10

DECLARATION OF

CONFORMITY

The machines described in

this manual comply with Di-

rectives 2006/42/EC; 2014/30/

UE; 2014/35/UE; 2011/65/UE,

Regulation (EC) 1935/2004.

The applicable harmonised

standards are: EN 12331 IPX2

Grade, EN 60204-1.

DESCRIPTION

Professional Meat Mincer

machines suitable for cut-

ting only the food products

of the types and within the

dimensional limits indicat-

ed in this manual. The main

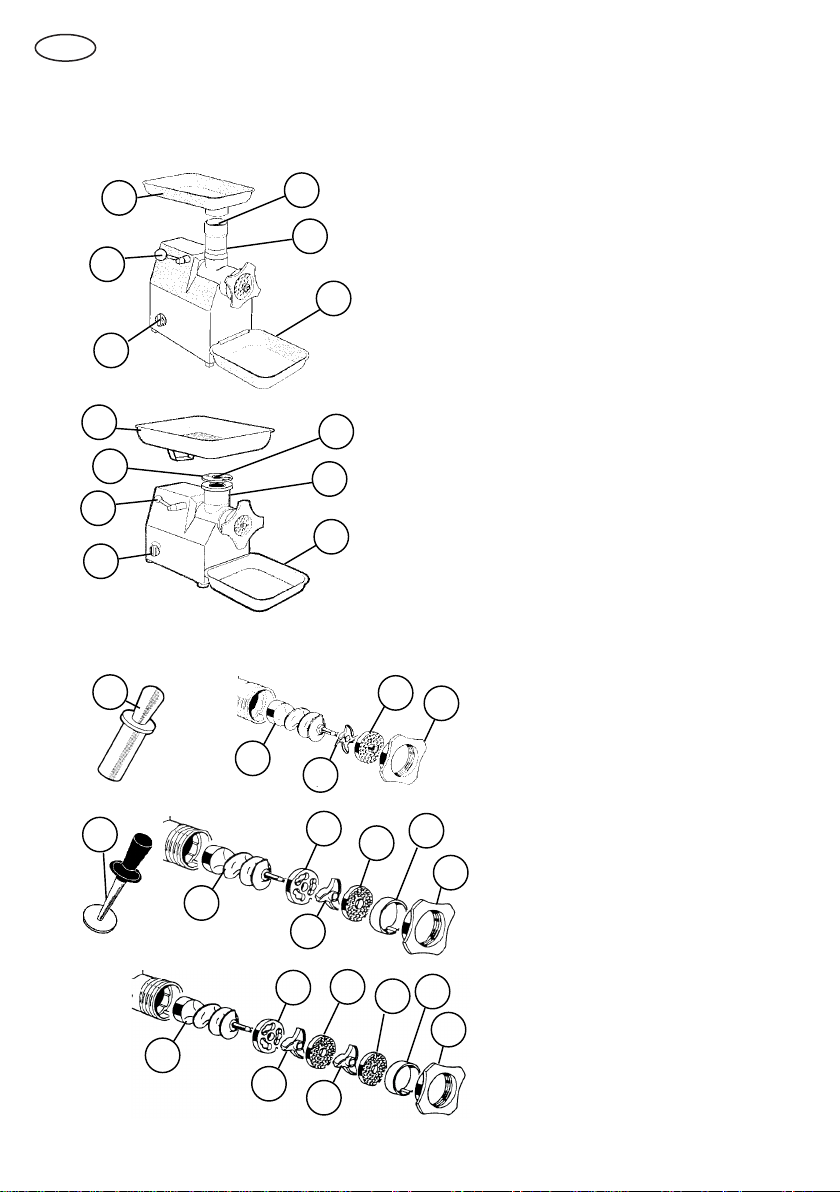

parts of the machine are

shown in the general com-

ponent diagram reported in

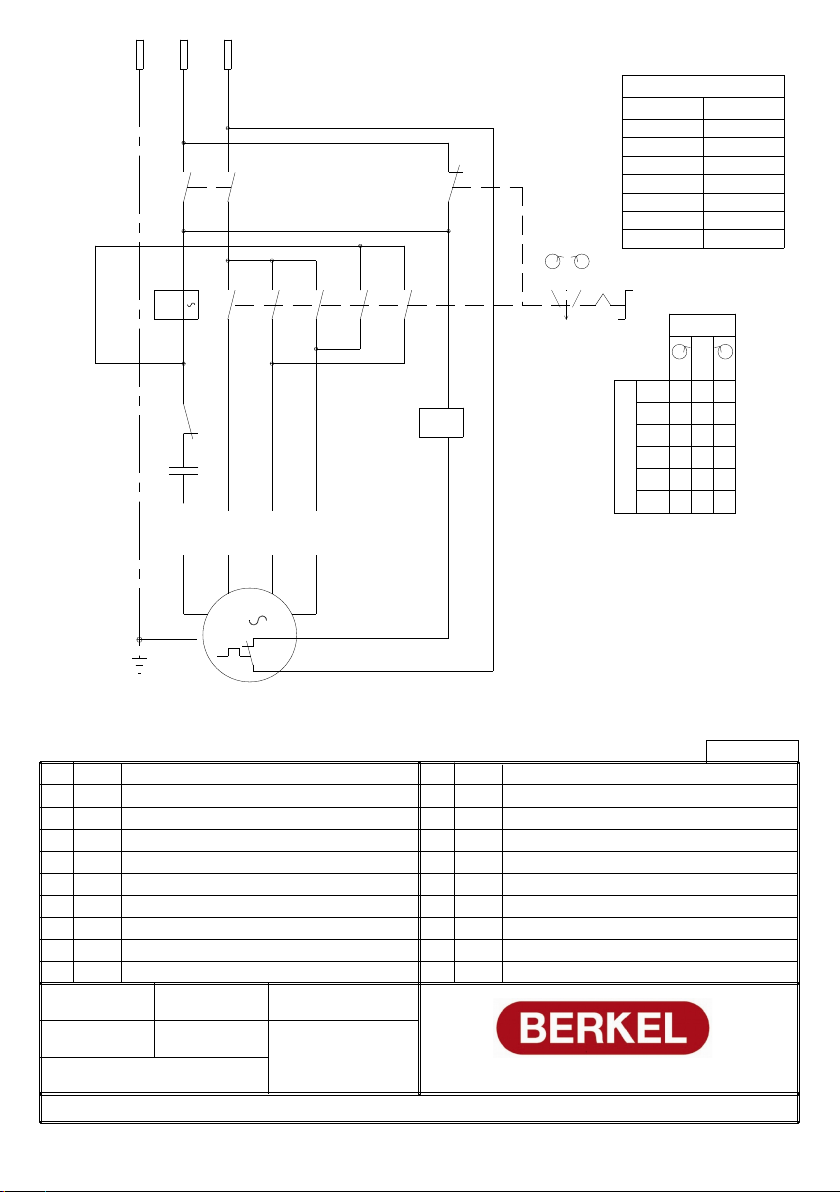

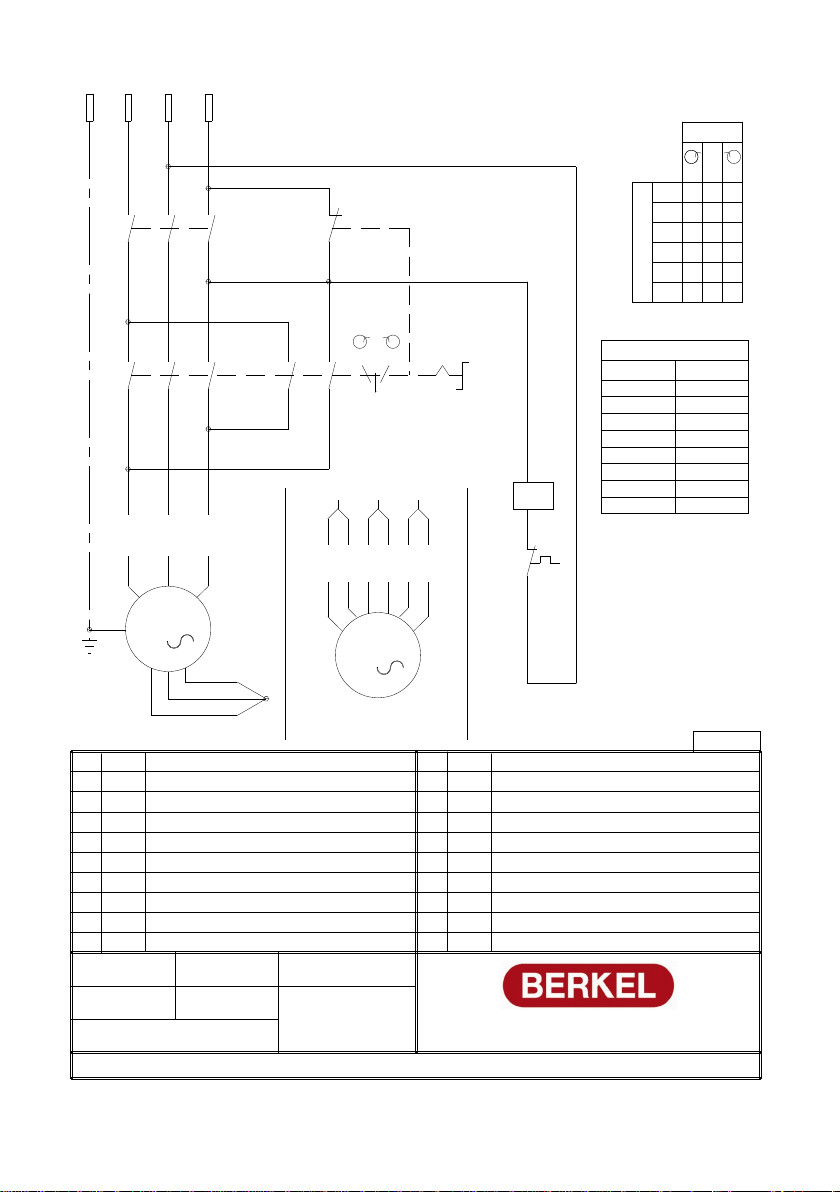

Fig. A. Electrical diagrams are

reported in Fig. B.

These appliances are intend-

ed to be used for commercial

applications, such as kitch-

ens in restaurants, canteens,

hospitals and in commercial

enterprises such as butchers

etc., but not for the contin-

uous production of food in

series.

The mincers are made of se-

lected materials that make

the machine particularly ro-

bust. The materials used in

their construction, anodized

aluminium and stainless

steel, have been selected in

accordance with the relevant

hygiene standards and main-

tain the machine in its origi-

nal condition over time.

-The high motor power pro-

vides high production capac-

ity

- No hand-arm vibration.

-Simple design with smooth

parts without sharp edges

provide for easy cleaning and

a practical use of the ma-

chine.

-The pusher is made in a

plastic material t for contact

with food- stuffs.

-The nal part of the cutting

unit is tted with an EDISON

screw thread according to

the USA NSF standard 8.

-Due to the particular con-

struction of the cutting unit

it is possible, in exceptional

circumstances, to place it in

a refrigerator. Such operation

does not exclude the neces-

sity of daily cleaning.

