Contents

CONTENTS .......................................................................................................................................................................... 3

1. INTRODUCTION ............................................................................................................................................................. 4

1.1 OBJECTIVE ................................................................................................................................................................... 4

1.2 GENERAL SAFETY NOTICE ........................................................................................................................................... 4

1.3 USE INSTRUCTION........................................................................................................................................................ 4

2. TECHNOLOGY SUMMARIZE....................................................................................................................................... 5

2.1 DESCRIPTION OF MAIN BOARD COMPONENT MAP ........................................................................................................ 5

2.2 MT6572 CIRCUIT SYSTEM............................................................................................................................................ 6

2.3 BASE BAND CIRCUIT ..................................................................................................................................................... 7

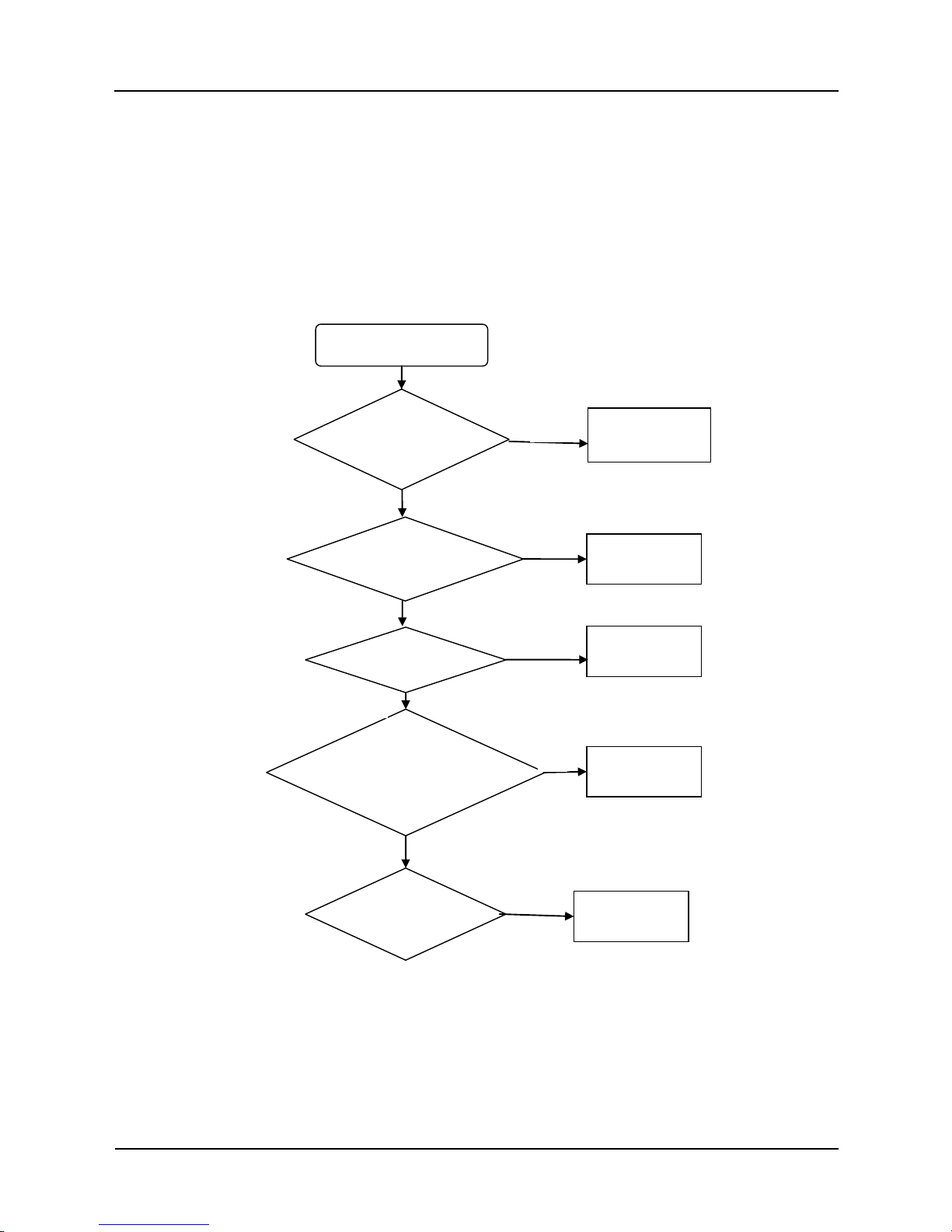

3. TROUBLE SHOOTING .................................................................................................................................................. 9

3.1 FAIL TO STARTUP/POWER ON........................................................................................................................................ 9

3.2 FAIL TO CHARGE ......................................................................................................................................................... 10

3.3 FAIL TO DISPLAY.......................................................................................................................................................... 11

3.4 FAIL TO CALL............................................................................................................................................................... 12

3.5 SPEAKER NO SOUND .................................................................................................................................................. 13

3.6 EARPHONE FAIL .......................................................................................................................................................... 14

3.7 VIBRATOR FAIL............................................................................................................................................................ 15

3.8 SIDE KEY FAIL ............................................................................................................................................................. 16

3.9 FAILURE TO IDENTIFY SIM CARD................................................................................................................................ 17

3.11 CAMERA FAIL ............................................................................................................................................................ 18

3.12 FAILURE TO READ T-FLASH CARD ............................................................................................................................ 19

4. BGA RELATED GND PAD........................................................................................................................................... 20

4.1 CPU AND MEMORY PIN MAP ....................................................................................................................................... 20

4.2 PMU PIN MAP ............................................................................................................................................................. 21