Stratus SAE-C12X Guide

Installaon & Operaon

Maintenance & Instrucons

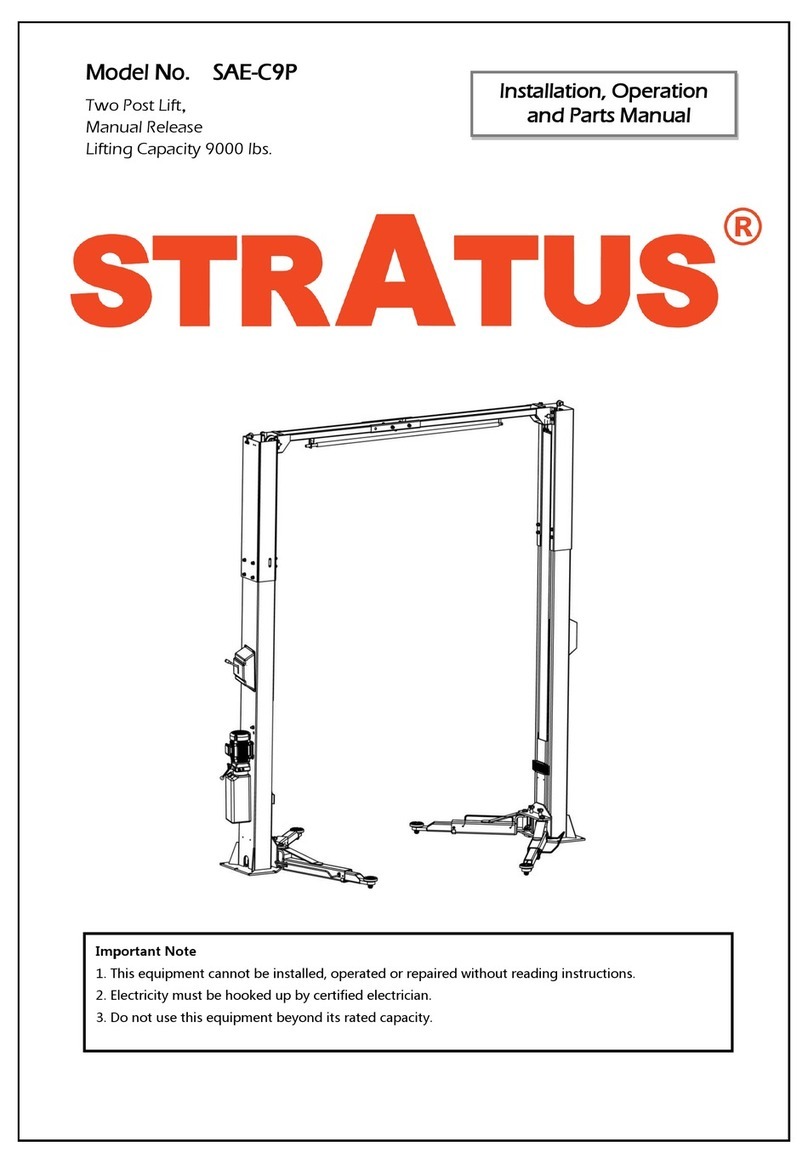

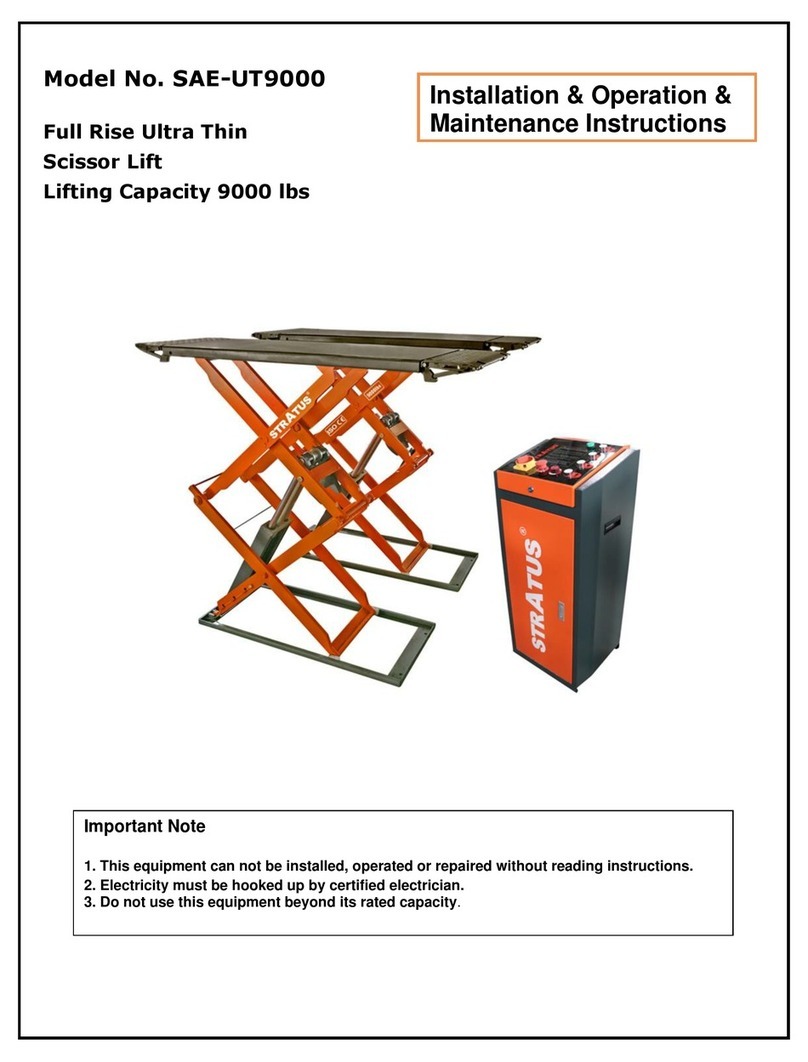

STRATUS 2 Post Overhead Li Installaon & Operaon & Maintenance Instrucons

Model No.: SAE-C12X

2 Post Overhead Li

Single (1) Point Manual Release

Liing Capacity:12000LBS

Important Note

1.This equipment can not be installed, operated or repaired without reading instrucons.

2.Electricty must be hooked up by cered electrician.

3.Do not use this equipment beyond its rated capacity.

2

CONTENTS

1-Equipment descripon

…………………………………………………………………………………………………

3

1.1-Descripon ……………………………………………………………………………………………………………3

1.2-Technical specicaons………………………………………………………………………………………………3

1.3-Installaon requirement………………………………………………………………………………………………5

2-Specicaons of concrete………………………………………………………………………………………………6

3-Installaon steps…………………………………………………………………………………………………………7

4-Operaon and use………………………………………………………………………………………………………18

4.1-Operaon ……………………………………………………………………………………………………………18

4.2-Raising Liing…………………………………………………………………………………………………………18

4.3-Stopping ………………………………………………………………………………………………………………18

4.4-Lowering ………………………………………………………………………………………………………………18

5-Safety ……………………………………………………………………………………………………………………18

