6

Rear Axle Brakes - The vehicle’s rear axle brakes are

controlled by the MC-14™modulator controller (EC-14™

controllerandM-12™modulator).Likethe standard service

relayvalveitreplaces,theM-12™modulatordelivers brake

application pressure to the service chambers on the rear

axle equally. Two speed sensors on the rear axle “report”

changes in acceleration and deceleration to the EC-14™

controller. If required, the EC-14™controller adjusts the

applicationpressureto the rear axle servicebrakes,viathe

M-12™modulator,basedonthewheelbehavior“reported”

toitbythe speed sensors. In thecaseofvehiclesequipped

with tandem rear axles (6x2, 6x4), the speed sensors are

installed on the axle that is most likely to lose traction first.

TheMC-14™modulator controllercontrolsallservicebrakes

onthe tandemequally.

TheEC-14™controller utilizesa “SelectSmart”brakecontrol

philosophy for the rear axle brakes. This means that the

EC-14™controllerwillinitiallyadjust application pressure to

allrearaxleservicechambersbasedonthespeedinformation

from the first wheel to approach a locked condition. The

initialpressure adjustment willattempttoprevent allwheels

ontheaxle(s)fromlocking.Ifasubstantialbrakingdifference

is detected between the two wheels on the axle equipped

withthespeedsensors,theEC-14™controller will override

the first air pressure adjustment and allow one wheel to

lock. Both wheels including the locked wheel will continue

to be monitored for speed and braking difference changes

thatwouldrequirepressure adjustments.

Steering Axle Brakes - The steering axle brakes are

controlledby theEC-14™controllerand theM-21™orM-22™

modulator.Althoughconnectedtothe EC-14™controllervia

a wire harness, the M-21™or M-22™modulator is not an

integralpartof the MC-14™modulator controller assembly.

Brake application air passes through the M-21™or M-22™

modulator on its way to the front axle service chambers

fromthe footvalve.

Two speed sensors on the front axle “report” changes in

accelerationanddecelerationtothe EC-14™controller.

The EC-14™controller uses a “Select Low” brake control

philosophyfor thefrontaxle brakes.Itwill attempttoprevent

wheel lock by adjusting application pressure to both front

axleservice chambersbasedonthespeed informationfrom

thefirst wheeltoapproach alockedcondition. TheM-21™or

M-22™modulator provides the EC-14™controller with the

means of adjusting front axle service application pressure

whenrequired.

NON-ANTILOCK BRAKE APPLICATION

During normal braking, the brake valve simultaneously

deliversair tothecontrolport oftheM-12™modulator onthe

rear axle(s) as well as to and through the M-21™or M-22™

modulatoron the frontaxle.The M-12™modulatorfunctions

thesameasstandardservicerelayvalveandapplies air to

therearaxleservicebrakes.Becausethe M-21™or M-22™

modulator does not have a relay valve function, service air

passesthroughitto a quick release valveandfromthereto

thefrontaxleservicechambers.The servicebrakes arethus

applied.

Ifthespeed sensors donotdetectan impending wheellock

up, the EC-14™controller does not initiate any corrective

actionandthevehiclecomestoastopinanormalfashion.

ANTILOCK CONTROLLED BRAKE

APPLICATION - SYSTEM FULLY OPERATIONAL

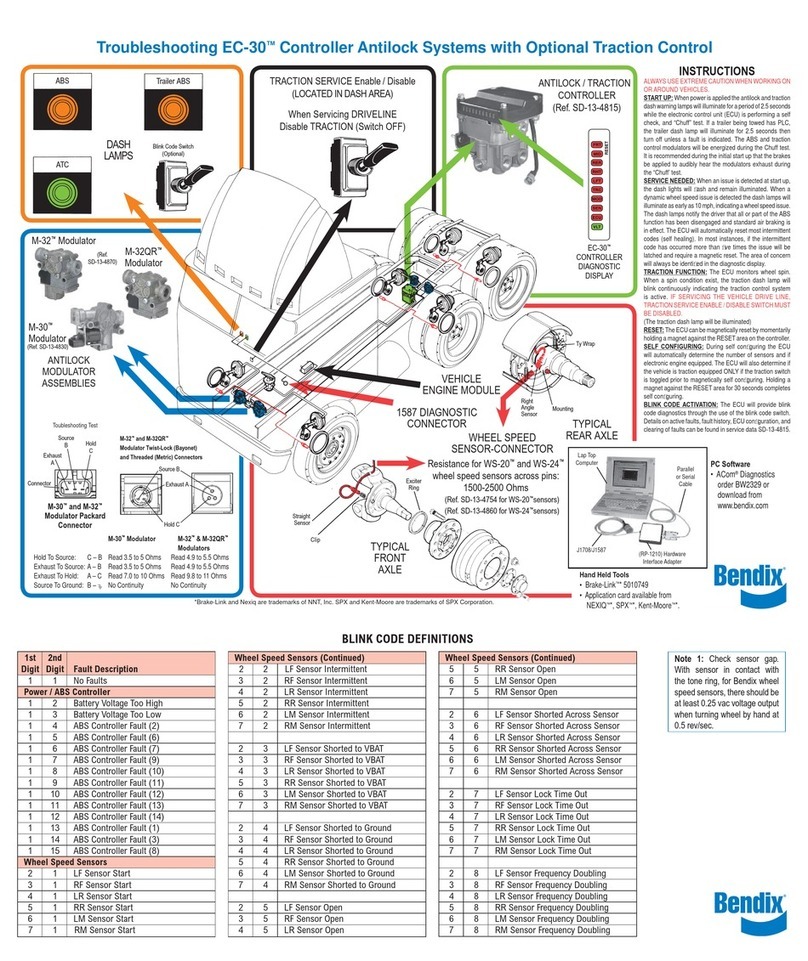

Ifaservicebrakeapplicationis madeand thespeedsensors

detect an impending wheel lockup on an axle, the EC-14™

controller will immediately begin modification of the brake

application using the antilock modulator(s) at the affected

axle(s).

Solenoid valves contained in the modulator are energized

anddeenergizedbytheEC-14™controllerinordertomodify

thebrakeapplication.Whenasolenoidcoilis energized its

shuttlemoves,anddependinguponthefunctionofthespecific

solenoid, it either opens or closes, thereby causing the

exhaustorre-applicationofairpressuretothebrakechamber.

The solenoids in either the M-12™or M-21™modulator are

controlled independently by the EC-14™controller. By

opening and closing the solenoid valves in the appropriate

modulator,theEC-14™controller is actuallysimulatingwhat

thedriverdoeswhen he “pumps the brakes”.

It must be remembered however that unlike the driver, the

EC-14™controller is able to “pump” brakes on either the

frontorrearaxle(s),orboth,independentlyandwithfargreater

speedandaccuracy.

ANTILOCK SYSTEM OPERATION -

COMPONENT FAULT STRATEGY

The Bendix®EC-14™controller handles equipment faults

usingaconservativefail-safephilosophy.Anysingleelectrical

problem with a component devoted to antilock braking,

resultsinsimultaneous illuminationoftheantilock condition

lampon thedashand atroubleshootingLED ontheEC-14™

controller. Depending upon the type of problem and its

position of occurrence the EC-14™controller can continue

antilockfunctionat a lower performance level, disableallof

the antilock on the vehicle or only a portion. When antilock

is disabled, the brakes on the affected axle(s) revert to

standardairbraking.

Complete antilock system shut down will occur if:

•Electrical power is below or above the 10 to 17 volt

operatingrange.

•A controller fault is detected.

•Twoormorefaults,regardless of where, are detected.