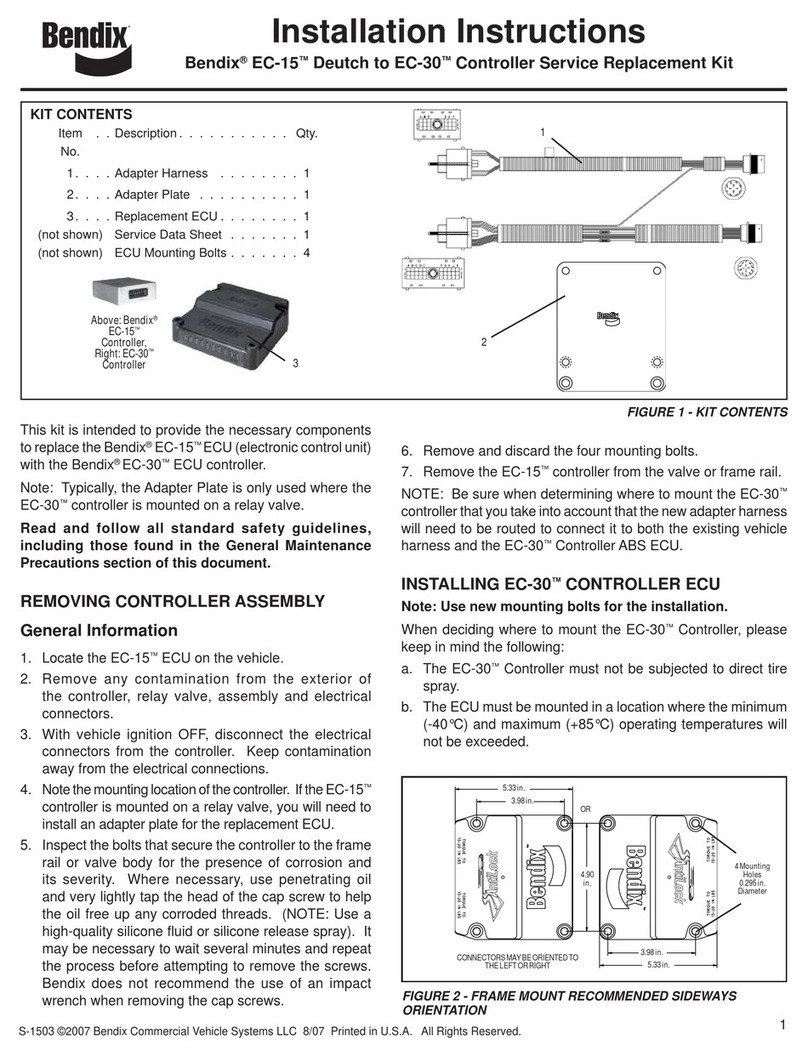

Installation

Instructions Bendix®EC-30™ECU

Replacement Kit

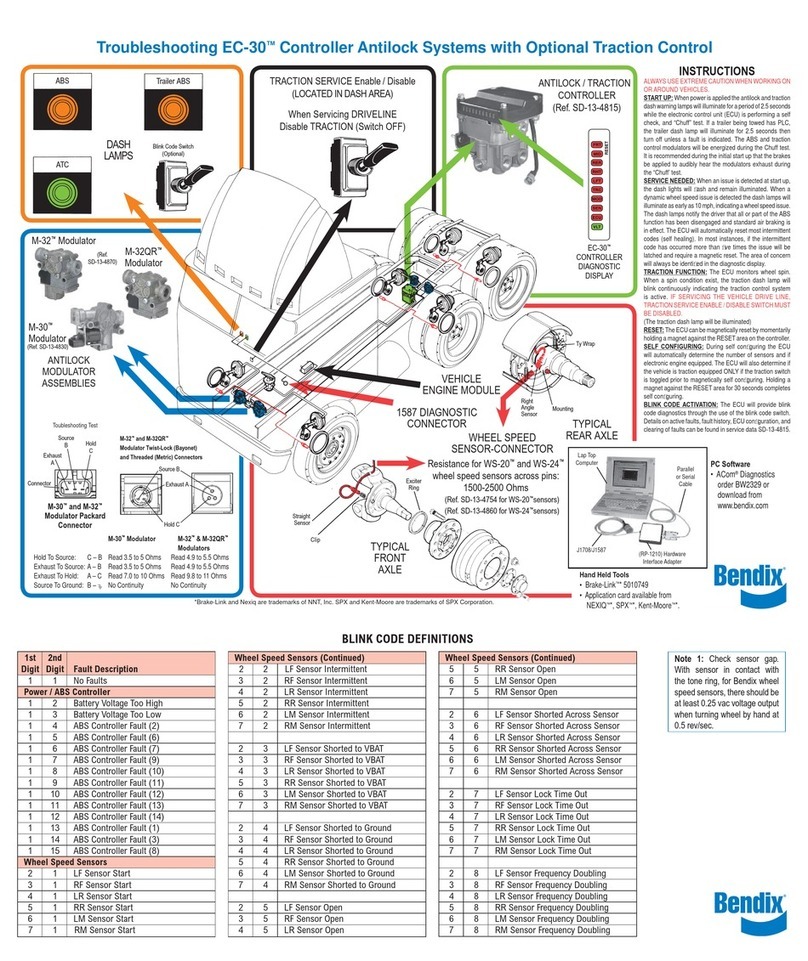

FIGURE 1 - BENDIX®EC-30™ECU, AND ACOM™DIAGNOSTICS SOFTWARE CD

This kit is intended for the replacement of a Bendix®

EC-30™Electronic Control Unit (ECU). The following are the

necessary steps to replace and configure the replacement

ECU.

PREPARATION:

Follow all standard industry safety precautions,

including, but not limited to, those listed at the end of

this document. Park the vehicle on level ground, chock

wheels,andturnofftheignition. LocatetheBendix®EC-30™

Electronic Control Unit (ECU) on the vehicle.

1. Remove the wire harness connectors from the ECU.

2. Remove the four fasteners securing the ECU and retain

for re-installation. Dispose of ECU.

3. Install the replacement ECU and tighten the fasteners to

98 in-lbs.

4. Inspectthewireharnessesandconnectorsforcorrosion,

damage, etc. Replace as necessary. Insert the wire

harnessconnectorsintothereplacementECUandensure

that the harness is securely attached to the vehicle.

Torque the connector retaining screws to 15-20 in-lbs.

CONFIGURATION PROCESS - PART ONE

Replacement ECUs typically require a self-configuration

to adjust to the number of wheel speed sensors and/or the

AutomaticTraction Control(ATC)configurationofthe vehicle.

To Self-Configure:

a. Verify that the following are connected to the EC-30™

ECU and are operational:

• All connectors to the ECU.

• J1939 or J1922 communication link to the engine.

• ATC active/indicator lamp.

• ATC enable/disable switch (NOTE: Switch must be

toggled prior to self-configuration if enabling ATC).

b. Self-Configuration Procedure

Verify that all ECU, communication, sensor, and ABS

modulator connectors are in place and then turn the ignition

poweron. ToggletheATC enable/disable switch ifequipped.

Activate an EC-30™controller self-configuration by one of

the following actions:

• Hold a magnet on the reset location of the Remote

DiagnosticUnit(RDU) for approximately 20 seconds (until

the LEDs begin to rapidly roll), then remove the magnet.

• Hold a magnet on the reset location of the diagnostic

displayfor more than 6seconds,but less than 11 seconds,

then remove the magnet to initiate a self-configuration.

• UsingACom™Diagnostic Software (version 5.9 or higher)

in the "configuration window" select the "self-config"

button or select "modify and configure the ECU" from the

parameters available in the "configuration window".

