BIFFI ICON3000 Series Installation guide

Biffi ICON3000

FF2000v4 FoundationtM Fieldbus Module

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

April 2021

Copyright © Biffi. The information in this document is subject to change without notice. Updated data sheets can be obtained from our website www.biffi.it or from your nearest Biffi Center:

Biffi Italia s.r.l. - Strada Biffi 165, 29017 Fiorenzuola d'Arda (PC) – Italy PH: +39 0523 944 411 – biffi_itali[email protected]

Revision Details

Rev. Date Description Prepared Checked Approved

1 April 2021 General update (Migration to new template)

0 April 2014 Instruction FF interface module L. Piacenti A. Battaglia

Revision Details

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Revision Details

Revision Details

i

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Table of Contents

April 2021

Table of Contents

Table of Contents

Section 1: Introduction

Introduction............................................................................................................1

Section 2: Operation and Storage

Operation and Storage ............................................................................................2

Section 3: Communication Features

Communication Features.........................................................................................3

Section 4: FF2000v4 rev. 3 Module

4.1 On Board Indications..................................................................................... 4

Section 5: Foundation™ Fieldbus Overview

5.1 Foundation Fieldbus Technology ..................................................................... 6

5.1.1 Physical Layer ..................................................................................... 6

5.1.2 Communication Stack ........................................................................ 7

5.1.3 User Application Layer - Blocks ........................................................... 7

5.2 Fieldbus Topology and Wiring ....................................................................... 9

5.2.1 Cable Selection ................................................................................ 10

5.3 Terminators ................................................................................................ 10

5.4 Shielding..................................................................................................... 11

5.5 Link Master Capabilities............................................................................... 11

5.6 Field Diagnostic Profile................................................................................ 12

5.7 Device Replacement.................................................................................... 15

Section 6: Function Blocks Description

6.1 Function Block: DO ..................................................................................... 16

6.1.1 DO Channels .................................................................................... 17

6.1.2 Discrete Output Channel Interlocks .................................................. 18

6.2 Function Block: DI ....................................................................................... 19

6.2.1 DI Channels ...................................................................................... 20

6.3 Function Block: AO...................................................................................... 22

6.3.1 AO Channel ...................................................................................... 22

6.4 Function Block: AI ....................................................................................... 23

6.4.1 AI Channels ...................................................................................... 24

6.5 Function Block: PID ..................................................................................... 24

ii

Table of Contents

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Table of Contents

Section 7: Resource Block

7.1 Transducer Blocks ....................................................................................... 35

7.1.1 Input Output Transducer Block......................................................... 36

7.1.2 Configuration Transducer Block........................................................ 41

7.1.3 Maintenance Transducer Block ......................................................... 45

Section 8: Configuration via Local Operator Interface of

FF2000v4 rev. 3

8.1 Bus Control ................................................................................................. 53

8.1.1 DIN 1 - DIN 2 .................................................................................... 53

8.1.2 Simulation........................................................................................ 54

8.1.3 Date Syncro...................................................................................... 54

8.1.4 Blank Node....................................................................................... 55

8.1.5 Reset Node....................................................................................... 55

8.2 Positioner Function ..................................................................................... 56

8.3 Fail Safe Function ........................................................................................ 57

8.4 Viewing Transmission Information .............................................................. 57

8.5 Bus Signal Failure Indication ........................................................................ 58

Section 9: ADDENDUM for Base Card FW 7.00

9.1 Multiple Functionality of ESD Command and Status .................................... 59

9.2 Multiple Functionality of Interlock Command.............................................. 60

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Introduction 1

Section 1: Introduction

Section 1: Introduction

The FF2000v4 rev. 3 is an electronic module that allows to connect the Biffi electrical actuator

ICON3000 to a Foundation™ Fieldbus serial communication line. The module has its microprocessor

and it is controlled by a program stored internally, it works as a pure bus interface and does not affect

the actuator control integrity.

It is installed inside the actuator housing and the communication interface is powered directly from

the fieldbus. The data lines are fully isolated from the actuator electronics.

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Operation and Storage

2

Section 2: Operation and Storage

Section 2: Operation and Storage

The module is designed to work and to be stored in the same environment of the actuator.

