Blusafe Origin Smart User manual

11

Please scan the QR to get newest

manuals on Blusafe Products

Blusafe

Origin Smart

Installation

v1.0

22

33

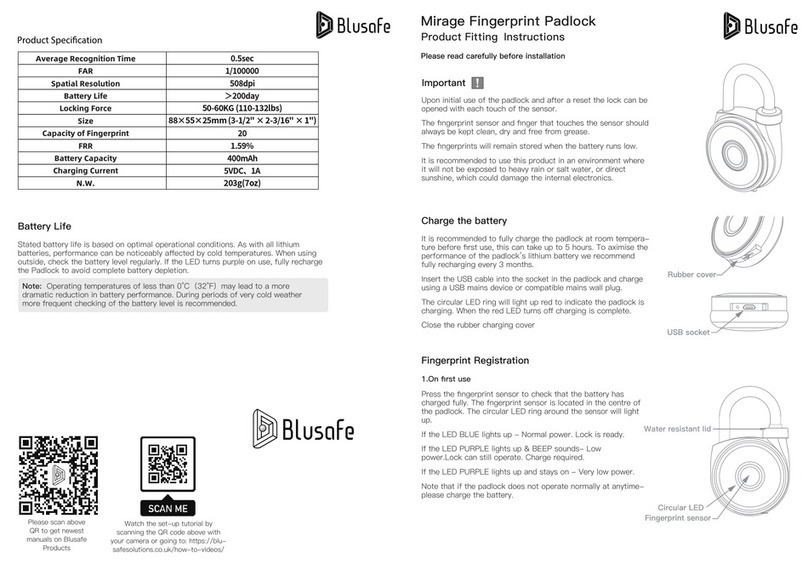

Origin Smart Handle

Battery Cover

Fingerprint Scanner

Proximity Reader

Wakeup Button and LED

Lever Handle

Louderspeaker Hole

