VCMC v1.1 - ASSEMBLY GUIDE

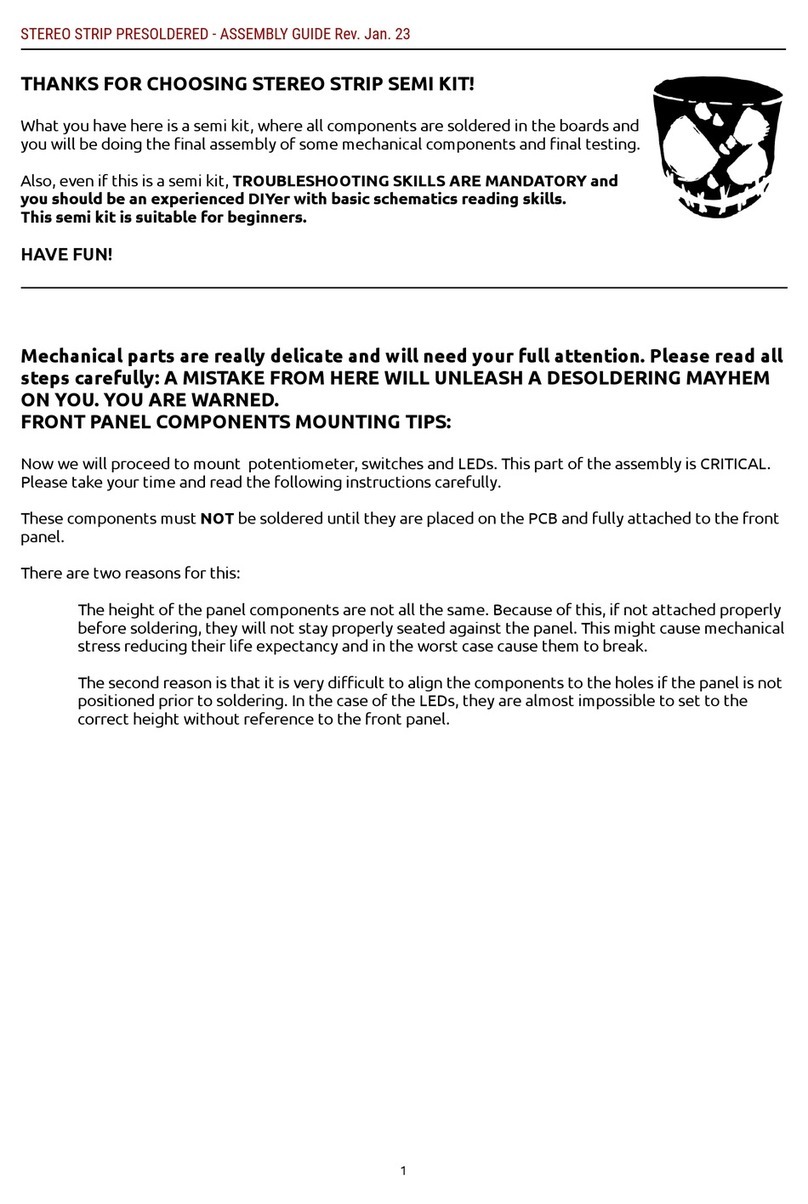

THANKS FOR CHOOSING ONE OF OUR KITS!

This assembly guide is a bi differen from he o her Befaco ones. We will be assembling sec ions, and es ing hem one

by one, so we will no keep building un il we make sure i is working nicely.

This will make our build a bi slower and careful, as his is quite a tricky build.

Some s eps are no obvious, so even if you're an experienced DIYer, please ake he ime o read he s eps horoughly

before s ar ing.

If his is your firs projec , please read his ar icle before you s ar assembling he ki :

