Barnstead International MEGA-PURE A440697 User manual

1

MEGA-PURE®

6A Water Still

927541 • 1/9/03

OPERATION MANUAL

AND PARTS LIST

Series 676

Model# Voltage

A440697 208V

A440518 240V

2

Table of Contents

General Information ........................................................................................................................................... 3

Safety Information ............................................................................................................................................ 3

Alert Signals ..................................................................................................................................................... 3

Warnings .......................................................................................................................................................... 3

Introduction ...................................................................................................................................................... 5

Electrical Requirements ................................................................................................................................... 6

Water Supply Requirements ............................................................................................................................ 7

Drain............................................................................................................................................................... 7

Unpacking .......................................................................................................................................................... 8

Assembly............................................................................................................................................................ 9

Pretreated Boiler Feed ................................................................................................................................... 10

3 1/2 Gallon Storage Bottle ............................................................................................................................ 11

Automatic Collection System.......................................................................................................................... 12

Plumbing Details .............................................................................................................................................. 12

Tap Water Feed ............................................................................................................................................ 12

Tap Water/Demineralizer .............................................................................................................................. 13

Tap Water/In-House Treated Water .............................................................................................................. 14

Installation ........................................................................................................................................................ 14

Location of Unit .............................................................................................................................................. 14

Wall Mounting .............................................................................................................................................. 15

Bench Mounting ........................................................................................................................................... 15

Operation ......................................................................................................................................................... 16

High Temperature Cut-off Switch ................................................................................................................... 17

Maintenance and Servicing .............................................................................................................................. 18

Cleaning ......................................................................................................................................................... 18

Troubleshooting ............................................................................................................................................... 20

Replacement Parts........................................................................................................................................... 23

Schematic Diagrams ........................................................................................................................................ 25

Ordering Procedures ........................................................................................................................................ 27

Warranty ........................................................................................................................................................... 28

3

General Information

Safety Information

Your Barnstead MEGA-Pure® 6A Water Still has

been designed with function, reliability, and safety

in mind. It is the user’s responsibility to install it in

conformance with local electrical codes. For safe

operation, please pay attention to the alert signals

throughout the manual.

Important Information

This manual contains important operating and

safety information. The user must carefully read

and understand the contents of this manual prior

to the use of this equipment.

Water purification technology employs one or

more of the following: chemicals, electrical

devices, mercury vapor lamps, steam and heated

vessels. Care should be taken when installing,

operating or servicing Barnstead products. The

specific safety notes pertinent to the Barnstead

MEGA-Pure® 6A Water Still are listed in the

Warnings section.

Warnings

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet

of correct voltage and current handling

capacity.

2. Disconnect from the power supply prior

to maintenance and servicing.

3. Ensure that the equipment is connected

to electrical service according to local

and national standards. Failure to prop-

erly connect may create a fire or shock

hazard.

MegaPure® is a registered trademark of

Barnstead Thermolyne.

Warning

Warnings alert you to a

possibility of personal injury.

Caution

Cautions alert you to a possibil-

ity of damage to the equipment.

Note

Notes alert you to pertinent facts

and conditions.

Hot Surface

Hot surfaces alert you to a

possibility of personal injury if

you come in contact with a

surface during use or for a

period of time after use.

Alert Signals

4

GENERAL INFORMATION

4. Do not mount your MEGA-PURE®6A

Water Still directly over equipment that

requires electrical service. Routine mainte-

nance of this unit may involve water spill-

age and subsequent electrical shock

hazard if improperly located.

5. For continued protection against possible

fire hazard, replace fuses only with the

same type and rating of fuse.

6. Do not connect unit to electrical service

until instructed to do so.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion

may result. This device contains compo-

nents which may ignite such materials.

2. Wear eye and hand protection when using

acid for cleaning, as acid spattering may

occur.

3. Use this device with water feed only. Fail-

ure to comply with the above could result

in explosion and personal injury.

4. Ensure all piping connections are tight to

avoid leakage of chemicals.

5. Always depressurize chemical lines before

disassembly.

6. To avoid lung injury or suffocation, ensure

adequate ventilation when using chemicals

for cleaning.

5

7. Carefully follow the manufacturers’

safety instructions on labels of chemical

containers and Material Safety Data

Sheets (M.S.D.S.).

