RIVIT RIV 503 User manual

MANUALE ISTRUZIONI

RIVETTATRICE OLEOPNEUMATICA CON

TRATTENUTA DEL RIVETTO E RECUPERO

DEL CHIODO TRANCIATO CON ARIA

APERTA PER RIVETTI IN TUTTE LE

LEGHE DAL Ø 2,4 AL Ø 4,8 SOLO PER

ALLUMINIO Ø 6,0

IT

IT

INSTRUCTION MANUAL

HYDRO-PNEUMATIC TOOL WITH

HOLDING OF THE RIVET AND NAIL

RECOVERY WITH OPEN AIR FOR BLIND

RIVETS IN ALL MATERIALS FROM Ø 2,4 TO

4,8 UP TO Ø 6,0 FOR ALUMINIUM ONLY

EN

IT

FR

MANUEL D'INSTRUCTIONS

RIVETEUSE OLEOPNEUMATIQUE

L'AIR OUVERT POUR LES RIVETS ALU/

ACIER/INOX DE Ø 2,4 A Ø 4,8. POUR

ALUMINIUM SEULEMENT Ø 6,0

RIV 503

CODICE | CODE | CODE 4035700

ITA ENG

FASTENERS & TOOLS

15 | 40

EN

REV | 02

RIV 503

INDEX

WARRANTY...........................................................................................................................................16

TECHNICAL DATA .................................................................................................................................17

ACCESSORIES SUPPLIED ...................................................................................................................18

ACCESSORIES ON REQUEST..............................................................................................................19

SAFETY MEASURES.............................................................................................................................20

OPERATING INSTRUCTIONS ...............................................................................................................20

SIZE CHANGING AND MAINTENANCE................................................................................................21

OIL TOPPING UP ..................................................................................................................................22

ELIMINATION OF THE TOOL ................................................................................................................22

LIST OF SPARE PARTS.........................................................................................................................23

16 | 40

EN

REV | 02

RIV 503

WARRANTY

The warranty has a validity of 12 months, as of the date indicated on the invoice.

The warranty only covers replaced parts; labour is not included.

The following are not covered by warranty: standard accessories and tool damages caused by:

• transport and/or handling

• user’s mistakes

• failed servicing/maintenance, as indicated in this manual

• faults and/or breakages that are not attributable to tool anomalies

• normal consumption of consumables.

The warranty is invalidated both in case of unauthorised tampering/replacements of tool components

and in case of use of accessories, tools or consumables different to those recommended by the manu-

facturer, which could even cause injuries to the tool’s user.

Rivit S.r.l. assumes responsibilities only if the tool is originally defective, but declines all forms of re-

sponsibility if the user fails to follow the given instructions.

