Magnetics that count

BOGEN Electronic GmbH · Potsdamer Straße 12-13 · 14163 Berlin · Germany

Fon +49 (0)30 81 00 02-0 · Fax +49 (0)30 81 00 02-60 · magnetics@bogen-electronic.com · www.bogen-electronic.com

IKS9 manual Rev 1.0 (2020/07/14)

3/7

Electromagnetic Compatibility

For the electrical connection it is essential that the

electromagnetic compatibility (EMC) is guaranteed.

• System and control cabinet must be connected to the

same ground potential.

• Use shielded cables. Connect the cabinet side of the

cable shield with protective earth (PE).

• Avoid installing in close proximity to power lines.

• The nominal operating voltage (see datasheet) must be

observed even if there is a voltage drop along the supply

line!

• Determine the place of installation so that inductive

and capacitive interferences cannot affect the sensor.

By adequately routing the cable, interferences can be

reduced.

Intended Use

The incremental magnetic sensing heads IKS9 are part

of a highly accurate measuring system consisting of

magnetic scales and sensing heads capable of contactless

position detection for linear and rotary applications.

Fields of deployment:

• mechanical engineering

• automation

• medical engineering

• electrical engineering.

The system consists of a sensing head and a linear

or rotating magnetic scale and can be incorporated

into various electronic systems. It can be configured

according to the customer‘s demands. In combination

with a suitable analysis software absolute and relati-

ve position and position changes can be measured. In

this way it is possible, for instance, to control machi-ne

tools, determine torsional forces or detect longitu-dinal

expansions.

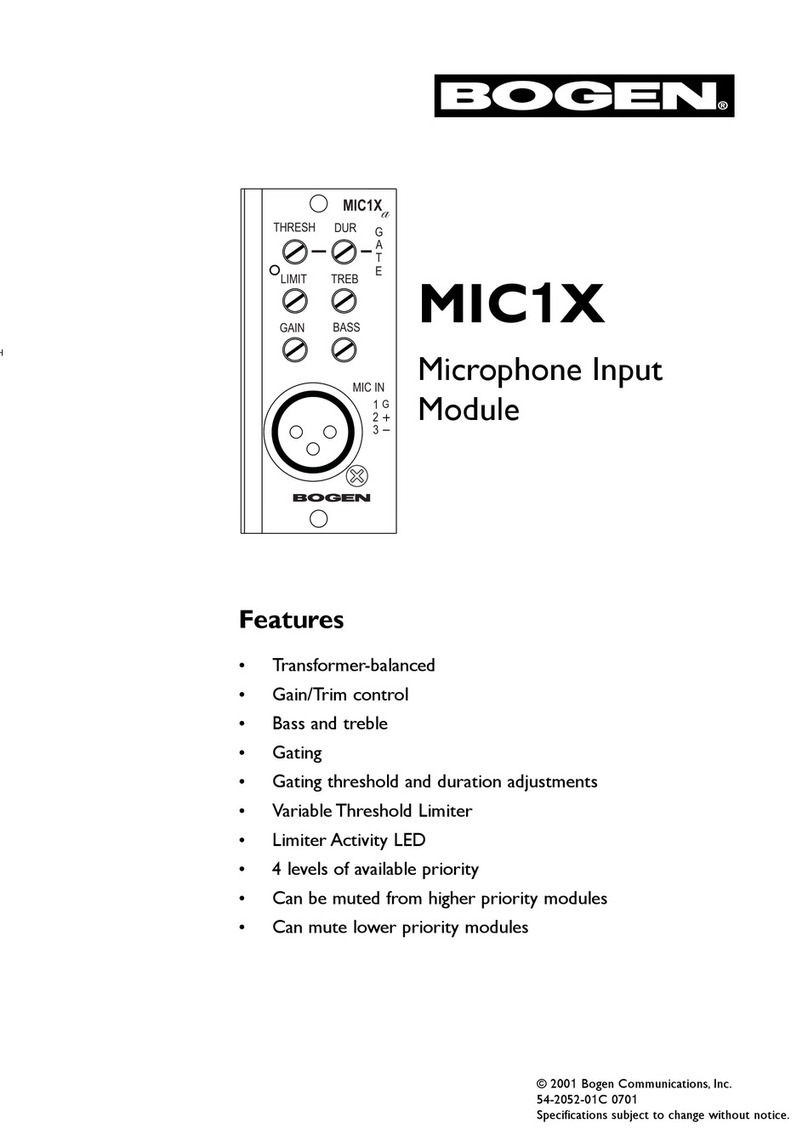

Function and Properties

The incremental magnetic sensing heads IKS9 are

suitable for non-contact, incremental distance measuring

systems. The measuring function is realized by magnetic

scanning.

The system has the following features:

• non-contact, quick position measurement

• high reproducability

• programmable with PC

• freely programmable resolutions

• adjustable maximum output frequencies

• different connectors with adaptable cable lengths

• no wear from usage

• high gap tolerance

• resistant to dust, cooling lubricant emulsion, oil, etc.

