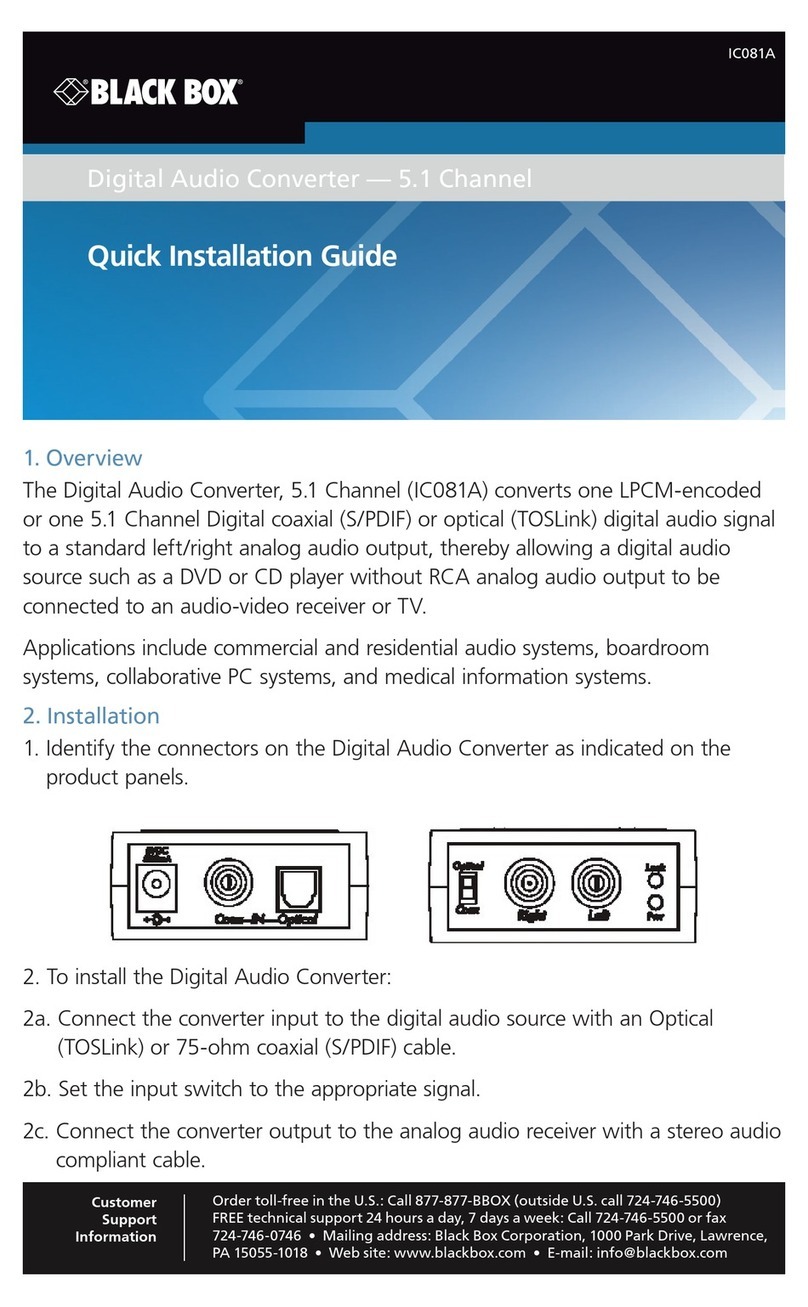

Configuring Compact Media Converter

Compact Media Converter features an 8-position

DIP switch for configuring the unit after installation.

This switch is accessed through a cut-out in the bot-

tom of the unit. After configuring the DIP switch,

power down the unit and then power up again for

the changes to take effect. Default settings for the

following features are shown to the right.

• TX LinkLoss • FX LinkLoss

• FiberAlert (Pulse) • MDI/MDI-X (Auto)

• Auto-Negotiation

Bottom of converter

TWISTED PAIR CROSSOVER/PASS-THROUGH

CONNECTIONS

Whether you are using crossover or straight-through CAT5 twisted pair

cabling, Compact Media Converter will support both types of connections by

one of the following methods:

AutoCross Switch 4: Compact Media converter includes AutoCross, a fea-

ture which automatically selects between a crossover workstation or pass-

through/ repeater hub connection depending on the connected device. To

enable AutoCross, move the Auto MDI/MDI-X switch to the ON position.

