Introduction . . . . . . . . . . . . . . . . . . . . . . . . . A3

Serial Number . . . . . . . . . . . . . . . . . . . . . . A3

Definitions of Safety and

Service Statements. . . . . . . . . . . . . . . . . A4

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . A6

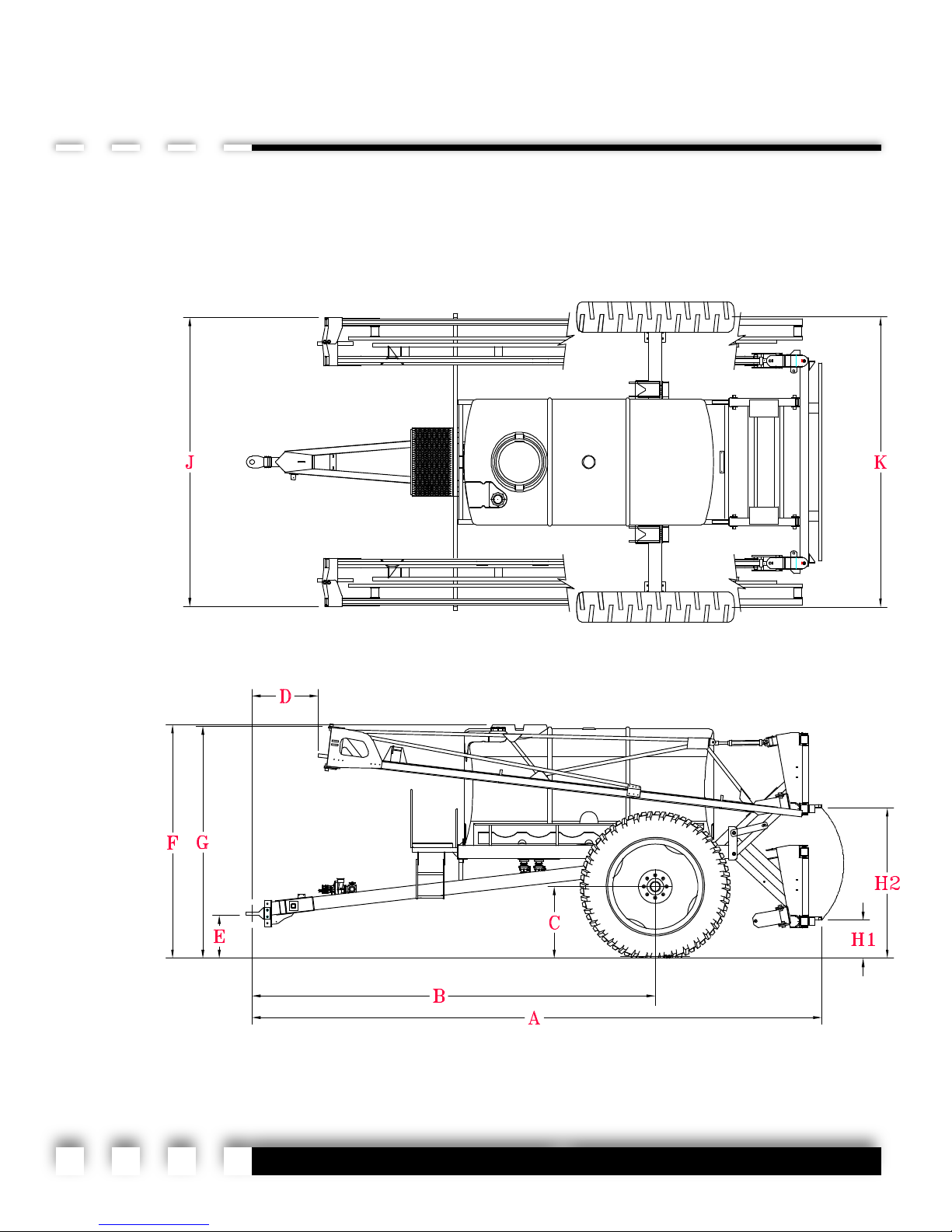

Specifications . . . . . . . . . . . . . . . . . . . . . . . A8

Safety Sign Locations . . . . . . . . . . . . . . . A10

Safety Sign Care . . . . . . . . . . . . . . . . . . . A12

Safety Information . . . . . . . . . . . . . . . . . . . . B1

Chemical Safety . . . . . . . . . . . . . . . . . . . . . B1

Equipment Safety. . . . . . . . . . . . . . . . . . . . B3

Lighting and Marking . . . . . . . . . . . . . . . . . B4

During Operation . . . . . . . . . . . . . . . . . . . . B4

Following Operation . . . . . . . . . . . . . . . . . . B4

Highway and Transport Operations . . . . . . B5

Remember . . . . . . . . . . . . . . . . . . . . . . . . . B5

Initial Preparation And Setup . . . . . . . . . . . C1

Tractor Preparation And Hookup . . . . . . . . C1

Initial Preparation Of The Sprayer . . . . . . . C5

Controller Installation . . . . . . . . . . . . . . . . . C7

Raven Controllers . . . . . . . . . . . . . . . . . . . C8

Hydraulic Boom Manifold. . . . . . . . . . . . . C14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . D1

