* SEE APPLICATION NOTES OR CONTACT BEA FOR TECHNICAL SUPPORT

75.5785.01 IXIO-ST UL INDUSTRIAL 20140402 Page 5 of 8

Select your language before

entering the first LCD-menu.

Available for the first 30 seconds after

power-on of the sensor .

ZIP all parameter settings in zipped format

ID # unique ID-number

CONFIG P/N configuration part number

SOFT P/N software part number

ERROR LOG the last 10 errors, time since last error

AIR: SPOTVIEW view of spot(s) that trigger detection

AIR: C1 ENERG signal amplitude received on curtain 1

AIR: C2 ENERG signal amplitude received on curtain 2

POWERSUPPLY supply voltage at power connector

OPERATINGTIME power duration since first startup

RESET LOG delete all saved errors

RC PASSWORD password for remotre control login

ADMIN enter code to access admin mode

BACK

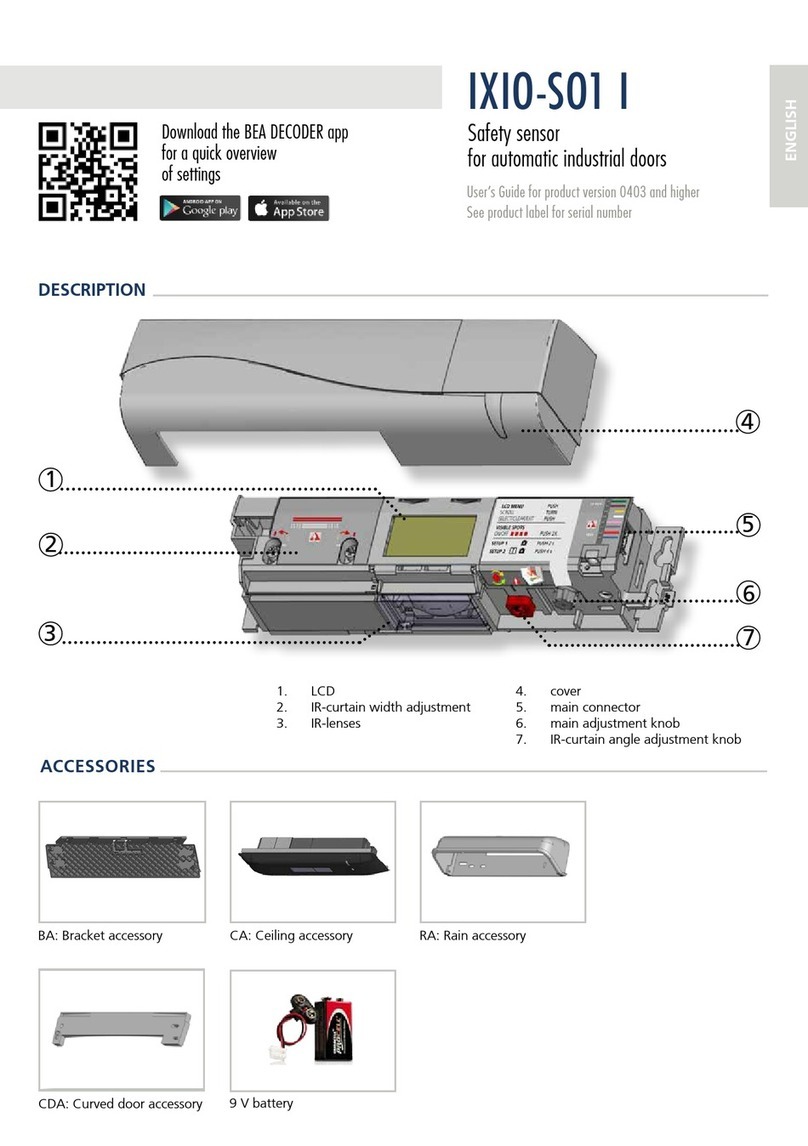

OVERVIEW OF SETTINGS

Back

More

More

Back

BASIC

0123456789

TEST * off on

AIR: WIDTH

Always additionally adjust the

arrow position on the

sensor with a screwdriver.

AIR: OUTPUT * NO

NC

NC

NO

NC

NC

NO

NO

Back

More

More

Back

Back

ALLDIAGNOSTICS

AIR: FREQ AB

AIR: WIDTH

Always remember to also adjust

the arrow position on the

sensor with a screwdriver.

AIR: NUMBER service

mode 12

Service Mode = no IR detection during 15 minutes (maintenance).

AIR: PRESTIME 30 s 1 min 2 min 5 min 10 min 20 min 60 min ∞

REDIRECTION motion motion

or

presence

activation output is active in case of: 0 motion detection

1 motion or presence detection

FACTORYRST restore to factory values

+

NO: normally open

NC: normally closed

AIR: OUTPUT * NO

NC

NC

NO

NC

NC

NO

NO

NO: normally open

NC: normally closed

TEST * off on

AIR: IMMUNITY normal enhanced mode B

+

Sensors mounted close to each other

should have a different frequency.