8. Refer servicing to qualified personnel.

To ensure safe mounting:

1. Wall composition and construction, as

well as fastener type, must be consid-

ered when mounting this unit. The

mounting surface and fasteners selected

must be capable of supporting a mini-

mum of 110 lbs.; inadequate support

and/or fasteners may result in damage

to mounting surface and/or equipment. If

you are unsure of mounting surface

composition, condition and construction,

or correct fasteners, consult your build-

ing maintenance group or contractor.

Introduction

The Barnstead MEGA-PURE®6A Water Still is a

compact, all glass and Teflon®unit designed to

provide 6 liters per hour of high purity distilled

water. The product water, as produced, is non-

pyrogenic per U.S.P. XIX and will have a

resistivity up to 1.7 megohm-cm or higher at the

product outlet using most tap water as feed.

Pretreatment may be required to achieve >1.0

megohm/cm water. This water still can be used

as a discrete unit, with customer supplied

pretreated water or in conjunction with a

Barnstead Demineralizer. It can also be

connected to the Barnstead Automatic Collection

System for complete automatic operation.

Avoid contact. Hot water and

steam heat the glass portions of

the still to dangerous

temperatures during operation.

Hot Surface

Teflon® is a registered trademark of Dupont.

GENERAL INFORMATION

6

The Barnstead MEGA-PURE®6A Water Still is

rated at 240V, 50/60 Hz, 5000 watts, single phase.

It is also available in 208V. Changing the unit for

use on either 240V or 208V operation requires only

replacing the Vycor®immersion heaters with

heaters having the required voltage rating.

The cabinet and glassware are protected against

damage from overheating by thermal switches.

Choice of a location for your MEGA-PURE®6A

Water Still is primarily a matter of convenience. This

unit may be located on a bench or wall mounted.

Electrical Requirements

To operate the Barnstead MEGA-PURE®6A Water

Still, the customer must provide a power source of

single phase, 50/60 Hz. 30 amp, 208 — 240VAC.

Your water still is supplied with a power cord and

plug. A certified electrician should install a

receptacle box within 5' of the still. The correct

receptacle to match the supplied plug is a NEMA

L6-30R. Figure 1 shows proper wiring for this

receptacle. As an alternate method, your electrician

may remove the supplied plug and wire the cord to

a 30A-250V breaker box as shown in Figure 2.

The Vycor® immersion heaters will be labeled

either 208V or 240V, according to your order. The

240 volt heaters may be used at 208V, 220V, 230V,

or 240V but at the lower voltages, there will be

some reduction in the volume of distilled water

produced. Exchange improperly ordered heaters

with your dealer. You cannot exchange heaters that

have been used.

Figure 2

30A - 250V Breaker Box

Caution

Never use 208V heaters on

voltage higher than 208 volts

as premature heater failure will

occur.

Figure 1

NEMA L6-30R Receptacle

Vycor® is a registered trademark of Corning, Inc.

GENERAL INFORMATION

Warning

Do not connect unit to electrical

service until instructed to do so.

7

Water Supply Requirements

Barnstead recommends one of the following

options for supplying water to operate your

MEGA-PURE®6A Water Still.

