3

Important Safety Notes

FAILURE TO COMPLY WITH ANY OF THESE REGULATIONS COULD LEAD TO PROSECUTION AND DEEM THE

WARRANTY INVALID.

This appliance has been designed to work on natural gas. It is law that all appliances using natural gas shall be

installed by a competent person who shall fit in accordance with the current Gas Safety Regulations, the relevant

British Standard Installation specifications, Codes of Practice and in accordance with the manufacturer’s

instructions and the various recommendations contained in the following regulations: -

All relevant sections of local regulations

All codes of practice relevant to the installation

The building regulations issued by the Department of the Environment and the building standards (Scotland) regulations

issued by the Scottish Department

BS 715 BS 5871 part 2 BS 5440 part 1 BS 8303 BS 4543

BS 1289 BS 1251 BS 6891 BS 6461 part 1 & 2

For Republic of Ireland reference should be made to the relevant sections of national and local rules in force and current

editions of IS 813, ICP 3 and IS 327.

This product is free from asbestos.

This product uses components containing Refractory Ceramic Fibre (RCF), which are man-made vitreous silicate fibres.

Excessive exposure to these materials may cause temporary irritation to eyes, skin and respiratory tract, consequently, it

makes sense to take care when handling these articles to ensure that the release of dust is kept to a minimum. To ensure

that the release of fibres from these RCF articles is kept to a minimum, during installation and servicing we recommend that

you use a HEPA filtered vacuum to remove any dust and soot accumulated in and around the fire before and after working

on the fire. When replacing these articles we recommend that the replaced items are not broken up, but are sealed within a

heavy polythene bag, and clearly marked as RCF waste. RCF waste is classed as a stable, non-reactive hazardous waste

and may be disposed at a landfill licensed to accept such waste. Protective clothing is not required when handling these

articles, but we do recommend you follow the normal hygiene rules of not smoking, eating or drinking in the work area and

always wash your hands before eating or drinking.

Appliance Data

The appliance data plate is on the control panel behind the ash pan cover.

•Full On Rated Input ( Gross ) 6.3 kW •Full On Heat Output 3.53 kW (Efficiency – Class II)

•Low Rated Input ( Gross ) 2.3 kW •Low Heat Output 1 kW

•Pipe Connection Size 8mm compression •Inlet Pressure 20 mbar

•Injector 1 off No 77 •Spark Gap 4mm+/-0.5mm

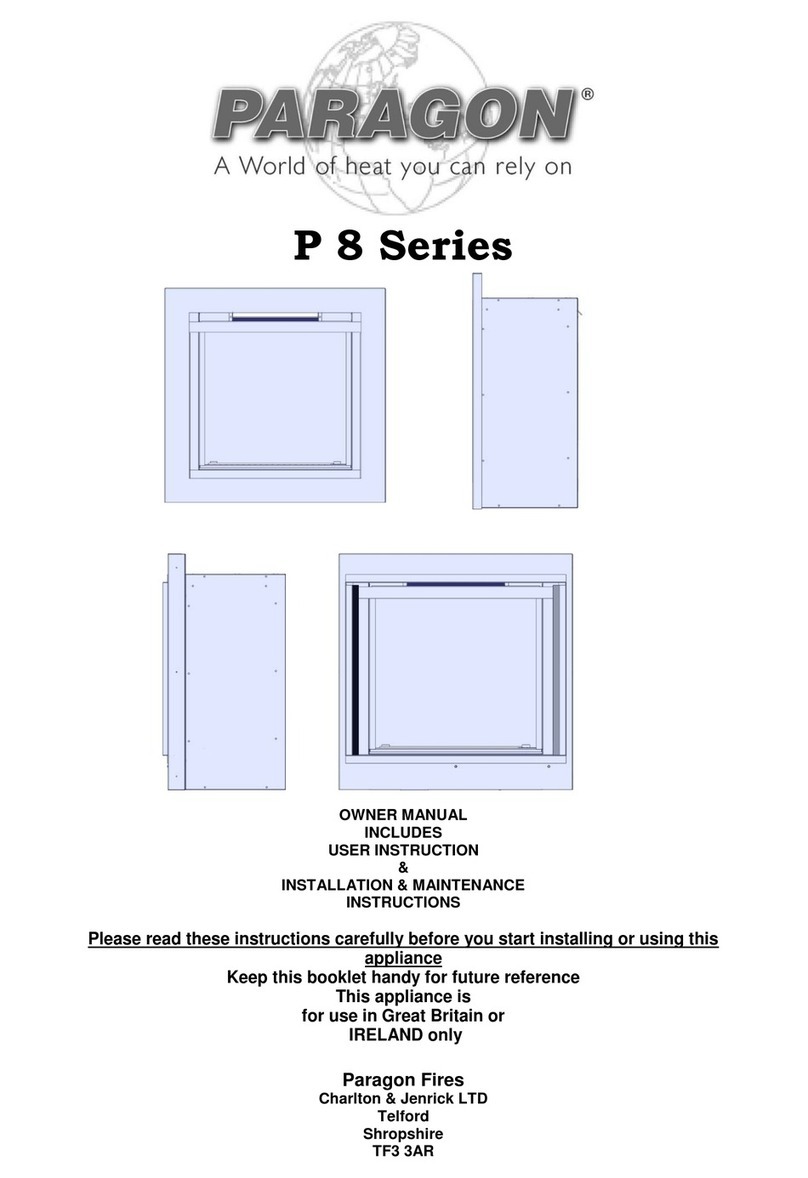

Overall Dimension Width Height Depth

470mm 585mm 120mm

General Installation Requirements

Prior to installation, ensure that the local distribution conditions and the adjustment pressure of the appliance are compatible.

(Natural gas G20 at 20mbar pressure. Category I

2H

). The fire must not be installed in a room containing a bath or in any

room where steam may be present. The fire is designed for installation into a builder’s opening conforming to BS 1251 and

twin walled metal flue boxes conforming to BS 715. The flue box must be installed on to a suitable non-combustible

insulating surface at least 50mm thick. This gas fire is suitable to use with precast flues with a minimum free internal cross

sectional area of 12500mm

2

. In perfect circumstances a precast flue will be built with an air gap between the flue bricks and

the plaster, but, some earlier precast flues built with plaster directly on the face of the blocks may show evidence of plaster

cracking when fitted with a gas fire. This is not normally a problem caused by the appliance however; the customer should

be advised insulation or an air gap should be included between the blocks and the plaster to prevent any further damage.

The flue must have an effective vertical height of not less than 3 meters, measured from the base of the hearth to the top of

the flue. The flue spigot on the reverse of the fire must not be obstructed by anything and should have at least 50mm

clearance above and behind them. Diagram 1B

Any dampers, plates or restrictors should be removed or fixed in the fully open position before installation. Check

that the flue pipe in the roof space is connected and the correct diameter.

A natural draught system is required and unless new, the flue or chimney should be swept before installation. Also the flue

must be checked to ensure a proper draw can be obtained and that there is no leakage from any of the joints. This is best

done with a smoke pellet.

The flue must only be connected to one fireplace and must not vent more that one gas appliance (i.e. back boiler).

In the case of flue problems it is recommended that a suitable approved terminal be fitted to the termination of the flue. The

terminal should prevent a down draught in any condition and prevent rain and debris from falling down the flue. In all cases it

is recommended that you seek professional advice.

This appliance is suitable to be installed in to back panels approved to a minimum temp’ rating of 150

o

C. A non-combustible

insulation of not less than 50mm must be fitted to the top surface of the metal flue box.

PLEASE NOTE: Local wind conditions can affect the performance of the flue.