Lever Handle

Thumb Turn

Setting Cover

44

0102030 40 50 60 70 80 90 100 1101020304050607080110 100 90120130140150

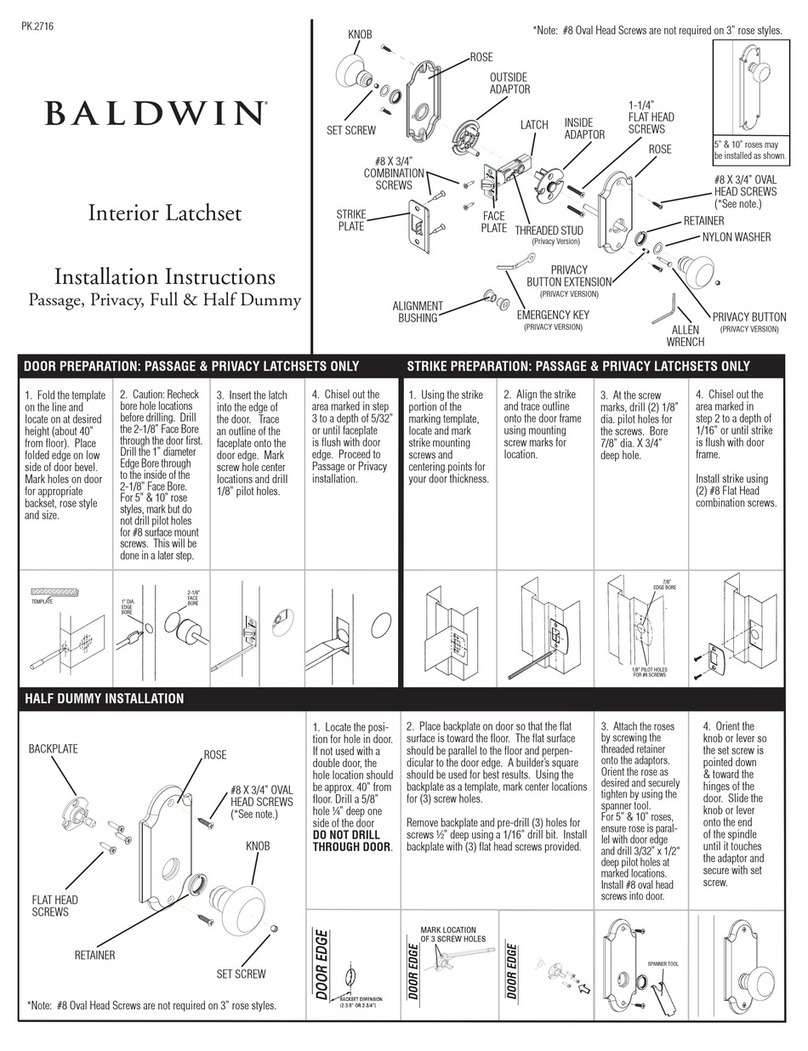

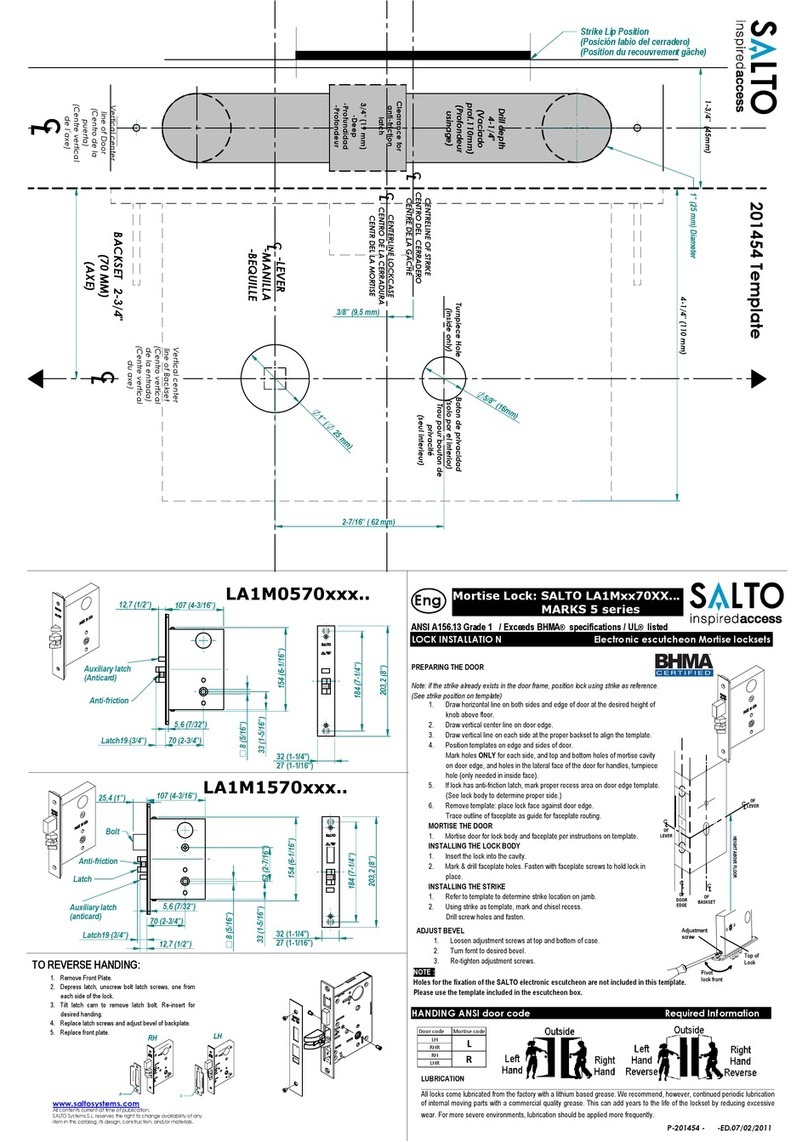

OPTION1:�Remove�the�handle,�measure�the�distance�from�the�spindle�centre�to�the�screw�holes�and�mark�on�the�tempIate

