5

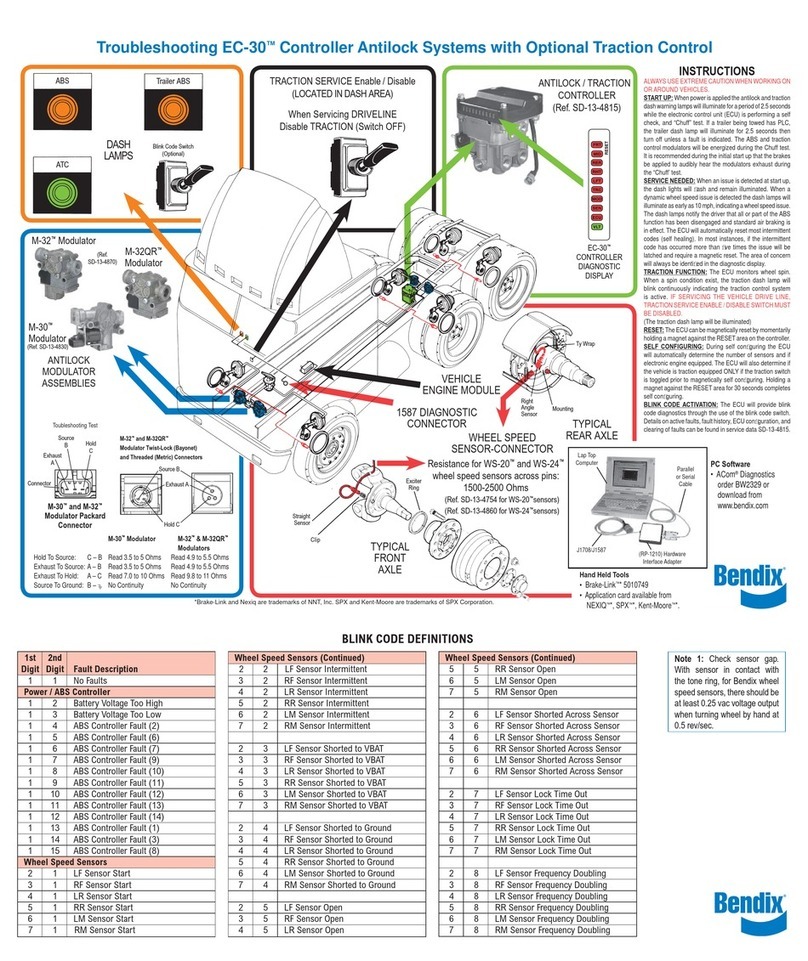

Trailer ABS Warning Lamp

EC-30™controller models with PLC can be configured to

controla trailerABSwarning lamp(located in thedash) that

indicates the status of the trailer ABS unit of one or more

trailers or dollies. The EC-30™controller directly controls

the trailer ABS warning lamp by providing a ground path

when the lamp is to be activated. Pin E2, of the 30-pin

connector, is the trailerABS warning lamp output.

J1939/J1587 Trailer ABS Warning Lamp

The EC-30™controller can be configured to broadcast the

trailer ABS status over the SAE J1939 or the SAE J1587

serialcommunicationslinks. Inthiscase, avehiclecontroller

will directly operate the trailer ABS warning lamp. When

configuredinthismanner,there isnowireinstalledinpinE2

of the 30-pin connector. In the event that communications

is lost between the EC-30™controller and the vehicle

controller, the dash controller will activate the trailer ABS

warninglamp.

J1708/J1587 Diagnostic Link (J1939)

The EC-30™controller provides a J1708/J1587 diagnostic

linkto communicatewith the vehicleand variousdiagnostic

tools. Diagnostics, system configuration, data uploading

anddownloadingandotherfunctionscanbeperformedusing

this link. The EC-30™controller is supported by tools such

asBendix®ABSDiagnosticSoftware,theBendix®DCIhand

held tool and the MPSI ProLink. The EC-30™controller

may also provide diagnostics using the SAE J1939 serial

communications link.

J1939/1922 Engine Torque Reduction - ATC

The EC-30™controllercanbe configured to reduce engine

torque over the SAE J1939 (J1922 for some service

replacement models) serial communications link. The

EC-30™controller will send a J1939 message to reduce

enginetorqueduringATCoperation.

ATC Active/Warning Lamp

PremiumEC-30™controller modelsconfigured forATCcan

controlanATC active/warninglamp toindicatethe statusof

theATCsystem. TheATCactive/warninglampflasheswhen

ATCisactiveand staysonif anATCsystem faultisdetected

orATC is disabled by theATC enable/disable switch. The

EC-30™controller directly controls theATC active/warning

lamp by providing a ground path when the lamp is to be

activated. PinC2,of the30-pinconnector,is theATCactive/

warninglamp output.

J1939ATCActive/Warning Lamp

PremiumEC-30™controller modelsconfigured forATCcan

be configured to broadcast the status of the ATC active/

warning lamp over the SAE J1939 serial communications

link. Inthis case a vehicledash controller directly operates

the ATC active/warning lamp. When configured in this

manner, there is no wire installed in pin C2 of the 30-pin

connector. In theevent thatJ1939 communicationsare lost

between the EC-30™controller and the vehicle dash

controller, the dash controller will activate the ATC active/

warninglamp.