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Communication Features 3

Section 3: Communication Features

Section 3: Communication Features

Communication protocol: Foundation™ Fieldbus

Electrical interface: IEC 61158-2, 2 wire communication

Bus type: H1 communication bus, Voltage Mode signalling

Data rate: 31.25 kbit/second

Transmission medium: 18 AWG shielded, twisted pair as specified in the IEC / ISA

Physical Layer Standard, Clause 22.7

Topology: Bus or tree structure

Device number: 32 devices per segment

Addressing capability: Up to 240

Bus length: 1,900 m per segment

Electrical power: Bus powered

Max. voltage 32 V

Min. voltage 9 V

Rated current In= 19 mA

Fault current Imax = 24 mA

Device capacitance: < 5 nF

Device inductance: Negligible

Temperature: -40 °C, +85 °C

EMC protections: Burst. EN 61000-4-4:1995 + A1:2001 + A2:2001

Electromagnetic compatibility (EMC)

Part 4 - 4: Testing and measuring techniques

Electrical fast transient/burst immunity test

Surge: EN 61000-4-5:1995 + A1:2001

Electromagnetic compatibility (EMC)

Part 4 - 5: Testing and measuring techniques -

Surge immunity test

Device type: Link Master or Basic Device

Field diagnostic: FD_VER 1.0

Device replacement: COMPATIBILTY_REV. 2

ITK version: 6.1.1

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

FF2000v4 rev. 3 Module4

Section 4: FF2000v4 rev. 3 Module

Section 4: FF2000v4 rev. 3 Module

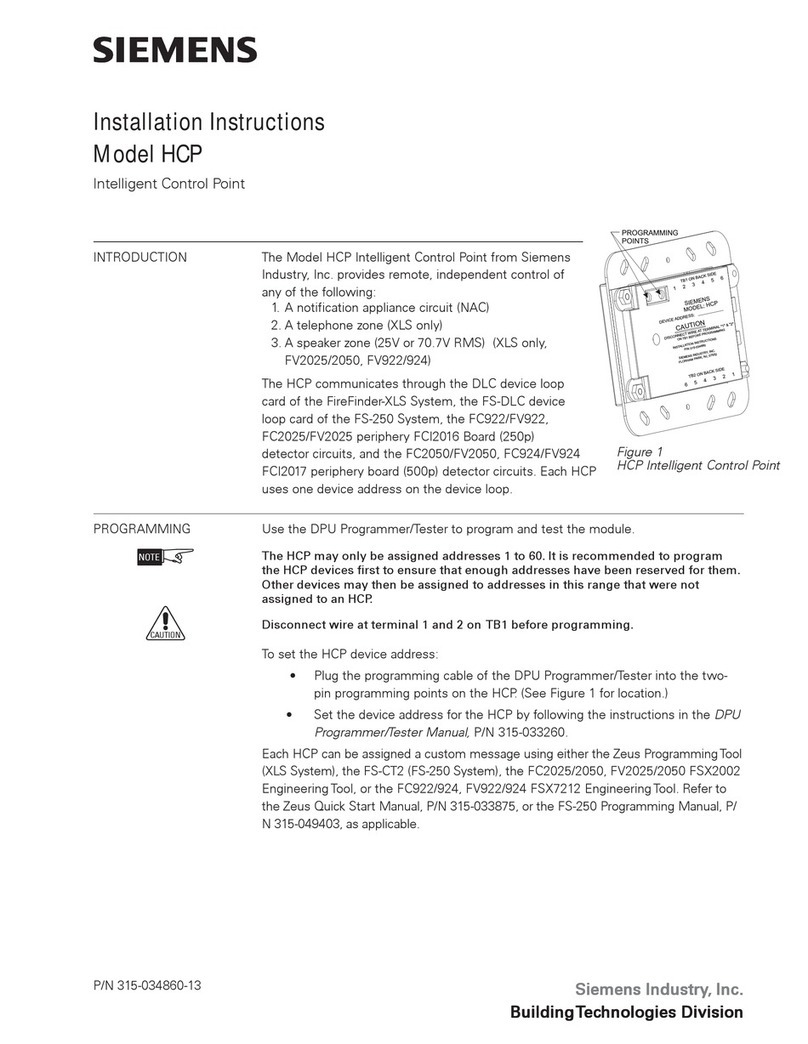

The module consists in a single PCB that is installed inside the actuator housing. It is connected to the

ICON3000 base card via strip connector.

The internal wiring connects the Foundation™ Fieldbus data lines to the actuator terminal board.

Figure 1

4.1 On Board Indications

Four LEDs are mounted on the FF2000v4 rev. 3 to give the following indications for the field service.

LEDs indicators are active only when jumper JP1 is closed. There is also the SW1 switch button that

performs a reset of the FF2000v4 rev. 3 card.

DL4 (red) Base comm: BLINK or ON: when the communication between the base card

and the interface is not working properly.

OFF: when the communication between the base card and the

interface is working properly.

DL3 (red) Data area empty: ON: when Data Area on interface card is not yet loaded.