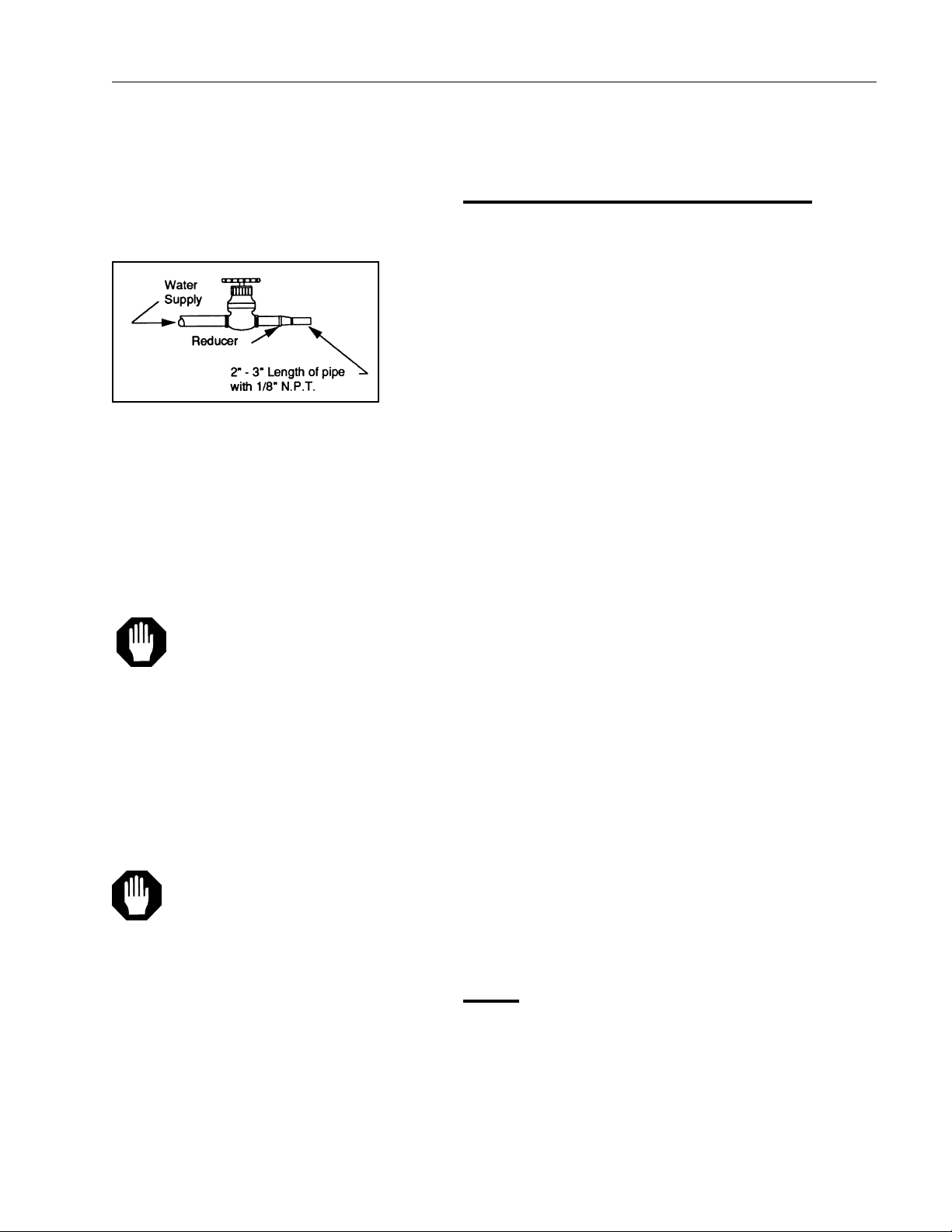

OPTION #1

A single, untreated cold water supply. The supply

must be capable of providing a minimum of 16

gallons per hour at a pressure of 20-100 psi and

be located within 4 feet of the water still. You must

provide a shut-off valve and reducer as shown in

Figure 3. With Option #1, approximately 16

gallons of untreated water will be used per hour in

the cooling section of the still, 2 gallons of this

water will be used as boiler feed. Water

connections are discussed on pages 12-14.

OPTION #2

An untreated cold water supply plus a source of

RO, demineralized or previously distilled water.

The untreated supply must be capable of

providing a minimum of 16 gallons per hour at a

pressure of 20-100 psi and be located within 4

feet of the water still. The treated supply must be

capable of providing 2 gallons per hour and be

located within 4 feet of the water still. You must

provide a shut-off valve and reducer at each water

supply (see Figure 3). In addition you will require

the optional double solenoid valve kit (Catalog No.

440236). With Option #2, approximately 16

gallons of untreated water will be used each hour

for cooling. The second (treated) water supply of

2 gallons per hour will be used as boiler feed.

Water connections are discussed on pages 12-14.

Drain

An open or atmospherically vented drain located

lower than the still is necessary to allow for gravity

flow. Barnstead supplies a 5 foot length of 1/2"

I.D. vinyl tubing for the drain. Additional tubing

may be purchased from your laboratory dealer.

Caution

Never use 208V heaters on

voltage higher than 208 volts as

premature heater failure will

occur.

Caution

Do not use NaCI regenerated

water softeners to supply boiler

feed as alkali attack will shorten

heater life.

Shut-off Valve

GENERAL INFORMATION

8

Unpacking

1. Remove the parts box and the still from

the shipping carton and place on a work-

bench.

2. Remove the two (2) shipping screws

located on the upper back of the unit and

discard. Turn the two (2) cover fasteners

located on the lower front of the unit 1/4

turn counterclockwise, and lift the cover

out and up to remove. Set the cover aside.

