Date 07-2016 Revisione - 08

GB

62

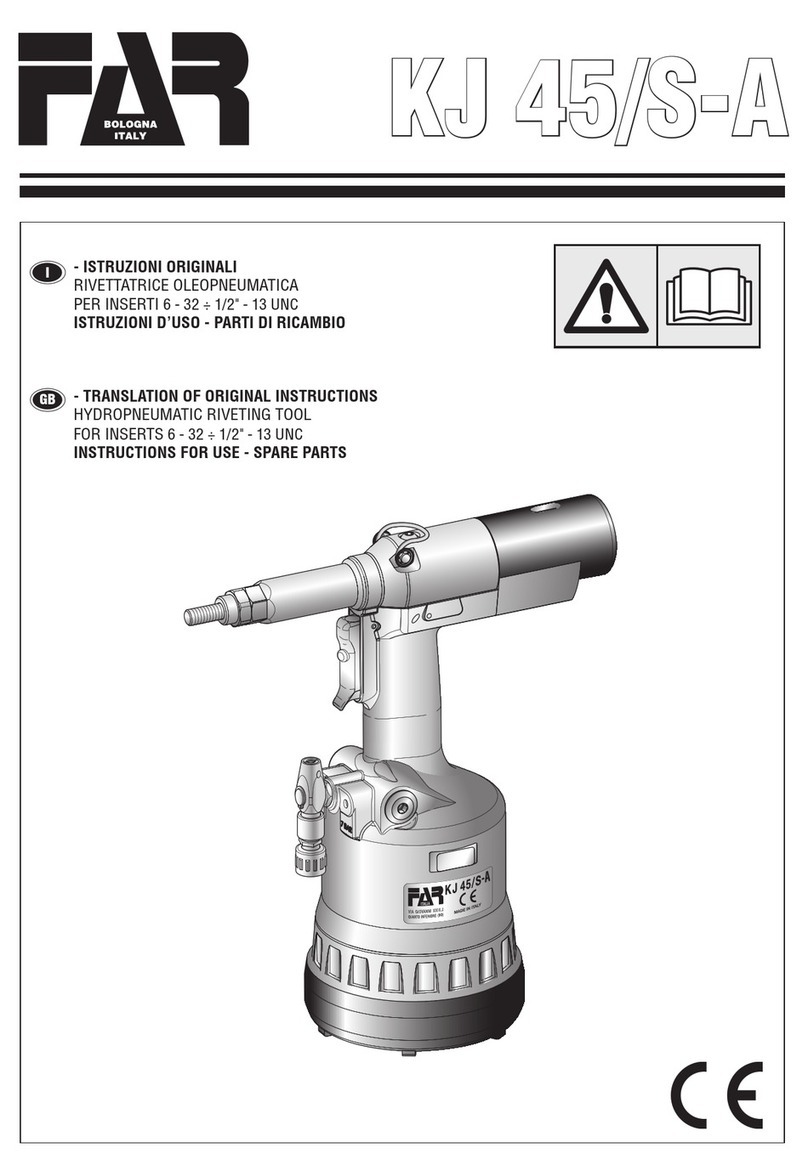

KJ 45/S

SPARE PARTS

Tab. 1/5

No. CODE Q.ty DESCRIPTION

001 713291 1 Head M 10

002 71C00281 1 Screw TCCE M10 x 70 UNI 5931 - 12,9

003 72A00105 1 Hexagonal unit for tie-rod M 10

004 713292 1 Head M 12

005 713177 1 Tie rod M 12

006 72A00104 2 Hexagonal unit for tie-rod M 8÷M 12

007 713290 1 Head M8

008 71345529 1 Spacer for screw M 8

009 71C00514 1 Screw TCCE M8 x 70 UNI 5931 - 12,9

010 713289 1 Head M 6

011 71345276 1 Spacer for screw M 6

012 71C00279 1 Screw TCCE M6 x 70 UNI 5931 - 12,9

013 72A00103 1 Hexagonal unit for tie-rod M 6

014 713288 1 Head M 5

015 71345275 1 Spacer for screw M 5

016 71C00278 1 Screw TCCE M5 x 70 UNI 5931 - 12,9

017 72A00102 1 Hexagonal unit for tie-rod M 5

018 713287 1 Head M 4

019 71345274 1 Spacer for screw M 4

020 71C00277 1 Screw TCCE M4 x 65 UNI 5931 - 12,9

021 72A00101 1 Hexagonal unit for tie-rod M 4

022 709033 1 Plastic case

023 75036018 1 Instructions for use

024 72A00053 1 Oil container

025 712225 1 Wrench 4 mm

107 71345831 1 Tie rod M8

KIT

KITA 74000042 Pneumatic Kit

030A 71C00295 1 Ring Parbak 8-028

031A 71C00296 1 Gasket OR 5-670

032A 710925 1 Gasket OR 027

035A 711062 1 Gasket OR 2-126

037A 710244 1 Gasket OR 2-130

038A 713275 1 Gasket OR 2-122

056A 713390 2 Gasket OR 2-007

058A 710258 1 Gasket OR 5-612

059A 710921 1 Gasket OR 2-115

060A 71C00529 1 Gasket XR 008 PP180 B.

061A 710528 1 Gasket OR 008

062A 710572 1 Gasket OR 2-120

063A 710385 2 Gasket OR 2-006

064A 713394 1 Gasket OR 2-106

066A 710376 2 Gasket OR 2-009

068AHI 711338 2 Gasket OR 2-003

069AHI 710918 2 Gasket OR 2-005

070AHI 716060 5 Gasket OR 2-010

075A 713400 7 Gasket OR 5-616

077A 71C00355 1 Gasket OR 1,78 x 8,73

078A 71C00356 1 Gasket OR 1,78 x 7,66

082A 71C00522 1 Gasket OR 5-615

083A 710914 1 Gasket OR 2-116

100A 71C00297 2 Gasket OR 6-700

101A 713398 1 Gasket OR 2-340