OPTION2:�Remove�the�handle,�place�the�template�on�the�door�with�the�spindle�holes�on�the�template

4954 44 39 34

INSERT INTO SLOT FULLY

TO SELECT BAR LENGTH

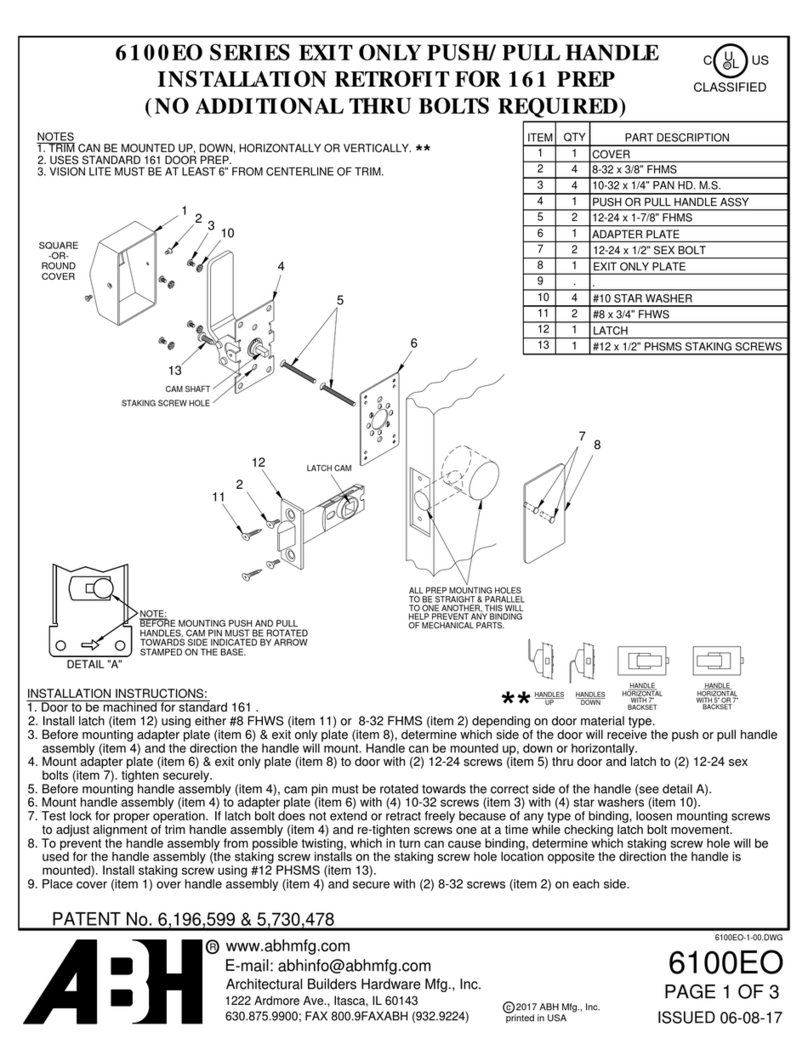

Box Contents

Key Card

Setting RulerSetting Tool

Mounting PlateInternal Handle External Handle

Fitting Jig

F

G

HL

K

J

A1A2B×4 C D

E

× 3

M N O

× 3 × 3

P001P001

Remove the Existing Handle & Cylinder

Put something in the bottom

of the door to prevent the door

closing and locking itself!

Remove the existing handles

and spindle. If a turn button

cylinder is fitted, remove

the internal handle with the

cylinder.

① Remove the existing

screws,there may be 2 or 3;

② Remove the internal handle;

③ Remove the external handle

and spindle to remove the

locking cylinder;

④ Remove the fixing screw and

turn the key/turn knob whilst

putting gentle pressure on

the opposite cylinderend,

until the cylinder starts to

withdraw. Pull the cylinder

out, if there is no movement,

try turning the key gently,

both ways, left and right.

