Technical Bulletin

Bulletin No: TCH-013-017 Effective Date: 7/30/08 Cancels: N/A Page: 1 of 2

Subject: Protect Your Bendix

®

ATR-1

™

, ATR-2

™

and R-14

®

Relay Valves from

De-icing Chemicals

Vehicles exposed to harsh winters, de-icing and/or

other chemical sprays, often experience excessive

corrosion and contamination. As a result, these

vehicles typically need maintenance more often,

and vehicle parts exposed to de-icing chemicals

tend to require replacement sooner. For air system

components, one potential result of exposure to

corrosion and contamination can be restricted or

blocked exhaust ports which can reduce air system

performance.

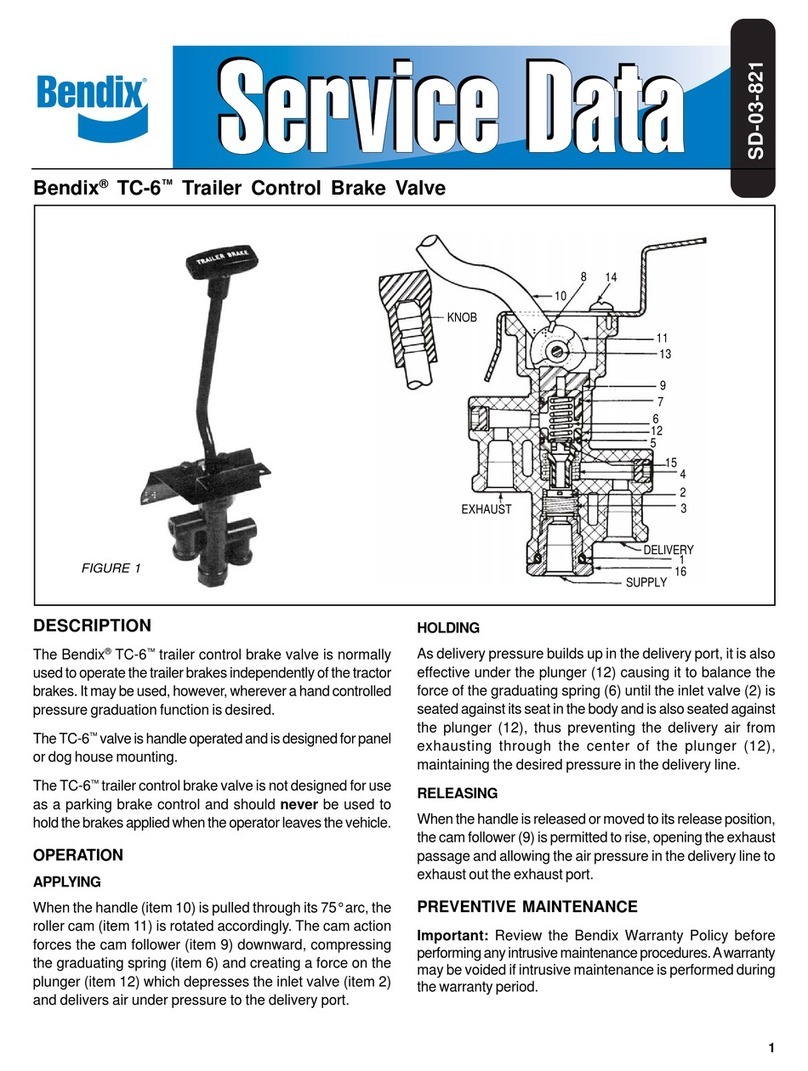

Regular maintenance routines typically include in-

spections for corrosion and contamination. Air control

valves with smaller secondary exhaust ports, such as

the Bendix®ATR-1™orATR-2™traction control valves

and R-14®relay valves (See Figure 1), are especially

important to check. These valves are often situated

in difficult-to-reach locations on the vehicle, however,

by following the steps outlined in this Bulletin, the

technician can verify that the valves are functioning

correctly.

Bendix recommends that potentially affected

vehicles:

• Use the specific test(s) below to determine if the

valves are functioning properly

• Install air system components in areas protected

fromdirect splashand roadspray, andinstall splash

guards where necessary

• Have more frequent inspection and maintenance

schedules in regions that have greater exposure

to de-icing chemicals

Early indications that maintenance is required include

reports of “brake drag” — that service brakes appear

to be slow to release following a braking or traction

control event.

When conducting the following Tests, follow all industry

standard safety guidelines, including, but not limited to,

those shown on page two of this Bulletin.

In all cases, consult your vehicle manufacturer’s

servicemanualfordetails of any further teststhatthey

recommend.