• unlimited measuring distance.

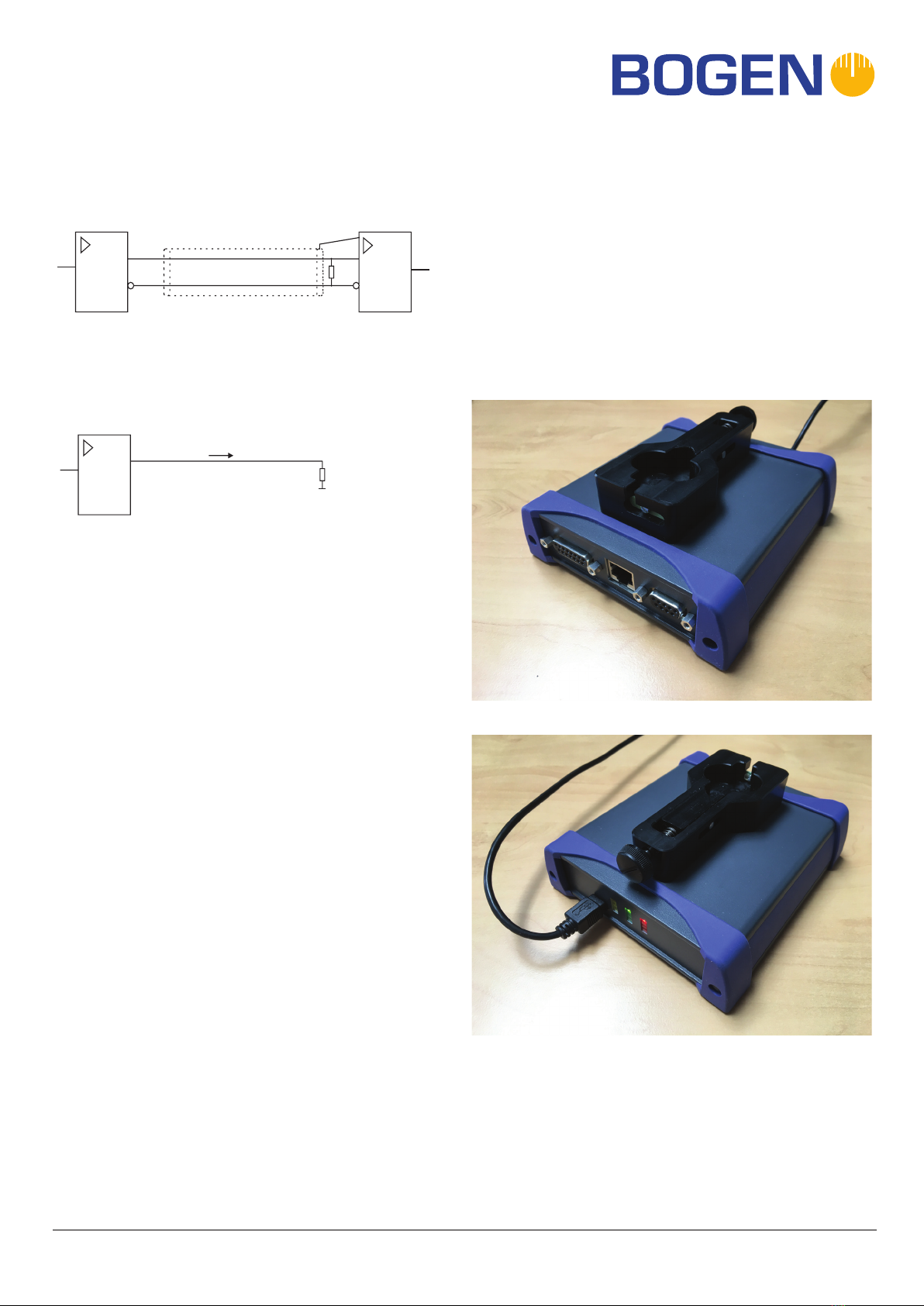

Mode of operation

The sensing head with its sensor is mounted on the

machine part whose position is to be measured. The

measuring magnetic scale is mounted along the

measuring distance. On the magnetic scale alternating

magnetic north and south poles are positioned with

a regular distance. The magnetic AMR sensor cells

(anisotropic magnetoresistive effect) in the sensing head

are scanning the magnetic poles on the scale contact-

free.

Permissive travelling speed

See technical data sheet of the respective type on the

website: www.bogen-electronic.com/download

Digital output

The sensing head with digital output signals converts

the analog signals into a digital quadrature signal (A/B

pulses) and transmits them to the controller. The two

digital square wave signals A and B are electrically phase

shifted by 90°.

The sign of the phase shift indicates the direction of

movement of the sensing head. Every change of A or B

(rise to fall or vice versa) is a count for the incremental

counter (up/down counter). If signal A is in advance, the

counter increments. If signal B is in advance, the counter

decrements. The controller thus knows at all times the

position of the sensing head, without having to query the

sensor periodically (real-time capability).