2

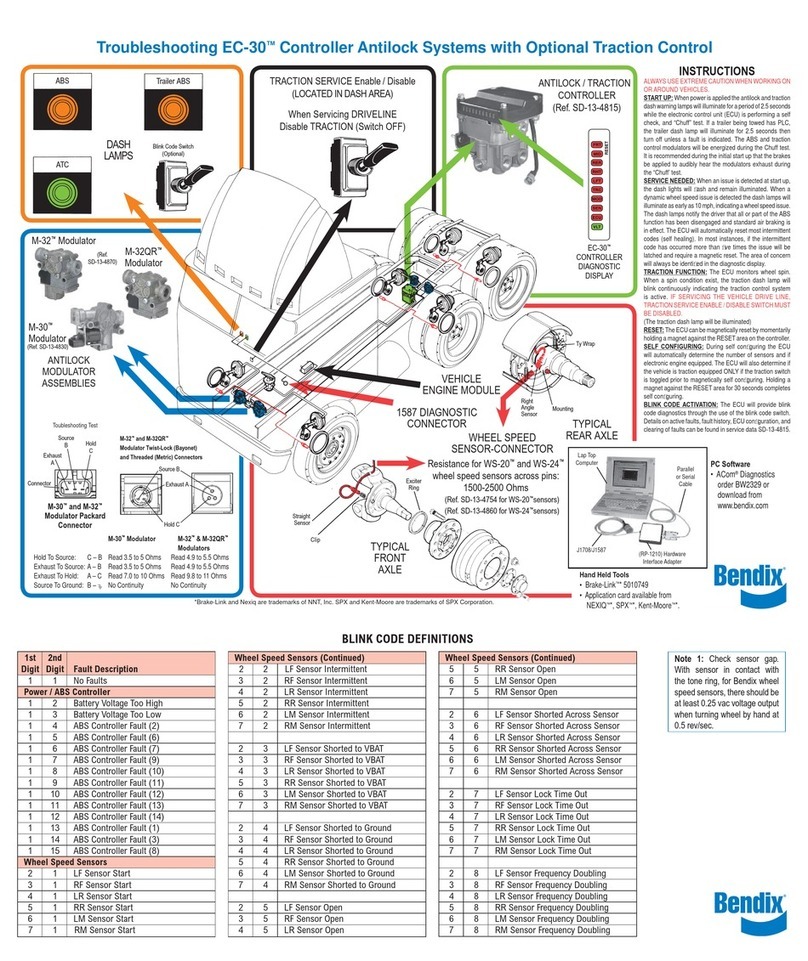

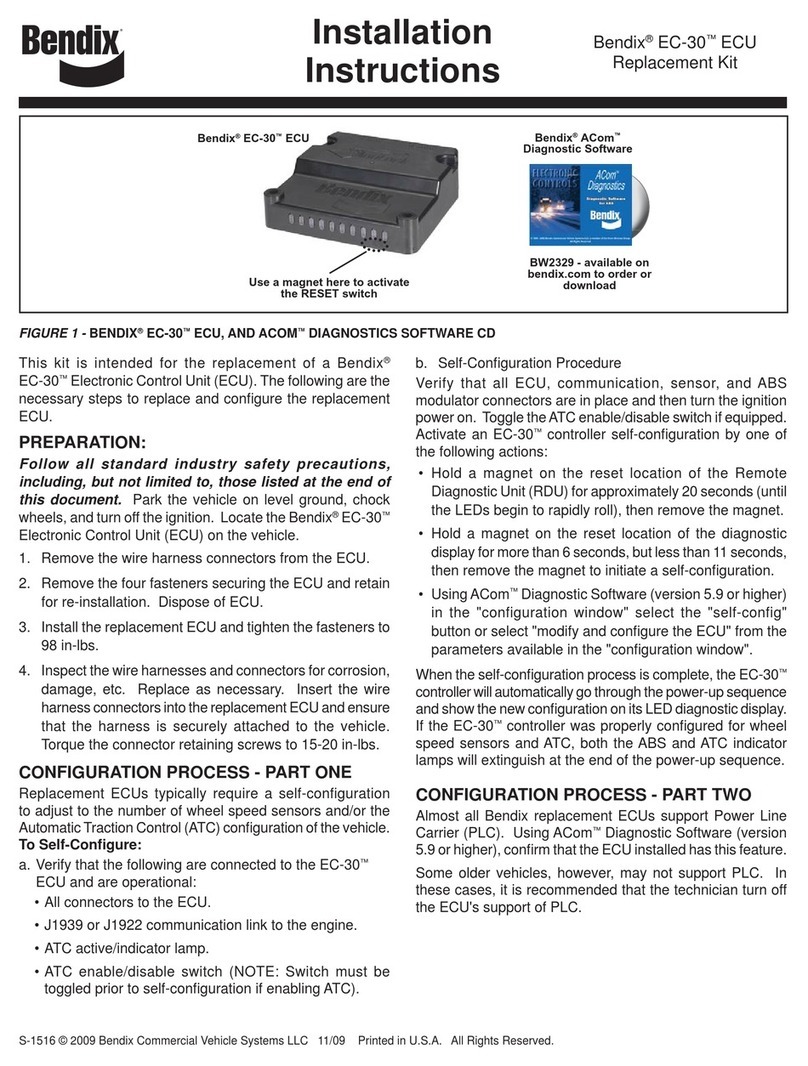

c. Determine if the EC-30™controller will be mounted on a

relay valve or on the frame. In either case, be sure that

the harness will reach both the old harness and the ECU

without strain.

d. If the EC-30™controller is mounted on the frame, Bendix

strongly recommends that the orientation is parallel to the

frame (see Figure 2). Mark the mounting hole locations,

and drill the 4 mounting holes (0.295 in. diameter).

e. If the EC-30™controller is to be mounted on a relay valve,

theadapterplateincluded in this kit will be required. Mount

the EC-30™controller using Grade 5 stainless steel bolts;

the maximum torque permitted is 98 in-lbs.

8. Perform the system check-out as outlined on page 3 of

these instructions.

GENERAL MAINTENANCE PRECAUTIONS

WARNING! PLEASE READ AND FOLLOW THESE

INSTRUCTIONS TO AVOID PERSONAL INJURY OR

DEATH:

When working on or around a vehicle, the following general

precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking

brakes, and always block the wheels. Always wear safety

glasses.

2. Stop the engine and remove ignition key when working

under or around the vehicle. When working in the engine

compartment, the engine should be shut off and the

ignition key should be removed. Where circumstances

require that the engine be in operation, EXTREME

CAUTION should be used to prevent personal injury

resulting from contact with moving, rotating, leaking,

heated or electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended procedures.

Use only the proper tools and observe all precautions

pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air brake

system, or any auxiliary pressurized air systems, make

