2

OPERATION

SPRING BRAKES RELEASED

Whenthespringbrakesarereleased,airfromtheparkcontrol

valveflowsthrough the QR-1C™valve, causing the double

checkvalveandquickreleasediaphragmstoflexandseal

thebalance andexhaustports.Air flowsintothe emergency

port of the spring brakes from the QR-1C™valve delivery

ports.

SPRING BRAKES APPLIED

Whenthespringbrakes areapplied, supplyline airpressure

tothevalve is exhausted through the parkcontrol valve.As

air pressure is removed from one side of the double check

valveandquickreleasediaphragms,theyflexintheopposite

directionopeningthebalanceandexhaustports.Springbrake

emergency pressure is released at the exhaust port of the

valvewhile thesmallamount ofairtrapped betweenthe two

diaphragmsisreleasedthroughtherelayvalveorbrakevalve

exhaust.

ANTI-COMPOUNDING

When a service brake application is made with the spring

brakesapplied,serviceair entersthe balanceportandflows

through the valve into the emergency ports of the spring

brakes. This prevents the compounding of a service and

spring brake application. Service air passing through the

valveflexesthedoublecheckandquickreleasediaphragms,

sealing the supply and exhaust ports. When the service

application is released, air is exhausted from the spring

brakes.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performinganyintrusivemaintenanceprocedures.Awarranty

maybe voided ifintrusivemaintenance is performedduring

thewarranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuableguide indetermining thebestmaintenance interval

for air brake system components. At a minimum, the

QR-1C™valveshouldbeinspectedevery 12monthsor3600

operatinghours,whichever comesfirst,forproperoperation.

Should the QR-1C™valve not meet the elements of the

operationaltestsnotedinthisdocument,further investigation

andservice of thevalvemay berequired.

REMOVAL

1. Blockvehicle wheelsand/or holdvehiclebymeansother

thanairbrakes.

2. Drainallairbrakesystem reservoirs.

3. Identifyand disconnect air linesfromvalve.

4. Removemounting bolts,thenvalve.

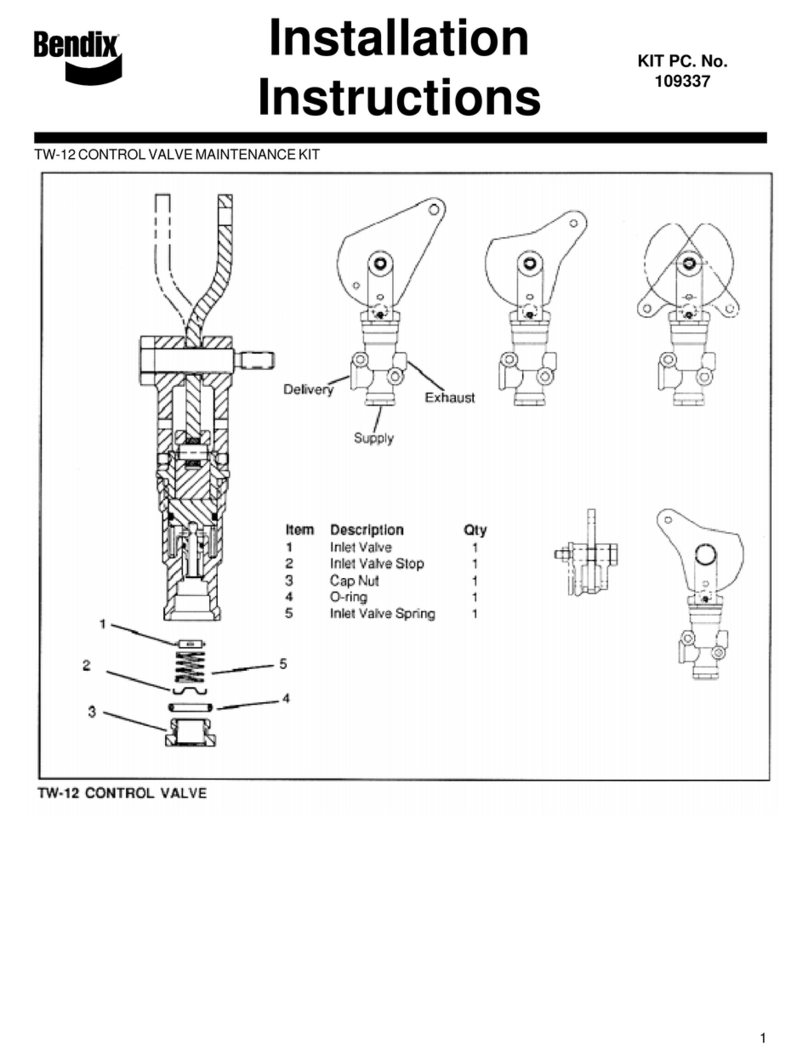

DISASSEMBLY

Marktherelationshipofthebodyandcoverbeforedisassembly.

1. Removecap nut.

2. Removesealing ring from capnut.

3. Removedouble checkvalve diaphragm.

4. Removefour Phillips headscrews.

5. Separate the body and cover and remove the sealing

ringand quick release diaphragm.

CLEANING AND INSPECTION

Cleanall metal partsinmineral spirits.Wipeall rubber parts

clean.It isrecommendedthat allrubberparts andanyother

partshowing signsofwear ordeteriorationbe replacedwith

genuineBendixparts.

ASSEMBLY

1. Install sealing ring on cap nut.

2. Installdouble check valvediaphragmin body.

3. Installcap nut and torque to 150-400 inch pounds.

4. Installsealing ring invalvebody.

5. Installthe quick release diaphragm in the cover.

6. Install the cover and diaphragm on body, aligning the

marksmade duringdisassembly.Securetogetherusing

the four Phillips head screws and torque to 30-60 inch

pounds.

7. Re-installtheQR-1C™valveandbeforeputtingthevehicle

inservice, perform the “Operation andLeakageTests.”

OPERATING AND LEAKAGE TESTS

Before performing these tests, park the vehicle on a level

surfaceandholdthevehiclebymeansotherthanthebrakes.

1. Withthe parkcontrolvalve inthereleased position,note

thatthespringbrakesarereleased.

2. Remove the air line connected to the QR-1C™valve

balance port and apply a soap solution to the exhaust

andbalanceport.A1"bubblein5secondsispermissible

at either location.

3. Reconnect the QR-1C™valve balance line; and using

theparkcontrolvalve,parkthe vehicle.NOTE:Aprompt

applicationof the springbrakeswithan exhaust ofairat

theQR-1C™valve exhaustport.

4. Remove the air line connected to the supply port of the

QR-1C™valve. With a service brake application hold

applied, apply a soap solution to the supply port and

aroundtheseambetweenthebodyandcover.A1"bubble

in 5 seconds is permissible at the supply port. No

leakageispermitted between the body and cover.

5. Reconnect the supply port air line. If the valve does not

function as described, or if leakage is excessive, it is

recommended that it be replaced with a new or

remanufacturedunit,orrepairedwithgenuineBendixparts.