17 | 40

EN

REV | 02

RIV 503

EN

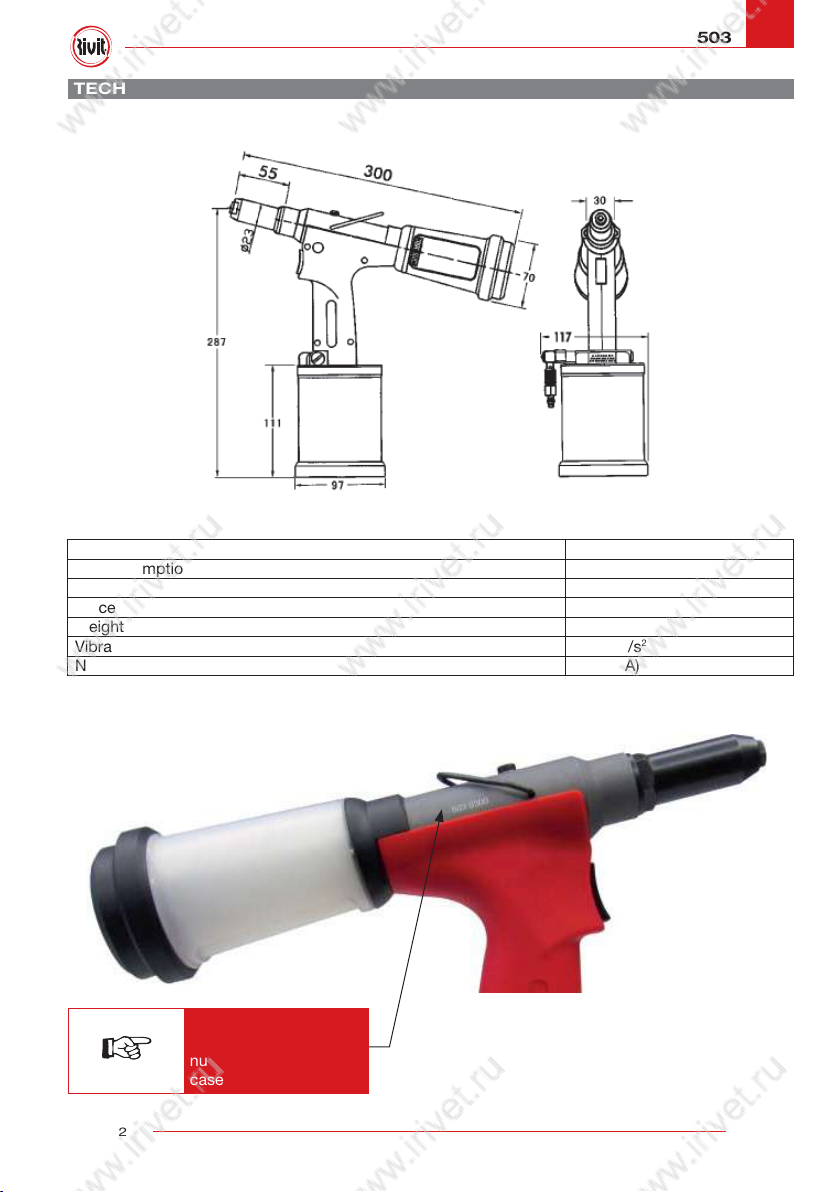

TECHNICAL DATA

EN

Air pressure 6 bar

Air consumption per stroke 4,35 litri

Stroke 20 mm

Force 10.900 N

Weight 1,546 Kg

Vibration < 2,5 m/s2

Noise level 78 dB (A)

In case of assistance

please specify the serial

number on the external

case

18 | 40

EN

REV | 02

RIV 503

ACCESSORIES SUPPLIED

PHOTO CODE QUANTITY ACCESSORIES SUPPLIED

41990 1 Nosepiece Ø 2,4

41991 1 Nosepiece Ø 3,2

41992 1 Nosepiece Ø 4,0

41691 1 Nosepiece Ø 4.8 (on head)

40417 1 Nosepiece Ø 6,0 for aluminium

25248 1 Nosepiece Ø 4,8 3/16 for Monriv rivet

12501 2 Jaws (3 pcs)

41392 1 Jaws opener

41340 1 Jaws return spring

41338 1 Cone holding jaws

- 1 Oil syringe

- 1 Oil

- 1 Hexagonal allen wrench 3 mm

- 1 10-12 mm wrench

- 2 16-17 mm wrench

Open valve

Close valve

The tools is prepared for Ø 4.8 blind rivet.