Filling The Tank . . . . . . . . . . . . . . . . . . . . . D1

Adding and Mixing Chemicals . . . . . . . . D2

Boom Operation. . . . . . . . . . . . . . . . . . . . . D4

Extending The Boom Wings. . . . . . . . . . D5

Retracting The Boom Wings . . . . . . . . . D6

Sprayer Operation . . . . . . . . . . . . . . . . . . . D7

Foam Marker Operation . . . . . . . . . . . . . D9

Controlling Drift. . . . . . . . . . . . . . . . . . . . D9

Types Of Drift . . . . . . . . . . . . . . . . . . . . D10

Factors Affecting Drift. . . . . . . . . . . . . . D10

Managing Drift . . . . . . . . . . . . . . . . . . . D11

Spray Nozzle Selection . . . . . . . . . . . . . . D12

Spray Tip Turret . . . . . . . . . . . . . . . . . . D12

Rinsing The Sprayer . . . . . . . . . . . . . . . . D14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . E1

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . E1

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . E2

Grease Fittings . . . . . . . . . . . . . . . . . . . . E2

Wheel Bearings . . . . . . . . . . . . . . . . . . . E2

Line Strainer Maintenance . . . . . . . . . . . . . E4

Sprayer Nozzle Maintenance . . . . . . . . . . . E4

Spray Tip Care . . . . . . . . . . . . . . . . . . . . E4

Tip Replacement. . . . . . . . . . . . . . . . . . . E5

Boom Breakaway Adjustment . . . . . . . . . . E6

Inner Section Adjustment . . . . . . . . . . . . E6

Outer Section Adjustment. . . . . . . . . . . . E7

Variable Ride Boom Suspension . . . . . . . . E8

Tire Pressure . . . . . . . . . . . . . . . . . . . . . . E10

Wheel Bearing Replacement . . . . . . . . . . E10

Tread Width Adjustment . . . . . . . . . . . . . . E11

Preparation For Storage. . . . . . . . . . . . . . E13

roubleshooting. . . . . . . . . . . . . . . . . . . . . . F1

Field-Pro IV Operation . . . . . . . . . . . . . . . . F1

Parts Listing. . . . . . . . . . . . . . . . . . . . . . . . . G1

1,200 Gallon Field-Pro IV Frame and

Tank Assembly . . . . . . . . . . . . . . . . . . . . G1

Base Plumbing details . . . . . . . . . . . . . . . . G7

Pro 60 Boom . . . . . . . . . . . . . . . . . . . . . . . G9

Pro 80 Boom . . . . . . . . . . . . . . . . . . . . . . G15

Hydraulic Schematic for Pro 60 Boom . . . G21

Hydraulic Schematic for Pro 80 Boom . . . G23

Pro 60 Boom Plumbing Schematic . . . . . G25

Pro 80 Boom Plumbing Schematic . . . . . . G27

Wheel / Hub Assembly . . . . . . . . . . . . . . G29

Inductor it. . . . . . . . . . . . . . . . . . . . . . . . G30

Inductor Assembly . . . . . . . . . . . . . . . . . . G31

Foam Guidance System,

Model 6 or 10 . . . . . . . . . . . . . . . . . . . . G33

9303C-HM1C-BU Pump it. . . . . . . . . . . G35

9306C-HM5C-BU Pump it. . . . . . . . . . . G36

Rinse System Assembly . . . . . . . . . . . . . G37

Deluxe Plumbing Plate W/ 4-Valve

Stack Assembly . . . . . . . . . . . . . . . . . . G39

Deluxe Plumbing Plate W/ 3-Valve

Stack Assembly . . . . . . . . . . . . . . . . . . G41

Electrical Wiring Details . . . . . . . . . . . . . . . H1

Field Pro IV 1200 Base Wiring Details . . . H1

Field Pro IV Light WIring Detail . . . . . . . . . H3

A2

ABLE OF CON EN S