English 8 English

Installation and Operator Instructions

Read this entire section before installation or operation of

the machine.

Location and Environment

This machine will operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable

operation.

Do not place or operate this machine on a surface with

an incline greater than 10° from horizontal.

Do not use this machine for pipe thawing.

This machine must be located where there is free

circulation of clean air without restrictions for air

movement to and from the air vents. Do not cover the

machine with paper, cloth or rags when switched on.

Dirt and dust that can be drawn into the machine

should be kept to a minimum.

This machine has a protection rating of IP21. Keep it

dry when possible and do not place it on wet ground

or in puddles.

Locate the machine away from radio controlled

machinery. Normal operation may adversely affect

the operation of nearby radio controlled machinery,

which may result in injury or equipment damage.

Read the section on electromagnetic compatibility in

this manual.

Do not operate in areas with an ambient temperature

greater than 40°C.

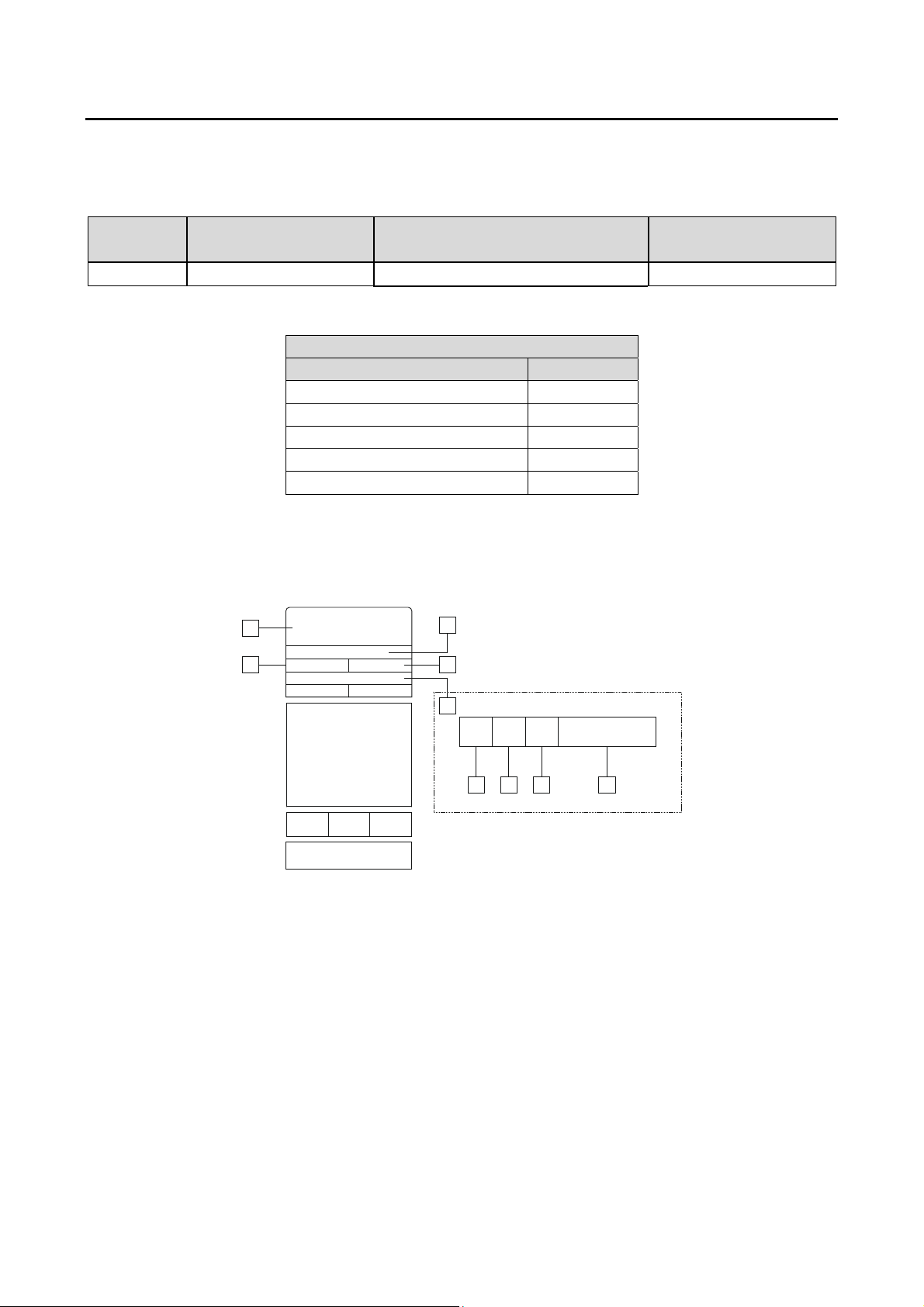

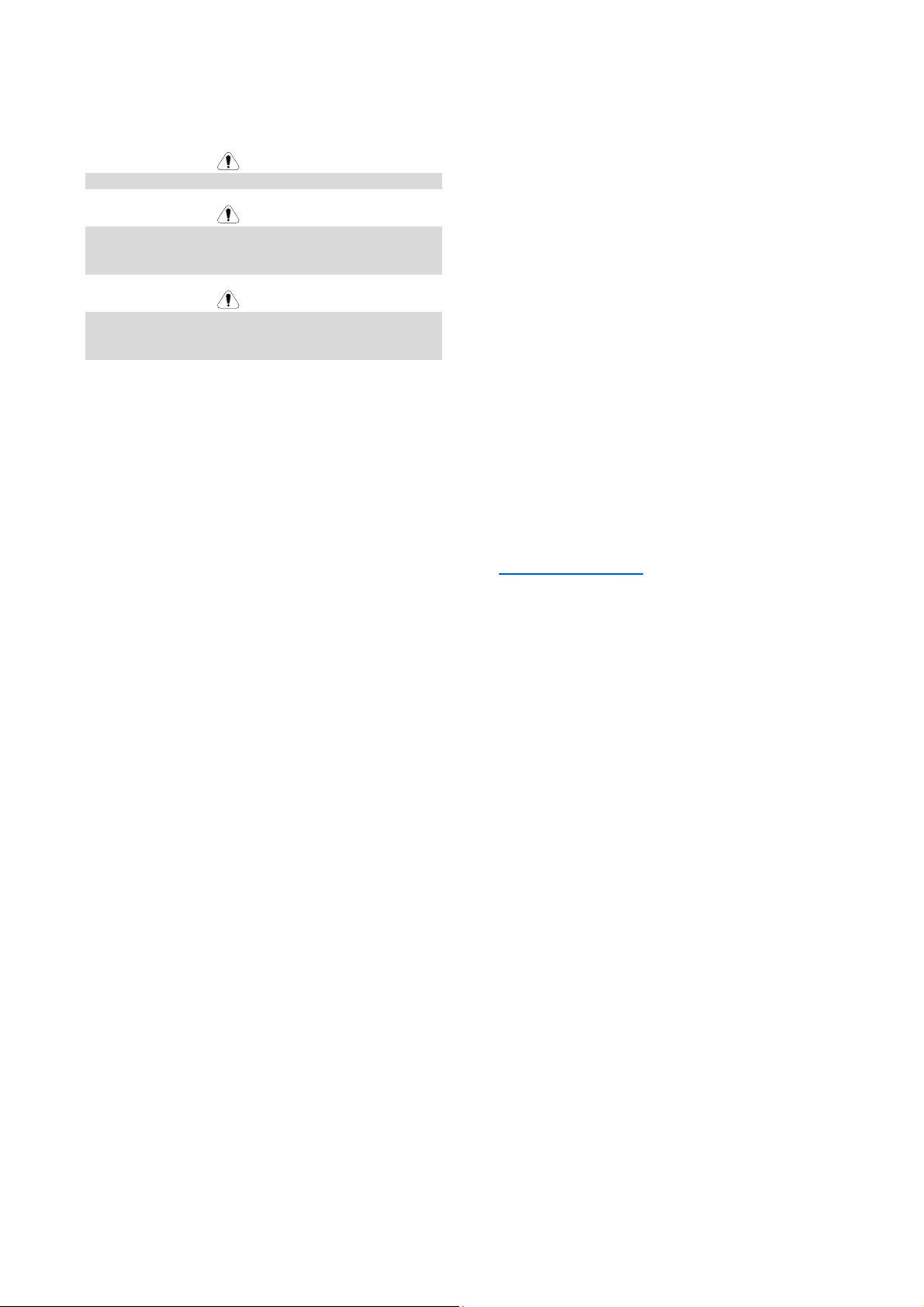

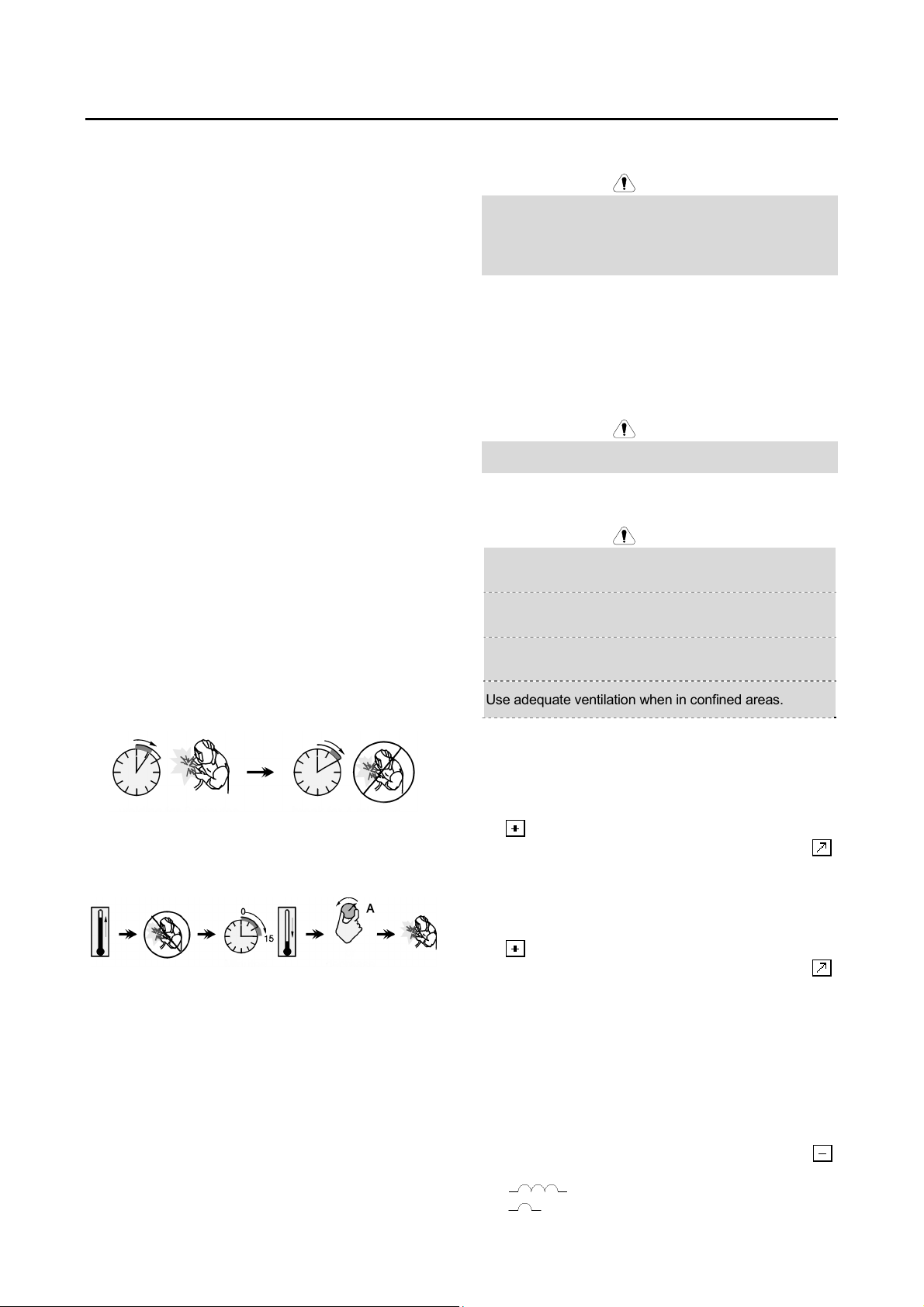

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage of

time in a 10 minute cycle at which the welder can operate

the machine at rated welding current.

Example: 60% duty cycle

Welding for 6 minutes. Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

Minutes or decrease

duty cycle

Input Supply Connection

WARNING

Only a qualified electrician can connect the welding

machine to the supply network. Installation the outlet plug

to power lead and connecting the welding machine had to

be made in accordance with the appropriate National

Electrical Code and local regulations.

Installation and mains outlet socket shall be made and

protected according to appropriate rules. Check the input

voltage, phase, and frequency supplied to this machine

before turning it on. For more information about input

supply refer to the technical specification section of this

manual and to the rating plate of the machine. Verify the

connection of grounding wires from the machine to the

input source.

WARNING

Equipment shall only be used on a supply system that is a

three-phase, four-wire system with an earthed neutral.