To Test ATR-1™and ATR-2™Traction Relay

Valves:

The antilock traction control (ATC) system is tested

by connecting the vehicle to a PC with the Bendix®

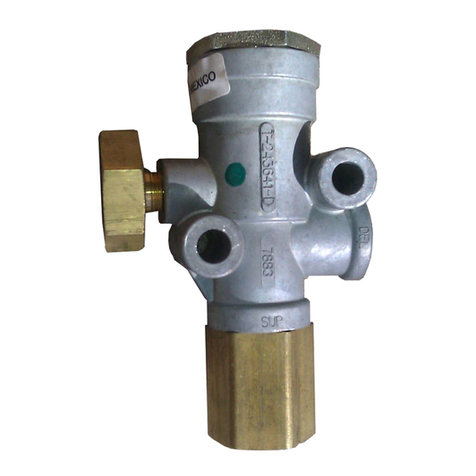

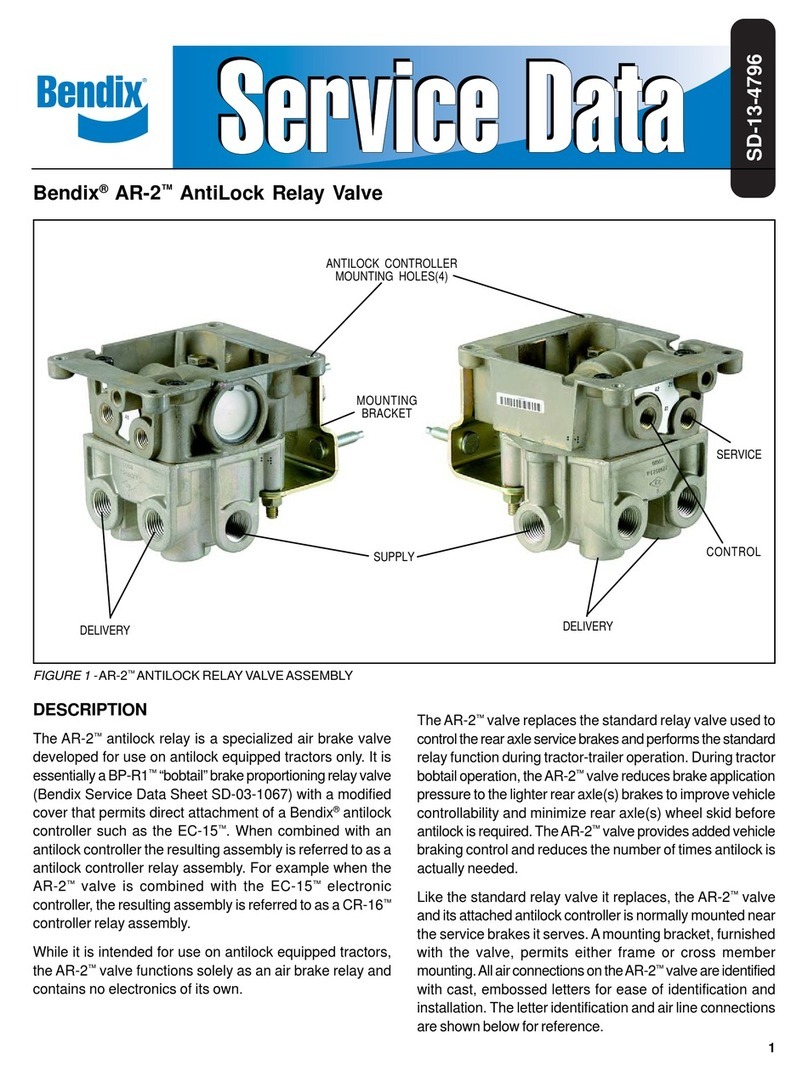

FIGURE 1 - EXAMPLES OF R-14®RELAY VALVE AND

ATR-1™AND ATR-2™TRACTION RELAY VALVES

ACom™diagnostics program loaded. (ACom™

software is available as a free download from www.

bendix.com). Run the ATC Valve Test provided in

ACom™diagnostics,andverify thatthebrakes arefully

releasing after the ATC event. If the brakes are slow

to release, replace the traction relay valve and repeat

the above check.

To Test R-14®Relay Valves:

Visually inspect (where possible) that the balance

exhaust port cover is present on the relay valve; in

cases where the cover is missing, replace the entire

valve with a new valve. During installation, confirm

that the exhaust cover is firmly attached.

If the cover is present, verify that the R-14®relay valve

used is functioning properly by fully charging the air

systemand blockand holdvehicle bymeans otherthan

the air brakes. Then make several brake applications

and check for prompt application and release of each

wheel’s brakes with no perceptible lag.

Ifthe brakesare slowto release,replace therelayvalve

and repeat the above test. If the brakes continue to

exhibitslowrelease,refertothetroubleshootingsection

in your vehicle manufacturer’s service manual.

R-14®Relay Valve

Cover for Balance/

Quick Exhaust Port

(Used for Anti-

Compound Functions)

Relay Valve Exhaust Port

Secondary Exhaust Ports (With Cover) are

Located Behind the Mounting Bracket

Relay Valve Exhaust Port