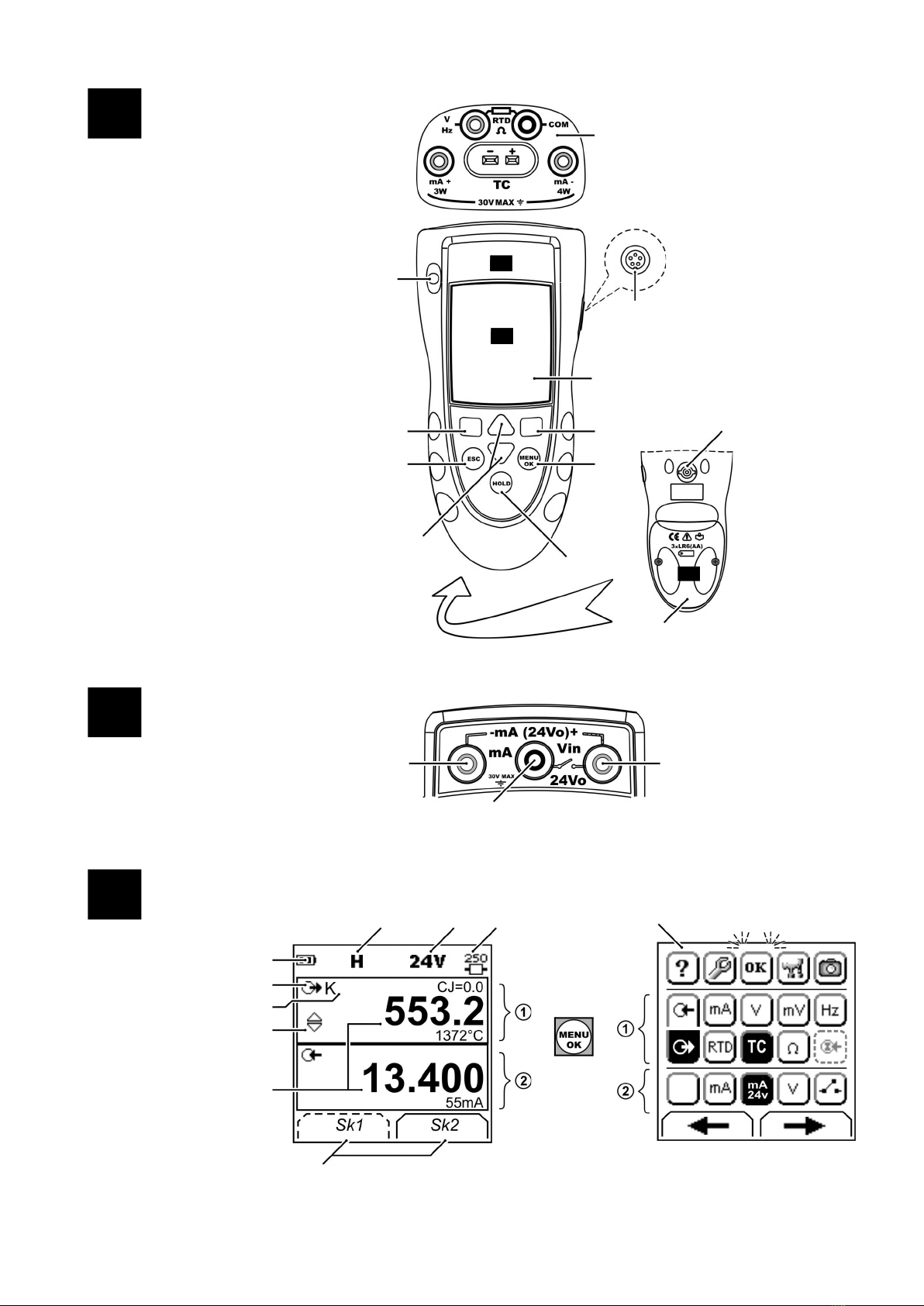

Key to figure A3 (Display)

Prepare the instrument

Before you use the instrument for the first time:

• Make sure that there is no damage to the instrument, and

that there are no missing items.

