7

2. Do not pierce wire insulation when testing. Check for

power, ground or continuity by disconnecting the

connector and testing the individual pins or sockets in

theconnector.

3. Always check the vehicle hand book for wire and

connectoridentification.Individual wireidentificationwill

differdepending uponthetype ofconnectors inuse, the

vehiclemanufacturer,and thesystem featuresinuse.

4. Whilethe retarderdisable andseriallinkconnections(3

total)are presentonall EC-15™controllersthey are not

alwaysused.

PREVENTATIVEMAINTENANCE

Every3 months; 25,000miles; or900operating hours,

1. Check all wiring and connectors to ensure they are

secureand freefromvisibledamage.

2. AlthoughtheEC-15™controllerincorporatesaselfcheck

diagnostics, the LED display should be inspected to

ensurethat theyare functional.With thevehicle ignition

on,amagnet(800gauss;capableofpickingup3ounces)

held to the LED reset switch should cause all of the

LED’stoilluminate.Ifone ormoreof theLED’sDO NOT

ILLUMINATEandtheantilockconditionlamponthedash

indicates the system is functioning properly, the

non-illuminated LED(s) should be noted for future

reference. Although the diagnostic capabilities will be

limited,thesystem willcontinueto functionasdesigned.

3. Road test the vehicle by making antilock stop from a

vehicle speed of 20 miles per hour. When an antilock

stop is made, the modulator solenoids pulsate and an

audibleburstof aircanbe heardfromoutside ofthecab.

Thewheelsshouldnotenteraprolonged“lock”condition.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

enginebe in operation,EXTREMECAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Useonly the propertools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems,makecertain to drain the airpressurefrom

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommendedprocedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix®replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

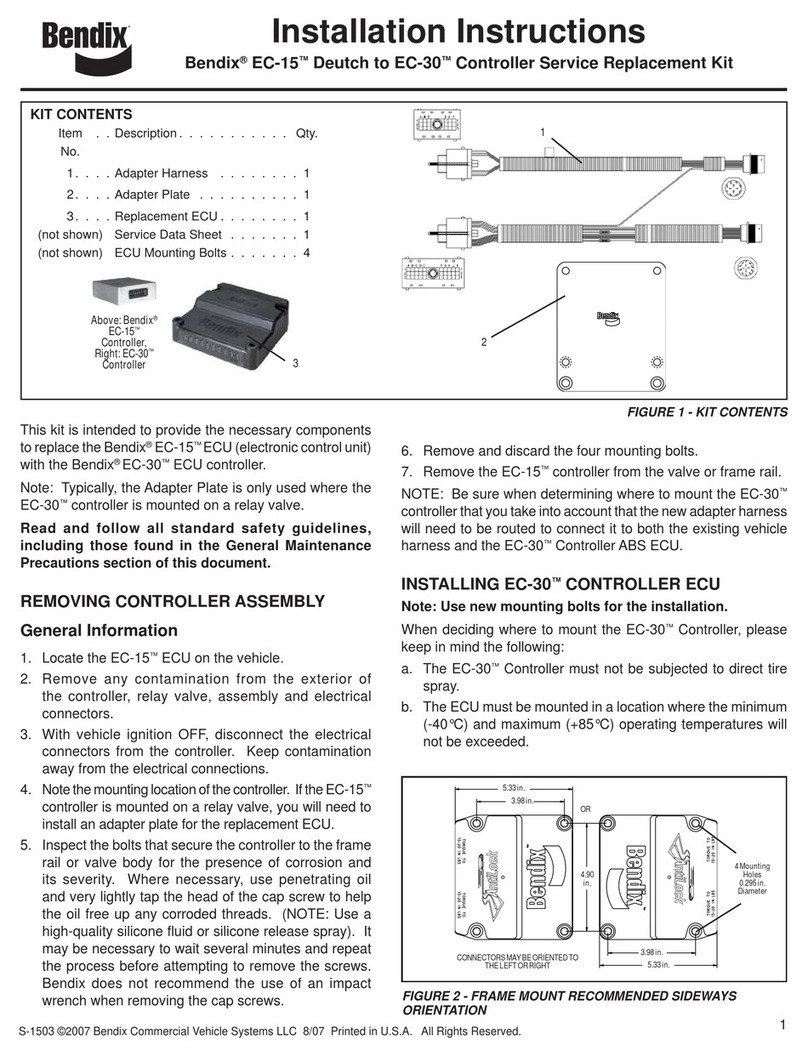

REMOVING THE EC-15™CONTROLLER

ASSEMBLY

EC-15™CONTROLLERMOUNTEDONANTILOCKRELAY

VALVE

1. Identifyand remove all airlines connected totheunit.

2. Disconnectthe electricalconnector(s) fromthe EC-15™

controller.

3. Note and mark the mounting position of the controller/

relay valve assembly on the vehicle. Loosen, remove

and save the nuts on the mounting hardware that

attaches the controller relay assembly bracket to the

vehicle.Remove the relayvalve andEC-15™controller

assemblyfrom thevehicle.

4. Remove as much contamination as possible from the

exterior of the assembly making sure to keep the

contaminationaway fromtheopen ports.

5. Note and mark the position of the EC-15™controller

relative to the antilock relay valve. Remove and retain

the four cap screws that secure the EC-15™controller

totheantilockrelayvalve.Carefullyseparate theEC-15™

controller from the antilock relay valve making certain

nottodamage thegasketbetweenthe twocomponents.

Peel the gasket from the EC-15™controller or antilock

relayvalveand retainforreuse.Note:Use anewgasket

if damaged during removal or if a new gasket is

immediatelyavailable.