3. Check the glassware inside the main

cabinet for damage. Check the parts in the

accessory box for damage. Identify any

broken or damaged parts and report them

to your dealer immediately.

Refer to Figure 4 for the following steps:

4. Using diagonal cutting pliers, cut and

remove the five (5) plastic shipping ties.

The shipping tie locations are: Two (2) on

the condenser (B), two (2) on the boiler (P)

and one (1) on the trap (U) .

5. Using a 7/16" wrench, loosen the nut (all

the way) on coupling (C) While holding

onto the condenser, remove springs (Y).

Carefully remove the condenser from the

coupling and the cabinet.

6. Remove the tape from the condenser

outlets. Allow the salt used as packing to

flow into the plastic bag around the con-

denser. Discard the bag and the salt.

Rinse the remaining salt residue from the

condenser.

Unpacking

9

Assembly

Tools required for assembly: 7/16"

open end

wrench, diagonal cutting pliers, common

screwdriver.

1. Reinstall the condenser (B) into the

coupling (C) and clamp the condenser

in place with springs (Y).

2. Tighten coupling (C) using a 7/16"

wrench. The coupling should be just tight

enough to prevent rotation with moder-

ate hand pressure.

3. Check the orientation of trap (U). If it is

not level or tilted back toward the boiler

as shown in Figure 4, move the con-

denser (B) up in its bracket. This will tilt

the trap as shown in Figure 4.

4. In the following steps, use warm water

on the connections for ease of assembly.

A. Connect tube (V) to upper the right

condenser tubulation using Teflon®

connector (W).

B. Connect the vinyl tubing from the flow-

meter to the lower right tubulation of the

condenser.

5. Remove the packing material and rotate

tube (Q) into the constant level chamber

of boiler (P) as shown in Figure 4.

6. Unpack the Vycor®immersion heaters

(R) and check the voltage rating on the

top cap. It should agree with the voltage

of your power supply. If it does not,

contact your dealer and order the correct

heater.

Caution

Do not remove the Teflon®

sleeve covering the molded

rubber sleeve on the heater

element.

Assembly

10

7. Insert the immersion heaters into the top

openings of boiler (P) as shown in Figure

4.

8. Thread the heater plugs and cords through

the large hole above the boiler (P), then

back through the hole below the control

box (O). Plug the heater plugs into the

receptacles on the bottom of the control

box. The plug is a twist-lock type and

requires a 1/4 clockwise turn to lock in

place.

9. Route the water supply and the drain

tubing through the side of the cabinet.

Pretreated Boiler Feed

When a supply of distilled, deionized or reverse

osmosis water is to be used as boiler feed, revise

the still connections as follows:

1. Remove boiler fill tubes (V) and (Q) and

set aside.

2. Locate the 3/8" I.D. x 44" long vinyl tubing

and one barbed tee (1/2 x 1/2 x 3/8) in the

parts box.

3. Install one end of the vinyl tubing to the top

right tubulation on the condenser (B) and

route the other end through the cabinet

and down the back as shown in Figure 5.

4. Cut the 1/2" I.D. vinyl drain tubing and

install the barbed tee fitting. Connect 3/8"

I.D. vinyl tubing from the condenser to the

barbed tee . Push the vinyl tubing all the

way onto the tee to assure a leak free seal.

Figure 4

Note

Refer to the Pretreated Boiler

Feed section if you will be

using a source of pretreated

water as boiler feed or to the

3 1/2 Gallon Storage Bottle

section if the optional 3 1/2

gallon storage bottle is being

installed. If neither applies,

move assembled still to its final

location. See pg. 14 for layout

recommendations, and pgs. 12-

14 for plumbing details.

ASSEMBLY

11

5. If the 3 1/2 gal. storage bottle is not

being installed, move the still to its final

location. See page 12 for layout recom-

mendations and pages 10-12 for final

plumbing details.

3 1/2 Gallon Storage Bottle

To install the optional 3 1/2 gallon storage bottle

inside the MEGA-PURE®6A Water Still cabinet,

first locate the following parts:

• Bottle dust cover (F)

• Product delivery tube (E)

• Thomas clamp (D)

• 20" length of 1/2" vinyl tubing

• Plastic tee (1/2 X 1/2 X 1/2)

1. Place the bottle dust cover on the 3 1/2

gallon bottle and route the product

delivery tube through the hole in the

cover. Place this assembly inside the still

cabinet below the condenser (B) and

connect the product delivery tube to the

condenser with clamp (D).