MDI/MDI-X Switch 3: To manually configure Compact Media Converter for

a pass-through (MDI) or a crossover (MDI-X) connection, move the Auto

MDI/MDI-X Switch 4 to OFF, then move Switch 3 to the desired connection

type: MDI=OFF and MDI-X=ON. If you are unsure of the type of connection,

set the DIP switch to a position that makes the twisted pair LNK (link) LED glow.

About FiberAlert and LinkLoss

Compact Media Converter comes with the following troubleshooting features:

•FX LinkLoss (a.k.a. "Fiber LinkLoss" or "LinkLoss")

•TX LinkLoss (a.k.a. "Twisted Pair LinkLoss” or "Reverse LinkLoss”)

•FiberAlert (including Pulsing FiberAlert)

LinkLoss and FiberAlert are advanced troubleshooting features that can help

you locate "silent failures" on your network. However, it is vital that you under-

stand exactly how FiberAlert and LinkLoss work, and how they will react in your

network configuration, before attempting to install the enclosed module(s).

Installing modules without understanding the effects of LinkLoss

and FiberAlert can cause perfectly functioning units to appear

flawed or even dead.

If you are unfamiliar with LinkLoss and FiberAlert, Black Box strongly encour-

ages you to read the following information. Contact Black Box technical support

for more information/assistance.

FIBER OPTIC CLEANING GUIDELINES

Fiber Optic transmitters and receivers are extremely susceptible to contamination by parti-

cles of dirt or dust, which can obstruct the optic path and cause performance degradation.

Good system performance requires clean optics and connector ferrules.

1) Use fiber patch cords (or connectors, if you terminate your own fiber) only from a rep-

utable supplier; low-quality components can cause many hard-to-diagnose problems

in an installation.

2) Black Box installs dust caps to ensure factory-clean optical devices. These protective

caps should not be removed until the moment of connecting the fiber cable to the

device. Assure that the fiber is properly terminated, polished and free of any dust or

dirt, and that the location is as free from dust and dirt as possible.

3) Store spare caps in a dust-free environment such as a sealed plastic bag or box so that

when reinstalled they do not introduce any contamination to the optics.

4) Should it be necessary to disconnect the fiber device, reinstall the protective dust

caps.

5) If you suspect that the optics have been contaminated, alternate between blasting

with clean, dry, compressed air and flushing with methanol to remove particles of dirt.

ELECTROSTATIC DISCHARGE PRECAUTIONS

Electrostatic discharge (ESD) can cause damage to your add-in modules. Always observe the

following precautions when installing or handling an add-in module or any board assembly.

1) Do not remove unit from its protective packaging until you’re ready to install it.

2) Wear an ESD wrist grounding strap before handling any module or component. If you

do not have a wrist strap, maintain grounded contact with the system unit throughout

any procedure requiring ESD protection.

WARNING! Integrated circuits and fiber optic components are extremely susceptible

to electrostatic discharge damage. Do not handle these components directly unless

you are a qualified service technician and use tools and techniques that conform to

accepted industry practices.

3) Hold boards by the edges only; do not touch the electronic components or gold connectors.

4) After removal, always place the boards on a grounded, static-free surface, ESD pad or

in a proper ESD bag. Do not slide the board over any surface.

WARRANTY

Contact Black Box for warranty information.

SAFETY CERTIFICATIONS

UULL//CCUULL::Listed to Safety of Information Technology Equipment, Including Electrical Business Equipment.

CCEE::The products described herein comply with the Council Directive on Electromagnetic

Compatibility (89/336/EEC) and the Council Directive on Electrical Equipment Designed for use

within Certain Voltage Limits (73/23/EEC). Certified to Safety of Information Technology

Equipment, Including Electrical Business Equipment. For further details, contact IMC Networks.

Class 1 Laser product, Luokan 1 Laserlaite,

Laser Klasse 1, Appareil A’Laser de Classe 1

72