Page 1 von 30 13.06.2014

Ver. 2.9 Copyright ©Berner Kochsysteme 2018

Summary

Summary................................................................................................................................. 1

Security indications ................................................................................................................... 3

Security regulations ............................................................................................................... 4

Description of danger symbols .................................................................................................. 4

Risks of the non-observance of the security regulations ............................................................... 4

Safe usage ............................................................................................................................. 4

Safety regulations for operators................................................................................................ 5

Improper usage ...................................................................................................................... 5

Modifications / usage of spare parts........................................................................................... 5

General.................................................................................................................................... 5

Application ............................................................................................................................. 6

Description of the product...................................................................................................... 6

Products................................................................................................................................. 6

Technical data........................................................................................................................ 6

Operation and control .............................................................................................................. 6

Technical data of the units........................................................................................................ 7

Functional conditions ............................................................................................................... 7

Installation............................................................................................................................... 8

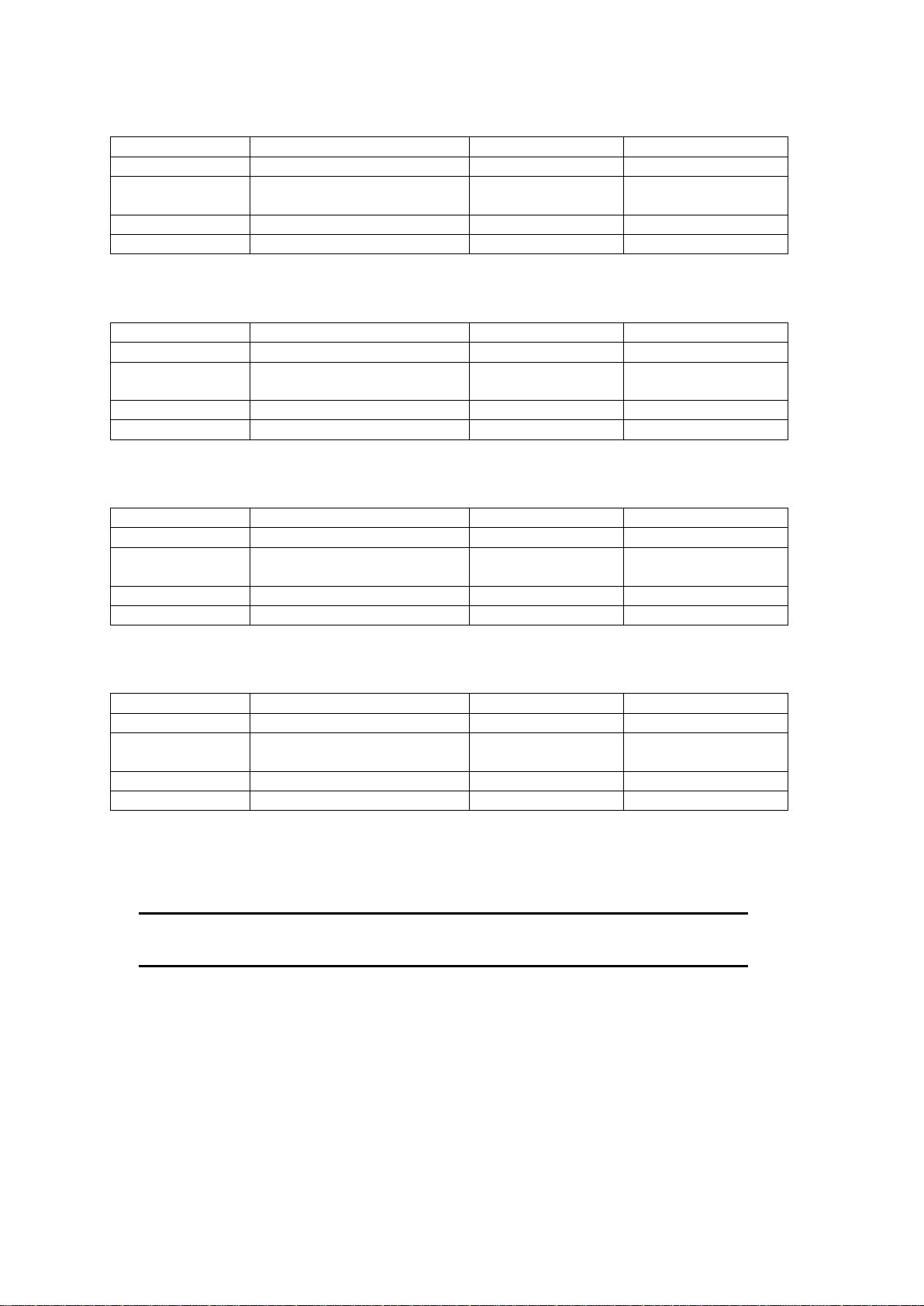

Electrical data of the units (8,0 kW)........................................................................................... 8

BKEA2/3, BKEA2/3H, BKEA2/3E, BKEA2/3HE, BKE2/3, BKE2/3E ................................................... 8

Electrical data of the units (10,0 kW)......................................................................................... 8

BKE1/1, BKE1/1E.................................................................................................................... 8

Electrical data of the units (12,0 kW)......................................................................................... 8

BKEA1/1, BKEA1/1E, BKEAQ1/1, BKEAQ1/1E, BKEAK1/1, BKEAK1/1E ........................................... 8

Electrical data of the units (15,0 kW)......................................................................................... 8

BKES1/1, BKES1/1E ................................................................................................................ 8

Installation conditions.............................................................................................................. 9

Installation instructions............................................................................................................ 9

Taking the unit into service.................................................................................................... 9

Installation............................................................................................................................. 9

Operation with 3 power level main switch knob & thermostat ..................................................... 10

Electronic control with potentiometer and digital display with 4 digits (E) ..................................... 11

Electronic control with digital touch panel (ESRTN).................................................................... 11

Automatic basket lift.............................................................................................................. 12

Functionality test ................................................................................................................. 13

BKEA, BKE ........................................................................................................................... 13

BKEA_E, BKE_E .................................................................................................................... 13

Operation ............................................................................................................................. 14

Cooking process.................................................................................................................... 14

Water tap............................................................................................................................. 14

Standard water drain:............................................................................................................ 14

Water drain (WAS) Optional.................................................................................................. 14