2. Locate the plastic tee (1/2 x 1/2 X 1/2)

and the 20" length of 1/2" vinyl tubing in

the parts box. Connect to the bottle

overflow tubulation and drain as shown

in Figure 6.

3. Move the still to its final location. See

page 14 for layout recommendations

and pages 12-14 for final plumbing

details.

Figure 5

Figure 6

ASSEMBLY

12

Automatic Collection System

Before connecting your MEGA-PURE®6A Water

Still to the Barnstead Automatic Collection System

move the still to its final location.

Locate ACS tube (Z) and Thomas clamp (D) in the

parts box. Assemble to the tubing from the

collection system as shown in Figure 10.

Plug the input jack from the ACS into the ACS

receptacle on the bottom of the still control box (O).

See pages 12-14 for final plumbing details.

Plumbing Details

Tap water feed only - Figure 7

1. Thread the solenoid valve onto the cus-

tomer supplied shut-off, “in’ side towards

shut-off.

2. Install 1/4" O.D. tubing and supplied fitting

to “out” side of solenoid valve.

3. Route 1/2" I.D. vinyl tubing to an atmo-

spherically vented drain.

4. Plug the solenoid valve power cord (not

shown) into the receptacle in the control

box (O).

Figure 7

Tap Water Feed

Plumbing Details

13

Tap water/Demineralizer - Figure 8

(Must have the optional still adapter kit: catalog

no. 440376).

1. Thread the solenoid valve (“in” side

towards shut-off) onto the customer

supplied shut-off.

2. Install 1/4" O.D. tubing and the sup-

plied fitting to the “out” side of the

solenoid valve.

3. Cut the 1/4" O.D. tubing from the last

step at a convenient point and install

the tee from the still adapter kit.

4. Connect the 1/4" O.D. tubing from the

demineralizer to the tee.

5. Locate the boiler fill tube (Q). Connect

3/8" I.D. vinyl tubing from the deminer-

alizer output to the end of the boiler fill

tube. Route as shown and install clip

(T) to support.

6. Route the 1/2" I.D. vinyl tubing to an

atmospherically vented drain.

7. Plug the solenoid valve power cord

(not shown) into the receptacle in the

control box (O).

8. Plug the still adapter kit cable into the

receptacle located on the right side of

the demineralizer and the receptacle

in the control box (O).

Figure 8

Tap Water Demineralizer

PLUMBING DETAILS

14

Tap water/In-House Treated Water - Fig. 9

(Must have the optional double solenoid valves:

Catalog No. 440236)

1. Thread the solenoid valves (“in” side towards

shut-off) onto the customer supplied shut-

offs.

2. Install 1/4" O.D. tubing and the supplied

fitting to the “out” side of the solenoid on the

tap water.

3. Connect the fitting and 3/8" I.D. vinyl tubing

from the double solenoid valve kit to the “out”

side of the treated water supply.

4. Locate boiler fill tube (Q). Connect 3/8" I.D.

tubing from the treated water supply solenoid

to the end of the boiler fill tube. Route as

shown and install clip (T) to support.

5. Route 1/2" I.D. vinyl tubing to an

atmospherically vented drain.

6. Plug the solenoid valve power cord (not

shown) into the receptacle in the control

box (O).

Installation

Location of Unit

Space allotment for a still should include a 6"

clearance at the sides and top to allow for cover

removal and air circulation.

Do not mount your MEGA-

PURE®6A Water Still directly

over equipment that requires

electrical service. Routine

maintenance of this unit may

involve water spillage and

subsequent electrical shock

hazard if improperly located.

Warning

Figure 9

Tap Water/In-House Treated Water

Installation

15

Wall mounting

The MEGA-PURE®6A Water Still has slotted

holes for wall mounting. To support the weight of

this unit, use 1/4" x 1 1/4" lag bolts for mounting.

An optional wall mounting bracket is available for

the Automatic Collection System. Barnstead

demineralizers have slotted holes for wall

mounting. Demineralizer location is not critical,

though it should be close enough to the still to

make all necessary connections and should not

be mounted over electrical equipment to avoid

shock hazard (see warning above).