5.1-Important Reminder…………………………………………………………………………………………………18

5.2-Vehicle Posion………………………………………………………………………………………………………19

5.3-Risk of Vehicle falling o from the li…………………………………………………………………………19

6-Maintenance ……………………………………………………………………………………………………………19

6.1-Every Month …………………………………………………………………………………………………………19

6.2-Every 3Month ………………………………………………………………………………………………………19

6.3-Every 6Month ………………………………………………………………………………………………………20

6.4-Every 12 Moth ………………………………………………………………………………………………………20

7-Troubleshoong guide …………………………………………………………………………………………………20

8-Structure and Parts List…………………………………………………………………………………………………21

8.1-Main column assembly……………………………………………………………………………………………21

8.2-Sun-column assembly………………………………………………………………………………………………21

8.3-Block assembly………………………………………………………………………………………………………22

8.4-Cross arm assembly…………………………………………………………………………………………………22

8.5-Cylinder assembly……………………………………………………………………………………………………23

8.6-Three-secon arm assembly………………………………………………………………………………………23

8.7-Main column safety lock assembly………………………………………………………………………………24

8.8-Secondary column safety lock assembly…………………………………………………………………………25

3

1.-Equipment Descripon

1.1-Descripon

This 2 Post Overhead Li is an advanced car maintenance equipment, mainly used for automove repair and

maintenance.

