7

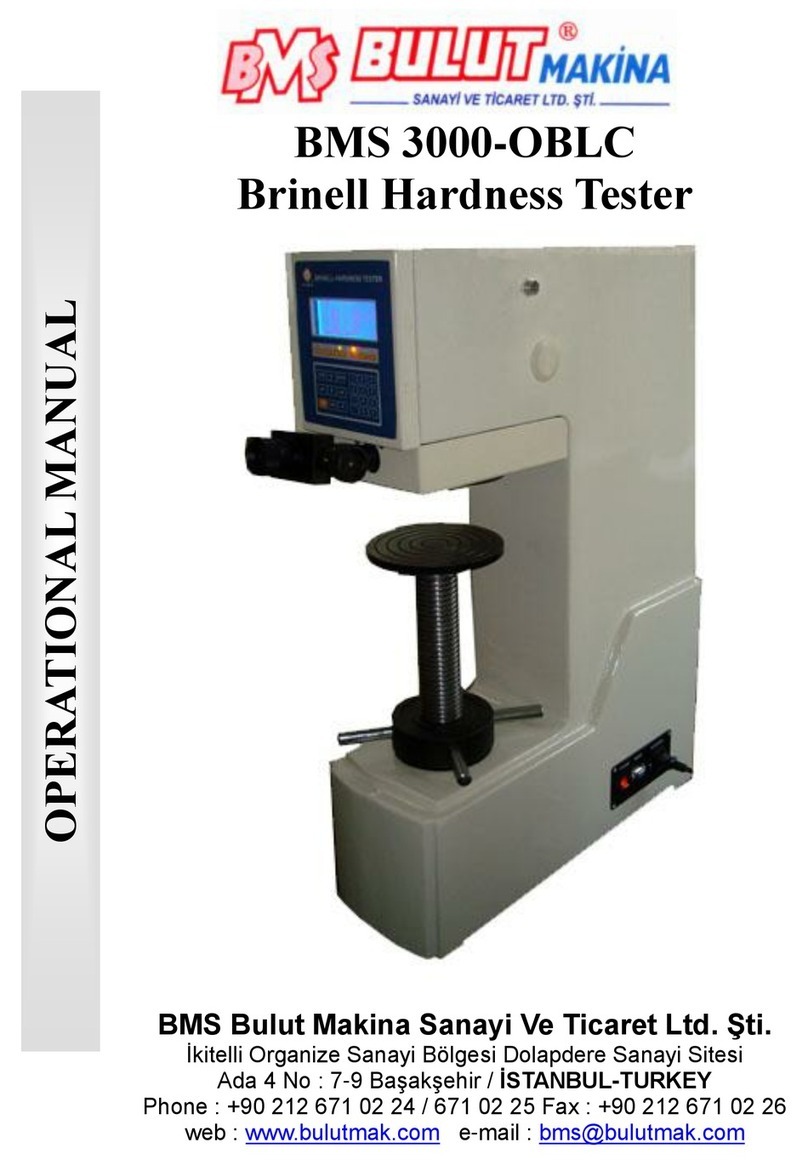

Test pieces shall be stably placed on the test table, during testing cannot move the specimen, and to ensure that the test force is applied

vertically on the specimen.

According to the specimen shape and size to select the appropriate test Table. Irregularly shape Specimens can manufacture special fixture

according to their own specific shapes to make hardness test shows correct value.

If test piece is cylindrical, you must use the "V" type test table. When testing HRC/HRA hardness and specimen diameter less than 38mm;

HRB hardness test specimen diameter less than 25mm, the test results should be corrected, the correction value is positive. (Table 6).

Operation sequence of hardness tester.