102A 710350 1 Gasket OR 2-109

105AP 713192 5 Cage

106A 713271 2 Gasket OR 2-014

KITB 74000027 Tie rod container kit

KITQ 74000037 Oil-dynamic kit

026Q 711722 1 Gasket B-094063/B/NEI

034Q 713389 1 Gasket 157118 - B / NEO

080Q 711827 1 Gasket TTS-12-19-5,7 / L

081Q 710390 1 Gasket B-075047

KIT It indicates that the part is sold in kits consisting of

different parts in different quantities.

Tab. 2/5

No. CODE Q.ty DESCRIPTION KIT

026Q 711722 1 Gasket B-094063/B/NEI Q

027 713402 1 Seeger ring JV 25

028 71345258 1 Jacket

029 71345261 1 Flange

030A 71C00295 1 Ring Parbak 8-028 A

031A 71C00296 1 Gasket OR 5-670 A

032A 710925 1 Gasket OR 027 A

033 71345264 1 Oil-dynamic piston

034Q 713389 1 Gasket 157118 - B / NEO Q

035A 711062 1 Gasket OR 2-126 A

036 71345260 1 Ring nut

037A 710244 1 Gasket OR 2-130 A

038A 713275 1 Gasket OR 2-122 A

039 72A00125 1 Pneumatic Motor F001

040 72A00188 1 Valve unit for motor control

041 71345263 1 Nut M 16 x 1

042 72A00107 1 Driving unit

043 71345516 1 Spring for tie-rod

044 71345515 1 Sleeve carrying tie rod

046 71345517 1 Sleeve

047 713170 6 Ring nut

048 716198 1 Screw TCCE M4 x 12 UNI 5931

049 72A00009 1 Fender motor

050 710555 1 Washer 400-004-4490

051 713405 1 Screw TBCE M6 x 10 ISO 7380

053 713308 2 Cap

054 713406 2 Screw TSCE M4 x 25 UNI 5933

055 72A00007 1 Air connector

056A 713390 2 Gasket OR 2-007 A

057 716150 2 Screw TSCE M4 x 12 UNI 5933

058A 710258 1 Gasket OR 5-612 A

059A 710921 1 Gasket OR 2-115 A

060A 71C00529 1 Gasket XR 008 PP180 B. A

110G 713158 1 Obturator G

111G 71345174 1 Right spear valve G

KIT

KITC 74000041 Oil-dynamic cylinder kit

KITD 74000025 Hook kit

KITE 74000021 Silencer kit

KITF 74000029 Rod kit

KITG 74000073

Spear valve group

110G 713158 1 Obturator

111G 71345174 1 Right spear valve

KIT It indicates that the part is sold in kits consisting of

different parts in different quantities.