6

Note: Amaintenancekit forthe SR-1™springbrake valveis

availablefrom any authorizedBendix outlet.Allparts

necessaryfor minorrepair are included.

REMOVAL

1. Prior to removing the SR-1™valve apply the parking

brakes and drain allthe vehicle reservoirs.

2. Identify all air lines before disconnecting.

3. Remove the two mounting bolts from the SR-1™valve

andremovethevalve.

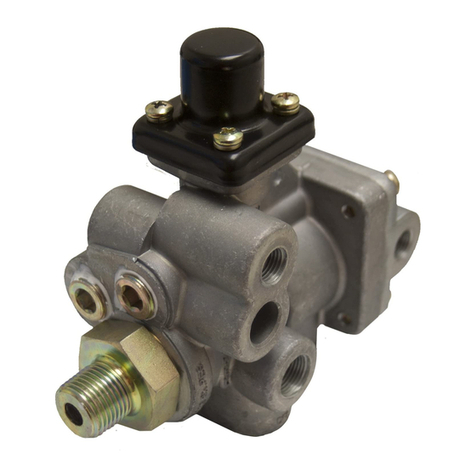

DISASSEMBLY (REFER TO FIGURE 2)

1. Remove the socket head pipe plug (1).

2. Remove thecheck valvespring (2)and thecheck valve

(4).

3. Remove the two phillips head screws and remove the

exhaust cover (5).

4. Separate the exhaust diaphragm (6) from the cover.

5. Remove theinlet andexhaustvalve assembly(7).

6. Remove the inlet and exhaust valve cap nut (8) and

separate the cap nut o-ring (9).

7. Remove the valve stop (10) valve spring (11) and inlet

andexhaust valve(12).

8. Remove thefour phillipshead screws andlockwashers

that secure the cover to the body. Caution: the cover is

undera springload, andshould beheld whileremoving

the screws.

9. Remove the cover (13) and the three piston springs

(14).Note: SomeSR-1™valve piecenumbershave one

large piston spring.

10.Remove the small piston (15) and the small and large

o-rings (16).

11. Remove the large piston (17). Remove piston o-rings

(18) & (19).

CLEANING & INSPECTION

Inspect all parts for excessive wear or deterioration.

Inspect the valve seats for nicks or burrs.

Check the springs for cracks or corrosion.

Replace all rubber parts and any part not found to be

serviceable during inspection. Use only genuine Bendix

replacementparts.

ASSEMBLY (REFER TO FIGURE 2)

Priorto assemblyofthe SR-1™springbrake valve,lubricate

all o-rings, o-ring grooves, and piston bores with Bendix

silicone lubricant BW-650-M piece number 291126.

Note: All torques specified in this manual are assembly

torques and can be expected to fall off, after

assembly is accomplished. Do not retorque after

initial assembly torques fall.

1. Assemble the check valve (4), and valve spring (2) and

install in body.

2. Apply pipe sealant to the socket head pipe plug (1) and

install in the body. Tighten to 130-170 inch pounds

torque.

3. Installinletandexhaustvalveassembly(7)invalve body.

4. Secure the exhaust cover (5) with two 10-24 phillips

screws and lockwashers. Tighten to 20-30 inch pounds

torque.

5. Install exhaust diaphragm (6) into the exhaust cover.

6. Place inlet exhaust valve (12) in the body. Install the

valvespring(11) andvalvestop(10).

7. Install o-ring (9) on cap nut and install cap nut (8) in

body. Tighten to 100-125 inch pounds torque.

8. Install the small and large o-rings (16) on the small

diameter piston (15) and install piston in the body.

9. Installlarge o-ring(18)and smallo-ring(19)on thelarge

diameter piston and install piston in the body.

10. Install thepiston springs(14)in theirrespective pistons.

11. Securethe cover tobodyusingfour 1/4"-20phillipshead

screwsand lockwashers.Tighten to50-80 inch pounds

torque.

TESTING THE REBUILT SR-1™SPRING BRAKE

VALVE

Test therebuilt SR-1™springbrake valve byperforming the

operationand leakagetest outlinedinthe “ServiceChecks”

section of this manual.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine bein operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.