BLINK: when Data Area is being read from base card.

OFF: when Data Area is completely loaded.

DL2 (green) FF module comm: BLINK: The communication between the interface card and FF bus

module is working properly.

OFF or ON: The communication between the interface card

and FF bus module is not working properly.

DL1 (green) Power: ON: when the FF2000v4 rev. 3 is correctly powered from the main

power supply.

OFF: when the FF2000v4 rev. 3 is not powered from the main

power supply.

SW1 DL4 DL3 DL2 DL1 JP1

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Foundation™ Fieldbus Overview 5

Section 5: Foundation™ Fieldbus Overview

Section 5: Foundation™ Fieldbus Overview

Foundation Fieldbus is an open networking standard which provides an open specification for both the

control application and the communication on the bus.

Foundation Fieldbus communication protocol is an industry proven international standard

(IEC 61158-2) designed for use in the process industry and also complies with the ISA-SP50

recommendation for fieldbus devices.

The major benefits in adopting this standard includes:

• Multi-drop capability with up to 32 devices per segment;

• Extended trunk length using repeaters which increase the total bus length and the number

of devices in the network;

• Power and communications over the same shielded twisted pair network that allow to know

the physical status of ICON3000 actuator even if it is without actuator mains power;

• Distribution of the control into the field devices reducing the amount of control equipment

in the plant.

This last item is one of the more advantages of Foundation Fieldbus which uses standards ‘Function

Blocks’ and Device Descriptions to implement control strategy. Function Blocks are standardized

automation functions with defined behaviour used to represent different type of functions such

as discrete input (DI), discrete output (DO), analog input (AI), analog output (AO), Proportional /

Integral / Derivative (PID), etc.

Furthermore, every Foundation Fieldbus device has a Resource Block and at least a Transducer Block.

Once the hardware of a Foundation Fieldbus device is configured, fieldbus communication is used to

configure the transducer block parameters. The desired transducer functionality is associated with a

specific function block via a Channel.

The host system is used to link the function blocks together to create a control application that can

be downloaded to the devices in the segment.

More information about Foundation Fieldbus are in the documents:

• Foundation Fieldbus – Technical Overview

• Foundation Fieldbus – Wiring and installation 31.25 kbit/second, Voltage Mode,

Wire Medium Application Guide

Available at the website http://www.fieldbus.org

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Foundation™ Fieldbus Overview6

Section 5: Foundation™ Fieldbus Overview

5.1 FoundationtM Fieldbus Technology

Foundation Fieldbus technology consists of:

• Physical Layer

• Communication “Stack”