1.2-Technical Specicaons

Model SAE-C12X

Liing capacity 12000lbs;5500KG

Overall Hight 173 3/8″;4403mm

Overall Width 155 1/8″;3940mm

Liing height 74 13/16";1900mm

Min. height 4 5/8";118mm

Column inside 129 15/16";3300mm

Drive through 115 11/16";2939mm

Liing me About 60 sec.

Lowering Time About 40 sec.

Column thickness of steel 6.0mm

Carriage thickness of steel 6.0mm

Arms thickness of steel 7.75mm

Arm range 35 1/16"-70 7/8";890-1800mm;

Diameter of cable Φ9mm

Voltage 220V

Power 3.0Kw/4Hp

Frequency 60Hz

Phase 1Ph

Breaker 30A

Hydraulic oil 3-5 Gallons AW46/AW32

Shipping Size 118"×44″×28";2997×1118×712mm

Equipment weight 2360lbs/1071KG

4

Installaon( See Fig 1 )

FIG 1

Features (See Fig 2)

FIG 2

5

1.3-Installaon requirement

Tools required

Name

Picture

Rotary hammer drill(Φ19)

carpenter's chalk

Hammer

Screw Sets

Level bar

Tap measure

English spanner(12")

Pliers

Ratchet spanner with socket(28#)

Socket head wrench(3#,5#,8#)

Lock wrench

Wrench set(10#,13#,14#,15#,17#,19,24#,27#,30#)

6

2-Specicaons of concrete ( See Fig 3 )

Specicaons of concrete must be adhered to the specicaon as following. Failure to do so may result in li and/or

vehicle falling.

◇Concrete must be thickness 200mm minimum and without reinforcing steel bars, and must be completely dry

before li installaon.

◇Concrete must be in good condion and must be of test strength 3500psi(245kg/cm²)minimum.

◇Floor must be level with no cracks or holes.

Steps of installaon

◇Locaon of installaon

Check and insure the installaon locaon( concrete, layout, space size etc.) is suitable for li installaon.

◇Use a carpenter's chalk line to establish installaon layout of baseplate( See Fig4).

FIG 3

FIG 4

7

3-Installaon steps

Step 1:Check the pats before assembly

Packaged li and hydraulic power unit( See Fig 5 )

Step 2:Move aside the parts and check the parts according to the shipment parts list (See Fig 6).

FIG 5

FIG 6

8

Step 3: Spare parts in the accessories box.