Tip

• It may be necessary to

use a little force to fully

remove the cylinder if it is

catching on the sides of

the prep hole.

• Some cylinders will only

withdraw to the outside,

some only to the inside,

try both ways.

• If a security clamp is

fitted, it will be necessary

to remove this first, an

Allen key will be needed

to do this. Please see

the FAQ section on the

Blusafe website for help if

you are unsure.

Remove the Cylinder

• Ensure the door is unlocked before removing the handles. Do not close the door until

installation is complete.

Warning!

Remove the Existing Handle

04

04

01

01

01

02

03

03

P002P002

Install Operating Cam

Fix - Reset the cam

If the cam is accidentally turned, re-set it

to vertical by pushing down the brass pin

and turning the cam so the pin is in the

central position.

① Insert the setting tool into the operating cam.

② Push the operating cam into the lock (the hole in which you removed the key/cylinder).

③ Fix it in place with the fixing screw shown in the diagram.

④ Insert the fixing screw but do not overtighten.

⑤ Remove the setting tool.

L

Cam

K

J

Setting Tool

04

05

01

02

03

P003P003

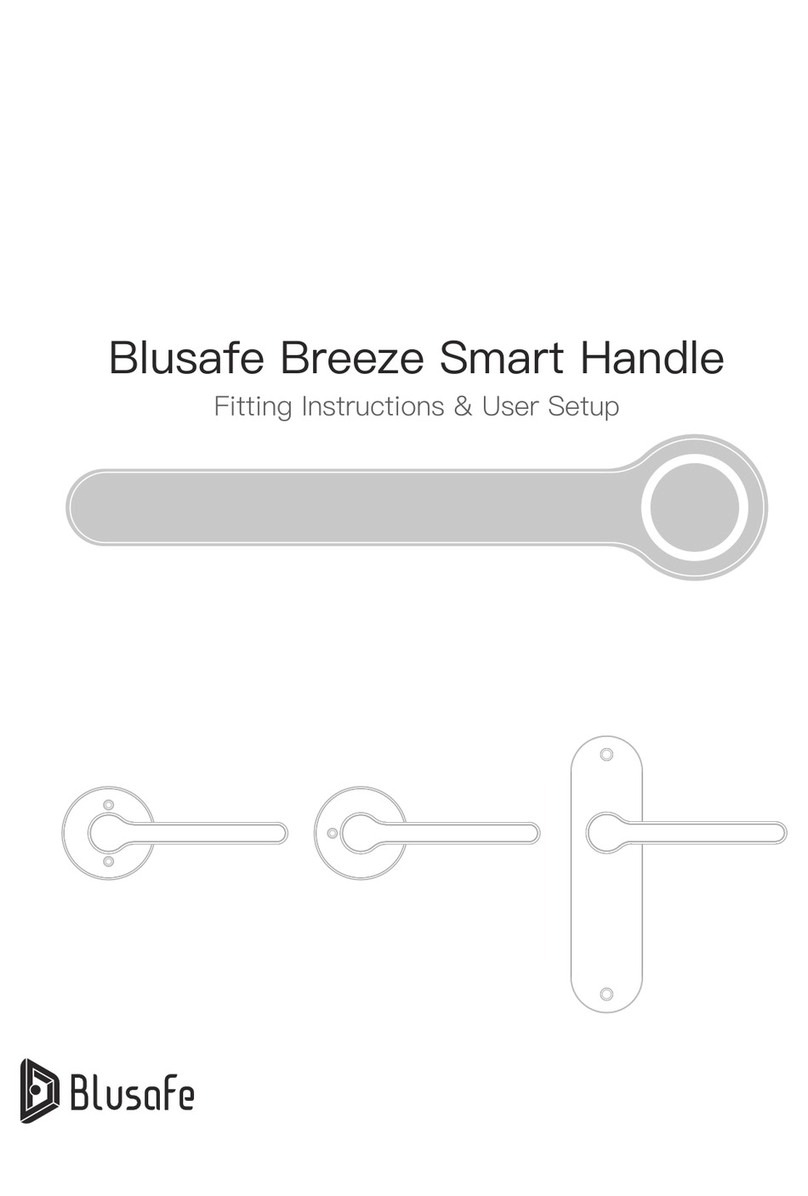

Determine Handle Direction

Depending on which way your door opens, determine which way the handles need to face.

The handles should always point towards the door hinges. Check the Origin/Origin Smart handles

against the current handles.

If the handles need to face the other way, please see next page.

P004P004

Change Internal Handle Direction