• User Application

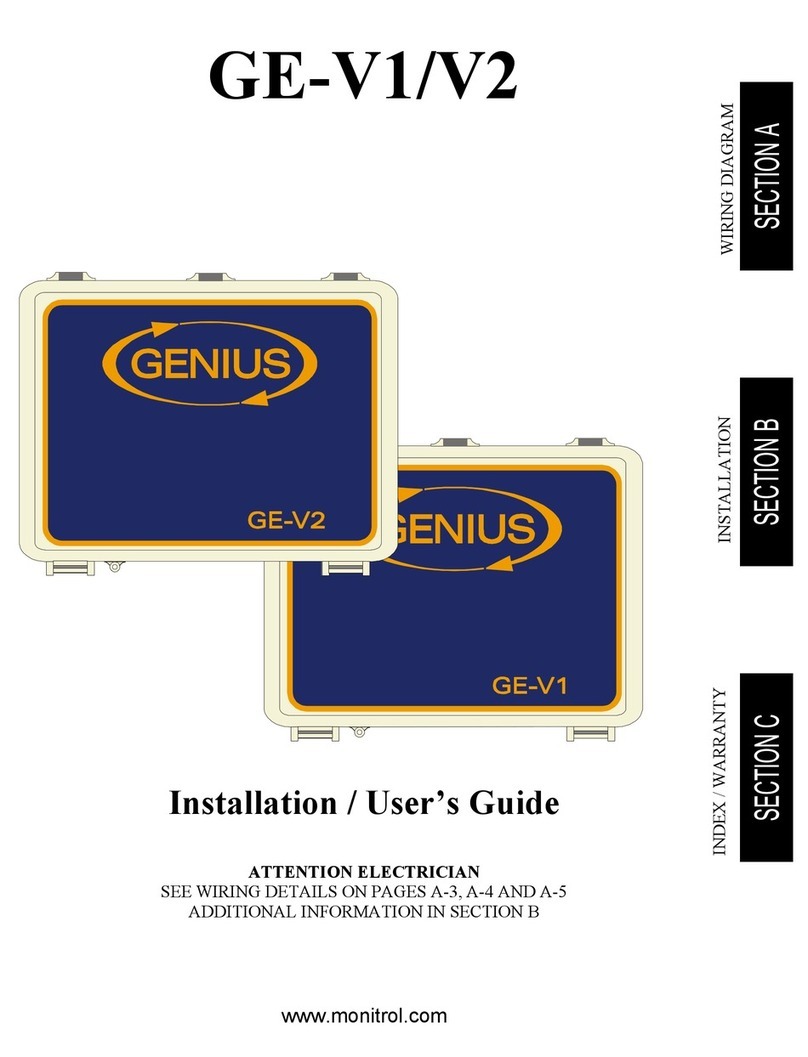

The Open System Interconnect (OSI) layered communication model is used to model these

components as shows in the following Figure:

Figure 2

The Physical Layer and the Data Link Layer correspond respectively to OSI layer 1 and layer 2.

The Communication Stack is comprised of OSI layers 2 and 7; the fieldbus protocol does not use OSI

layers 3, 4, 5 and 6.

The User Application is not defined by the OSI model. Fieldbus Foundation has specified a User

Application model that Biffi has applied for FF2000v4 rev. 3 interface.

5.1.1 Physical Layer

FF2000v4 rev. 3 implements the Physical layer standards H1 that Foundation Fieldbus defines for

field device connections. The bus communication is fixed at 31.25 kbit/second, the devices can be

powered directly from the fieldbus and operate on wiring previously used for 4 - 20 mA devices.

FF2000v4 rev. 3 module is a bus powered interface: it will continue to communicate to the other

devices in the segment even if the actuator is powered off.

H1 fieldbus also supports intrinsically safe (I.S.) applications: in this case the appropriate barriers will

be used.

Biffi electrical actuators ICON3000 and are certified explosion proof and do not require an

intrinsically safe network. To preserve hazardous area protection armoured cables or conduits

will be used.

APPLICATION LAYER 7 APPLICATION LAYER

COMMUNICATION

"STACK"

PRESENTATION LAYER 6

SESSION LAYER 5

TRANSPORT LAYER 4

NETWORK LAYER 3

DATA LINK LAYER 2 DATA LINK LAYER

PHYSICAL LAYER 1 PHYSICAL LAYER PHYSICAL LAYER

OSI model Foundation Fieldbus model

Foundation Fieldbus

USER

APPLICATION

USER

APPLICATION

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Foundation™ Fieldbus Overview 7

Section 5: Foundation™ Fieldbus Overview

5.1.2 Communication Stack

Two types of devices are defined in the Data Link Layer specification: Basic Device and Link Master.

FF2000v4 rev. 3 module acts both type, Basic Device or Link Master.

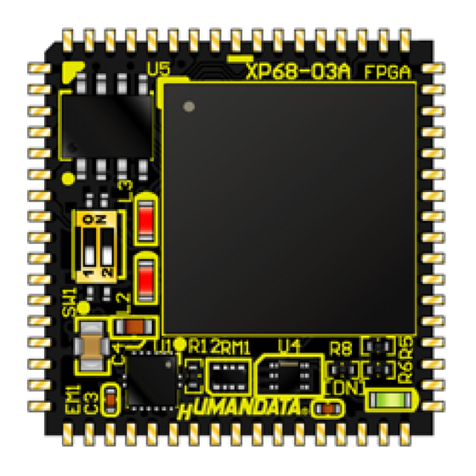

5.1.3 User Application Layer - Blocks

The Fieldbus Foundation™ has defined a standard User Application based on ‘Blocks’. Blocks are

representations of different types of application functions.

Figure 3

The following Function Blocks are implemented in the FF2000v4 rev. 3 module:

Discrete Output (DO) 8 blocks for commands to the actuator

Discrete Input (DI) 6 blocks for data coming from the actuator

Analog Output (AO) 1 block for set-point in inching service

Analog Input (AI) 2 blocks for analog data from the actuator

PID 1 block

Transducer Blocks 1 Input Output Transducer Block,

1 Configuration Transducer Block,

1 Maintenance Transducer Block

Resource Block 1 block

USER

RESOURCE

BLOCK

TRANSDUCER FUNCTION

BLOCK

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Foundation™ Fieldbus Overview8

Section 5: Foundation™ Fieldbus Overview

The following Figure shows the blocks contained in the FF2000v4 module as seen by NI-FBUS,

National Instruments configuration tool:

Figure 4

The characteristics of fieldbus devices are described by the Device Description (DD) and the

Capability File (CF) that provides an extended description of each data from the device. From the CF

file is possible achieve information about the execution time of each function block.