19 | 40

EN

REV | 02

RIV 503

EN

REF. CODE QUANTITY DESCRIPTION

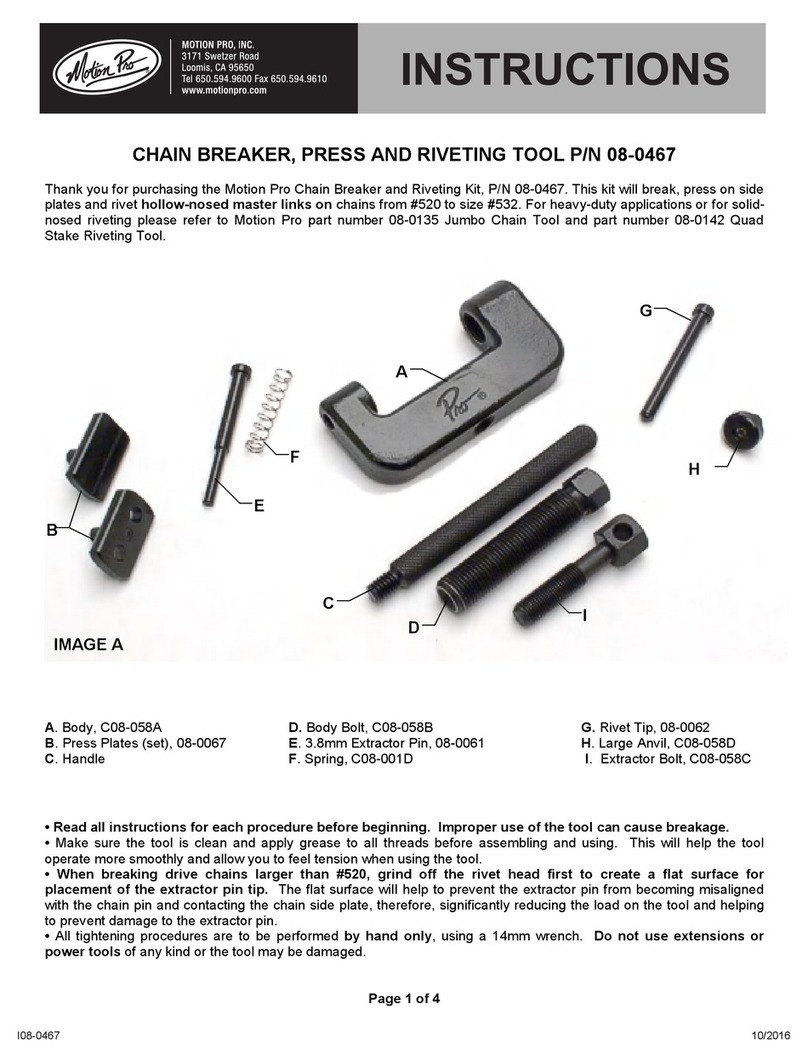

A+B 42043 1 Kit 503 - Extension 100 mm

A 42024 1 Extended sleeve 100 mm

B 41993 1 Adaptor x internal extension x 100 mm

REF. CODE QUANTITY DESCRIPTION

A+B 42268 1 Kit 503 - Extension 200 mm

A 42267 1 Extended sleeve 200 mm

B 42265 1 Adaptor x internal extension x 200 mm

ACCESSORIES ON REQUEST

Kit 503 - Extension 100 and 200 mm.

Ø 23

91

100

A B

Ø 23

195

200

A B

To get the 100 mm and the 200 mm extensions you need to disassemble the parts and assemble the

new correspondent ones (A and B) in the same sequence.

20 | 40

EN

REV | 02

RIV 503

SAFETY MEASURES

• Use the riveting tool properly and for the purposes for which it has been manufactured.

• Any kind of modication made on the riveting tool and its equipment by the customer itself, will be

done under the fully responsibility of the customer. In this case, Rivit srl declines any responsibility.

• The riveting tool must be always kept in safety conditions and must be revised at regulkar intervals

by expert and authorized workers, following the maintenance producers of Rivit srl.

• The riveting tool will always be used following the EC normative "on health and safety measures

on job" (Directive 2006/42/EC). Any problem or information regarding the correct operating of the

tool, will have to be returned to Rivit srl.

• The safety measures to be observed during the use of the riveting tool, must be explained from

the customer to all users. Always detach the air feeding from the take-off point of the toll before

regulating, repairing and cleaning operations.

• Dont'use the tool if is turned towards other persons.

• Operating pressure have not to exceed 7 bar - 100 LBF/IN2.

• Make sure that the air discharges are not blocked or covered and the feeding hoses are always in

good working conditions.

• The operations of maintenance, repairing and cleaning must be done when the tool is not fed.

• When using the riveting tool, wear protective glasses or visors and gloves.

• Use only original spare parts for repairing and maintenance. Rivit srl declines any responsibility

for any kind of damages caused by not observing the above and following instrucions (directive

CEE 85/734).

• If the noise level is over the safety limit of 85 dB (A), use the proper hearing protections (antinoise

headset etc.).

OPERATING INSTRUCTIONS

Air feed

All the tools works with compressed air, with a pressure of 6 bar.

We suggest to use regulators of pressure and automatic ltering systems on the main net of feeding air.

These will have to stay to 3 meters of distance from the tool (see the drawing), in order to assure an

optimal pressure in the tool and its maximum duration-life with a minimum maintenance.

The exible tubes for the air compressed in entrance must be in a position to supporting a pressure

of 10 bars and will have to be resistant to the oil, covered of a material resistant to the abrasions and

protected in case bad job conditions could damage them.

All the exible tubes for the compressed air must have a diameter of minimum passage of 6,4 mm or

1/4 of inch.