ATC Modulator

PremiumEC-30™controllermodelsconfiguredfordifferential

braking ATC will activate the ATC modulator during ATC

situations. TheATC modulator is an electrically controlled

air valve integral to theATR valve. Pins D2 and D3, of the

18-pinconnector,control theATC modulator. Aconnection

to the ATC modulator is provided via a two-pin Deutsch

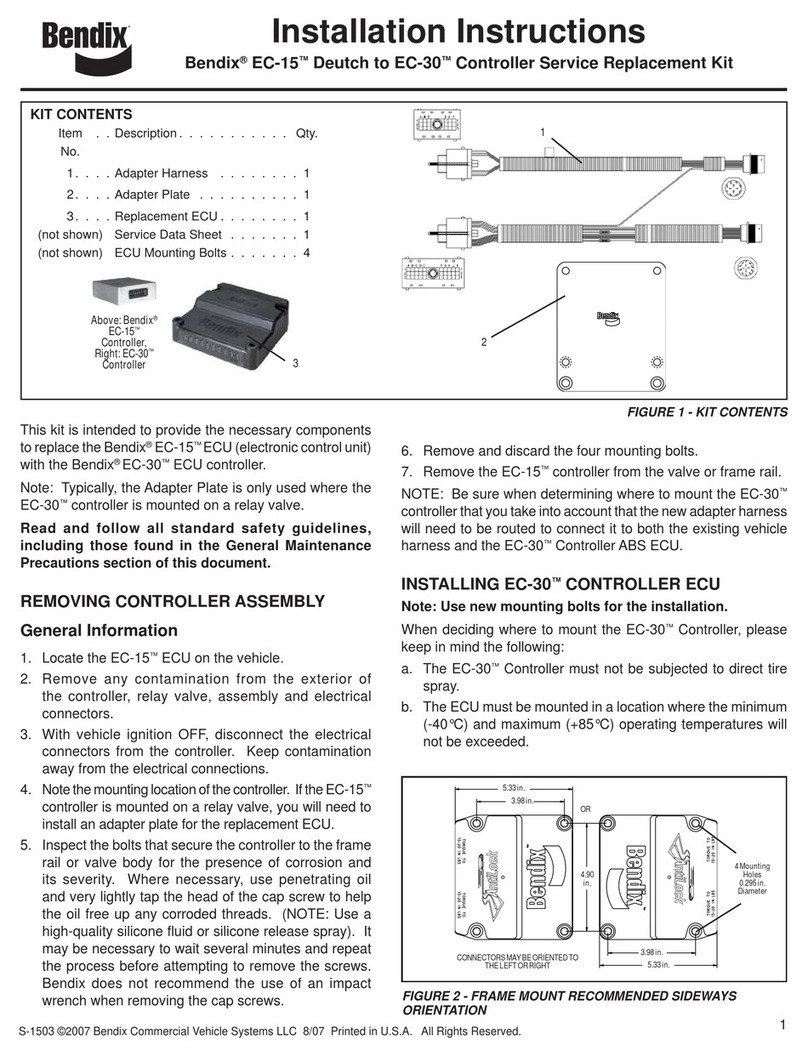

connectorfrom theATRvalve. See figure 2.

ABS Warning Lamp

The EC-30™controller controls an ABS warning lamp to

indicatetheABSunitstatus. TheEC-30™controllerprovides

aground signal to activate anABS warning lamp relay and

turn the ABS lamp off. The actual ABS warning lamp is

connected to the normally-closed contacts of the relay in

orderto illuminatein afail-safemanner duringanABS ECU

failure. PinE3, of the30-pinconnector,is theABS warning

lampoutput.

J1939ABS Warning Lamp

The EC-30™controller can be configured to broadcast the

ABSstatusovertheSAEJ1939serial communicationslink.

Avehicle dash controller directly controls theABS warning

lamp. When configured in this manner, there is no wire

installed in pin E3 of the 30-pin connector. If J1939

communicationsis lost between theEC-30™controllerand

the vehicle dash controller, the dash controller will activate

theABS warning lamp.

Retarder Disable Relay

The EC-30™controller controls an engine or transmission

retarderdisablerelay. Theretarderactivation wire isrouted

through the normally-closed contacts of the relay. The

EC-30™controller provides a ground path to activate the

relayandinterruptpowertotheretarderduringABSoperation.

This output may also connect directly to a transmission

ECU. PinK1,of the30-pinconnector,is theretarderdisable

relayoutput.

J1939/J1922 Retarder Disable

The EC-30™controller can be configured to interrupt the

engine or transmission retarder over the SAE J1939 serial

communicationslink. (J1922forsomeservice replacement

models). The retarder will be disabled duringABS via the

serial communications. When configured in this manner,

there is no wire installed in pin K1 of the 30-pin connector.

Use of the retarder disable function via the serial link may

beessentialtoABSperformanceandishighlyrecommended

forvehicles equippedwith a capableretarder.

J1939/J1922 Torque Converter Lock Disable

The EC-30™controller can be configured to interrupt the

automatictransmission torqueconverter lockfunction, over

theSAEJ1939serialcommunicationslink. (J1922for some

service replacement models). The converter lock will be

disabledduringABS viatheserial communications. Useof

thetorque converter lockdisable function maybeessential

toABSperformanceand ishighlyrecommendedforvehicles

equippedwith a capable transmission.