certain to drain the air pressure from all reservoirs

before beginningANY work on the vehicle. If the vehicle

is equipped with an AD-IS®air dryer system or a dryer

reservoir module, be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power from the

vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing

pressure; it may whip. Never remove a component or

plug unless you are certain all system pressure has been

depleted.

8. Useonly genuine Bendix®replacement parts, components

and kits. Replacement hardware, tubing, hose, fittings,

etc. must be of equivalent size, type and strength as

original equipment and be designed specifically for such

applications and systems.

9. Components with stripped threads or damaged parts

should be replaced rather than repaired. Do not attempt

repairsrequiring machining orwelding unless specifically

stated and approved by the vehicle and component

manufacturer.

10. Prior to returning the vehicle to service, make certain all

components and systems are restored to their proper

operating condition.

11. For vehicles with Antilock Traction Control (ATC), theATC

function must be disabled (ATC indicator lamp should

be ON) prior to performing any vehicle maintenance

where one or more wheels on a drive axle are lifted off

the ground and moving.

*If any of the questions were answered with a “No”, the

Antilock system should be review by a qualified individual.

Fortechnicalassistance,call the BendixTechnicalAssistance

Team at (800)-247-2725.

INSTALLING THE ADAPTER HARNESS

1. Connect the Deutch vehicle harness connectors into the

appropriate Deutch connectors of the adapter harness.

2. Besurethattheadapterharnesshasadequatestrainrelief

when installed so that it can be routed freely and is not

pulled tight.