The pressure regulator must be set up to 6,5 bars in consideration of the pressure fall.

21 | 40

EN

REV | 02

RIV 503

SIZE CHANGING AND MAINTENANCE

Size changing

For changing the size of nosepiece, use the 12 mm spanner (equipped).

Maintenance

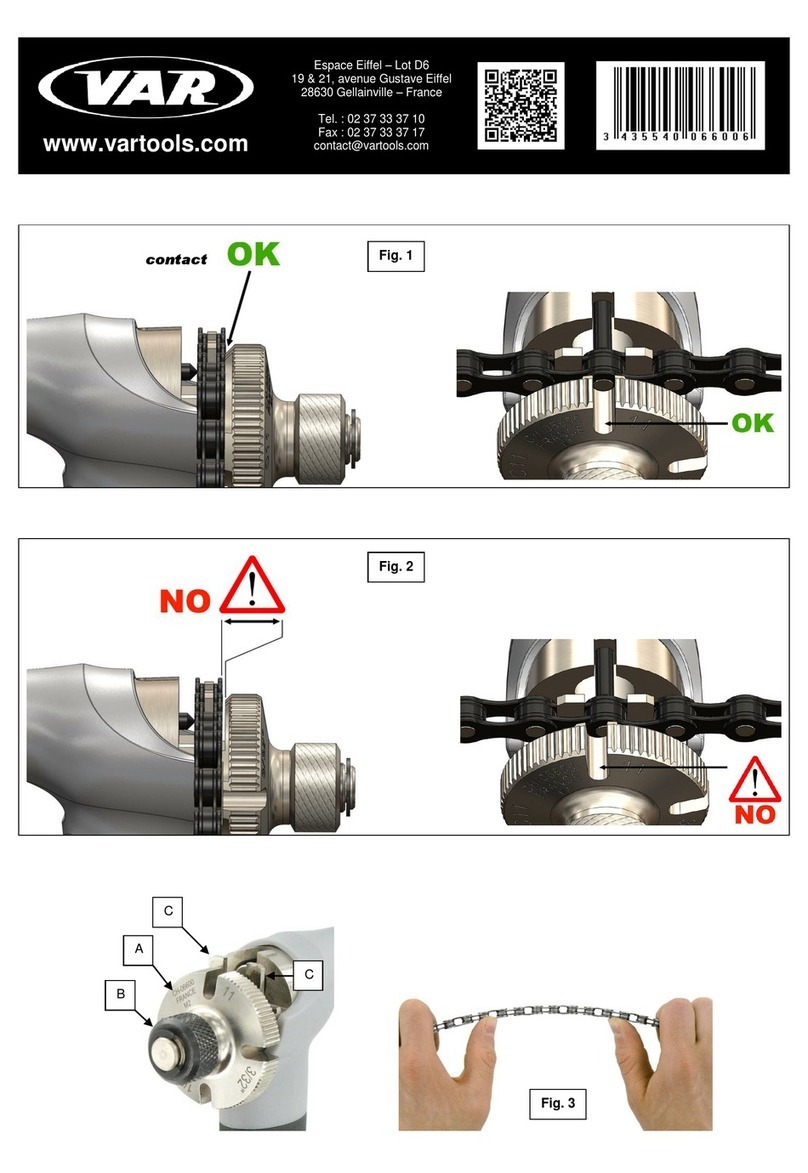

Check the grip of the jaws on the rivet's nail.

If it is anomalous, this is due to a problem on the jaws: dirty jaws or wear of the jaws.

In the rst case, proceed with cleaning and oiling the jaws; in the second case, it is necessary to sub-

stitute the jaws with new ones.

In order to do these operations, rst of all, disconnect the air feeding; then remove the head carrying

nosepiece with a 25 mm spanner.

Then with 16 mm and 17 mm spanner keep off the cone holding jaws and proceed with cleaning or

changing the jaws.

Check the air pressure, which don't have to exceed 7 bar.

Check eventual losses of oil or air.

Check the stroke of the riveting tool. If it is anomalous, proceed with topping up new oil.

Knob for suction

adjusting: to adjust

the air suction rotate

the knob

The container must

not be disassambled

because it collects

the mandrel

For instructions

read label

22 | 40

EN

REV | 02

RIV 503

OIL TOPPING UP

The topping up of the oil is necessary when occurs a power loss of the riveting tool or after a long

period of use.

