Page 8 of 9

Instruction Manual A70 Version 6 19th April 2004

BEKA associates Ltd, Old Charlton Road, Hitchin, Hertfordshire. SG5 2DA. UK. Tel: +44 (0) 1462 438301

9) General Operation

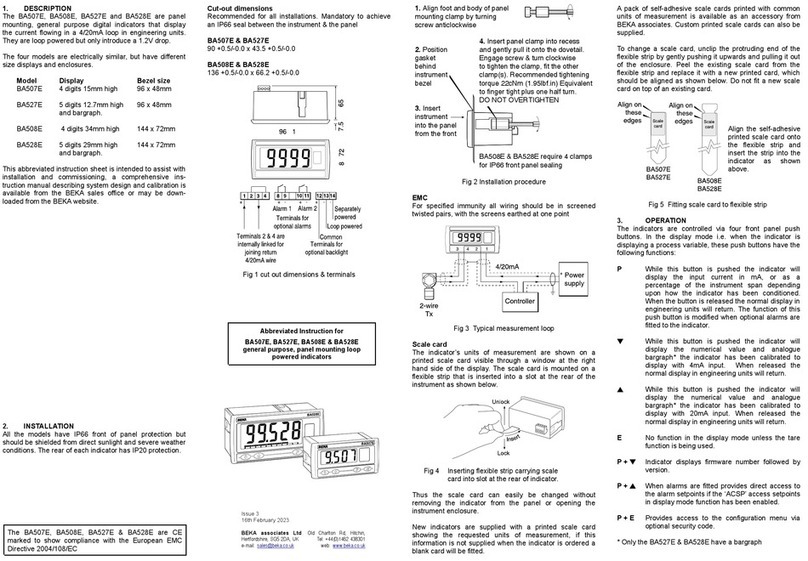

9.1 Button Functions – In Normal Display

Mode

Pressing this button causes the display to show one

of the following parameters. Listed in order of priority;

i) The minimum value held in the max/min register (if

enabled).

ii) The display at which 4mA is re-transmitted on the

analogue output (if fitted)

iii) The display reading corresponding to the lower end

of the calibrated range.

After 5 seconds of pressing and holding the down button, the

display brightness is reduced.

Pressing this button causes the display to show one

of the following parameters. Listed in order of priority

i) The maximum value held in the max/min register (if

enabled)

ii) The display at which 20mA is re-transmitted on the

analogue output (if fitted)

iii) The display corresponding to the upper end of the

calibrated input range.

After 5 seconds of pressing and holding the up button, the

display brightness is increased.

Pressing this button has several effects depending

on what parameters have been programmed. It can

be programmed to display the input signal in actual

units or as a percentage of the input range. It can also be

used to silence alarm outputs, acknowledge latched alarms

and to activate the tare function.

This button has no effect during Normal Display

Mode.

9.1.1) Gaining access to the alarm setpoints.

It may be necessary for an operator to regularly change alarm

setpoints. There is an option to allow quick access to the

setpoints only. This also means that unauthorized access to

the other programming menus can be prevented. To access

the alarm setpoint (if the function has been switched on in

program mode) the up and scroll buttons should be pressed

simultaneously. The operator will then be able to access

either SP1 or SP2 by pressing the up or down button. New

setpoints can then be set with the up, down and scroll buttons

followed by the return button.

A security access code can be programmed to verify

authorized access to the setpoints. If this is the case, the

operator must enter the security access code using the up,

down and scroll buttons, followed by the return button.

9.1.2) Resetting the Max/Min Register

Pressing the up and down buttons simultaneously the

max/min hold register is reset to store the present display

reading.

9.1.3) Display brightness

It is possible to adjust the display brightness of an Advisor at

any time during Normal Display Mode.

To increase the display brightness, press and hold the up

button. After 5 seconds, all the segments on the display will

light up and the brightness with steadily increase to its

maximum. Release the button when the desired brightness is

reached. Likewise, the brightness can be reduced by pressing

and holding the down button. The display brightness is

“remembered” if there is a power failure.

9.1.4) Unlatching alarms and alarm silencing

(if fitted)

A latched alarm is unlatched by pressing the scroll button (to

set an alarm latch see section 8.6.8). The alarm output

changes state and the alarm LED annunciator is extinguished.

An alarm is also silenced (or acknowledged – see section

8.6.7)) with the same button press. With a silenced alarm, the

alarm LED annunciator will remain lit if the signal input is still

within the alarm band.

9.1.5) Tare Function (if fitted)

The tare function is designed primarily for use in weighing

applications and is fitted at the factory. A tare function allows

the instrument display to be zeroed at any stage so that any

further change in input signal can easily be measured. For

example, if the Advisor was showing the weight of a container

as 25kg and an operator wanted to add 18kg of fluid, the

display could be tared and the operator would easily see

when 18kg of fluid had been added. Without the tare function,

the operator would have to calculate the combined weight.

The tare is initiated by pressing and holding the scroll button

for 4 seconds, the word “tArE” is then briefly displayed to let

the operator know that the request has been fulfilled. The

asterisk LED annunciator will also light up to show that the

display is tared. Brief pressing of the scroll button allows the

operator to toggle between the tared (net) display and the

untared (gross) display. The asterisk LED annunciator

switches on and off accordingly. The display can be re-tared

again at any time by pressing and holding the scroll button for

4 seconds. The tare value is stored even if there is a power

failure.

10) - Troubleshooting

There is no display. Check all the connections are correctly

made and check for the correct power on the supply.

The display is not very bright/too bright. Adjust the

brightness by pressing and holding the up or down button.

(Section 9.1.3)

Display doesn’t seem to be responding to a change of

input signal. Check the input signal. It may also be possible

that someone has accidentally re-calibrated the unit to display

the same value over the full input range – check the span and

zero settings in the “cAL” parameters (Section 8.5.6) – if

necessary re-calibrate with the “Int” (internal) settings.

Alternatively, the internal references may have been

accidentally reset – re-program them. (Section 8.5.7)

None of the pushbuttons seem to be working. It may be

that the pushbuttons have been disabled (i.e. anti-tamper

function has been switched on). Enter the button re-enable

sequence. (Section 8.7)

The display is too “jumpy”. Check the signal source, it may

be noisy. If the signal source cannot be “damped” down,

change the resolution of the Advisor. (Section 8.5.2)

I’ve forgotten my password – how do I get access ? Enter

“FPAc” (the emergency code – mnemonic “Forgotten Panel

Access Code”) and re-enter a new password in “F.PAn” menu

option. (Section 8.5.9)

The alarms are on when they should be off and vice

versa. Check the high and low alarm settings (Section 8.6.4)

and/or check you have the normally energized (“nE”)

parameter correctly programmed (Section 8.6.5)

The analogue output current doesn’t seem to be correct.

The analogue output can be adjusted. (Section 8.5.8)