The blocks in the FF2000v4 rev. 3 module have the following execution time:

Table 1.

Bock Type Execution Time

Discrete Output (DO) 30 milliseconds

Discrete Input (DI) 20 milliseconds

Analog Output (AO) 30 milliseconds

Analog Input (AI) 30 milliseconds

PID 40 milliseconds

Maintenance Transducer Not Applicable

Configuration Transducer Not Applicable

Input_output Transducer Not Applicable

Resource Not Applicable

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Foundation™ Fieldbus Overview 9

Section 5: Foundation™ Fieldbus Overview

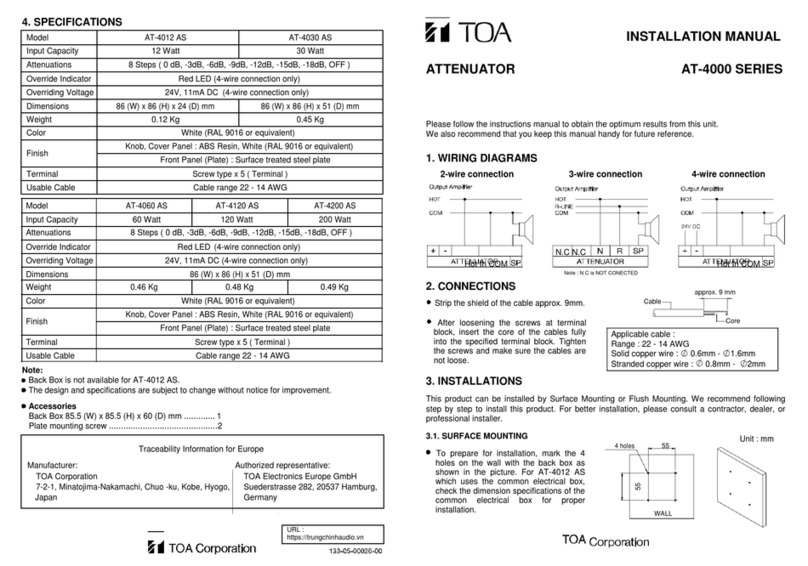

5.2 Fieldbus Topology and Wiring

General structures of H1 networks are shown in the following Figure:

Figure 5

An appropriate termination conditioning network (terminators) must be placed at the beginning

and at the end of each segment. A suitable power supply has to be added in the segments where bus

power devices are connected.

The following Table shows the types of cables indicated by IEC / ISA Physical Layer Standard.

Table 2.

Type Description Size Max Length

Type A Shielded, twisted pair 18 AWG 1,900 m

Type B Multi twisted pair with shield 22 AWG 1,200 m

The total length of the H1 fieldbus is determined by several factors as the cable type, I.S. option and

also the total spurs length has to be considered in the total fieldbus length.

Furthermore, it is also necessary to grant to each bus powered device the minimum requested

voltage to work properly since the cable length will cause a voltage drop over the line.

The FF2000v4 rev. 3 module is a bus powered device and it will work with the following

electrical parameters:

Voltage supply: minimum 9 V DC

maximum 32 V DC

Current drain: nominal 19 mA

maximum (fault) 24 mA

Point to Point Daisy Chain Bus with spurs Tree

Fieldbus I/O

segments

spurs Junction

Box

V0= 24 V DC

L2= 200 m

V1= 20.5 V DC V2= 20.5 V DC V3= 19.9 V DC V4= 19.9 V DC

V5= 19.9 V DC

V6= 19.9 V DC

Fieldbus I/O

Fieldbus Power Supply

H1 segments

L1= 800 m

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Foundation™ Fieldbus Overview10

Section 5: Foundation™ Fieldbus Overview

NOTICE

Each spur has been considered 3 m long.

As shown in the Figure, the current drawn by the actuators cause a voltage drop of 5.8 V on the

Section L1and a voltage drop of 0.9 V on the Section L2.

5.2.1 Cable Selection

The preferred cable is specified in the IEC / ISA Physical Layer Standard, Clause 22.7.2 for conformance

testing and it is referred to as “Type A” fieldbus cable.

Belden 3076F is a “Type A” fieldbus cable. The following Table shows the electrical characteristics:

Table 3.

Belden 3076F

Description 18 AWG (7x26) Tinned Copper conductor, Polyethylene

insulation, Aluminium Foil-Polyester Tape (Beldfoil) shield

Shielding 100% shield coverage

Size 18 AWG (0.78 mm2)

Nominal Resistance 24 Ω/km @ 25 °C

Nominal Mutual Capacitance 78.7 pF/m @ 1 KHz

Nominal Impedance 100 Ω @ 31.25 KHz

Temperature rating -40 to +105 °C

5.3 Terminators

Each segment must be properly connected to a termination conditioning network (terminators)

placed at the beginning and at the end of each segment.

