TABLE OF CONTENTS

1. SAFETY.............................................................................................................................................................. 1

1.1 INTRODUCTION....................................................................................................................................... 1

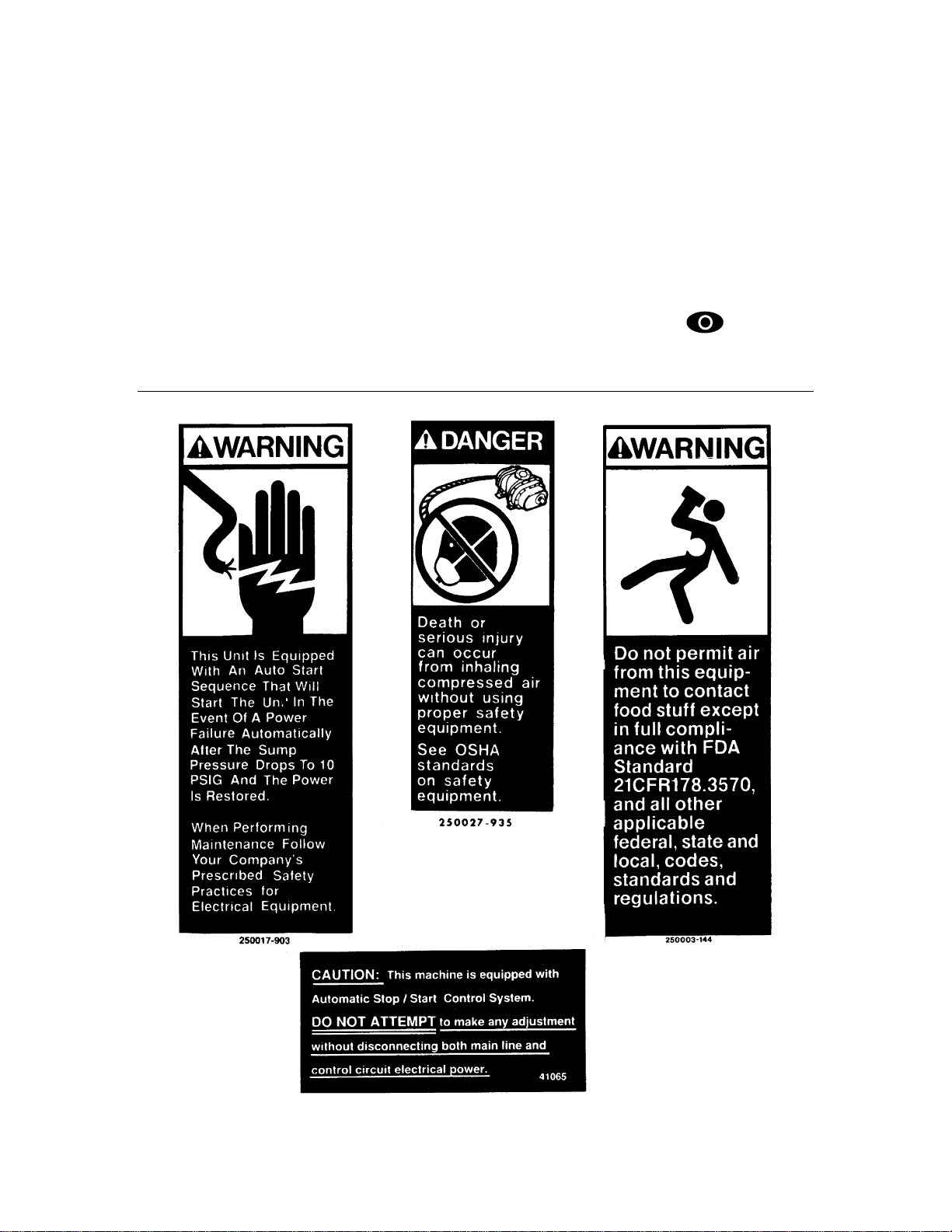

1.2 ELECTRICAL SHOCK .............................................................................................................................. 1

1.3 VARIABLE SPEED DRIVE........................................................................................................................ 1

1.4 DECALS.................................................................................................................................................... 1

1.5 EMERGENCY STOP ................................................................................................................................ 2

2. STARTUP PROCEDURES................................................................................................................................. 5

2.1 INTRODUCTION....................................................................................................................................... 5

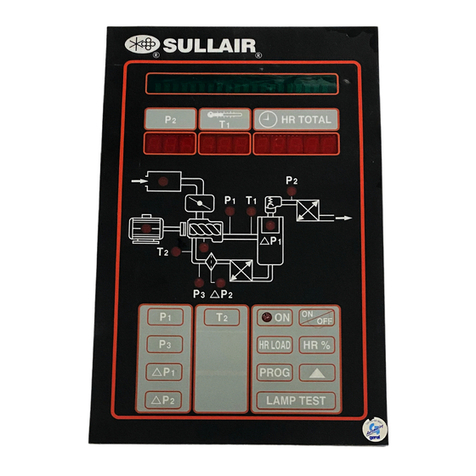

2.2 WS CONTROLLER PANEL LAYOUT....................................................................................................... 5

2.3 WS START UP PROCEDURES ............................................................................................................... 6

2.3.1 COMPRESSOR MOTOR ROTATION DIRECTION CHECK (at installation)................................ 6

2.3.2 FAN MOTOR ROTATION CHECK (at installation) ....................................................................... 6

2.3.3 INITIAL START-UP AFTER INSTALLATION................................................................................ 6

2.3.4 SUBSEQUENT START-UP PROCEDURE................................................................................... 7

2.4 SHUTDOWN PROCEDURE..................................................................................................................... 7

3. ADJUSTMENTS ................................................................................................................................................. 9

3.1 INTRODUCTION....................................................................................................................................... 9

3.2 COMPRESSOR ADJUSTMENT PROCEDURES..................................................................................... 9

3.3 USER ADJUSTABLE CONTROL PARAMETERS.................................................................................. 10

3.4 CALIBRATION OF P2 PRESSURE TRANSDUCERS ........................................................................... 12

3.5 REMOTE UNLOAD................................................................................................................................. 12

4. WS CONTROLLER DESCRIPTION................................................................................................................. 13

4.1 INTRODUCTION..................................................................................................................................... 13

4.2 TOUCH PAD BUTTON DESCRIPTION.................................................................................................. 13

4.3 INDICATOR LED DESCRIPTION........................................................................................................... 13

4.4 DISPLAY SCREEN................................................................................................................................. 14

4.4.1 NORMAL VIEW ........................................................................................................................... 14

4.4.2 COMPRESSOR STATUS VIEW ................................................................................................. 14

4.4.3 COMPRESSOR ADJUSTMENT VIEW – CONTROL PARAMETERS........................................ 15

4.5 OPERATING MODES............................................................................................................................. 15

4.6 OPERATING STATES............................................................................................................................ 16

4.7 NORMAL VIEW SERVICE REMINDERS............................................................................................... 18

4.8 WARNING MESSAGES.......................................................................................................................... 18

4.9 FAULT MESSAGES................................................................................................................................ 19

5. TROUBLESHOOTING...................................................................................................................................... 21

5.1 TROUBLESHOOTING INTRODUCTION ............................................................................................... 21

5.2 TROUBLESHOOTING GUIDE................................................................................................................ 22

5.3 MACHINE BEHAVIOR AFTER A POWER Interruption.......................................................................... 24

TELEPHONES, FAX AND ADDRESSES.......................................................................................... BACK COVER

OPERATOR IS REQUIRED TO READ

ENTIRE INSTRUCTION MANUAL