Serial

number

Name Photo Parameter Quanty

1Arm sha Φ40×250L 4

2Arm sha xing screw

Countersunk Hexagon Screw M10×15L 4

3Arm boom pad Φ70mm 4

4Increased set Φ60×100L 4

5Heightening bracket 2

6Heightening sleeve bracket xing

screw

Hexagon socket screws M8×10L 2

7An-collision tape 2

8An-collision rubber strip xing screws

Hexagon socket screws M8×30 4

9Power unit frame 1

10 Power unit frame xing screws

Hexagon socket screws M10×16L Each 2

11 Power unit xing screws

Hexagon Screw M8×25L Each 4

12 Manual unlocking lever M10 Each 1

13 Safety lock release cable 1

14 Wire rope U-shaped chuck M3 2

15 Expansion screw

M20×160L 14

9

Serial

number

Name Photo Parameter Quanty

16 Plasc gasket 15

17 Plasc cable e 30

18 Main column upper limit switch 1

19 Main column upper limit switch xing screw Phillips round head screws M5×10L 2

20 Upper limit plate and limit switch M4×10 and M4×25 1

21 Upper limit board 1

22 Upper limit plate xing screw Hexagon Screw M10×20L Each 4

23 Two cross arm connecng screws Hexagon Screw M8×20L Each 6

24 Two-secon cross arm end xing screws Hexagon Screw M10×25L Each 8

25 Heightening secon and column connecng

screw

Hexagon socket screws M10×12L Each 16

26 Wire rope support frame at the upper end of

the heightening secon

2

27 Fixing screws for the upper wire rope sup-

port frame of the heightening secon

Hexagon socket screws M5×10L 4

28 Plasc buckle cover xing screw Phillips round head screws M6×8L 8

29 Increased fuel-saving pipe pressure pocket 6

30 Increased the fuel-saving pipe pressure pock-

et xing screw

Hexagon socket screws M6×10L Each 12

31 Block rubber cover 2

32 Locking and unlocking rope seat assembly

accessories

2

33 User’s manual 1

10

Step 4: Install anchor bolts

Posion the columns on the installaon layout of baseplate. Install the anchor bolts. Check the columns plumbness

with level bar, and adjusng with the shims if the columns are not vercal. Do not ghten the anchor bolts (See Fig 7).

Note: Anchor bolts driven into the ground at least 150mm.(See Fig 8)

FIG 8

FIG 7

11

STEP 5:Column and height-increasing joint connecon installaon. (See Fig 9)

Step 6:Cross arm installaon (See Fig 10) FIG 9

FIG 10

NO. Name Qty.

1Main column heightening secon 1

2Main column welding 1

3Socket head cap screws M10×12 10

4Flat pad 10

No. Name Qty.

1Main cross arm assembly 1

2Assembly of auxiliary crossarm 1

3Hex bolts M10×20 4

4Flat pad Φ10 4

5Spring cushion Φ10 4

6Hex nuts M10 4

7Hex bolts M8×20 6

8Flat pad Φ8 6

9Spring cushion Φ8 6

10 Hex nuts M8 6

12

Step 7:Cross arm and height-increasing secon connecon installaon (See Fig 11)

FIG 11

Step 8: Unlock wire rope installaon (See Fig12)

No. Name Qty.

1Main column heightening secon 1

2Main cross arm assembly 1

3Hex bolts M10×25 4

4Flat pad Φ10 4

5Spring cushion Φ10 4

6Hex nuts 4

No. Name Qty.

1Main column heightening secon 1

2Secondary column heightening secon 1

3Unlock the thin wire rope 1

4Unlock wire bracket 1 1

5Unlock wire bracket 2 1

6Tubing pressure pocket 6

13

FIG 12

No. Name Qty.

1Main column assembly 1

2Unlock the thin wire rope 1

3Unlock the sheave seat 1

4Safety lock cover (Opening) 1

5Unlock lever 1

6Phillips round head screw M6×10 4

No. Name Qty.

1Sub-column assembly 1

2Unlock the thin wire rope 1

3Unlock the sheave seat 1

4Safety lock cover 1

5Phillips round head screws M6×10 4

14

Step 9:Equalized cable installaon (See Fig13)

Connect steel cables

1. Route and x according to the following diagram of steel cable connecon.

2. Raise both carriages to the rst locking point.

3. Make sure that the mechanical safety locks in each post are fully engaged before aempng to route cables.

4. Aer the cable being xed, adjust and make the cable at both sides be with the same ghtness which could be

judged by the sound emied during liing process. Make judge and adjustment aer trial running.

5. Grease aer being xed. (It is a must.)

Step 10: Hydraulic tubing connecon installaon (See Fig 14).

FIG 13

FIG 14

No. Name Qty.

1Power unit 1

2Hydraulic cylinder 2

3Hose 1 1

4Tee connector 1

5Hose 2 1

6Hose 3 1

Step 11:Limit switch connecon installaon (See Fig15)

Funconal descripon of each part of the power unit

Fig 15

**Important Informaon**

Pressure Valve: Clockwise adjustment increases pressure to make the power

unit to have more power, counterclockwise adjustment decreases pressure to

make the power unit to have less power.

Hydraulic Oil ow valve: Clockwise adjustment to speed up, counterclockwise

adjustment to slow down.

16

Fill with hydraulic oil.

CLEAN AND FRESH OIL ONLY

DON’T FILL THE TANK COMPLETELY FULL.

