Industrivej 62

DK-6740 Bramming

Denmark

Original

IceTech R1000H

Operator Manual for Reformer

TABLE OF CONTENTS

GENERAL INFORMATION......................................................................................................... 3

SYSTEM IDENTIFICATION ....................................................................................................... 4

TECHNICAL DATA ................................................................................................................... 5

TECHNICAL FACTS OF FROZEN CO2......................................................................................... 6

SAFETY REGULATIONS............................................................................................................ 7

General Measures........................................................................................................... 7

Personnel Qualifications .................................................................................................. 7

Security and Risk............................................................................................................ 7

Danger of Suffocation ..................................................................................................... 7

Static Electricity.............................................................................................................. 8

Danger of Congelation .................................................................................................... 8

Pinch Point Hazard.......................................................................................................... 9

Danger of burns ............................................................................................................. 9

Wear Protective Gloves ................................................................................................... 9

How to Lift / Transport the IceMaker...............................................................................10

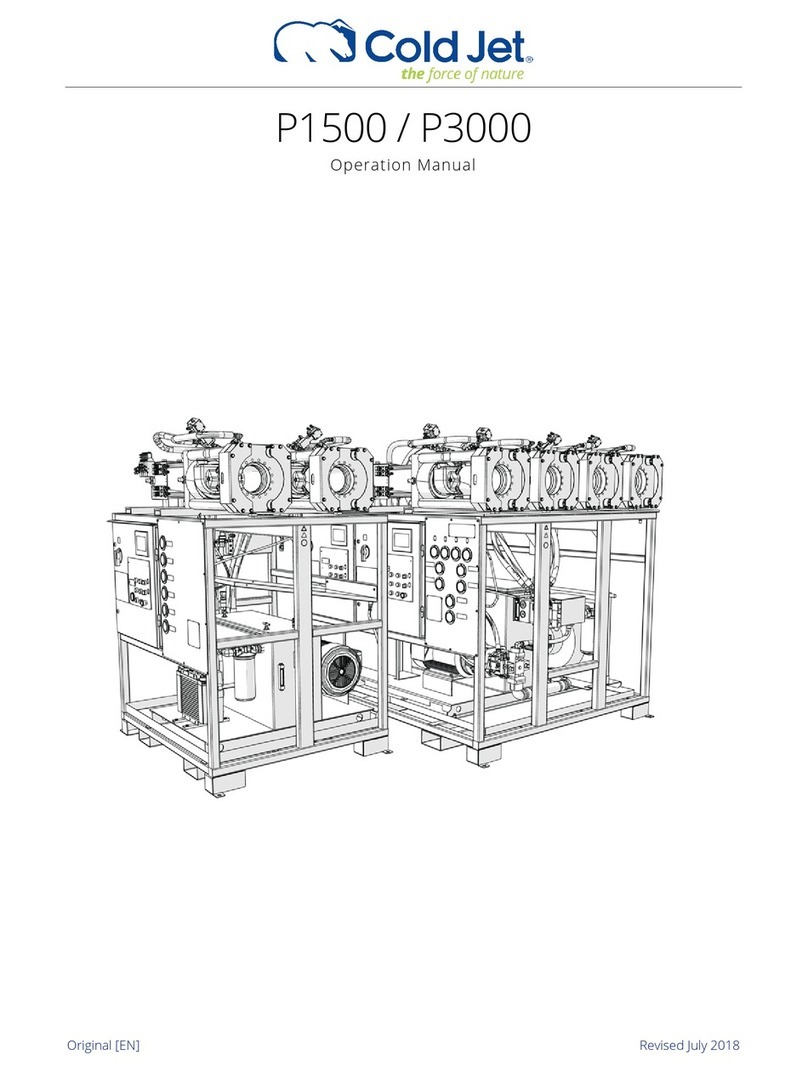

MACHINE STUCTURE SL1000H................................................................................................11

MACHINE OPERATION START-UP............................................................................................12

MACHINE CONTROLS.............................................................................................................15

STOP PRODUCTION ...............................................................................................................18

REPAIR AND WARRANTY........................................................................................................18

Repair ..........................................................................................................................18

Terms of Warranty ........................................................................................................18

COMMUNICATION WITH EXTERNAL EQUIPMENT .....................................................................19

Communication to IceTech R1000H –Input.....................................................................20

Communication from IceTech R1000H –Output...............................................................20

INSTRUCTION - UNPACKING AND PREPARATIONS BEFORE INSTALLATION ...............................22

Unpacking and Examination for Transport Damages .........................................................22

Requirements on the Environment Surrounding the IceMaker............................................22

How to Lift / Transport the IceMaker...............................................................................22

Floor Characteristics and Minimum Clear Distances...........................................................22

Installation....................................................................................................................22

DRAWING NR. A1..........................................................................................................23

DRAWING NR. A2..........................................................................................................23