The terminators prevent distortion and signal loss and are typically purchased and installed as a

pre-assembled sealed module.

The actuator is not equipped with termination facilities.

The following Figure shows an H1 segment where 6 actuators are connected in a tree structure;

the example highlight the voltage at each device:

Figure 6

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Foundation™ Fieldbus Overview 11

Section 5: Foundation™ Fieldbus Overview

5.4 Shielding

When using shielded cable, connect each spur’s shield to the trunk shield and connect the overall

shield to ground at one point. Do not connect the spur’s shield in to the actuator ground.

Figure 7

5.5 Link Master Capabilities

FF2000v4 rev. 3 has Link Master (LM) capabilities; It contains Link Active Scheduler (LAS)

functionality, that can control communications on H1 fieldbus Link.

The LAS schedules and controls the segment communication. There must be at least one LM on an

H1 Link; one of those LM devices will be elected to serve as LAS. In a redundant system containing

multiple Link Masters, one of the Link Masters will become the LAS if the active LAS fails.

The LM functionality could be enabled or disabled by the configuration utility.

Figure 8

FoundationtM

Fieldbus

Interface

FD = Field Device

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Foundation™ Fieldbus Overview12

Section 5: Foundation™ Fieldbus Overview

5.6 Field Diagnostic Profile

The FF2000v4 rev. 3 interface, implements FF-912 Field Diagnostic Profile specification. It is

implemented by a specific parameter group of Resource Block. The diagnostics are divided into four

categories: Failure, Out of specification, Maintenance and Check Function - consistent with NAMUR

NE-107. Each of these categories share 32 conditions. Each condition can be mapped or unmapped

for each category by selecting the appropriate bit in FD_*_MAP parameter. If a condition is mapped,

then it is indicated in the parameter FD_*_ACTIVE. If the condition in FD_*_ACTIVE parameter is

not masked the corresponding bit in parameter FD_*_MASK, then the condition will be queued for

transmission using the corresponding FD_*_ALM parameter associated with the priority indicated by

the parameter FD_*_PRI.

The four categories of conditions are defined below.

Table 4.

Maintenance Although the output signal is valid, the wear reserve is nearly exhausted or a function will

soon be restricted due to operational conditions e.g. build-up of deposits.

Off-Specification

Off-specification means that the device is operating outside its specified range or an internal

diagnostic indicates deviations from measured or set values due to internal problems in the

device or process characteristics (e.g. bubble formation in flow metering or valve sticking).

Check Function Output signal temporarily invalid (e.g. frozen) due to on-going work on the device.

Failed Output signal invalid due to malfunction in the field device or its peripherals.

With the FD_*_ACTIVE parameters you know the result after the filtering by FD_*_MAP. Prior to

filtering by FD_*_MAP, the detected conditions may be observed in the FD_Simulate.Diagnostic_Value.

The complete list and functionality of Field Diagnostic parameters implemented in FF2000v4 rev. 3

interface is reported on the Resource Block paragraph. All the parameter related to Field diagnostic

are prefixed with FD_.

In Table below are listed all the conditions handled by FF2000v4 rev. 3 with respectively manufacturer

default mapping and Recommended Action.

Table 5.

FC CONDITIONS TABLE

BIT CONDITION

FAILURE-F

OFF-SPECIFICATION-S

CHECK FUNCTION-C

MAINTENANCE-M

DESCRIPTION RECOMMENDED ACTION

31 MAIN_POWER_SUPPLY x

Indicates whether device has

lost a power supply, or in case

of fault of one of the phases

that supply the actuator

transformer, or main voltage

lower than -20% or higher

than+20% of the value stated in

the nameplate menu.

Indicates whether device has

lost a power supply, or in case

of fault of one of the phases

that supply the actuator

transformer, or main voltage

lower than -20% or higher

than+20% of the value stated

in the nameplate menu.

30 SPEED_SENSOR x Measure of motor speed

not valid. Replace speed sensor

29 POSIT_SENSOR x Value of the actuator position

not valid.

Replace position sensor or

recalibrate both stroke limits.