Proceed as per the following instructions:

• Disconnect the air supply from the tool and keep the tool in a vertical position.

• Remove oil screw using a 3 mm allen wrench, screw the oil syringe (equipped) until it makes no

resistance, use oil viscosity 32°.

• Remove the syringe, then screw the oil screw with its o-ring and tighten.

• Place air without pressing the trigger.

• Unscrew the screw slowly so that the exceeding oil comes out (bleeding).

• Tighten screw.

• The tool is ready.

• N.B. In case of doubt check stroke, whose regulation should never be lower than the technical data.

N.B. During the operation, wear protective gloves and don't waste oil in the environment. In case of

contact of oil with skin, wash carefully the part with water and soap.

ELIMINATION OF THE TOOL

For the elimination of the tool, make reference to your national laws for safety and evironments care.

Disassemble the tool, dividing its components by materials (aluminium, steel, plastic etc.) then proceed

to scrap in compliance to the current law.

Oil topping up

23 | 40

EN

REV | 02

RIV 503

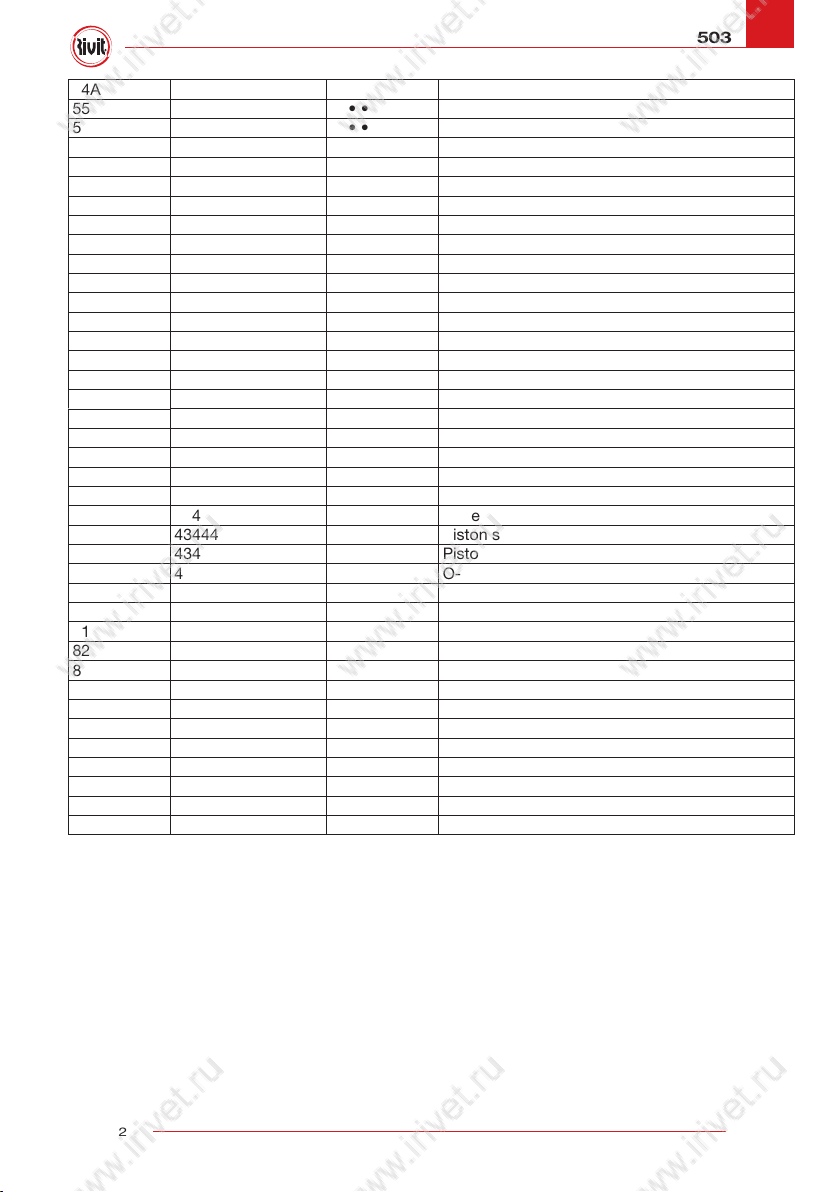

LIST OF SPARE PARTS

24 | 40

EN

REV | 02

RIV 503

REF. CODE QUANTITY DESCRIPTION

2 41692 1 O-ring

3 41337 1 • Nosepiece holder

4 41721 1 O-ring

5 41338 1 • Cone holding jaws

6 12501 3 • • Jaws

7A 41392 1 • • Jaws opener

9 41340 1 • • Jaws return spring

10 41722 1 O-ring

11 42455 1 Connector

12 41726 1 O-ring

13 43408 1 Connector

14 41727 1 O-ring

15 41728 1 O-ring

16 42397 1 Intake mandrel

17 43409 1 Spacer

18 41341 1 Gasket

19 43410 1 Head cylinder

20 41342 1 Gasket

21 41347 1 Anti-extrusion ring

22 41348 2 O-ring

23 41349 1 Gasket

24A 43411 1 Piston

25A 43983 1 Spring return piston

26 42250 1 O-ring

27 41350 1 • • Gasket

28A 43984 1 Plug

30A 43985 1 Collector connection

32 42253 1 O-ring

33 41359 1 Nail collector lid

34 41360 1 Nail collector body

35 43378 1 Ring nut

36 41729 1 Silencer

37 41733 1 Collector lock

38 41730 1 Silencer

39 41734 1 Collector cap

40 41443 1 Right handle

41 41444 1 Left handle