If the internal handle direction is not correct, follow the below steps to adjust.

① Insert your screwdriver into the

inside of the handle as shown below.

Push it all the way to the end to

locate the screw.

② Unscrew the handle screw. Remove

it and the spring washer and discard

③ Remove the handle and rotate 180 degrees.

Use the new handle screw and spring washer

(D/E) to fasten the handle

Tip

• For external handle, simply

rotate the handle to the

required position before

inserting spindle.

D E

P005P005

Fitting the Screw Pillars

3 screw pillars are supplied,

but generally only 2 will be

required.

They can be added or removed

where necessary.

The pillars can slide up or

down when loosely tightened

to match the current holes.

Fitting the Screw Pillars

Method 1

Measure the screw holes of

the existing handle. Insert the

old spindle and use the setting

ruler supplied and fit the screw

pillars in the correct positions.

Alternative

Method 2

Use the old internal handle and spindle, join together with

the Origin/Origin Smart outer handle.

Fix the screw pillars loosely - in line with the old handle

screw ports.

Using the old handle screws, pass them through the old

handle into the screw pillars and turn to locate, then gently

tighten the pillars with fingers.

Remove the screws, old handle and spindle and fully tighten

the pillars with the setting tool.

Important!

• Ensure the bottom pillar

is below the electrical

contact wire.

Important!

• Ensure you fully tighten

the screw pillars with the

setting tool or at head

screwdriver.