Li must be fully lowered before changing or adding hydraulic oil

Pour 13 liters HM32 an-abrasion hydraulic oil into the oil tank. The level of oil shall reach the ppets volume mark

of the tank.

Add more oil aer running the li for several cycles unl the li can rise to the maximum liing height.

Note:As running speed of the li is mainly decided by the viscosity of the hydraulic oil, we suggest using NO.46

hydraulic oil when average temperature of the locaon is above 18 degree Celsius and using NO.32 hydraulic oil

when temperature is below 18 degree

Celsius. Change the oil 6 month aer inial use and change once per year thereaer.

Step 12: Power unit installaon (See Fig 16)

Fig 16

No. Name Qty.

1Main column assembly 1

2Power unit 1

3Power unit backpack 1

4Flat pad Φ10 2

5Spring cushion Φ10 2

6Socket head cap screws M10×16 2

7Hex nuts M8 4

8Flat pad Φ8 4

9Spring cushion Φ8 4

10 Hex bolts M8×25 4

11 Heightening bracket 1

12 Socket head cap screws M8×10 2

13 Increase the set 1 1

17

Step14: Trial running. (See Fig 18)

Get familiar with li controls by running the li through a few cycles before loading vehicle on li. This step is of par-

cular importance for it can check if the oil hose is well connected. The connecon is qualied when there is no ab-

normal sound or leakage aer having been tested for 5-6 mes.

Bleeding the hydraulic system

Unscrew but don't remove the nut on top of the oil cylinder and slightly press the UP buon unl oil gets out. Screw

the nut ght thereaer. Aer bleeding, oil level in power unit reservoir may be down. Raise and lower li several

cycles. Add more oil if necessary to raise li to full height. It is only necessary to add oil to raise li to full height.

Step13: Install liing arms. (See Fig 17)

Connect the liing arm and the carriage. The arm pin shas must be greased at the installaon Ensure the arm lock

can engage and release eecvely. .

Aenon: Install Liing arms and x feet protecon bars ONLY aer the complete assembly has been erected and

anchored.

FIG 17

FIG 18

No. Name Qty.

1Arm sha 2

2Socket head cap screws M10×16 2

3Arm boom pad 2

4Welding of support arm 2

5An-collision tape 1

6Socket head cap screws M8×30 2

18

4-Operaon and Use

4.1-Operaon

Place the liing arm at the support point specied by the vehicle and adjust the rubber tray to the same height.

Check the posion of the rubber tray under the vehicle chassis before each single raising or when vehicle is lowered

to the ground and need to raise again.

4.2-Raising/ Liing

Press the power switch unl the vehicle reaches desired height. When the vehicle is raised, the safety lock automa-

cally engaged.

During raising/liing, whether the arm lock has been locked, it can be visually checked when it is raised to a certain

height (stop and check).

*Danger*: Unlocked arms can cause vehicle fall o from the li.

4.3-Stopping

Aer raising to desired height, press the lower lever and the li will automacally lower to a safe posion, the safety

lock will be engaged and the li will be locked.

4.4-Lowering

The safety lock must be released before lowering.

1. Press the power switch to raise the car by approximately 30mm/1.2".

2. Pull the safety lock release cables on both sides to unlock.

3. Press the lower lever to start lowering process, the arm lock will be automacally released and allow the arm ro-

tang when the vehicle is completely lowered to the ground.

5-Safety

Please read this manual carefully as it contains important safety informaon that the operators need to know.

*WARNING*: The design and construcon of this li is only suitable for liing whole vehicle. All other uses are unau-

thorized, this li CAN NOT be used to : wash vehicles, build liing plaorms, liing personnel, use as cargo lis and

use as liing paral of the vehicles.

5.1-Important Reminder: Personal and Equipment Safety

1. During vehicle liing process, operators should be at a safe posion/area.

2. Turn o the vehicle engine and manual brake on.

3. Load vehicle correctly (Fig 19).

4. The vehicle CAN NOT exceed the rated liing capacity and required size.

Fig 19

19

5.2-Vehicle Posion

Once the vehicle is raised, vehicle CAN NOT be moved backwards or forwards as it may cause falling.