28 HI_HI_LO_LO_INT_TEMP x

Temperature inside the

actuator enclosure higher than

90 °C or lower than -40 °C

Ambient temperature too

high or too low. Verify

insulation among actuator

and heat source

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Foundation™ Fieldbus Overview 13

Section 5: Foundation™ Fieldbus Overview

FC CONDITIONS TABLE

BIT CONDITION

FAILURE-F

OFF-SPECIFICATION-S

CHECK FUNCTION-C

MAINTENANCE-M

DESCRIPTION RECOMMENDED ACTION

27 HW_ERROR x

The diagnostic program

detects some malfunction in

the electronics controlling

the actuator.

Some circuit is damaged

and does not work (Call Biffi

After-sales service to solve

the problem).

26 CONFIG_ERROR x

The checksum of the EEPROM

memory that contains the

configuration data is wrong.

Reconfigure all parameters

(See details next page).

25 BASE_COM_FAIL x

The communication

between Interface card and

motherboard card is lost.

Check the main power

supply, or replace the

Hardware

(Base card and Interface

card).

24 MOT_THERMOST x

Motor thermostat open for

high temperature in the

motor windings.

Wait until the motor

cools down.

23 CONTACTOR x

The test routine reports a

failure of contactor (coil or

auxiliary contact).

Check the contactor.

22 MID_TRAV_AL x

The valve does not move in

presence of an open or

close control.

Check status of actuator

and valve mechanical parts.

Recalibrate both stroke

limits.

21 JAMMED x

No position change after

receiving an open or

close control.

Check status of actuator and

valve mechanical parts.

20 HI_HI_TORQUE x

Measured torque greater than

the relevant value configured in

torque setup or stroke

limits routine.

Operate the actuator in

opposite direction. Check the

torque needed to operate

the valve.

19 LOW_9V_BATTERY x

The voltage of the lithium

battery is too low (only

detected if the lithium battery

is present and the relevant

parameter of the miscellaneous

routine is set to “present”).

Change lithium battery.

18 EFS_MID_TRAVEL x The position is > 4% after

ESD action.

Check reset time,

check electrical stroke limits,

check mechanical stops.

17 PST T-PST x

Time needed to change the

position of the PST TRAVEL by

the spring action out

of specification.

Check baseline values and

parameter T-PST.

16 PST T-RET x

Time to return to position

before testing out of

specification.

Check baseline values and

parameter T-RET.

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Foundation™ Fieldbus Overview14

Section 5: Foundation™ Fieldbus Overview

FC CONDITIONS TABLE

BIT CONDITION

FAILURE-F

OFF-SPECIFICATION-S

CHECK FUNCTION-C

MAINTENANCE-M

DESCRIPTION RECOMMENDED ACTION

15 PST OV-TR x Position change greater than

allowable.

Check PST travel and

parameter OV-TR.

14 PST_ABORTED x PST cycle aborted due to

external condition.

Check if condition to abort

has happened.

13 HI_LO_MAINS x

Value of the main voltage out

of the correct range (-15% or

+10% of the value stated in the

nameplate menu) or wrong

frequency.

Check section of wires

and values of voltage and

frequency.

12 WRONG_LIMITS x

The routine that monitors the

stroke limits detects a wrong

end of travel condition.

Recalibrate both stroke

limits.

11 HI_TORQUE x

Measured torque 10% lower

than the relevant value

configured in torque setup or

stroke limits routines.

Check the torque necessary

to move the valve.

10 MAX_CYCLES_CONTACT x Maximum number of contactor

cycles reached.

Change contactor and reset

operation log.

9 HI_LO_INT_TEMP x

Temperature inside the actuator

enclosure higher than 80 °C or

lower than -35 °C.

Find the heat source and

insulate the actuator.

8 MOTOR_CUR x Motor current greater or lower

than limits. Check electrical motor.

7 MAINTEN_REQ x Date of the next maintenance

reached.

Perform maintenance and set

next maintenance date.

6 MANUAL_OPER x

The actuator is changing the

position without electrical

command.

Operator is changing the

actuator position

by handwheel.

5 ESD_ON x ESD command active

(hardwired or from FF).

Check and remove the ESD

condition (C4 pin of terminal

board or FF ESD command).

4 INTERLOCK_ON x Interlock open or close active

(hardwired or from FF).

Check the Interlock condition

(B4 and B5 pin of terminal

board or FF Interlock

command).

3 LOC_STOP_ON x Local stop button pressed. Release the Local Stop

button.

2 REM_HARDWIRED_OPER x Local selector in remote with

manual mode enabled.

Check B/HW (C8 connection

on terminal board) signal.

1 LSEL_OUT_OF_REM x Local selector not in

REMOTE position.

Switch the Local selector

to REMOTE.

0 CHECK x Check function. Allow ITK to verify operation

of Field Diagnostics.