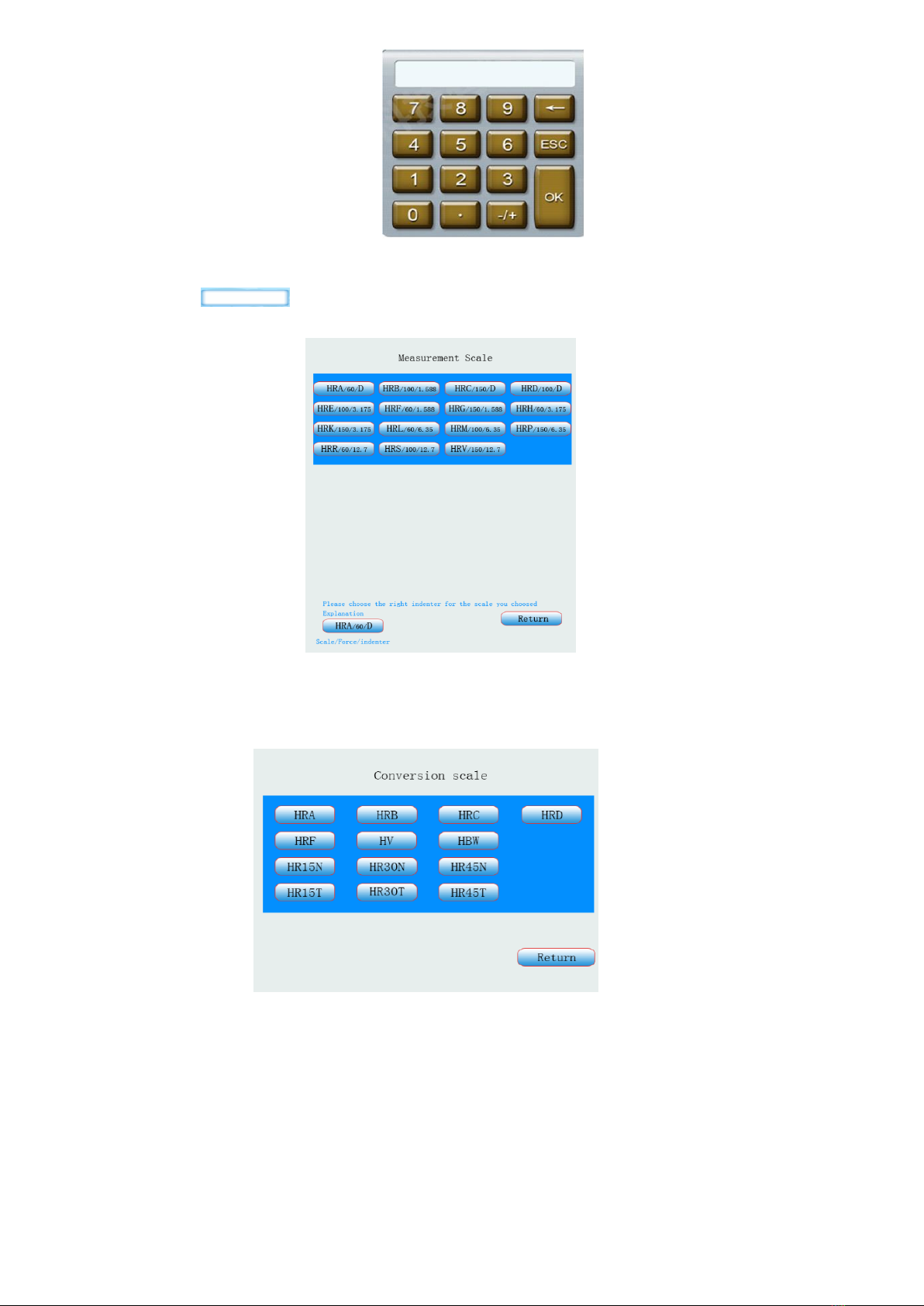

According to the hardness of materials (Table,1) select test scale (follow tips choose indenter)

For example: test the hardness of HRC:

Push the diamond indenter (5) towards the spindle hole, snapping the bearing surface, the flat face of the indenter towards indenter screws

(4), slightly tightened.

Turn on the power switch, the screen reach to operating interface.

Click on the “hardness type”, select HRC; if you need to change hardness type please click “conversion type”.

Click “dwell time”, select 5s. turn the rotating wheel (8) clockwise, lift up the working table (6). The specimen slowly touches the indenter

without any shock until the tester displays 580~610; at this time, the working table (6) stops lifting up, the hardness tester load test force

automatically. (When the working table moves up too fast and the screen display a value over610, the buzzer produces a long sound,

showing the operation is not correct. At this point, the buzzer sounds, it means the operation is wrong. The working table (6) should be

lowered and the position be changed for another test.

Load the test force automatically and the dwell time is 5s. At this time, 5s to 0s counts down, the dwell time is over, then the machine works

and unload the test force automatically. When the buzzer sounds, read out the hardness value displayed on the screen.

Note: During the loading and unloading of the test force, it prohibited turning the load change hand wheel (9), otherwise you would damage

the gears, and cause the disorder to the test force.

According to qualification requirements, the first measurement should not be documented. Document hardness value starting from second

point and 3-5 points are necessary and use the average.