*WARING*: Do not aempt to move the vehicle while it is parked on the li.

5.3-Risk of Vehicle falling o from the li

Note that when posioning the vehicle on the li, incorrect center of gravity of the vehicle can cause the vehicle

falling o from the li (Fig 20).

Important Note: Make sure that the front and rear of the vehicle need to be balanced and the cables on both sides

also need to be balanced. Do not board/step on the vehicle or the li when the li is raised.

Below acons may cause the vehicle fall o from the li .(Fig 21)

Fig 21DO TOT do

FIG 20

6-Maintenance

6.1-Every Month

Hydraulic System

1. Check hydraulic oil level, ll hydraulic oil if necessary.

2. Check the pump, hose and cylinder and see if there is hydraulic oil leaking.

6.2-Every 3 Month

Safety Maintenance

1. Check the condion of the safety lock and the wear of the stop block.

2. Check the anchor bolts, ghten nuts if necessary.

3. Check if any nuts are loose, ghten nuts if necessary.

4. Check if the arm locking system is working properly.

5. Lubricate/grease all moving parts.

6. Check if the arm locking system is working properly.

7. Check if the 2 carriage on both sides are at the same level.

20

7. Troubleshoong Guide

Troubleshoong Guide

Malfuncon Possible reason Soluon

The motor does not

work

Check the air switch. Turn o or replace the air switch.

Check if the voltage is correct. User correct power supply.

The motor burned. Replace the motor.

Start switch burned. Replace the start switch.

Top limiter switch burned. Replace the top limiter switch.

AC contactor burned. Replace the AC contactor.

The motor works

but can’t li

Pressure valve pressure is too small. Clockwise adjust the pressure valve( ne adjust-

ment).

Pump staon takes in air.

Unscrew check valve on the power unit, and then

start the motor unl hydraulic oil ows out from the

check valve.

Hydraulic oil sucon hose is detached or broken. Install/replace the sucon hose.

Insucient hydraulic oil. Fill more hydraulic oil.

Does not lowering

Safety lock engaged. Slightly raise the device and then pull the safety lock

release cable.

Other object inside the columns stops the carriage. Check and remove the objects.

The ow valve needs to be adjusted. Counterclockwise adjust the ow valve (ne adjust-

ment).

Self-Lowering

Dump valve failure. Replace the dump valve.

Hydraulic oil leaks. Check and repair.

The valve body of the power unit has holes. Replace the valve body.

Raise without load,

but doesn’t raise

with load

The voltage is too low. Install the voltage stabilizer.

Objects in the dump valve. Remove objects from the dump valve.

The pressure valve pressure is too small. Increase pressure properly( ne adjust the pressure

valve).

Overload. This operaon is prohibited.

Liing is not leveled The cables are not balanced. Balance cables by adjusng the cable’s length.

Aer raising to the highest point, the motor is sll working

and the top limiter switch is disabled. Replace the top limiter switch.

Loud motor noise Hydraulic oil polluon. Replace the hydraulic oil.

Overload. This operaon is prohibited.

6.3-Every 6 Month

Hydraulic Pump

1. Check the condion and aging of the hydraulic uid. Unqualied hydraulic uid is the main reason to cause valve

failure and reduces the life of the gear pump.

2. Check the noise variaon of the motor and gear pump while normal operang.

6.4-Every 12 Month

1. Visually inspect all structural and mechanical parts to make sure there is no abnormalies have occurred.

2. Check and see if there is anything wrong with the motor, wiring ,top limiter switch and circuit breaker.

Table of contents

Other Stratus Lifting System manuals

Stratus

Stratus MS9000XT User manual

Stratus

Stratus SAE-F12X Guide

Stratus

Stratus SAE-C10C Guide

Stratus

Stratus SAE-P410 User manual

Stratus

Stratus SAE-F10P Guide

Stratus

Stratus SAE-F14X Guide

Stratus

Stratus SAE-C12XE Guide

Stratus

Stratus SAE-S66M User manual

Stratus

Stratus SAE-P166M Guide

Stratus

Stratus SAE-UT9000 Guide