December 2020

Installation, Operation and Maintenance Manual

MAN 608 Rev. 5

Installation

14

Section 2: Installation

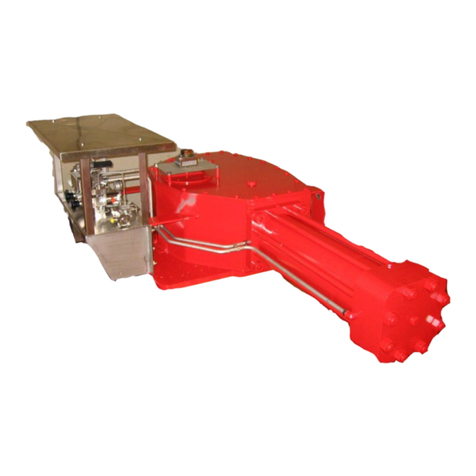

2.5 Hydraulic Connections

! WARNING

Check that the values of hydraulic supply available are compatible with those reported on

the identication plate of the actuator.

NOTICE

The connections should be made by qualied staff. Use pipes, ttings and connections

appropriate as for type, material and dimensions.

Connect the actuator to the hydraulic feed line with ttings and pipes in accordance to the

plant specications. They must be sized correctly in order to guarantee the necessary oil

ow for the operation of the actuator, with pressure drops not exceeding the maximum

allowable value. The shape of the connecting piping must not cause excessive stress

to the inlets of the actuator. The piping must be suitably fastened so as not to cause

excessive stress or loosening of threaded connections, if the system undergoes strong

vibrations. Every precaution must be taken to ensure that any solid or liquid contaminants,

which may be present in the hydraulic pipework to the actuator, are removed to avoid

possible damages to the unit or loss of performance. The inside of the pipes used for the

connections must be well-cleaned before use: wash them with suitable substances and

blow through them with oil or nitrogen. The ends of the tubes must be well debarred and

cleaned. Once the connections are completed, operate the actuator and check that it

functions correctly, that the operation times meet the plant requirements and that there

are no leakages in the hydraulic connections.

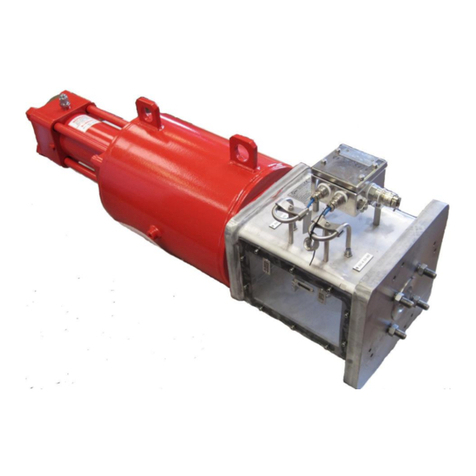

2.6 Electrical Connections (If Any)

! WARNING

Use components appropriate as for type, material and dimensions. The connections should

be made by qualied staff . Before carrying out any operation, cut line power off.

Safety provisions:

2006/95/EC: Directive for low voltage equipment (until 19 April 2016)

2014/35/EU from 20 April 2016

2004/108/EC: Directive for the electromagnetic compatibility (until19 April 2016)

2014/30/EU from 20 April 2016

94/9/CE: Directive and safety instructions for use in hazardous Area

(until 19 April 2016) 2014/34/EU from 20 April 2016

Remove plastic plugs from cables entries

• Screw rmly the cable glands.

• Introduce connection cables.

• Make the connections in compliance with applicable wiring diagrams on the

documentation supplied.

• Screw the cable gland.

• Replace the plastic plugs of unused entries with metal plugs.