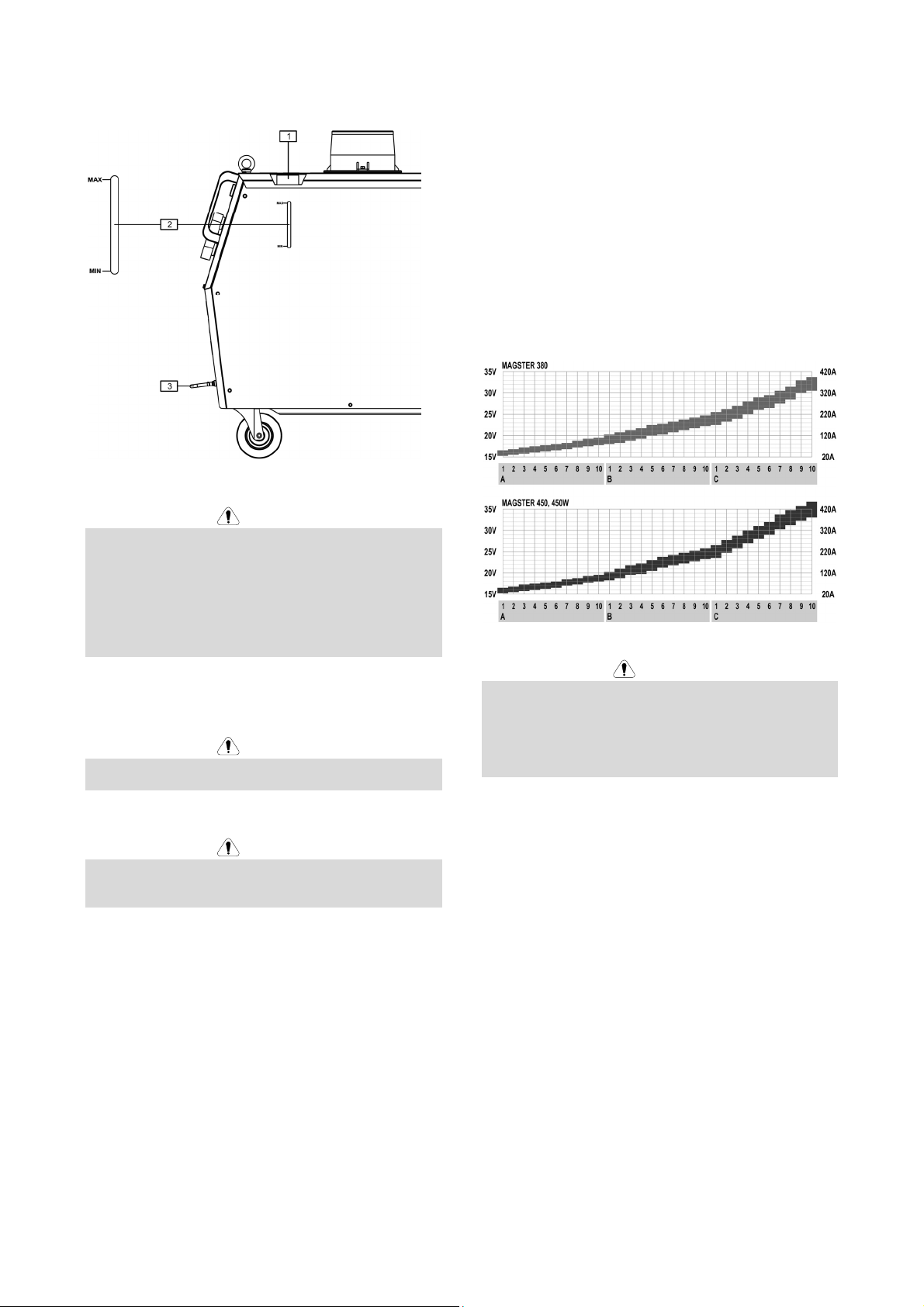

Power Source Placement

WARNING

Avoid excessive dust, acid and corrosive materials in the

air.

Keep protected from rain and direct sun when in use

outdoors.

There should be 500 mm space about for the welding

machine to have good ventilation.

Use adequate ventilation when in confined areas.

Wire Feeder Connection

To connect the wire feeder to the power source Magster

380 or 450 you should use the combined cable (see

chapter “Accessories”) and do the following:

Connect the combined cable to the socket marked by

.

Connect the control cable to the socket marked by

To connect the wire feeder to the semi power source

Magster 450W you should use the combined cable (see

chapter “Accessories”) and do the following:

Connect the combined cable to the socket marked by

.

Connect the control cable to the socket marked by .

Disconnect the hose, which closes the circuit of the

water cooling system and connect hoses to the

welding source and wire feeder according to colour

marks (the blue hose to the socket with blue

bordering).

Wire diagram of the welding source and wire feeder is

shown in the chapter “Wiring Diagrams”.

Ground Cable Connecting

Connect the ground cable to one of the two sockets ,

additionally marked by:

: high inductance output socket.

: low inductance output socket.