BEA LZR FLATSCAN S User manual

Other BEA Security Sensor manuals

BEA

BEA IXIO-ST User manual

BEA

BEA IXIO-ST INDUSTRIAL User manual

BEA

BEA FOCUS 2 User manual

BEA

BEA LZR-FLATSCAN 3D SW User manual

BEA

BEA MS51W User manual

BEA

BEA IXIO-DT3 User manual

BEA

BEA LZR- FLATSCAN REV-PZ User manual

BEA

BEA Eagle5 User manual

BEA

BEA FALCON EXXL User manual

BEA

BEA PHOENIX EX User manual

BEA

BEA IXIO-DO1 I User manual

BEA

BEA LZR-WIDESCAN User manual

BEA

BEA IXIO-ST INDUSTRIAL User manual

BEA

BEA Matrix2-S User manual

BEA

BEA ACTIV8 ONE ON User manual

BEA

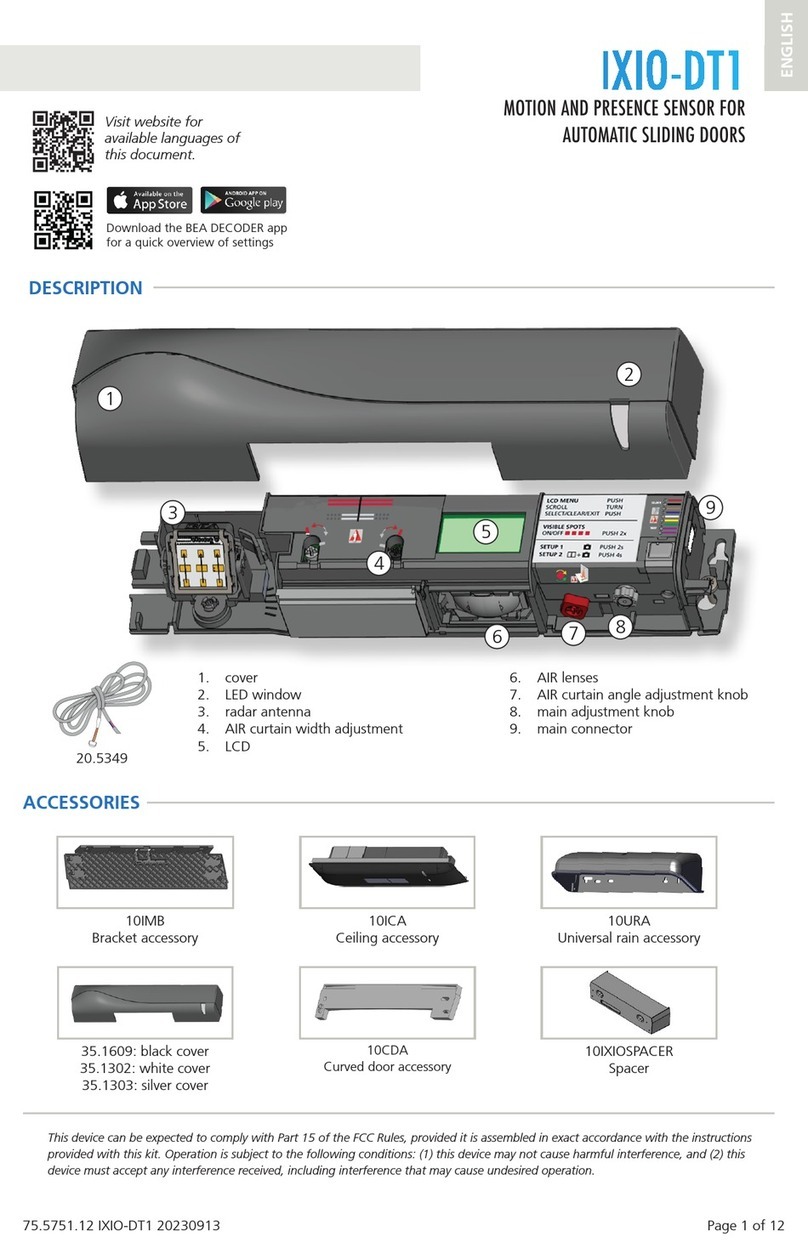

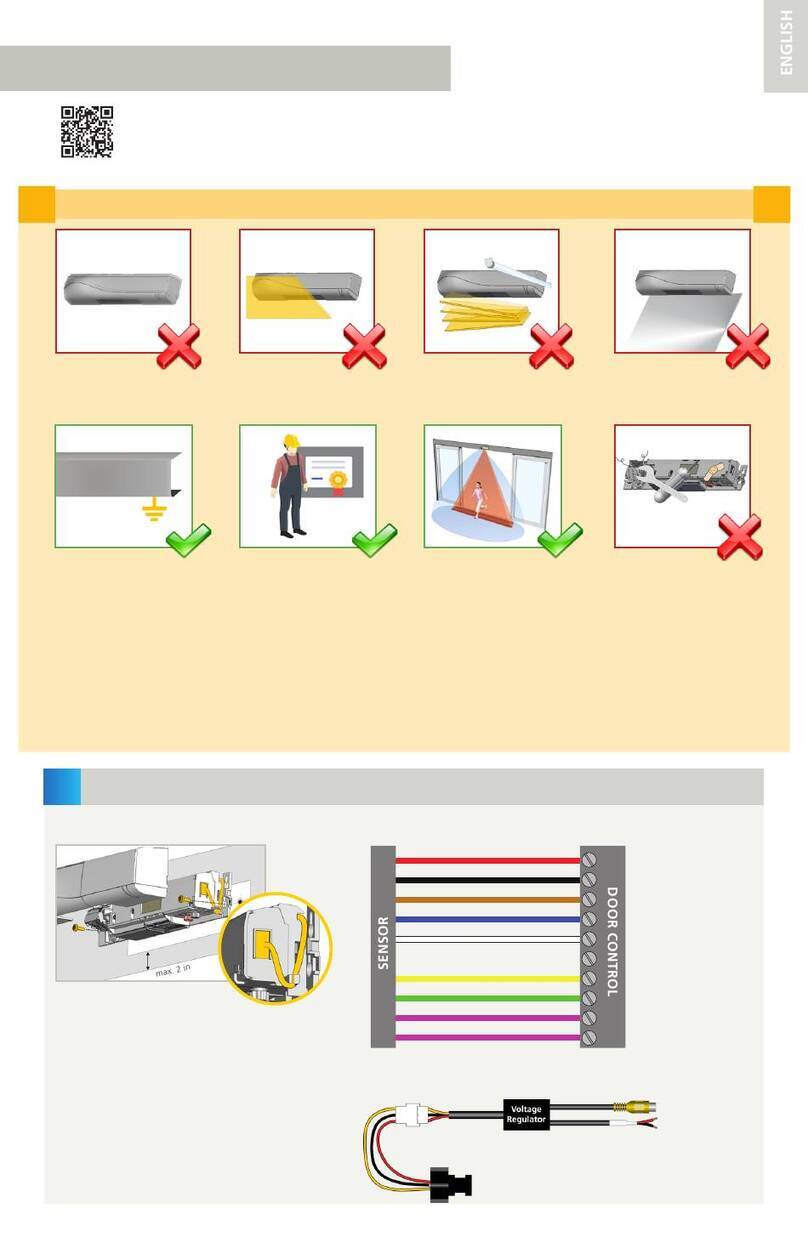

BEA IXIO-DT1 User manual

BEA

BEA IXIO Series User manual

BEA

BEA IXIO-DT1 User manual

BEA

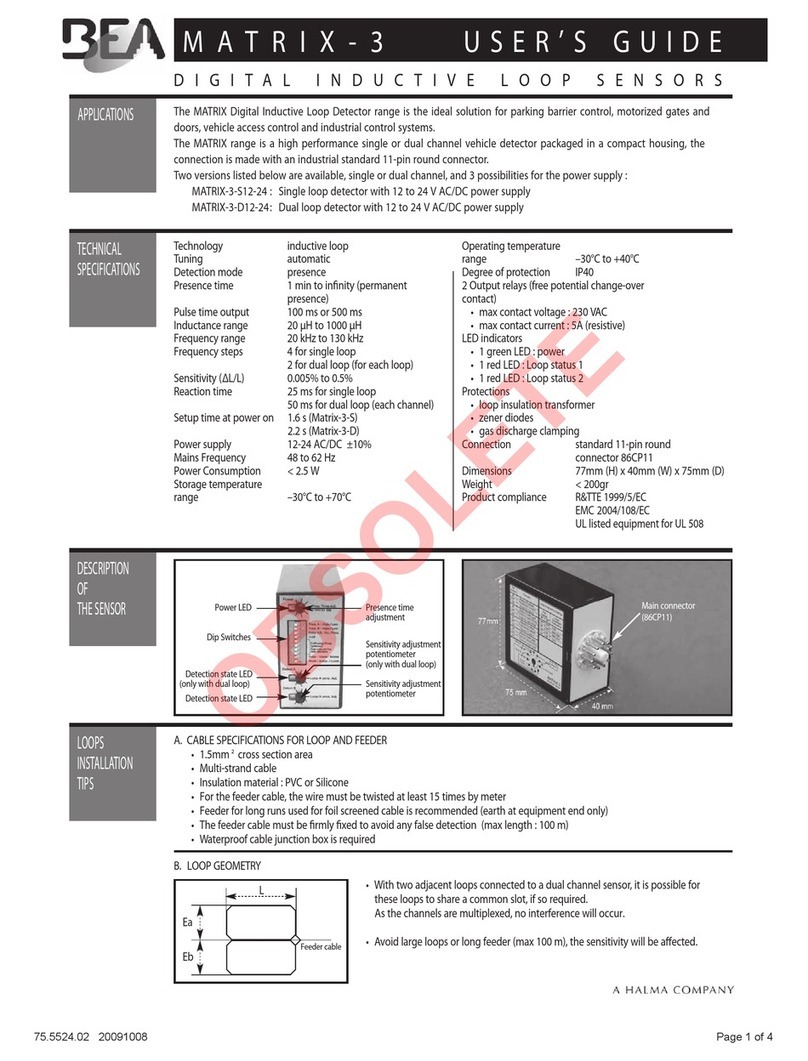

BEA MATRIX-3 User manual

BEA

BEA 10LZRWIDESCAN User manual