When the self-configuration process is complete, the EC-30™

controllerwillautomaticallygo throughthe power-upsequence

andshow thenewconfigurationon itsLEDdiagnostic display.

If the EC-30™controller was properly configured for wheel

speed sensors and ATC, both the ABS and ATC indicator

lamps will extinguish at the end of the power-up sequence.

CONFIGURATION PROCESS - PART TWO

Almost all Bendix replacement ECUs support Power Line

Carrier (PLC). Using ACom™Diagnostic Software (version

5.9or higher), confirmthatthe ECU installed hasthisfeature.

Some older vehicles, however, may not support PLC. In

these cases, it is recommended that the technician turn off

the ECU's support of PLC.

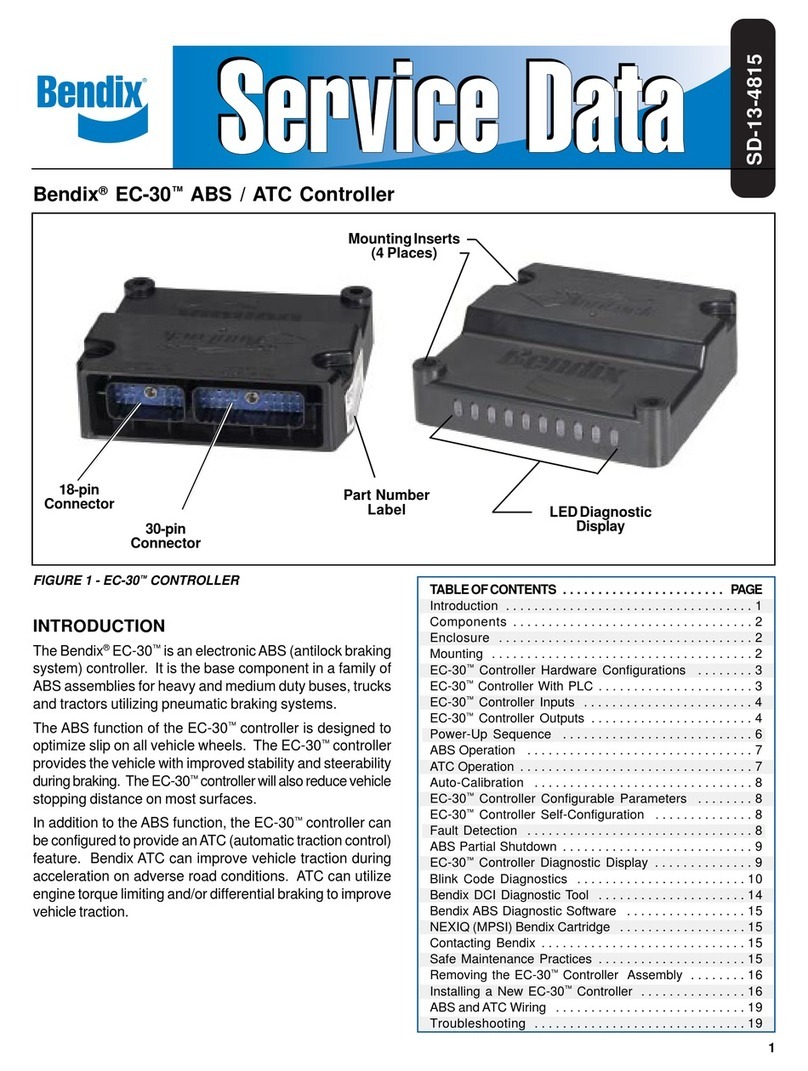

Bendix®EC-30™ECU

S-1516 © 2009 Bendix Commercial Vehicle Systems LLC 11/09 Printed in U.S.A. All Rights Reserved.

Use a magnet here to activate

the RESET switch

Bendix®ACom™

Diagnostic Software

BW2329 - available on

bendix.com to order or

download