42 41449 1 • Trigger

43 43382 1 Button

44 43383 1 Valve

45 43384 6 O-ring

46 43385 6 Collector

47 43386 6 Hose stop

48 43387 3 Air hose

49 43171 1 Suction ring nut

50 43172 1 Nut

51 43415 1 Valve

52 43416 2 O-ring

53 41450 6 Tapping screw

• Recomended spare parts

•• Spare parts of highest consumption

25 | 40

EN

REV | 02

RIV 503

54A 43152 1 Air valve body

55 41376 1 • • Air valve ring

56 41377 2 • • O-ring for air valve piston

57 41378 1 • Air valve base

58 43115 1 Connector

59 42254 2 O-ring

60 43389 1 Connector

61 42255 1 O-ring

62 42940 1 • Rotating connector + air hose

62A 42258 1 Air hose

63A 41379 1 • Air valve piston

64 43052 1 Cap

65 41731 1 Silencer

66A 43393 1 Cylinder bottom

67 41380 1 O-ring

68A 43400 2 Hexagonal socket head cap screw

69 43402 1 ring nut

70 41810 2 Shock absorber cap

71 41381 1 Gasket

72 41382 2 O-ring

73 43404 1 Piston

74 42257 1 Piston washer

75 43418 1 Hose

76 43444 1 Piston stem

77 43406 1 Piston plate

78 41385 1 O-ring

79 42654 1 Screw

80 42655 2 O-ring

81 43425 1 Cylinder

82 43173 1 Protection bottom

83 42396 1 Gasket

84 43174 1 Screw

85 43175 1 Hook balancer

86 41990 1 Nosepiece Ø 2,4

87 41991 1 Nosepiece Ø 3,0 - 3,2

88 41992 1 Nosepiece Ø 4,0

89 40417 1 Nosepiece Ø 6,0

90 41691 1 Nosepiece Ø 4,8

91 25248 1 Nosepiece Ø 4,8 3/16 for Monriv rivets

• Recomended spare parts

•• Spare parts of highest consumption

26 | 40

EN

REV | 02

RIV 503

Kit 503 - Kit nail collector

REF. CODE QUANTITY DESCRIPTION

42042 1 • Nail collector kit

32 42253 1 O-ring

33 41359 1 Nail collector lid

34 41360 1 Nail collector body

36 41729 1 Silencer

37 41733 1 Collector lock

38 41730 1 Silencer

39 41734 1 Collector cap

Kit 503 - Kit pneumatic piston

REF. CODE QUANTITY DESCRIPTION

- 43424 1 • Pneumatic piston kit

74 42257 1 Piston washer

76 43444 1 Piston stem

77 43406 1 Piston plate

78 41385 1 O-ring

79 42654 1 Screw

80 42655 2 O-ring

• Recomended spare parts

• Recomended spare parts

This manual suits for next models

1

Table of contents

Other RIVIT Rivet Tools manuals