Bench mounting

No special consideration for a “still only” setup.

When used with the ACS, the MEGA-PURE®6A

Water Still must be placed on a 12" platform to

allow for gravity feed of distilled water to the ACS.

Caution

Replace front protective cover

before proceeding.

Wall composition and

construction, as well as fastener

type, must be considered when

mounting this unit. The mounting

surface and fasteners selected

must be capable of supporting a

minimum of 110 lbs.; inadequate

support and/or fasteners may

result in damage to mounting

surface and/or equipment. If you

are unsure of mounting surface

composition, condition and

construction, or correct fasteners,

consult your building

maintenance group or contractor.

Warning

Figure 10

INSTALLATION

16

Operation

Refer to Figure 11:

1. Close the drain stopcock (K) on the bottom

of the boiler (P).

2. Open the valve at the tap water source and

the treated water source if so installed.

3. Switch on the main power breaker on the

control at the customer power source.

4. Push “Water” switch on control box (O)

and allow boiler to fill. Set Flowmeter (L) to

approximately 15 Gal/Hr.

5. Push “OPERATE” switch. Light will light

and heaters will come on.

6. Allow the still to operate for 15-20 minutes.

For distillate at maximum purity, set the

flowmeter (L) at 11-12 GPH. For maximum

volume of distillate, increase flow at flow-

meter (L) to the point where only a slight

wisp of steam is visible at the condenser

vent (A).

7. Your MEGA-PURE®6A Water Still should

now be operational. Run the still for 4-5

hours to allow it to cleanse itself before

collecting water for use. (Dispose of the

water produced during the 4-5 hour cleans-

ing period.)

8. To shut your water still off, push the OFF

switch. This will shut the water supply and

the heaters off.

Pretreated feedwater-flow rate

to be adjusted so as to “just

maintain a full boiler”. Too fast

a flowwater will exhaust

pretreatment cartridges

prematurely.

Note

Operation

Warning

Do not use in the presence of

flammable or combustible

materials; fire or explosion may

result. This device contains

components which may ignite

such materials. Use this device

with water feed only. Failure to

comply with the above could

result in explosion and personal

injury. To avoid electrical shock,

always use a properly grounded

electrical outlet of correct voltage

and current handling capacity.

Ensure that the equipment is

connected to electrical service

according to local and national

standards. Failure to properly

connect may create a fire or

shock hazard.

Avoid Contact. Hot water and

steam heat the glass portions of

the still to dangerous

temperatures during operation.

Hot Surface

17

If any difficulties are encountered in operating this

water still, check all operating and assembly

steps to be sure the still was assembled and is

being operated correctly. If the difficulty still

exists, consult the Troubleshooting section of

this manual.

High Temperature Cut-off Switch

Your MEGA-PURE®6A Water Still is protected

against overheating by dual thermal switches

located in the brackets at the sides of the boiler.

Should the boiler overheat, a switch will open

causing the heaters and water supply to shut-off.

When the boiler cools (5-15 minutes), the switch

will reset automatically, but the still will have to be

restarted by the operator. When unit has cooled,

press the “WATER” and “OPERATE” switches to

restore normal operation. Check the boiler

occasionally for proper water level.

OPERATION

Caution

Do not use the flowmeter to turn

the water off.

Caution

Always allow the unit to cool

completely before resuming op-

eration. Cool water on hot glass

could cause boiler damage.

Note

Under most feedwater

conditions, the 11-12 GPH

flow rate will provide

greater than 60°C at the

condenser vent. Very cold

feedwater may require

slightly less than 11-12

GPH to maintain vent

temperature above 60°C.

To optimize product water

purity, use thermometer to

verify vent temperature to

> 60°C.

18

Maintenance and Servicing

Cleaning

For top performance and efficiency, the

MEGA-PURE® 6A Water Still should be kept

clean and free of scale. It is recommended that

the boiler be drained and refilled with fresh water

daily to flush the boiler of the concentration of

contaminants from the previous day’s run.

When using untreated boiler feed, cleaning is

recommended after every 15-20 hours of

operation. The unit should be cleaned with a

hydrochloric acid solution. This is done as follows:

1. Push the unit’s “OFF” switch.

2. Disconnect the output tubing at the

condenser (B) from the collection vessel

and temporarily place a beaker under

the condenser outlet.

3. Drain the boiler 2/3 by opening the

stopcock (K). Close the stopcock (K)

after the boiler has drained.