OLD SPINDLE

Method 1

Setting Tool

Setting Ruler

P006P006

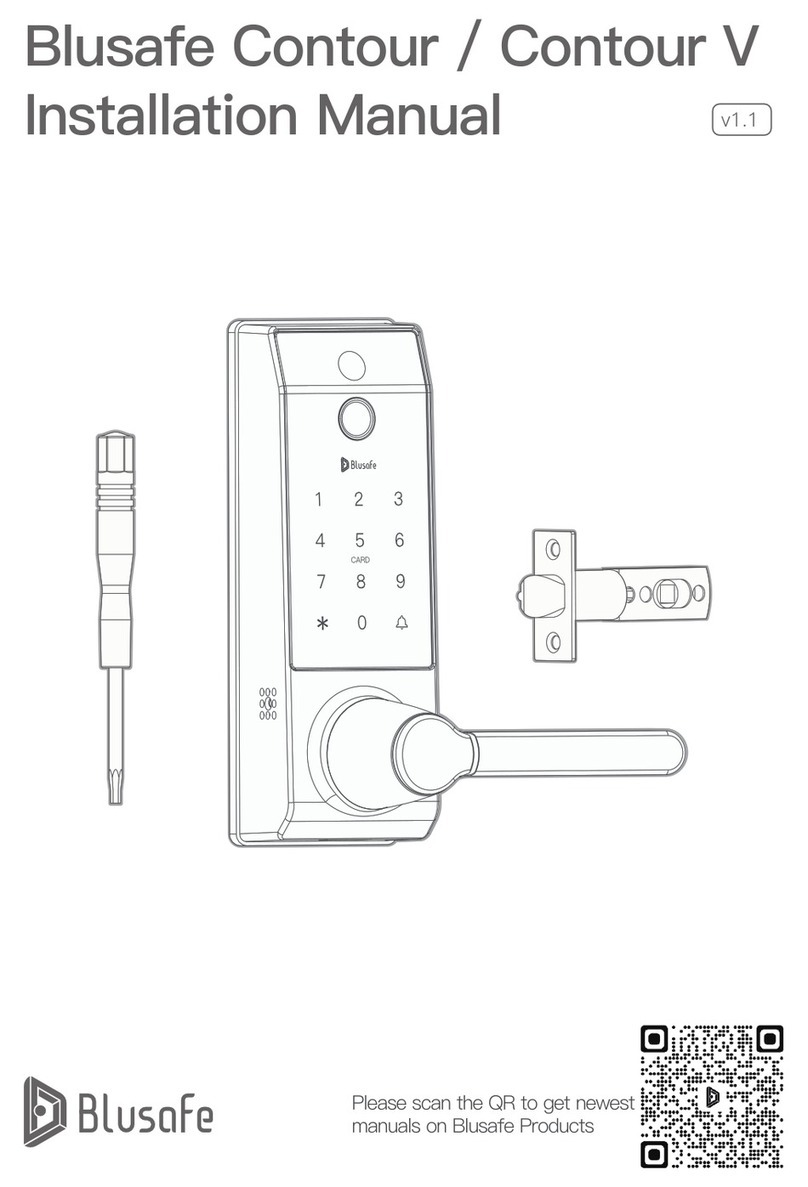

Please measure the total thickness of your

door. Select the spindle and fixing screw pack

as shown below.

Before fitting the handle assembly, please

ensure that the internal and external handle,

backplate, spindle and fixing screws are

removed from the packaging and within easy

reach.

Warning!

• Please make sure the main door lock is

in the unlocked position. If unsure, use

the old handle and spindle and push the

handle down before proceeding.

Door thickness

44-50mm

58-65mm

68-75mm

Measure Your Door Thickness

48mm×3

M·130mm

N·145mm

O·155mm

70mm×3

60mm×3

P007P007

① Fit the spindle into the

external handle.

② From the outside face of

the door, take the leading

tube and put it over the

cable connector head, then

feed the cable through the

bottom fixing hole as shown.

UPVC doors will have 2

internal walls to pass the

cable through as well as

the outer and inner walls.

Push the spindle all the way

through.

③ Make sure the screw pillars

pass through the middle of

the holes in the door.

Gently pull the connector

cable with leading tube

through if necessary and

check it's not caught or

trapped, as this could

damage the cable. Remove

leading tube from the cable.

Hold the external handle in

place and fit the mounting

plate (see next page).

Install External Handle

LEADING TUBE

02

02

03

03

03

NOTE

• Please note, you may need to increase the size of the

bottom fixing hole to allow both the cable and screw to

pass through. Please see FAQ's on Blusafe website.

P008P008

Install Internal Mounting Plate

④ Ensure the mounting plate

is in the correct orientation

with the rubber pad against

the door face (see diagram).

⑤ Feed the electrical connector

and cable through the

bottom slot, you may need

help to do this as you will be

holding the outer handle in

position at the same time.

⑥ Push through and loosely

tighten the fixing screws into

the screw pillars on the outer

handle. Check the mounting

plate is firmly against the

door face. Remember, there

may only be 2 screws not 3.

Warning!

• DO NOT fully tighten the

fixing screws.