www.befaco.org/how o/

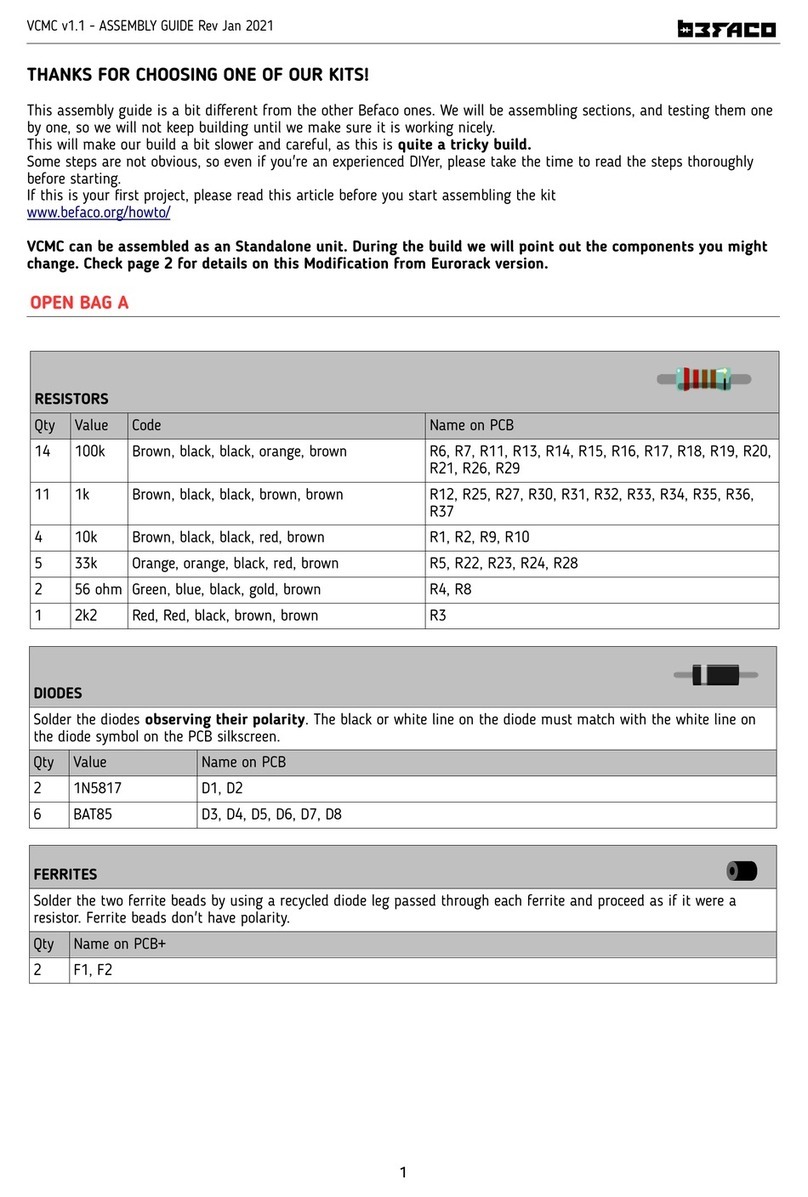

OPEN AG A

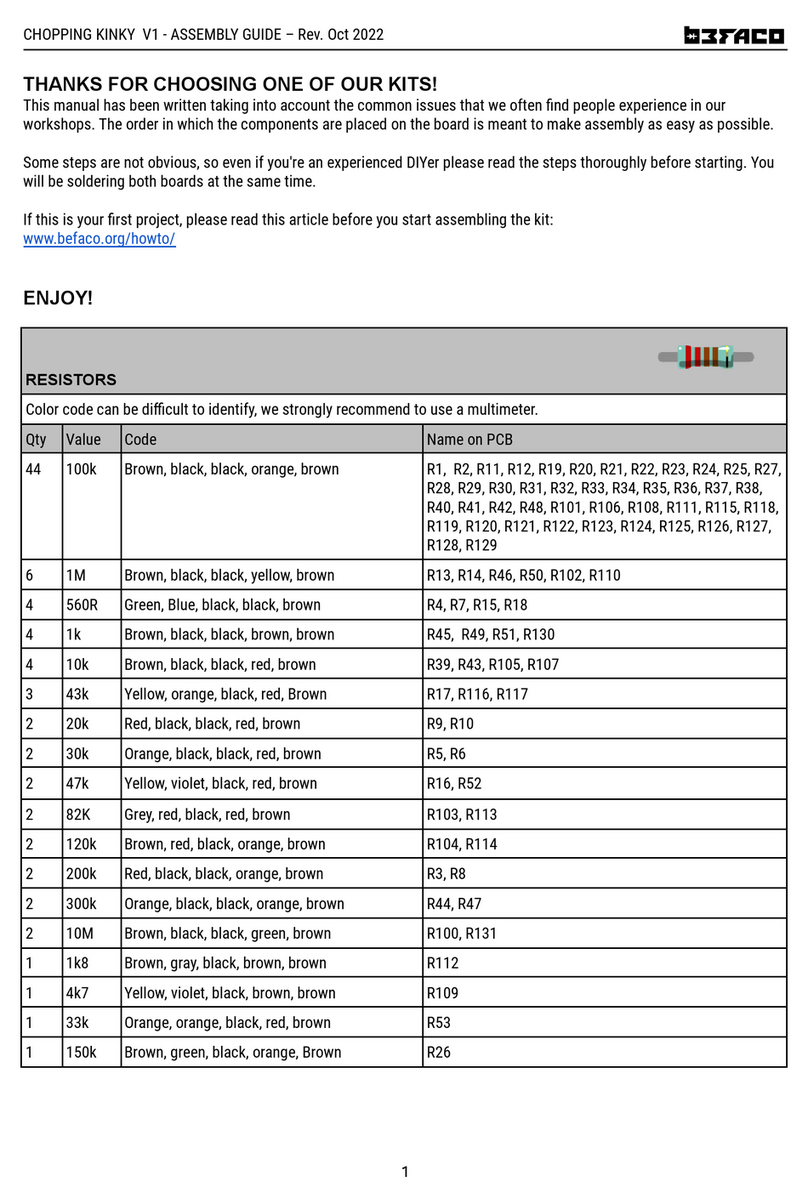

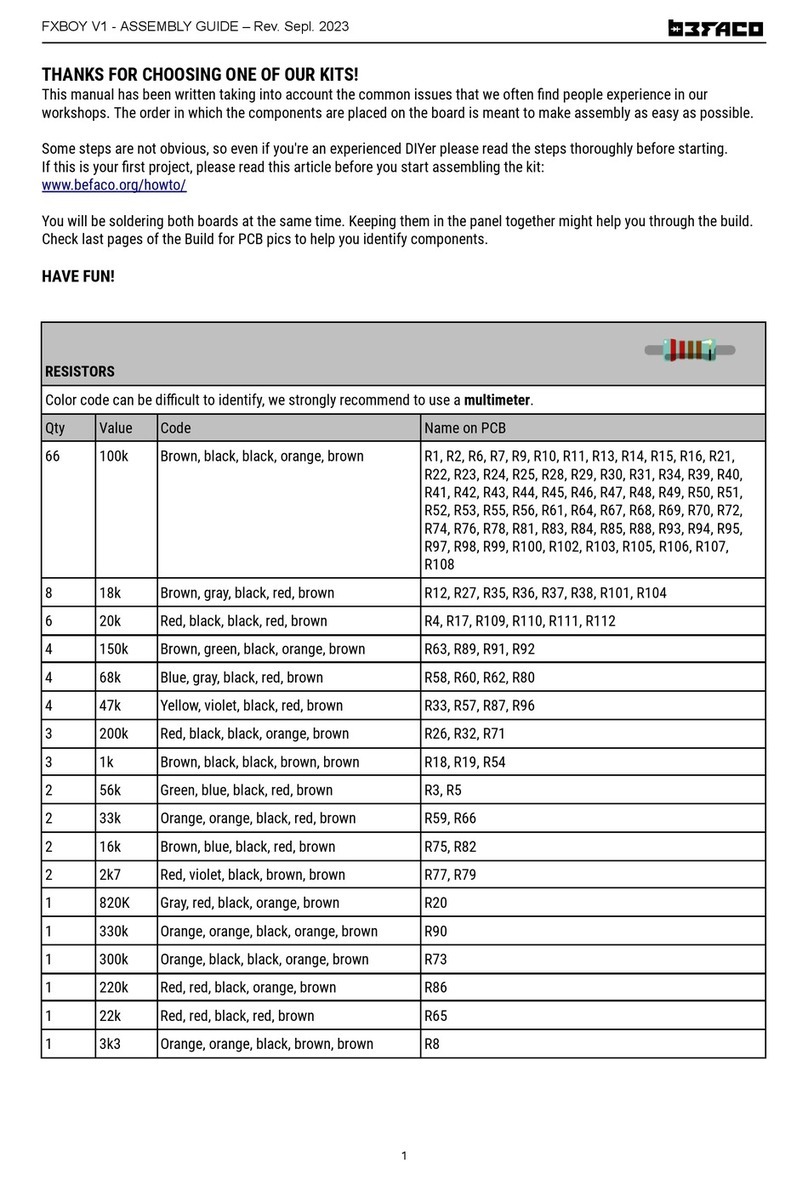

RESISTORS

Q y Value Code Name on PCB

14 100k Brown, black, black, orange, brown R6, R7, R11, R13, R14, R15, R16, R17, R18, R19, R20,

R21, R26, R29

11 1k Brown, black, black, brown, brown R12, R25, R27, R30, R31, R32, R33, R34, R35, R36,

R37

4 10k Brown, black, black, red, brown R1, R2, R9, R10

5 33k Orange, orange, black, red, brown R5, R22, R23, R24, R28

2 56 ohm Green, blue, black, silver, brown R4, R8

1 2k2 Red, Red, black, brown, brown R3

DIODES

Solder he diodes observing their polarity. The black or whi e line on he diode mus ma ch wi h he whi e line on

he diode symbol on he PCB silkscreen.

Q y Value Name on PCB

2 1N5817 D1, D2

6 BAT85 D3, D4, D5, D6, D7, D8

FERRITES

Solder he wo ferri e beads by using a recycled diode leg passed hrough each ferri e and proceed as if i were a

resis or. Ferri e beads don' have polari y.

Q y Name on PCB+

2 F1, F2

1