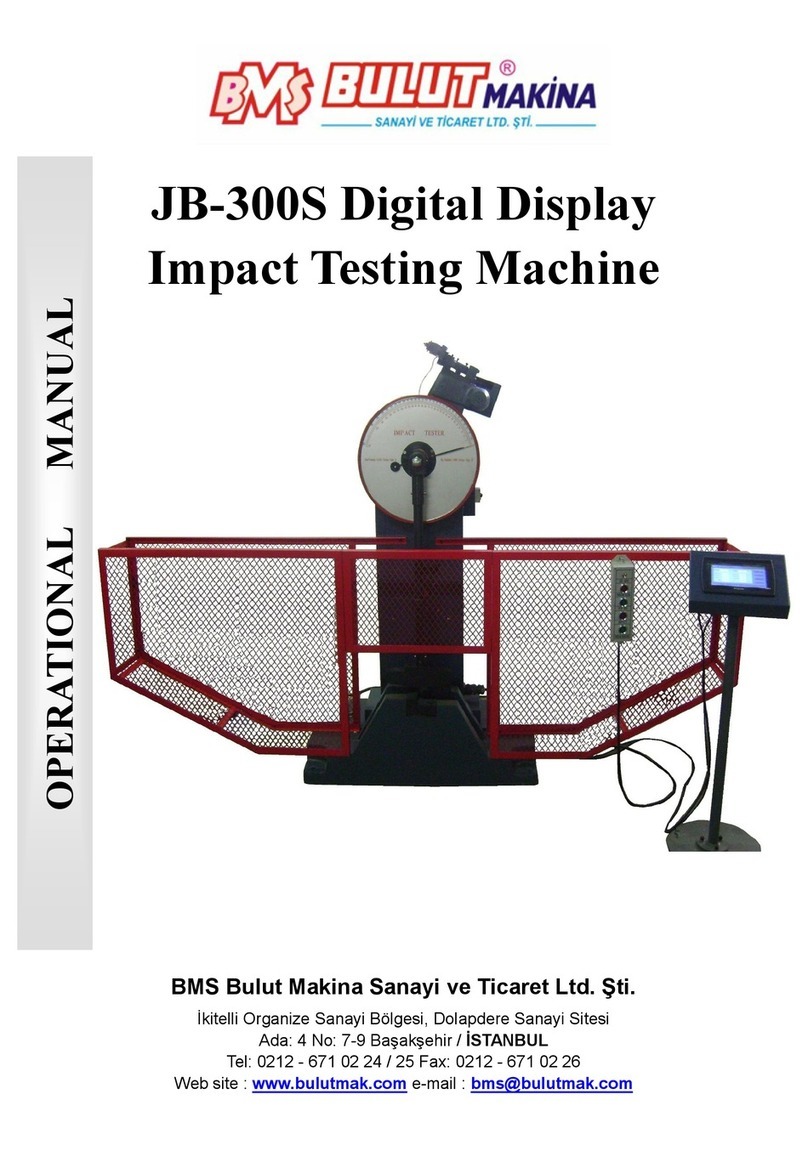

5Maintenance and Precautions

Before ex-factory this instrument is up to the state standards through overall test for delivery, but due to the causes of assembly and

disassembly, transportation or voltage, it may cause some changes in the instrument data. Generally, it can be handled as follows:

Without loading indenter, apply 29420N test force to press several times in each starting of the instrument, so as to eliminate mechanical

deformation amount, make electric components in normal operation and decrease test errors.

Loading and unloading signal of each level test force is feedback by the sensor, and the output signal of the sensor is very sensitive. So, we

equip the anti-interference assembly in the circuit. But in order to ensure the instrument normal work and avoid unnecessary damage, the

instrument should avoid using around strong current interference source.

The test force must be perpendicular to the surface of the test piece at the time of loading, so the device cannot test the parts with surface of

inclined plane.

The instrument power source should be reliably grounded and have a voltage stabilizing device.

The instrument will issue some noise in the process of loading and unloading; it is a normal phenomenon that the loading device is

automatically adjusting.

The active surface of such as the lifting screw (5) should be periodically lubricated with grease.

Turn off the power source after the test is completed.

The instrument should be kept clean and covered with dust shield after finishing the test. The hardness blocks and the ball indenter should be

coated with antirust oil to prevent rusting.

The instrument should do periodic inspection, at least once a year to ensure the accuracy of the hardness tester.

(Table 5)