• Remove the plastic film that protects the display. Use the

tag ( ) in the top right-hand corner.

• Install the batteries (refer to B1). Then re-attach the cover.

Power on or off

To set the power on or off, press (A1 -item 1). The

instrument does a self test and then shows the applicable

data.

When the power is off, the last set of configuration options

stays in memory. Refer to “Maintenance”.

Set up the basic operation

Use the Set Up menu to set up the basic operation of the

instrument.

If there is additional data for a menu option, select

Settings () to see the values that are set up. If necessary,

adjust the values.

Table 1: Menu options - Set Up

Select a task (Measure and/or supply)

When the instrument is set up (Table 1), use the task

selection menu to select the applicable task.

If you attach a Universal Measurement Module (UMM) to the

communications port (A1 - item 9), the task selection menu

shows the applicable IDOS options.

Make the necessary selections from each area ( and ).

One task is permitted in each area.

Item Description

1. Task indication for the switch test.

= switch closed = switch open

UPM only. Task indication for the leak test.

There is a 250series resistor in the mA circuit.

Refer to: Table 2/3

2. The loop power supply is on.

Refer to: Table 2/3

3. The data on the display is on hold. To continue, press the

HOLD button again.

4. Shows the battery level: 0 to 100%.

5. Identifies the type of data.

= Input = Output

= IDOS input

Refer to: Table 2/3

21. to 22. The settings applied to the input or output:

6. K The thermocouple type (K, J, T ... ) - (Table 4/5).

CJ= ... The cold junction temperature (Table 1)

Pt... The RTD type (Pt50, ...) - (Table 4/5).

RTD input connections: 2, 3, or 4 (Figure 7)

5.0V ...V The input trigger level (Table 4) or the output

amplitude (Table 5).

7. , ... , = Output operation (Table 5)

8. 13.400

55mA

The measured values applicable to the task selections in

item 25, area and

+ the measurement range and units.

9. Sk1/2 A soft-key function. To select an available function, press

the soft-key below it. Example:

= Move left = Move right

10. The task selection menu. One task selection is permitted

in each area ( and ).

= cursor position (flashes on/off)

= a button or task selection is set in area or .

Sets the Dual Function, area selections to off. This

saves the battery power.

Refer to: Table 2/3

Help: Shows a connection diagram for the task

selections you have set.

Set Up: Shows the Set Up menu to set up the basic

operation. Refer to Table 1.

OK: Accepts the selections on the menu.

Note: MENU/OK also does this.

Utilities: Leak Test. Use this function with a UPM. Refer

to Figure 13.

Snapshot: Optional item - To use this facility, install the

data logging upgrade kit. Refer to the user manual -

K0397: DPI 800 series data logging upgrade kit.

1 2 Task selection

menu: 3Menu:

Set Up 4 5

+

(Table 2) (Table 1) []/[ ]

Options Description

... Scale To select the applicable international temperature

scale: IPTS 68 or ITS 90.

To add a 250 series resistor into the mA circuit. You

can then use this instrument together with a HART®

communicator to set up and calibrate HART® devices.

To select and set up the backlight facility + timer.

Additional data: Select Settings ( )

To select and set up the power off facility + timer.

Additional data: Select Settings ( )

To show the battery level (%).

To set the display contrast (%).

Increases %, decreases %

To set the time + date. The calibration facility uses the

date to give service and calibration messages.

To set the language option.

To calibrate the instrument.

Additional data: Refer to “Calibration”.

To select and show the applicable status data.

(Software Build, Calibration Due date, Serial Number,

IDOS Information).

1Task selection

menu: 2345

+

+

(Table 2/3) Task = mA output

Task selection

menu: 6Display:

mA output

(Table 2/3) Sk1 = Edit

Sk2 = Settings