6

May 2021

Installation, Operation and Maintenance Manual

MAN610-1 Rev. 5

Section 2: Installation

Installation

2.3 Storage

If the actuator needs storage, before installation follow these steps:

• Place it on a wood surface in order not to deteriorate the area of valve coupling.

• Make sure that plastic plugs are present on the hydraulic and electrical

connections (if present).

• Check that the cover of electrical housings (if present) is properly closed.

If the storage is long-term or outdoor (maximum allowable 36 months):

• Keep the actuator protected from direct weather conditions.

• Replace plastic plugs of hydraulic and electrical connections (if present) with metal

plugs that guarantee perfect tightness.

• Coat with oil, grease or protection disc, the valve coupling area.

• Periodically operate the actuator (Section 3.3).

• For lifting unbalanced loads, use ropes of different lengths or chains with

adjustable length.

• Check each time the conditions of all lifting equipment used and discard it if

not in perfect working order.

• Do not knot or twist the ropes so as not to reduce the lifting capacity or

produce torsional effects on the load being lifted.

• Use the utmost caution and remain at a safe distance from lifted actuator

unless absolutely necessary; do not stand or pass under suspended loads.

• Pay attention in putting under tension the ropes to prevent the load shifting

sideways in an uncontrolled manner.

• Use slings of such length that the angles of the leg from vertical are as narrow

as possible (αMAX < 20°).

• During handling, do not transport the suspended actuator above staff

members in charge of the operation.

! WARNING

Do not use the lifting eyelets on actuator to lift valve + actuator assembly.

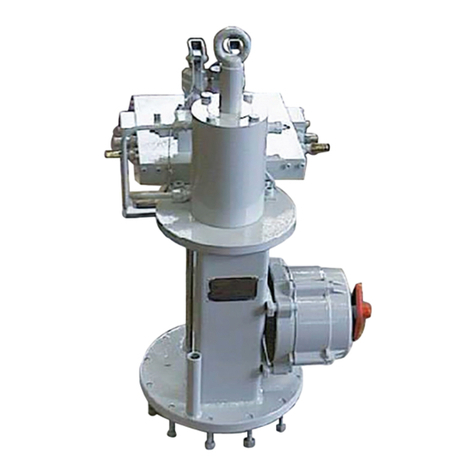

2.4 Actuator Assembly on the Valve

2.4.1 Types of Assembly

For coupling to the valve, the housing is provided with a ange with threaded holes

according to Bif standard tables (SCN6200 and SCN6201). The number, dimensions and

diameter of the holes are made in accordance with ISO 5211, but for actuator models

0.3 to 6 the holes are drilled on the centreline in order to allow an easier assembly of an

intermediate ange, when required. This intermediate ange (or spool-piece) can be

supplied when the valve ange can not directly match the actuator ange in its “standard”

conguration. For the biggest actuator models, the actuator ange can be machined in

accordance with the valve ange dimensions.

The yoke has bored with keyways for coupling to the valve stem, the dimensions of which

are according to Bif standard tables SCN6200 and SCN6201.