4. Use the spare pinch clamp from the

parts box to shut-off the overflow tube

from the constant level chamber (N) as

close as possible to the overflow stem.

5. Carefully pour approximately 400 ml. of

10% hydrochloric acid solution into the

top of the constant level chamber (N).

May need to add water to boiler to bring

solution level up to scale level.

6. Wait approximately 10 minutes or until

the residue disappears. If additional

cleaning is required, drain the boiler

Warning

Ensure adequate ventilation

when using chemicals for clean-

ing. Wear eye and hand protec-

tion when using acid for clean-

ing, as acid spattering may

occur.

Warning

To avoid electrical shock, al-

ways disconnect from power

supply before maintenance and

servicing. Refer servicing to

qualified personnel. For contin-

ued protection against possible

fire hazard, replace fuses only

with the same type and rating of

fuse.

Maintenance and Servicing

19

down 1 inch and turn the unit on for a

few minutes until the residue disappears.

Do not boil. Turn still off. If scale re-

mains that the 10% hydrochloric solution

will not remove, rinse boiler three times

with feedwater (fill and drain). Add 400

ml of 6% NaOH to boiler and let stand

for 30 minutes. Flush boiler several

times after draining.

7. Carefully drain the unit, remove the

clamp from the overflow tube and refill

with fresh water. Drain the boiler, refill

with fresh water and operate for 30

minutes. Reconnect the tubing from the

collection vessel to the condenser (B).

MAINTENANCE AND SERVICING

20

Troubleshooting

General

melborPsesuaCnoituloS

skaeL

enosikaelnommoctsomehT

niardlynivehtnignirrucco

sesuacretawtoH.gnibut

taesoolgnillupdnagninetfos

.srotcennocdebrabcitsalpeht

gnibutlynivfosnuR

otdetroppusebdluohs

ehtnollupehtecuder

.srotcennoccitsalp

ebyamspmalcllamS

ehtdlohylmrifotdesu

ehtotgnibutlyniv

.srotcennoccitsalp

gnilioBhguoR

fotluserehtsigniliobhguoR

hsinifettamehtotkcattailakla

tsomehT.sretaehehtno

retawgnisusiesuacnommoc

ICaNhtiwdetaerterp

.srenetfosretawdetareneger

dnaretaehevomeR

ecafrusnehguorylthgil

tirg051htiw

.repapdnas

pu-dliuBelacS

ehtnielacsetihw-hsinworbA

reliobehttahtsetacidnireliob

.gninaelcseriuqer

repreliobnaelC

.snoitcurtsnigninaelc

ebtondluohselacS

etalumuccaotdewolla

ebyamsretaehsa

.degamad

eruliaFretaeH

®rocyVnoefiltrohS

yllausunacsretaehnoisremmi

retawfoesuotdetubirttaeb

ICaNhtiwdetaerterp

rosrenetfosretawdetareneger

.pu-dliubelacsevissecxe

asadesuretawdenetfoS

asesuacdeefreliob

snoimuidosfonoitartnecnoc

ehtfokcattaenilakladna

gniliobhguoR.ssalg®rocyV

fonoitacidnitsrifehteblliw

eht,eruliaftA.kcattaenilakla

dnaelohnipyllausulliwsretaeh

ehttuotrohslliwgniretneretaw

.tnemele

nehwruccolliwpu-dliubelacS

gniebtonsideefreliob

.dezinoied

tsumretawdenetfosfI

efilretaeh,desueb

degnolorpebnac

gniniardybtahwemos

.yadyrevereliob

llitsehtgnisunehW

,rezinoiedehttuohtiw

ebtsumpu-dliubelacs

yreveretfadevomer

fosruoh02-51

eeS(.noitarepo

.)snoitcurtsnIgninaelC

lliwosodoteruliaF

dliubotsretaehesuac

dnayllanretnitaehpu

ssalgesuacroliaf

.eruliafepolevne

tamaetS

tneVresnednoC

tagnitixemaetsfopsiwthgilsA

.lamronsitnevresnednoceht

oslaeramaetsehtnisesaG

.devomergnieb

evissecxenasierehtfI

maetsfotnuoma

resnednocehtgnivael

ehtesaercni,tnev

etarwolfretawgnilooc

.)L(retemwolfta

This manual suits for next models

1

Table of contents