Page 1 Of 15 26.08.2014

See. 1.3 Copyright Berner Kochsysteme 2017

Table

Table.............................................................................................................................................1

Safety ...........................................................................................................................................2

Safety regulations ...........................................................................................................................3

Description of Hazard Symbols .......................................................................................................3

Dangers in case of non-compliance with safety regulations .................................................................3

Safe use .....................................................................................................................................3

Safety regulations for operators......................................................................................................3

General..........................................................................................................................................4

Application ..................................................................................................................................4

Product ..........................................................................................................................................4

Products .....................................................................................................................................4

Technical data..............................................................................................................................4

Operation and control ................................................................................................................4

Technical device data .................................................................................................................4

Funktionsbedingungen ...............................................................................................................4

Installation.....................................................................................................................................5

Electrical data of the devices ..........................................................................................................5

Devices by power (3,2 kW, BBFSM).............................................................................................5

Devices by power (4.8 kW, BBFSMXL) ..........................................................................................5

Installationsvorrausetzungen .........................................................................................................5

Installationsvorschriften ................................................................................................................5

Commissioning ...............................................................................................................................6

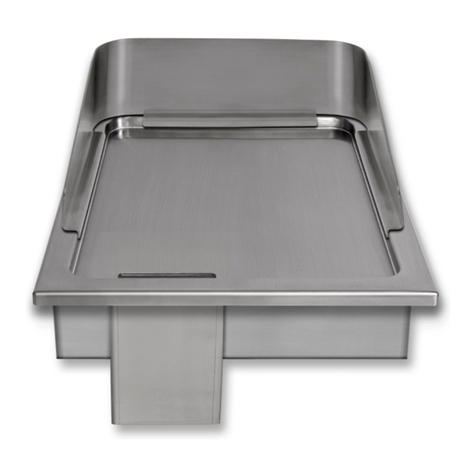

Mounting.....................................................................................................................................6

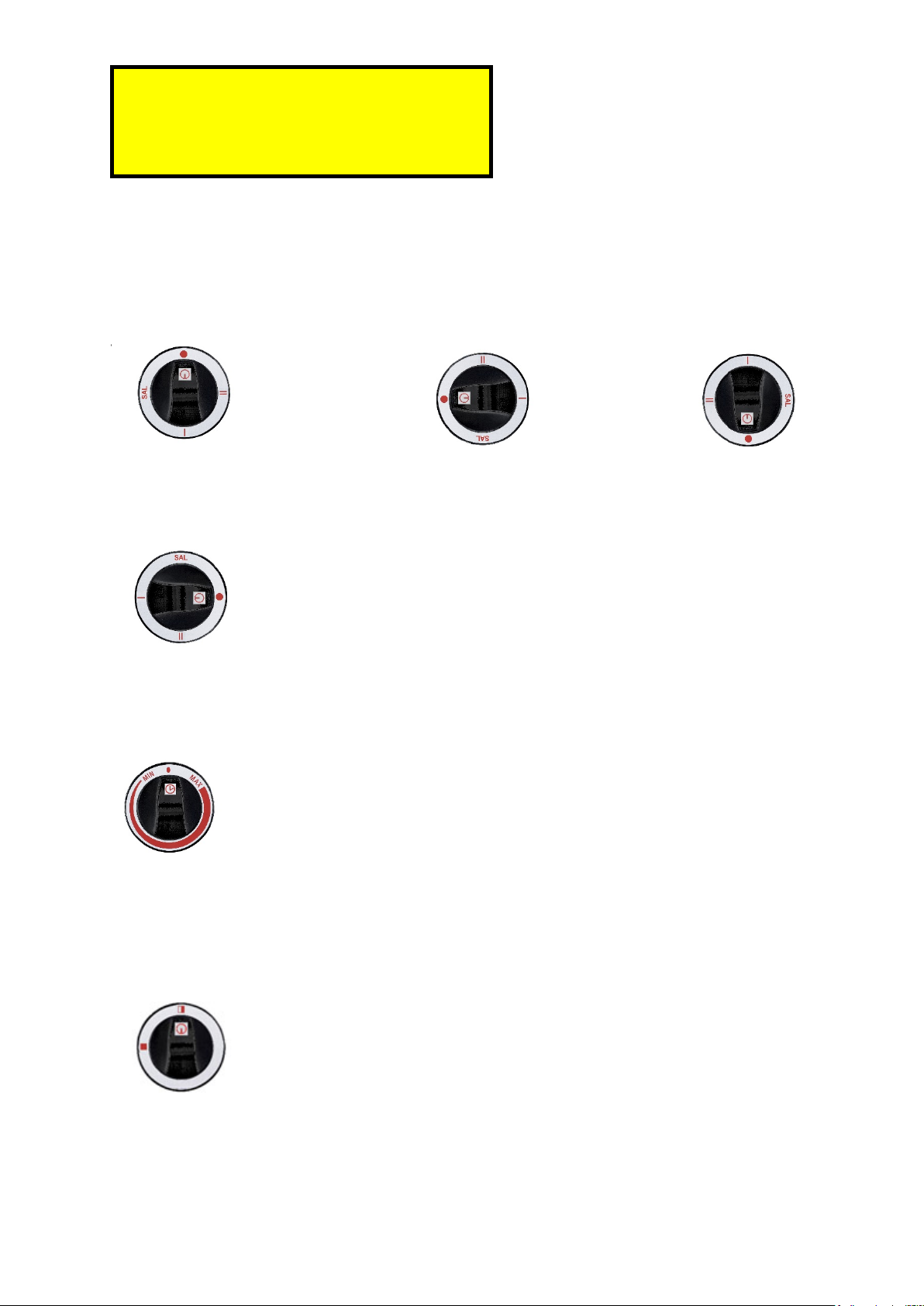

Controls ......................................................................................................................................7

