2

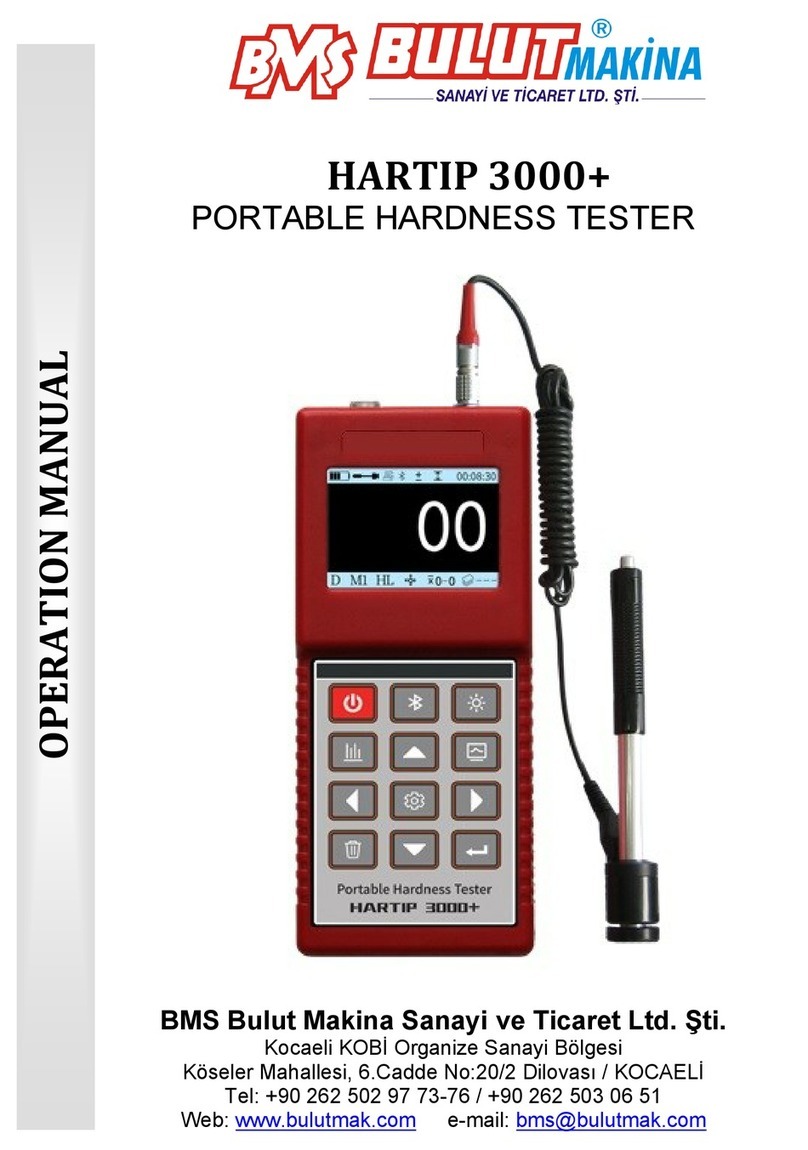

1OVERVIEW .......................................................................................................................................................................... 4

1.1 MEASUREMENT PRINCIPLE......................................................................................................................................................... 4

1.2 STANDARD PACKAGE ................................................................................................................................................................. 5

1.3 LAYOUT OF THE INSTRUMENT...................................................................................................................................................... 5

1.3.1 Main unit..................................................................................................................................................................... 5

1.3.2 Probe ........................................................................................................................................................................... 5

1.3.3 Display......................................................................................................................................................................... 6

1.3.4 Function of key ............................................................................................................................................................ 6

1.4 BASIC CONNECTION METHOD...................................................................................................................................................... 6

1.4.1 Assembling and dis-assembling of the probe.............................................................................................................. 6

1.4.2 Charger and battery charging ..................................................................................................................................... 7

2MEASUREMENT OPERATION............................................................................................................................................... 7

2.1 PREPARATION BEFORE MEASUREMENT.......................................................................................................................................... 7

2.2 SWITCH ON ............................................................................................................................................................................. 7

2.3 MEASUREMENT CONDITIONS MODIFICATION ................................................................................................................................ 8

2.3.1 Sampling length .......................................................................................................................................................... 8

2.3.2 Measurement Range................................................................................................................................................... 9

2.3.3 Filter ............................................................................................................................................................................ 9

2.3.4 Parameter ................................................................................................................................................................... 9

2.4 SYSTEM SETTING.................................................................................................................................................................... 10

2.4.1 Unit system................................................................................................................................................................ 10

2.4.2 LCD Back-light ........................................................................................................................................................... 10

2.5 FUNCTION SELECTION ............................................................................................................................................................. 10

2.5.1 Stylus position ........................................................................................................................................................... 10

2.5.2 Calibration of indicating value .................................................................................................................................. 10

3OPTIONAL ACCESSORIES AND THE APPLICATION .............................................................................................................. 11

3.1 HEIGHT SUPPORT AND PROBE HOLDER........................................................................................................................................ 11

3.2 HEIGHT STAND....................................................................................................................................................................... 12

3.3 EXTENSION ROD..................................................................................................................................................................... 12

3.4 PROBE ................................................................................................................................................................................. 12

3.4.1 General purpose probe.............................................................................................................................................. 12

3.4.2 Curved surface probe ................................................................................................................................................ 12

3.4.3 Small bore probe ....................................................................................................................................................... 13

3.4.4 Super small bore probe ............................................................................................................................................. 13

4TECHNICAL PARAMETERS.................................................................................................................................................. 13

4.1 ROUGHNESS PARAMETER AND DISPLAY RANGE.............................................................................................................................. 14

4.2 TEMPERATURE/HUMIDITY RANGE .............................................................................................................................................. 14

4.3 CONNECTION WITH PRINTER..................................................................................................................................................... 14

5DAILY CARE AND MAINTENANCE ...................................................................................................................................... 14

5.1 FAULT TREATMENT.................................................................................................................................................................. 14

5.2 FAULT MESSAGE ..................................................................................................................................................................... 14

6BATTERY ON/OFF SWITCH................................................................................................................................................. 14

7REFERENCES...................................................................................................................................................................... 15

7.1 PROFILE AND FILTER ................................................................................................................................................................ 15