×3

M

or

N

or

O

×3

×3

04

05

06

06

06

P009P009

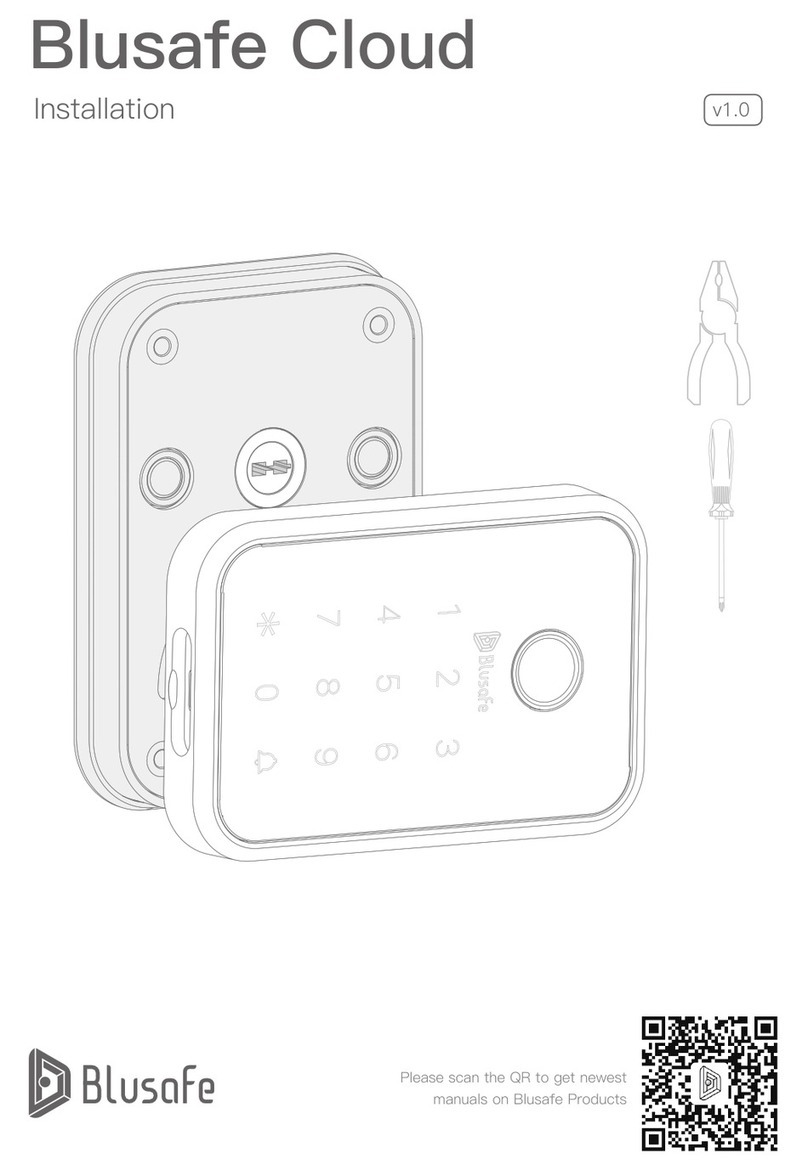

Fit the Drive Bar

Push the setting tool fully into the slot in the

operating cam (see fig.1).

The mark nearest to the face of the backplate

shows the correct bar length to use (see fig.2).

Withdraw the setting tool making sure the slot

in the cam is in the vertical position.

Select the correct length drive bar shown by

the setting tool.

Then, wider square end in first, push the bar

firmly into the slot until it hits the bottom of the

slot.

fig.1

fig.2

fig.3

Bar NO Bar Length (mm)

35

42.5

50

Reading on Setting Tool (mm)

34 - 39

39 - 47

47 - 51

G1

G2

G3

P010P010

Use Fitting Jig to Align

Important!

• Ensure the drive bar is vertical.

Refer to page 2 to re-set the cam if

required.

Important!

The jig MUST be used.

⑦ Slide the black plastic fitting jig over the

spindle as shown and check that the drive

bar is located correctly in the slot.

Move the internal mounting plate slightly if

required until the jig is fully located.

⑧ Tighten up the fixing screws firmly but do

not over tighten.