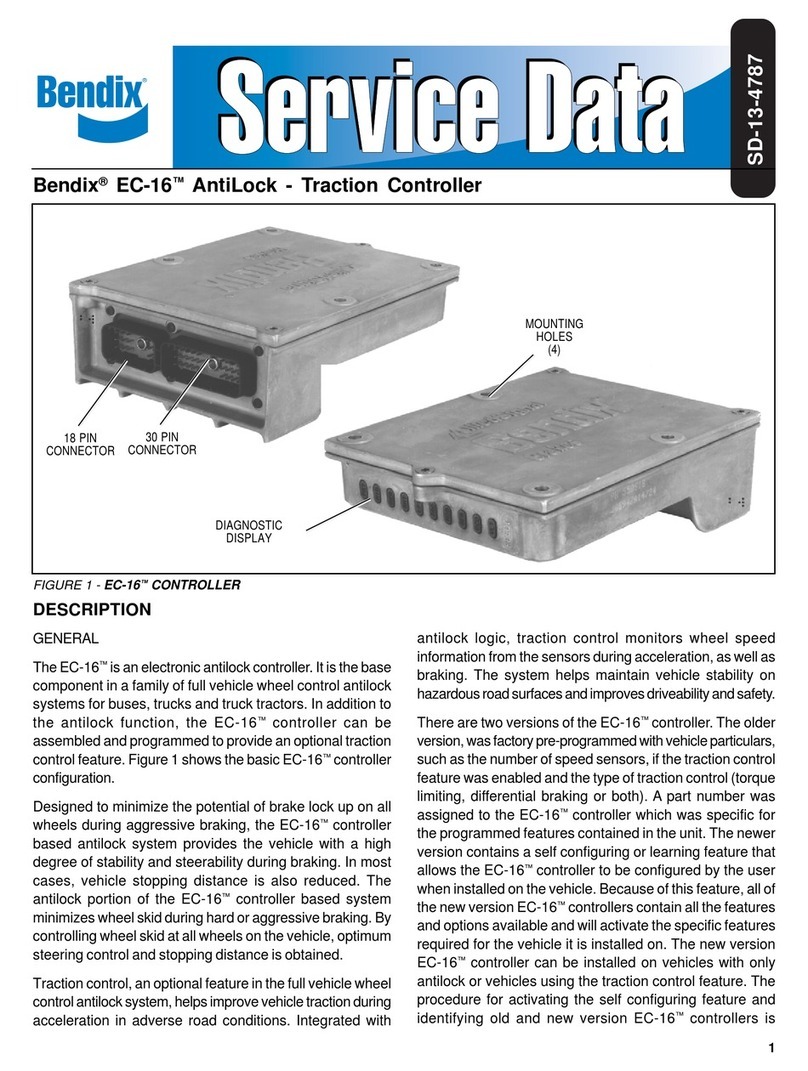

3. Install the 30- and 18-pin connectors to the EC-30™

controller ABS ECU, torquing the retaining cap screws to

15-20 in-lbs.

4. Apply ignition power and monitor the EC-30™Controller

power-up sequence and the LEDs on the ECU. Verify

that only a green VLT LED is illuminated, no red LEDs.

For all other Diagnostic Trouble Codes, including where

reconfiguration is needed, see the Service Data sheet in

this kit for full instructions.

5. EC-30™Controller Self-configuration Procedure.

Verifythat allECU,communication,sensor,ABSmodulator

andATC modulator connectors are in place and then turn

the ignition power on.

ActivateanEC-30™controller self-configuration byholding

a magnet on the "reset" location of the diagnostic display

for about 20 seconds (until the LEDs begin to rapidly roll)

then remove the magnet.

6. Use sealing plugs to cover any unused wire harness

terminals.

7. Checkthat all ECU connectors are completelyseated and

torqued correctly.

ECU Installation yes no*

Is the ECU mounted where it will not be

subjected to direct wheel spray or temperatures

of lower than -40° C or more than +85° C?

Is the ECU mounted in a location where

moisture can drain away from it?

Is the ECU (frame) mounted in a sideways

manner (see Figure 2)?

Are the ECU mounting bolts properly torqued

(maximum permitted is 98 in-lbs.)?