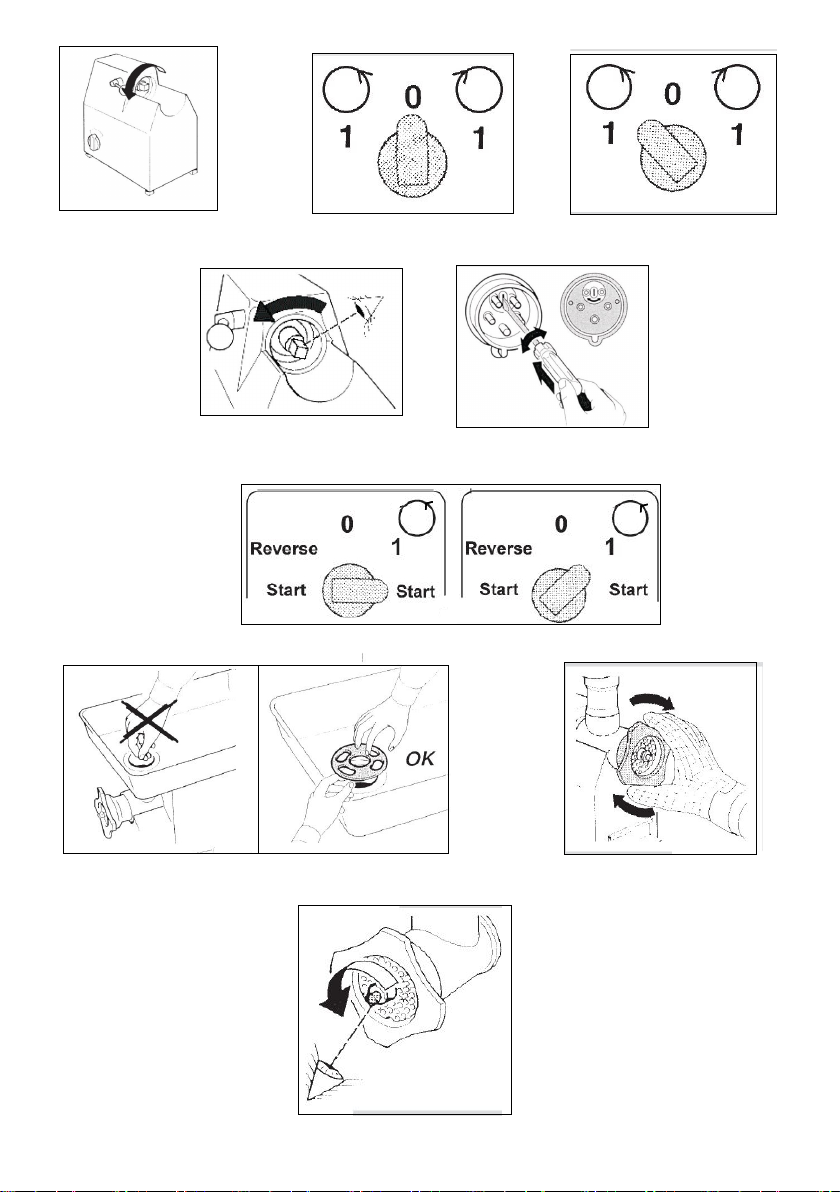

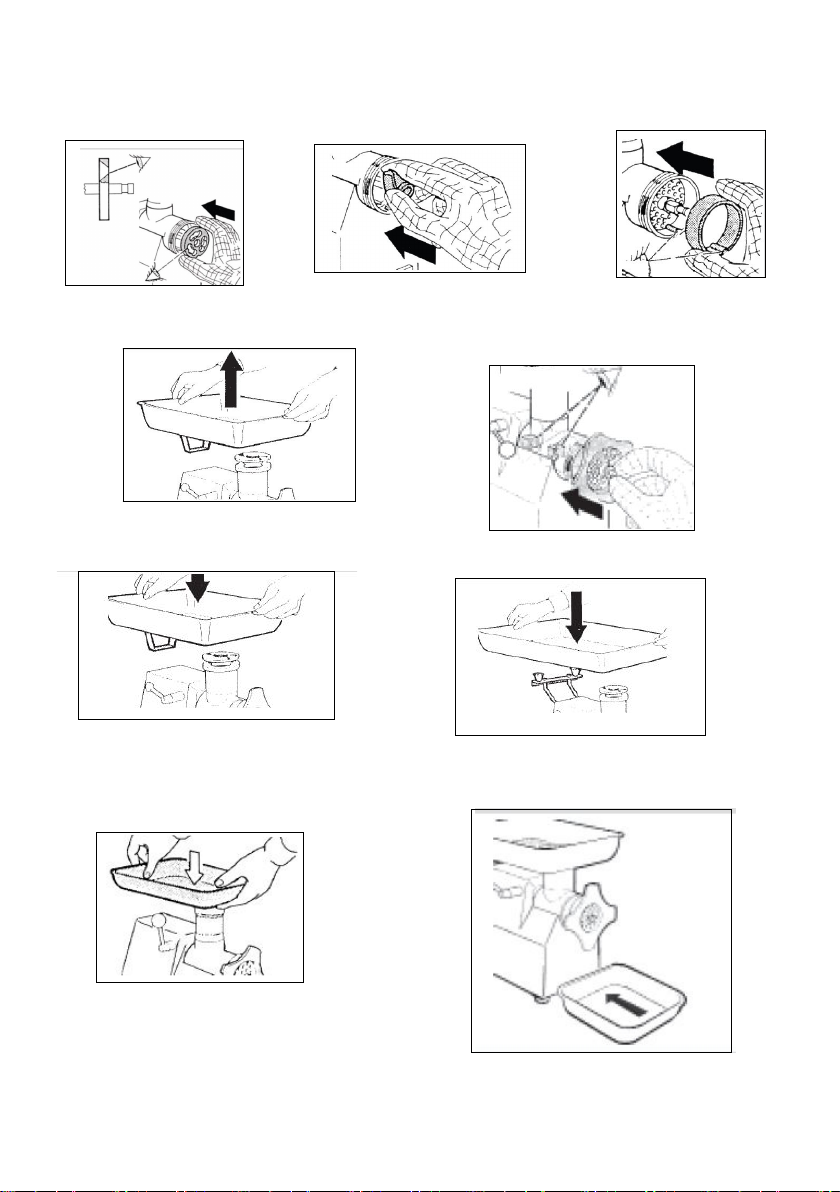

-The easy assembly and dis-

assembly of the components

simplify the use and mainte-

nance of the machine.

MACHINE IDENTIFICATION

In any communication with

the manufacturing company

always quote the serial num-

ber indicated on the identi-

cation label of the machine.

SAFETY

Pay attention to the follow-

ing basic safety precautions:

-read all the instructions be-

fore using the machine;

-operate the machine only if

properly trained and in per-

fect psycho-physical condi-

tions;

-the appliance can be used

by children under the age

of 8 and by people with re-

duced physical, sensory or

mental abilities, or without

experience or the necessary

knowledge, as long as they

are supervised or after they

have received instructions re-

lating to the safe use of the

appliance;

-cleaning and maintenance

intended to be carried out by

the user must not be carried

out by unsupervised chil-

dren;

-do not use the machine in

any way other than what in-

dicated in this manual;

-use the machines only in full

structural, mechanical and

system efciency;

-install the machine in con-

formity to the instructions

indicated in the “Installation”

section;

-install the machine in a lo-

cation out of the reach of

personnel unauthorized to

operate it;

-stay highly concentrated

when using the machine

and avoid any distraction

during use;

do not allow the machine

to be used by others who

have not read and fully un-

derstood the content of this

manual;

-do not wear baggy cloth-

ing or clothing with open

sleeves;

-do not allow anyone else,

other than the operator, to

approach during product

cutting operations;

-do not remove, cover or

modify the tags located on

the machine body and, in

case of damage of these, re-

place them promptly;

-do not remove and do not

modify or bypass any me-

chanical and electrical pro-

tective devices;

-mince only the permitted

products, do not attempt to