Remove the fitting jig. Make sure the spindle

and drive bar are in the centre of their holes

respectively.

Drive Bar

07

08

08

08

P011P011

Fix the Mounting Plate

⑨ If the top of the backplate

is not ush with the face of

the door, fit the additional

self-tapping screw A1

supplied.

Some composite doors have

steel skins so it may be

necessary to use a powered

driver with a self-drilling

screw A2 (supplied).

Please be careful to tighten

by hand to avoid stripping

the door skin.

Other optional (OP) fixing

points are available if

required (screws not

provided).

Note

• Screw A1 is a

self-tapping screw.

• Screw A2 is a

self-drilling screw.

OP OP

OP

OP

09 A1 A2

P012P012

Important!

• Make sure the drive bar

is vertical and the cam

slot arrows are vertical

before fitting.

Fitting the Internal Handle

⑩ Check that the handle is

facing the correct way (see

page 3).

⑪ Check the alignment arrows

on the turn cylinder are

facing straight up as shown

below.

⑫ Carefully connect the

connector to the handle as

shown, red side to red side.

10

11

12

RED

RED

P013P013

Fitting the Internal Handle

⑬ Locate the handle onto the

spindle.

⑭ Push the handle in slowly

ensuring that the cable goes

around the thumb turn as

shown in the diagram.

⑮ Check that the drive bar is

fitting into the slot in the

thumb turn cylinder and push

the handle fully home.

Finally, double check that the

handle is seated correctly

on the backplate and that

the cable is not visible (not

caught under the edge of

the handle).

Important!

• Please make sure cable is

tucked into allocated slot

when fitting handle.

13

14

15

P014P014

Fitting the Internal Handle

⑯ Fit the 4 fixing screws

supplied manually (do not

use a power screw driver).

Do not over tighten the

screws.

Warning!

• DO NOT push down or lift

the handle at this stage.

B

16

16

16

16

P015P015

Internal Handle Set Up

⑰ Please insert the 4 AA

batteries supplied with the

handle and fit the cover.

You will hear a ‘beep’ to

confirm that the batteries

are correctly fitted.

You will be instructed to

‘PLEASE PUSH THE LEVER

HANDLE DOWN’. Once

done, you will be instructed

to ‘PLEASE LIFT THE

LEVER HANDLE’.

You should hear the motor

turn and then hear ‘DOOR IS

LOCKING’.

Try to push the handle

down. If the handle has been

correctly fitted, the handle

should not push down.

Important!

• The batteries will work in

the handle for 8 months

depending upon usage

and environment. It is

recommended to change

the batteries every 6

months for optimal

performance.

• When the batteries are

running low, you will

hear a ‘Low Battery’

warning upon each use

of the handle. You will

have approximately 50

warnings before the

battery runs out.

Warning!

• Do NOT turn the thumb

turn until the above

sequence has been

completed.

17

P016P016

Check Thumb Turn

Check the operation of the internal thumb

turn.

⑱ To unlock the door from the inside, press the

thumb turn slightly and it will drop into a slot,

push firmly and turn the thumb turn.

Turn clockwise if the handle is on the left

side of the door.

Turn anti-clockwise if the handle is on the

right side of the door.

You will hear and feel a click, now push the

handle down.

Once you are happy that the thumb turn is

operating easily and isn't sti or sticking,

you can tighten up the cam fixing screw

(Page 2). Be careful not to tighten too much

and still leave a small amount of slack. Once

tightened, lift the handle to lock the door,

then unlock via the thumb turn. Make sure

that this is still operating easily and freely.

To set up the handle please do not fit the

bottom cover yet.

Fix

• If the thumb turn is sticking or is sti to

operate, the cam fixing screw may be

too tight. Undo the screw by 1 turn and

try again.

• If after this it is still sticking, please refer

to the FAQs on the website to see how

to fix this.

18

Other manuals for Origin Smart

1

Other Blusafe Door Lock manuals