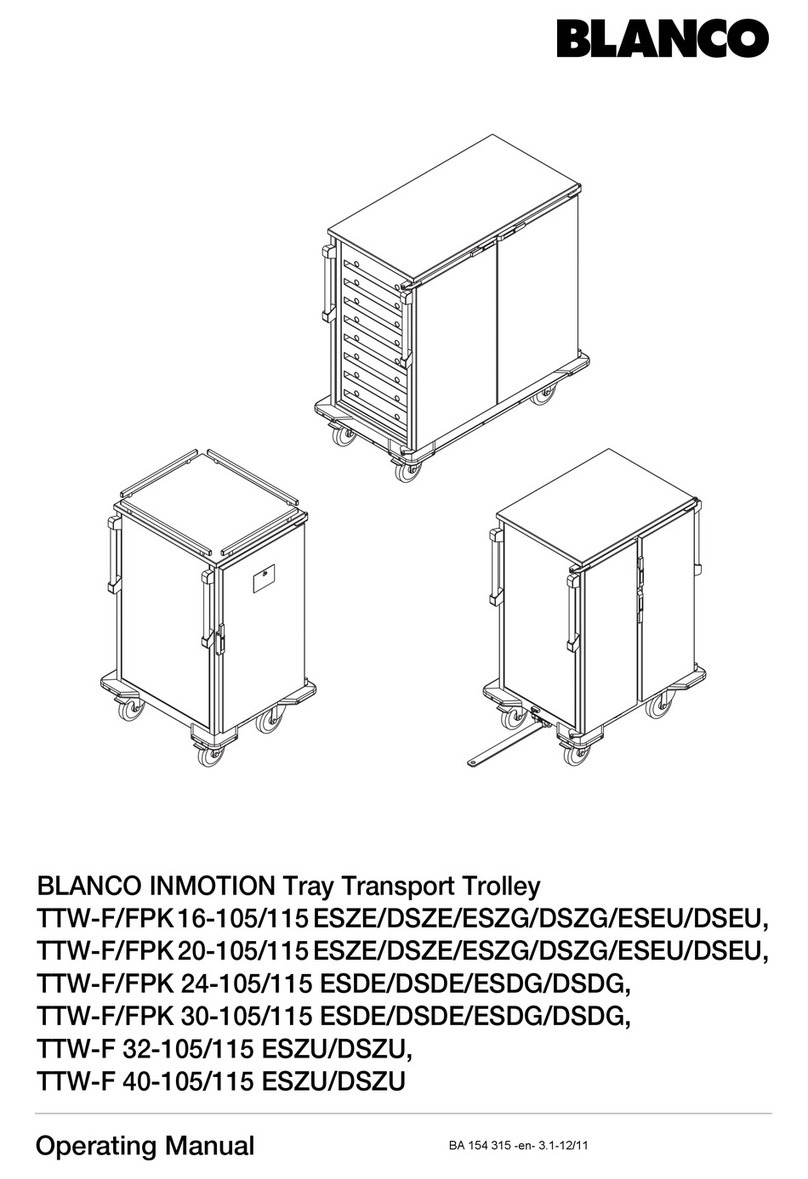

BLANCO INMOTION Heated Tray Transport Trolleys

Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Removing areas of corrosion on stainless steel . . . . . . . . . . . . . . . . . . . . 25

Maintenance Having the unit regularly maintained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Checking locking brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Commissioning a periodical electrical safety inspection . . . . . . . . . . . . . . 26

Check connection cable and power plug . . . . . . . . . . . . . . . . . . . . . . . . . 26

Repairs Authorized persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Description of problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replacing components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Disposal Disposing of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Technical data General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ordering information TTWF 16115 DBZG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 16105 DBZG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 16115 DBZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 16105 DBZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 16115 DBEU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 16105 DBEU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 20115 DBZG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 20105 DBZG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 20115 DBZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 20105 DBZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 20115 DBEU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 20105 DBEU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 24115 DBDG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 24105 DBDG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 24115 DBDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 24105 DBDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 30115 DBDG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 30105 DBDG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 30115 DBDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 30105 DBDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 32115 DBZU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 32105 DBZU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 40115 DBZU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTWF 40105 DBZU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Accessories Gastronorm/European norm trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Dishes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cloches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Eutectic plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Menu cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

BLANCO microfiber cleaning cloth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Stainless steel cleaning and care agent BLANCOPOLISH . . . . . . . . . . . . 33

Service CD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33