FD_FAIL_PRI FD_OFFSPEC_PRI FD_MAINT_PRI FD_CHECK_PRI

ALARM

BROADCAST

RECORD

FD_FAIL_ALM FD_OFFSPEC_ALM FD_MAINT_ALM FD_CHECK_ALM

DS87

ALARM

BROADCAST

ENABLE

ALARM

INDICATION

(POLLING)

ALARM

DETECTION

ENABLE

FD_FAIL_MASK FD_OFFSPEC_MASK FD_MAINT_MASK FD_CHECK_MASK

FD_FAIL_ACTIVE FD_OFFSPEC_ACTIVE FD_MAINT_ACTIVE FD_CHECK_ACTIVE

FD_FAIL_MAP FD_OFFSPEC_MAP FD_MAINT_MAP FD_CHECK_MAP

Bitstring

32 bits

Bitstring

32 bits

Bitstring

32 bits

FF2000v4 rev. 3 specific conditions

3

1

3

0

2

9

2

8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

1

9

1

8

1

7

1

6

1

5

1

4

1

3

1

2

1

1

1

0

0

9

0

8

0

7

0

6

0

5

0

4

0

3

0

2

0

1

0

0

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1 April 2021

Foundation™ Fieldbus Overview 15

Section 5: Foundation™ Fieldbus Overview

The Figure below explains in schematic mode the functionality of Field Diagnostic.

Figure 9

5.7 Device Replacement

The FF2000v4 rev. 3 interface, implements AN-007 Device Replacement specification.

This DEV_REV 3 is a “Like Device” of previous version DEV_REV 2. It can be used as replacement of

previous FF2000v4 rev. 2 in a working plant.

The FF2000v4 rev. 3 can run the same configuration that was running in the FF2000v4 rev. 2 without

reengineering the host configuration or changing the configuration of any other element of the H1

network other than the new device.

The host system is informed by the backward compatibility with older DEV_REV 2 of FF2000v4

by COMPATIBILITY_REV parameter in Resource Block. For more detail about Device replacement

specification, check the FoundationtM Fieldbus literature.

April 2021

Installation, Operation and Maintenance Manual

MDE 255 Rev. 1

Function Blocks Description16

Section 6: Function Blocks Description

Section 6: Function Blocks Description

6.1 Function Block: DO

A Discrete Output block converts the value received across the fieldbus to something useful to the

hardware in the device. In the FF2000v4 rev. 3, there are 8 available DO Function Blocks.

Figure 10

Each DO may be connected by means of any FoundationtM Fieldbus Configuration Tool to one of the

related channels defined in the paragraph “DO Channels”.

Figure 11

Other manuals for ICON3000 Series

10

Table of contents

Other BIFFI Control Unit manuals

Popular Control Unit manuals by other brands

Giacomini

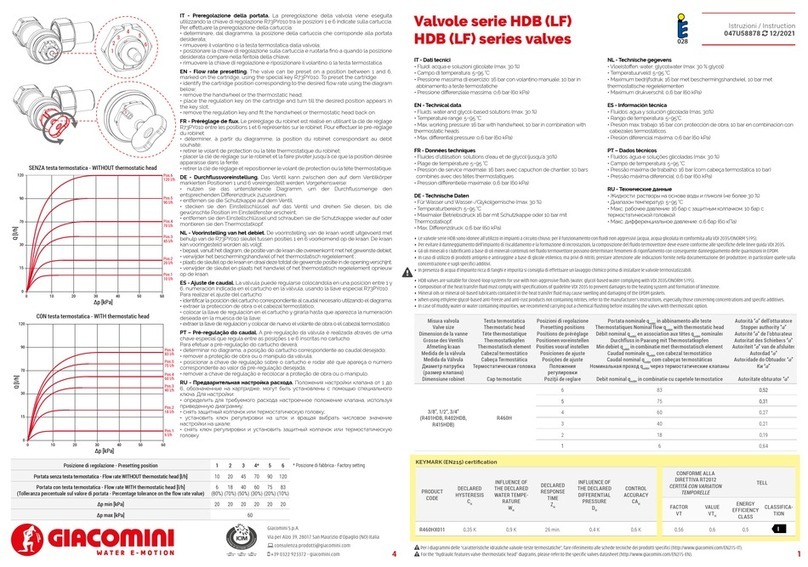

Giacomini HDB Series instructions

Huawei

Huawei SmartAX MA5612 Maintenance Guide

LEGRAND

LEGRAND IC5010 Instruction/installation sheet

Wilo

Wilo Yonos MAXO Series Installation and operating instructions

Eclipse

Eclipse BoilerMag Installation and servicing instructions

Agilent Technologies

Agilent Technologies 1100 Series user guide