Gag main switch........................................................................................................................7

Gag time setting: ......................................................................................................................7

Operation.......................................................................................................................................8

Improper operation.......................................................................................................................8

Changes / use of spare parts..........................................................................................................8

Monitoring of the heating zone .......................................................................................................8

Decommissioning ............................................................................................................................9

Fehlerfindung .................................................................................................................................9

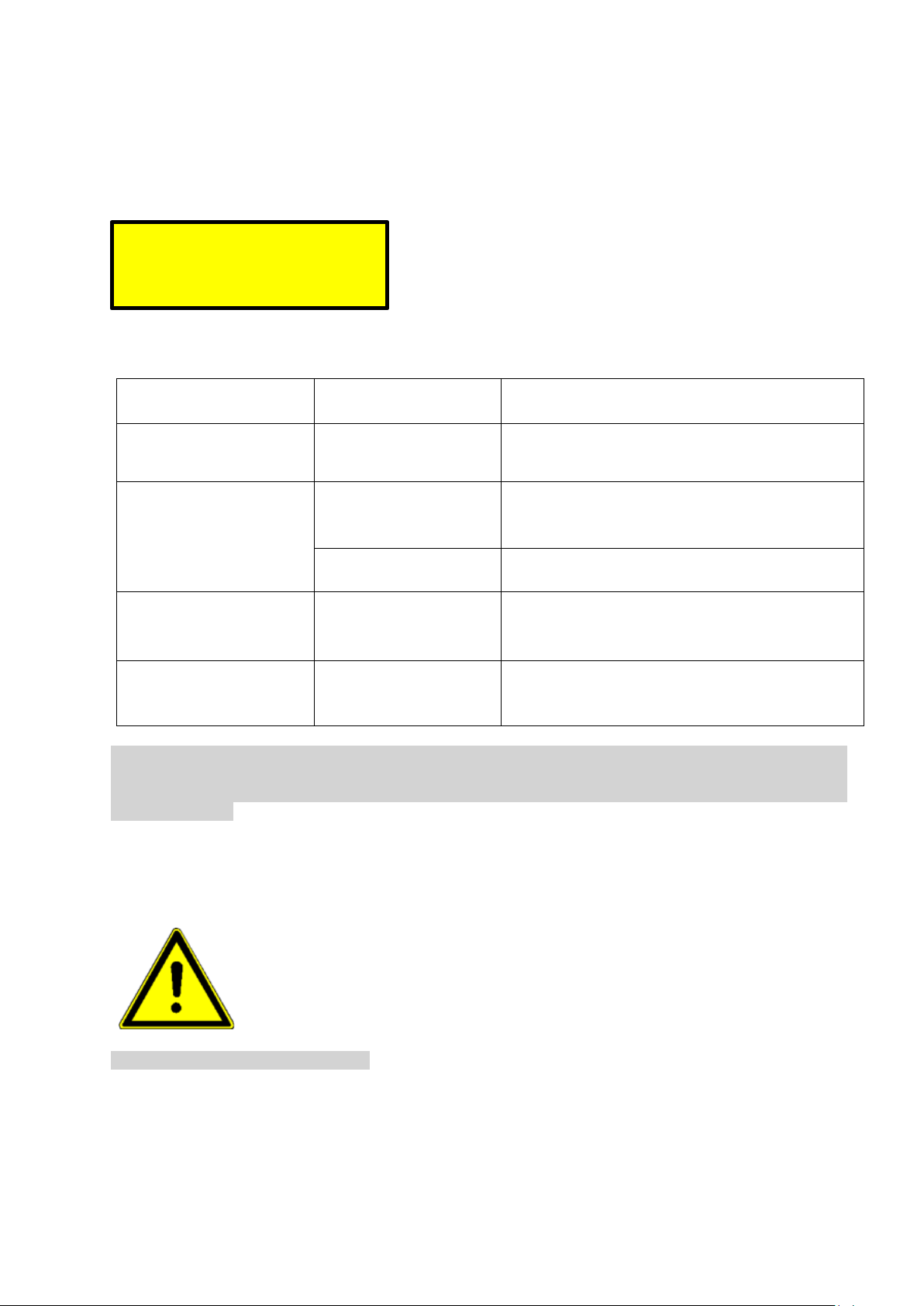

Troubleshooting ..............................................................................................................................9

Cleaning ........................................................................................................................................9

Maintenance .................................................................................................................................10

Disposal....................................................................................................................................... 10

Warranty................................................................................................................................... 10

Repair during the warranty period................................................................................................. 10

List of spare parts BBFSM ............................................................................................................... 11

Schematic BBFSM....................................................................................................................... 12

List of spare parts BBFSMXL............................................................................................................13

Schematic BBFSMXL ................................................................................................................... 14